The best Lưỡi Dao Tạo Hạt in 2025 come from trusted names known for precision, durability, and easy fit. If you want the best pelletizing solution, look for blades that provide even pellet size and long-lasting performance. Whether you need a standard or lưỡi dao tùy chỉnh, these options ensure easy installation and reliable operation. A quick comparison table helps you find the right blade for your pellet type and specific needs. The best pelletizing blades make pellet production efficient, helping companies grow while reducing downtime. These pelletizing blades are easy to maintain and adjust, giving every pellet maker an edge in a competitive market. Reliable pelletizing choices support market growth by meeting evolving demands.

Những điểm chính

- Pick pelletizing blades that fit your machine well and match the material you cut. This helps you get good results and makes installation easy.

- Find blades made from strong materials like high-speed steel or tungsten carbide. Blades with special coatings last longer and cut better.

- Check and take care of blades often by cleaning them and adjusting settings. This keeps pellet quality high and helps avoid machine stops.

- Top brands like Nanjing Metal give custom blades, good help, and quality checks. They help you find the best blade for your job.

- The right blade saves money by making less waste, working faster, and needing less fixing.

Best Pelletizing Blades 2025

Bảng so sánh nhanh

| Thương hiệu | Tùy chọn vật liệu | Application Range | Độ bền | OEM Compatibility | Service Features | Tốt nhất cho |

|---|---|---|---|---|---|---|

| Nanjing Metal | SK2, HSS, M2, SKD11 | Recycling, Compounding, Lab, Resin | ★★★★★ | Wide | OEM/ODM, QC, Real-time Tracking | Best overall, Custom |

| Fordura | HSS, Cacbua | Compounding, Large-Scale | ★★★★☆ | Select | Fast Delivery, Support | High throughput |

| American Cutting Edge | Tool Steel, Carbide | Recycling, Masterbatch | ★★★★☆ | Broad | Stock Blades, Tech Support | Best value |

| Sollex | Cacbua Vonfram | Specialty, Abrasive Materials | ★★★★☆ | Niche | Custom Orders, Consultation | Abrasive applications |

Mẹo: This table helps you pick the right blade fast. Match your needs with the best blade for your job.

Tổng quan về các tính năng chính

Pelletizing blades are important for making good pellets in plastics factories and recycling plants. The best pelletizing blades in 2025 are known for being accurate, strong, and flexible. Operators get the best results when they choose blades that fit their process and materials.

- Cắt chính xác:

The best pelletizing blades make pellets that look the same. Sharp rotor and bed knives, plus the right gap, keep pellet size even. When these things are set right, operators see fewer bad pellets and less dust. - Durability and Material Quality:

High-speed steel, SKD11, and tungsten carbide help the best pelletizing blades last a long time. Special coatings like titanium nitride make blades slippery and stop rust. These features help blades work well with tough plastics and fillers. - Tính linh hoạt:

The best pelletizing blades can be used for many jobs. They work for recycling, new resin, mixing, and lab tests. Custom shapes and OEM compatibility make it easy to use them in most pelletizing machines. - Performance Optimization:

Operators get the best pellets by watching process settings. Knife sharpness, feed-roll gap, air pressure, and water temperature all matter. Checking these things with setup sheets keeps pelletizing working well. The pellets themselves show if something is wrong, so it is easier to find and fix problems. - Service and Support:

Top companies give OEM and ODM services, strict quality checks, and real-time tracking. These things help customers get the best pelletizing blades for their needs. - Hiệu quả chi phí:

The best pelletizing blades save money and time. Strong materials and careful design mean you change blades less and waste less.

Note: Blade design is important, but how you set up and run the process matters a lot too. Operators who check and adjust key settings get the best pellets.

Choosing Pelletizing Blades

Picking the best pelletizing blades means looking at a few things. Operators need to think about how well the blade works, how long it lasts, if it fits their machine, and if it is worth the money. Each thing helps make sure pellets are always good and made fast.

Performance Factors

Độ chính xác và tính nhất quán khi cắt

Blades that cut very well make pellets all the same size and shape. When cuts are even, there is less waste and better products. Blade materials like D2 steel, carbide-coated, and ceramic each have special strengths. D2 steel is tough, carbide coatings make blades harder, and ceramic blades do not wear out fast. Special blade shapes, like high-speed and V-type, help cut better. Rotor types such as bolt-on and wedge-lock also help make cuts more exact. These things help operators get the best pellets.

- Custom blades help keep pellets the same.

- Special coatings can make blades last three times longer.

- Automation and AI systems help blades work better and stop machines from breaking down.

Throughput and Efficiency

The best blades help make lots of pellets quickly. Good blades cut more pellets every hour and stop the machine less. A furniture company in China used new pelletizing systems for LDPE waste. They made 200 tons of recycled pellets each month. This saved them 35% on raw materials and made $1.2 million more each year. Picking the right blade shape and material helps make more pellets and more money.

Heat Resistance and Stability

Pelletizing gets very hot and has a lot of rubbing. Blades must stay sharp and keep their shape in these tough conditions. Coatings like tungsten carbide and nano-ceramic help blades handle heat and stop rust. These coatings help blades work well in wet places and during long runs. Strong blades keep pellet quality high even when it is hot.

Durability & Materials

Blade Material Types (e.g., HSS, Tungsten Carbide)

Many materials are used to make pelletizing blades. High-speed steel (HSS) is tough and keeps its edge. Tungsten carbide blades are very hard and do not wear down fast. SKD11 and M2 are also used for hard jobs. The best material depends on the plastic, heat, and how much you make.

Wear Resistance and Maintenance Needs

How long a blade lasts depends on how well it resists wear. Coatings like titanium nitride and chromium plating make blades slippery and stop rust. These features mean less fixing and longer blade life. Operators should check blades often and plan when to fix or change them. Automation and AI can help know the best time to change blades and stop long breaks.

Expected Service Life

The best blades last longer because they use better materials and coatings. For example, tungsten carbide coatings can make blades last three times longer than regular steel. Operators change blades less, stop less, and spend less on fixing. Long-lasting blades help keep pellet making steady and quality high.

Compatibility & Fit

Machine Model Compatibility

Pelletizing blades must fit the right machine. Companies like Fordura make blades for many pelletizer brands like EREMA, NGR, MAAG, Gala, and Coperion. They also fit machines from Vecoplan, Andritz, Cumberland, and more. Blades must match the shape, holes, and speed of each machine. This helps blades cut well and make good pellets.

- Fordura makes blades that fit OEM and custom needs.

- Their blades work with strand, underwater, and die-face pelletizing systems.

- They help upgrade old machines and improve new ones.

Installation and Adjustment Requirements

Blades must be put in and set up the right way. They need to line up with the rotor and stator. Operators should follow the maker’s rules for gaps and how to mount blades. Easy-to-install blades save time and stop mistakes. Some makers give setup sheets and help so operators get the best results.

OEM vs. Aftermarket Options

Operators can pick OEM or aftermarket blades. OEM blades come from the machine maker and always fit. Aftermarket blades, like Fordura’s, can be tougher, more exact, and save money. Many aftermarket companies offer OEM and ODM services, like design, testing, and making special blades. This helps operators find the best blade for their job.

Tip: Always check if the blade fits your machine before buying. This makes sure it goes in easy and makes good pellets.

Price & Value

Initial Cost vs. Long-Term Savings

Pelletizing blade prices change by material and shape. Good blades may cost more at first but save money later. Strong blades need fewer changes and less fixing. Operators should look at both the price and how long the blade will last.

Tổng chi phí sở hữu

Total cost means the price, fixing, stopping, and changing blades. Blades with good coatings and strong materials cost less over time because they last longer and work better. Automation and checking systems help save more by planning fixes and stopping surprise breaks.

Warranty and Support Considerations

Good makers give warranties and help for their blades. Good support means quality checks, tracking, and easy buying. These services help operators keep making pellets and fix problems fast.

Custom Blade Solutions and Manufacturer Recognition

If you need a special blade, Nanjing Metal is a trusted maker. They have 20 years of experience making industrial blades. Their team is skilled at making custom cutting tools for pelletizing. They make sure every blade is high quality and fits what each customer needs.

Top Brands Overview

Nanjing Metal

Nanjing Metal is a top maker of pelletizing blades. The company is also called Maxtor Metal. It has been making custom blades for 20 years. These blades are used in many pelletizing jobs. Nanjing Metal is trusted by many people. They make the Plastic Pelletizer Blade. This blade comes in SK2, HSS, M2, and SKD11. These blades are used in plastics recycling, resin making, compounding, and labs.

The design team at Nanjing Metal checks every blade for quality. The company gives OEM and ODM services. They also track production and check quality often. Customers can buy blades easily and get help with importing. First article inspection is also offered. Nanjing Metal has many blade types for different machines. This helps users pick the right blade for their needs. The company works hard to make new products and keep customers happy. This has made them well-known around the world.

More companies are choosing Nanjing Metal for good blades. Their blades work well and last a long time. People who want strong and accurate blades like this brand.

Fordura

Fordura is a strong brand in the pelletizing blade market. They focus on making lots of pellets fast. Their blades are made from HSS and carbide. Fordura’s blades are good for big jobs and tough places.

Their blades fit many pelletizer models. These include strand, underwater, and die-face systems. Fordura makes sure their blades work with OEM machines. This means users can change blades easily. Fast shipping and good customer service help Fordura’s reputation. Many people pick Fordura for good prices and strong blades.

Fordura is known for being reliable and quick. This makes them a good choice for busy factories.

American Cutting Edge

American Cutting Edge has over 50 years of experience. They make blades for many big brands like Gala, Erema, Beringer, BKG, and Cumberland. Their blades are made from tool steel and carbide. These are used for recycling and masterbatch jobs.

People like that American Cutting Edge keeps blades in stock. This means less waiting and saves money. They also give tech support and have many replacement blades ready. For example, the Conair 208-1299 Pelletizer Bed Knife uses tungsten carbide. This makes it last longer and fit well.

- American Cutting Edge is known for quality and good service.

- Their blades fit many machines and are easy to get.

Sollex

Sollex makes blades for special and tough jobs. They use tungsten carbide for hard plastics and fillers. Sollex lets customers order custom blades and get advice. This helps people find the right blade for their needs.

Sollex is known for new ideas and skill. Their blades are great where wear resistance and sharp cuts matter. People in special markets pick Sollex for strong blades that last.

Sollex stands out for custom help and support. They are a top pick for special blade needs.

Market Data Table

| Brand/Model | Max Capacity (kg/h) | Power (kW) | Applicable Materials | Phạm vi giá (USD) |

|---|---|---|---|---|

| Coperion ZSK Series | Up to 2000 | 250 | Engineering plastics, PE/PP | 150,000 – 300,000 |

| Wintech | Up to 800 | 90 | PE film, agricultural film waste | 45,000 – 65,000 |

| Domestic Economic | Up to 300 | 55 | PVC, ABS | 15,000 – 25,000 |

This table shows that top brands have many choices and sizes. They are trusted and have a strong place in the market. Some brands use smart screw designs and filters. Wintech uses SKD-11 steel blades. This makes blades last 50% dài hơn. This shows how brands work to make better and stronger blades.

OEM Compatibility and Service Features

- American Cutting Edge makes blades that fit many pelletizer brands. They help factories with good service and have blades ready to ship.

- Jiadeblade makes custom blades in many sizes and materials. Their blades meet or beat OEM rules for factories everywhere.

Pelletizing blades keep getting better as factories want higher quality and better service. Each brand has something special. Nanjing Metal is great at custom blades. Sollex is best for special jobs. Factories win because brands compete and make better blades.

Brand Reviews

Nanjing Metal Industrial CO., Limited

Many people in the industry know Nanjing Metal Industrial CO., Limited as a top pelletizing blade maker. This company is also called Maxtor Metal. They have been making blades for 20 years. The team at Nanjing Metal designs and makes custom blades for many uses. Their skilled team checks every blade to make sure it is high quality.

Nanjing Metal is good at making both OEM and ODM blades. They offer many materials like SK2, HSS, M2, and SKD11. These materials help the blades work well in recycling, compounding, new resin, and labs. Customers like that they can track orders and get first article checks. Many companies pick Nanjing Metal because buying is easy and importing is simple.

Customers say Nanjing Metal’s blades last long and cut well. The company cares about quality and making customers happy. This is why many people choose them for their blades.

Fordura

Fordura is one of the top pelletizing blade makers. They focus on making blades for big jobs and fast work. Fordura makes blades from HSS and carbide for tough jobs. Their blades fit many pelletizer types like strand, underwater, and die-face.

Many users say Fordura ships fast and answers questions quickly. Their blades fit OEM machines, so changing blades is easy. Fordura makes blades that work well and last long. This makes them a good pick for busy factories.

- Fordura helps with tech support and custom blades.

- Their strong and tough blades are getting more popular.

American Cutting Edge

American Cutting Edge has over 50 years of experience. They make blades for big brands like Gala, Erema, Beringer, BKG, and Cumberland. Their blades are made from tool steel and carbide. These are used for recycling and masterbatch jobs.

Operators say American Cutting Edge always has blades in stock. This means less waiting and fewer delays. The company also helps pick the right blade and gives tech support. Their focus on quality and service makes them a trusted partner.

American Cutting Edge is known for fitting many machines and shipping fast. They help factories keep running with ready blades.

Sollex

Sollex is a specialist in pelletizing blades. They make blades for hard and special jobs. Sollex uses tungsten carbide and special coatings to make blades last longer. Customers can order custom blades and get expert advice.

Many users say Sollex is creative and solves hard problems. Their blades are good for tough plastics and last a long time. Sollex is known for quality and helping customers.

- Sollex is a top pick for custom and high-quality blades.

Application Guide

Plastics Recycling

Pelletizing blades are very important in plastics recycling. Operators use these blades to cut old and factory plastic waste into small, even pellets. They must control the temperature carefully so the plastic does not get ruined. This helps keep the pellets good. Blades made from high-speed steel and D2 tool steel are strong and last a long time. The market likes blades that stay sharp and do not wear out fast. This means machines stop less and helps recycling. Keeping the right temperature helps make pellets the same size and keeps the final product good. Special coatings like titanium nitride make blades slippery and last longer. This makes recycling better for the environment and helps the blades work well.

| Performance Metric / Material Property | Details / Values |

|---|---|

| Tốc độ lưỡi dao | 1,500–3,500 RPM typical operating range |

| Độ chính xác cắt | Độ chính xác ±0,05 mm |

| Độ cứng của vật liệu | 60-72 HRC (Rockwell Hardness Scale) |

| Tuổi thọ của lưỡi dao | 6–18 months depending on blade type and application |

Virgin Resin & Compounding

Pelletizing blades in virgin resin and compounding must handle high heat and many additives. Operators need to keep the temperature just right to stop problems. The market wants blades that can cut many resin types and keep pellets the same size and quality. Stainless steel and carbide blades are best here because they do not rust and can take the heat. Makers work to shape blades and set smoke levels to help make more pellets and keep them good. New blade designs can save up to 14% energy, so many factories like them.

Masterbatch & Lab Use

Making masterbatch and doing lab work needs pelletizing blades that are accurate and flexible. Operators often work with small amounts and must change settings fast. The market likes blades that work well and are easy to clean or fix. Fine grinding and sharp cutting make sure each pellet has the right color or additive. This keeps the color and taste the same. Checking and sharpening blades can make them last up to 40% longer. This saves money for labs and helps them try new things.

Sản xuất quy mô lớn

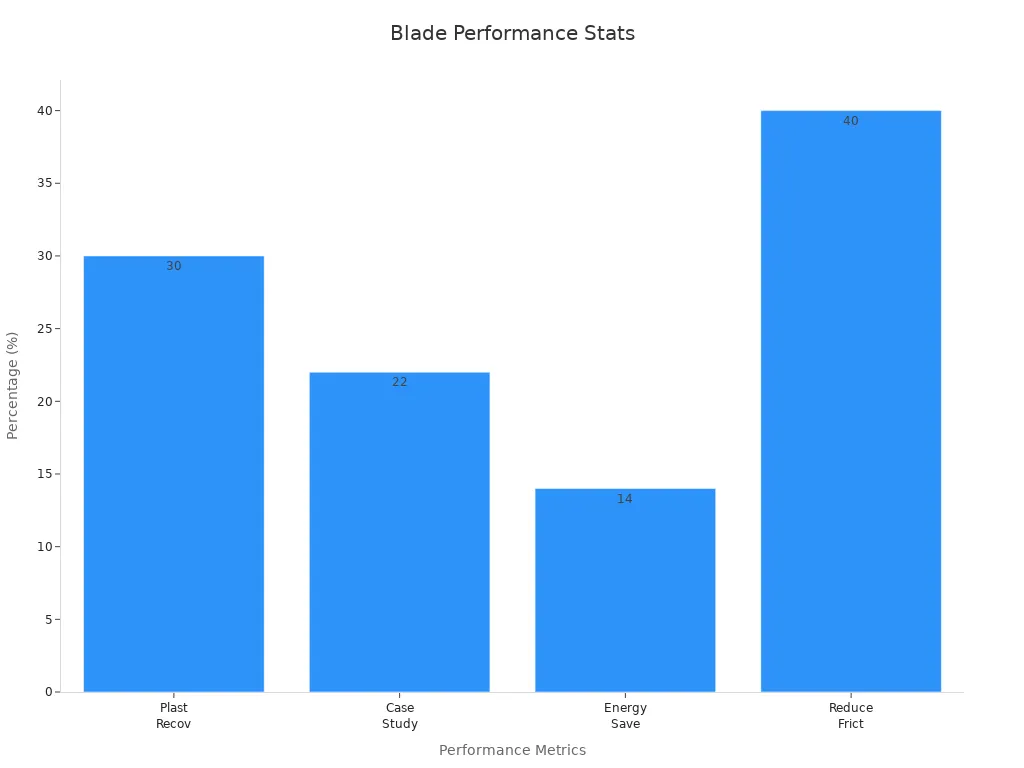

Big factories need pelletizing blades that are tough and work fast. Operators must keep the temperature steady and make lots of pellets that are all the same. Tungsten carbide blades are very hard and last a long time, up to 72 HRC. The market knows that good temperature and smoke settings help make high-quality pellets. Better blades can help recover up to 30% more plastic. One plant in Germany got 22% better results after using new blades.

Pelletizing Blades Market Overall

Global Trends

The pelletizing industry is growing fast all over the world. In 2023, the pelletizing blades market was worth about USD 300 million. By 2032, it could reach USD 500 million. This means the market grows by 5.5% each year. More people want to make pellets for plastics, food, and chemicals. The wood pellet market is also getting bigger. It was worth over $13.5 billion in 2023 and grows by 15% every year. Because of this, more pelletizing blades are needed to turn raw materials into even pellets.

Many things help this market grow. Plastic recycling around the world grew by 23% in the last three years. This makes more people want better pelletizing machines. Makers are now using new ideas like modular blade designs. They use strong materials such as SKD-11 alloy and tungsten steel coatings. These changes help blades last longer and cut better. Quick-change blade parts make fixing machines cheaper by 30%. This helps factories work better. Most people use single-screw pelletizing machines. But twin-screw machines are becoming more popular, growing by 40%. This shows that customers want new things.

A new study shows that the market is very competitive. Big companies spend money on making better products and working with others. Asia Pacific is the top region, growing at 6% each year. North America and Europe are also growing steadily. Companies try to win by using better materials, more automation, and improved coatings. All these things help the pelletizing market get bigger.

| Diện mạo | Chi tiết |

|---|---|

| Market Size (2023) | USD 300 million |

| Projected Size (2032) | USD 500 million |

| CAGR | 5.5% |

| Leading Region | Asia Pacific (6% CAGR) |

| Key Drivers | Recycling demand, automation, advanced materials, sustainability |

Note: New technology and caring for the environment are changing the pelletizing market. Blade quality and how well they work are now more important than ever.

Japan Pelletizing Knives Market

The japan pelletizing knives market is an important part of the world’s pelletizing industry. Japan’s companies make very accurate pelletizing blades for plastics, chemicals, and food. The japan pelletizing knives market is known for high quality and always trying to get better. Companies spend money on research to make new blade materials and cutting methods.

The japan pelletizing knives market can change quickly when people want new things. Local companies make both rotary and fixed pelletizing blades. They use high-speed steel, carbide, and ceramic materials. These blades are used for many jobs, like recycling and making medicine. The japan pelletizing knives market sells a lot of blades to other Asian countries and other places.

In this region, people care about working well and having blades that last a long time. Makers often use double-sided cutting edges and special coatings to make blades last longer. The japan pelletizing knives market also uses quick-change systems. These help users fix machines faster and make more pellets.

The japan pelletizing knives market is known for great quality and new ideas. This makes it a leader in the pelletizing world.

How to Find the Best Fit

Step-by-Step Selection

To pick the best pelletizing blade, follow a simple process. First, check if the blade matches your pelletizer machine. This makes sure it fits and works with your pellets and heat settings. Next, think about what material you will cut. Some plastics need blades made from D2 steel or tungsten carbide. These materials work better for certain jobs. Make sure the blade is easy to use and put in. This helps stop long breaks in work. Blades that are simple to clean and change keep the line running well.

Look for blades with non-stick coatings and heat resistance. These features help control heat and stop stuff from sticking. Ask experts or trusted makers for advice. They can help you get a blade that fits your needs. Custom blades can help you work faster and waste less. Use tools like the Analytical Hierarchy Process to compare blades. This helps you look at cost, risk, and how well the blade works. Using this method makes it easier to pick the right blade for your job.

Tip: Clean, oil, and check blades often to make them last longer and keep pellets good. Teach workers how to put in blades and control heat to stop problems.

Những lỗi thường gặp

Many people make mistakes when picking pelletizing blades. Using the wrong blade can make pellets uneven or cause blades to break. Not watching the heat can make pellets have tails, bumps, or holes. If water flow or bath length is wrong, you might get double pellets or zippers. Not checking for damage or changing old blades on time causes more breaks and bad pellets.

Some people skip expert help or buy blades that are hard to use. Buying from unknown sellers can also be risky. Sometimes, people forget to check if the blade fits their machine or is easy to install. Not picking strong materials like D2 steel or tungsten carbide makes blades wear out faster. If you do not clean and oil blades, stuff can build up and cause friction.

Note: Beginners should use a checklist, ask experts, and pick blades that are easy to use and care for. This helps get the best results in any market.

Picking a pelletizing blade means thinking about how well it works, how long it lasts, and if it fits your machine. If you want to save money, you might pick American Cutting Edge. People who need top results often go with Fordura or Sollex. Some jobs, like plastics recycling or compounding, need you to look at the comparison table closely. Use the guide to find the right blade for your job, even if you use it for plastics or a wood pellet grill. If you want more info or a custom blade, you can talk to a sales engineer đây.

Câu hỏi thường gặp

What factors determine the lifespan of a pelletizing blade?

A blade lasts longer if it is made well and has a good coating. How often you clean and check the blade also matters. Using the right blade for each job helps it last. If you look at the blade often and keep it clean, it will not wear out too soon.

Can pelletizing blades be used for different types of plastics?

Most pelletizing blades can cut many kinds of plastics. You should make sure the blade fits your machine and the plastic you use. Some blades are better for hard or rough plastics because they are stronger and have special coatings.

How do I know if a blade fits my pelletizer machine?

You need to check your machine’s model and the blade’s details. Makers give charts or help to show what fits. The right blade makes it safe to use and gives you good pellets.

Are pelletizing blades suitable for use in a wood pellet grill or cooking applications?

Pelletizing blades are not made for food or cooking. They are for factory jobs like recycling plastic. For a wood pellet grill, only use blades that are safe for food.

Where can I get custom pelletizing blades from a trusted manufacturer?

Nanjing Metal is a trusted company that makes custom blades for many jobs. Their team has been making blades for 20 years.

Xem thêm

Cách chọn dao tạo viên phù hợp cho ngành của bạn

Hướng Dẫn Toàn Diện Chọn Lưỡi Dao Tạo Hạt Tốt Nhất cho Máy Của Bạn

Lưỡi Dao Máy Tạo Hạt là Gì và Chúng Hoạt Động Như Thế Nào Trong Công Nghiệp?

Lựa Chọn Giữa Lưỡi Dao Thay Thế Máy Nghiền Nhựa OEM và Aftermarket cho Máy Móc Công Nghiệp

2 bình luận