Việc lựa chọn vật liệu tốt nhất cho lưỡi dao công nghiệp của bạn là rất quan trọng và Cacbua Vonfram nổi bật với độ cứng và khả năng chống mài mòn vượt trội. Điều này khiến nó trở nên lý tưởng để cắt các vật liệu cứng hoặc thô một cách nhanh chóng và hiệu quả. Nam Kinh Metal chuyên cung cấp lưỡi dao Tungsten Carbide chất lượng cao, được thiết kế riêng để đáp ứng các nhu cầu công nghiệp cụ thể. Mặc dù thép gió (HSS) rất linh hoạt và phù hợp cho các ứng dụng đòi hỏi thay đổi dụng cụ thường xuyên, nhưng Tungsten Carbide vẫn là lựa chọn ưu tiên về độ bền và hiệu suất. Bảng dưới đây nêu bật mức tiêu thụ vonfram toàn cầu năm 2024:

| Loại vật liệu | Tỷ lệ tiêu thụ vonfram toàn cầu |

|---|---|

| Sản phẩm cacbua vonfram | 65% |

| Thép / Siêu hợp kim (bao gồm HSS) | 14% |

| Sản phẩm Vonfram Metal | 12% |

| Hóa chất & Các loại khác | 9% |

Như đã trình bày, phần lớn vonfram được sử dụng trong các sản phẩm cacbua vonfram, nhấn mạnh tầm quan trọng của nó trong các lưỡi dao công nghiệp. Khu vực Châu Á - Thái Bình Dương dẫn đầu thị trường này, với nhu cầu đáng kể về lưỡi dao tùy chỉnh giải pháp.

Những điểm chính

- Lưỡi dao Tungsten Carbide sắc bén trong thời gian dài. Chúng cắt vật liệu cứng nhanh hơn lưỡi dao thép tốc độ cao. Điều này giúp chúng phù hợp cho các công việc khó khăn và dự án lớn.

- Lưỡi thép tốc độ cao cứng hơn và chịu được va đập tốt hơn. Chúng phù hợp cho những công việc có va đập đột ngột hoặc khi bạn thường xuyên thay lưỡi.

- Bạn nên chọn lưỡi dao dựa trên vật liệu cần cắt. Hãy cân nhắc tần suất cắt và ngân sách của bạn. Cacbua Vonfram phù hợp nhất với vật liệu cứng, thô và khi bạn sử dụng lưỡi dao thường xuyên. Thép gió phù hợp hơn với vật liệu mềm và các loại công việc khác nhau.

- Lưỡi cắt công nghiệp tùy chỉnh có thể giúp bạn cắt chính xác hơn. Chúng vừa vặn với máy móc của bạn hơn và giảm thời gian chết. Điều này giúp bạn tiết kiệm thời gian và tiền bạc.

- Nanjing Metal cung cấp cho bạn lưỡi dao tùy chỉnh chất lượng cao. Họ cung cấp dịch vụ hỗ trợ chuyên nghiệp, sản xuất tiên tiến và dịch vụ tốt cho nhu cầu cắt của bạn.

Sự khác biệt chính

Bảng so sánh

Cacbua Vonfram so với Thép gió cao tốc (HSS) – Tính chất chính

Điều quan trọng là phải biết cách thức hoạt động của những vật liệu này khi cắt. Bảng dưới đây liệt kê những điều chính cần lưu ý đối với người sử dụng lưỡi cắt công nghiệp:

| Tài sản | Thép tốc độ cao (HSS) | Cacbua Vonfram |

|---|---|---|

| Độ cứng và độ mài mòn | Cao; ổn định ở nhiệt độ lên tới ~500°C | Cực kỳ cao; ổn định ở nhiệt độ lên tới 1000°C |

| độ dẻo dai | Cao; ít giòn hơn | Thấp hơn; giòn hơn, có thể bị sứt mẻ |

| Độ ổn định nhiệt | Tốt lên đến 500°C | Tuyệt vời lên đến 1000°C |

| Tốc độ cắt và tuổi thọ dụng cụ | Phù hợp với tốc độ vừa phải; độ bền tốt | Xử lý tốc độ cao hơn nhiều; kéo dài lâu hơn nhiều |

| Chi phí & Sản xuất | Giá cả phải chăng hơn; dễ làm hơn | Đắt hơn; cần thiết bị đặc biệt |

| Ứng dụng tiêu biểu | Mũi khoan, vòi, dụng cụ cắt thông thường | Lưỡi dao công nghiệp, tấm mài mòn, khoan đá |

| Khả năng gia công | Dễ dàng xử lý | Khó xử lý; cần có công cụ đặc biệt |

Mẹo: Nếu bạn muốn một lưỡi dao sắc bén trong thời gian dài và cắt được những vật cứng, hãy chọn Cacbua Vonfram. Nếu bạn cần một lưỡi kiếm có thể chịu được nhiều đòn đánh hơn và dễ dàng thay thế, HSS có thể tốt hơn.

Thành phần vật liệu

Cacbua Vonfram

Cacbua Vonfram được chế tạo bằng cách trộn bột cacbua vonfram với chất kết dính kim loại, thường là coban. Hỗn hợp này thường có cacbua vonfram từ 70% đến 97% và coban từ 3% đến 30%. Hàm lượng cacbua vonfram cao giúp lưỡi dao rất cứng và bền hơn. Coban giữ lưỡi dao cố định và tạo độ cứng nhất định, giúp lưỡi dao không dễ gãy.

Kích thước hạt và lượng coban ảnh hưởng đến cách thức hoạt động của lưỡi dao. Hạt nhỏ hơn và ít coban hơn giúp lưỡi dao cứng hơn và bền hơn. Lượng coban nhiều hơn và hạt lớn hơn giúp lưỡi dao cứng hơn và chịu được va đập tốt hơn. Đối với lưỡi dao công nghiệp, hạt mịn được sử dụng để giữ cho lưỡi dao sắc bén và chống sứt mẻ.

Thép tốc độ cao (HSS)

Thép tốc độ cao là một loại thép được pha trộn nhiều nguyên tố. Nó bao gồm vonfram, molypden, crom, vanadi và cacbon. Tỷ lệ pha trộn thông thường là 0,6% đến 1,3% cacbon, 4% đến 18% vonfram, 1% đến 5% molypden, 3% đến 5% crom, và 1% đến 4% vanadi. Các nguyên tố này kết hợp với nhau để tạo thành HSS bền, chịu nhiệt và hữu ích cho nhiều công việc.

HSS có một cấu trúc phức tạp với các hạt và cacbua nhỏ. Những điều này giúp lưỡi dao bền hơn và chắc hơn. Vonfram và molypden làm cho nó cứng hơn và giúp nó chịu nhiệt. Crom và vanadi tăng thêm độ bền và giúp chống mài mòn. Hỗn hợp này tạo nên HSS một lựa chọn tốt cho các công cụ cần xử lý các cú đánh và thay đổi tải trọng.

Ghi chú: Chọn vật liệu phù hợp nhất với nhu cầu của bạn. Chọn vật liệu có độ cứng và khả năng chống mài mòn cao nhất, hoặc vật liệu có độ bền và khả năng chống va đập tốt hơn.

- Cacbua Vonfram công cụ có thể tồn tại lâu hơn tới 10 lần HSS công cụ trong những công việc khó khăn.

- HSS có khả năng xử lý va chạm tốt hơn, do đó phù hợp với những công việc có va chạm đột ngột hoặc tải trọng thay đổi.

- Cacbua Vonfram đắt hơn và khó sản xuất hơn, nhưng hiệu quả nhất trong những công việc nhanh và khó khăn.

Cacbua Vonfram trong Lưỡi dao Công nghiệp

Độ cứng và khả năng chống mài mòn

Dữ liệu so sánh độ cứng và khả năng chống mài mòn

Khi chọn lưỡi dao để cắt, độ cứng rất quan trọng. Cacbua Vonfram Lưỡi dao cứng hơn nhiều so với lưỡi dao thép tốc độ cao. Độ cứng Vickers của chúng nằm trong khoảng từ 1600 đến 2200 HV. Lưỡi dao thép tốc độ cao chỉ khoảng 700 đến 900 HV. Điều này có nghĩa là Cacbua Vonfram Lưỡi dao sắc bén lâu hơn. Chúng hoạt động tốt ngay cả trên các vật liệu cứng hoặc thô.

Những lưỡi dao này giữ nguyên độ cứng ở nhiệt độ cao, lên tới 1000°C. Thép tốc độ cao mất độ cứng ở nhiệt độ trên 500°C. Vì vậy, Cacbua Vonfram Phù hợp hơn cho các công việc đòi hỏi nhiều nhiệt. Sự kết hợp đặc biệt giữa cacbua vonfram và coban giúp lưỡi dao hoạt động tốt hơn. Quá trình thiêu kết cũng giúp lưỡi dao bền chắc. Bạn có thể tin tưởng sử dụng lưỡi dao này cho các công việc khó khăn và vật liệu cứng.

Mẹo: Lưỡi dao cứng hơn sẽ bền hơn và ít phải thay hơn. Điều này giúp bạn tiết kiệm thời gian và tiền bạc.

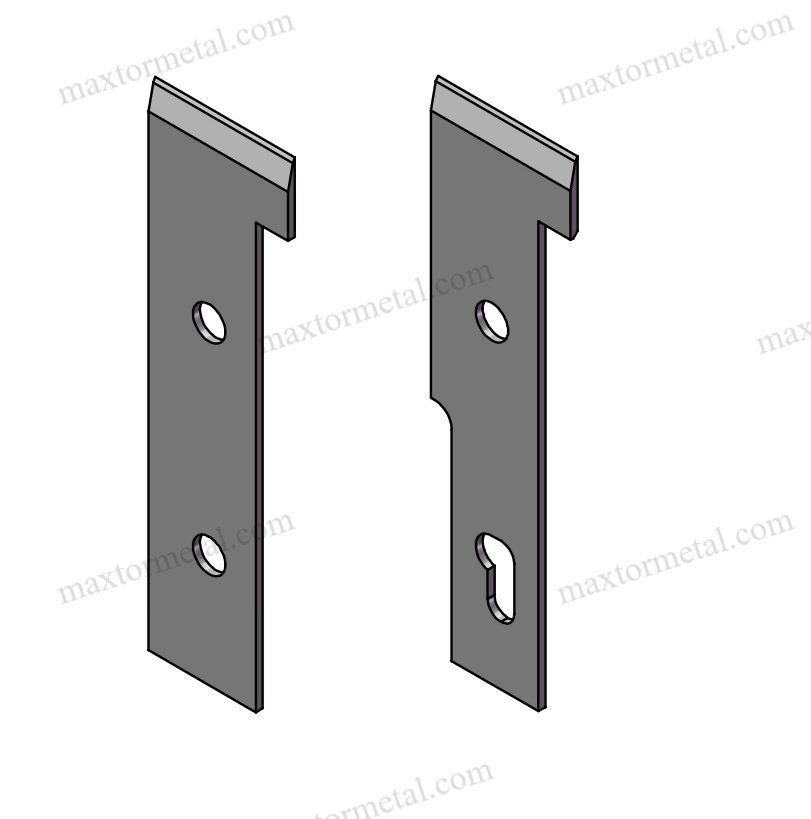

Ví dụ ứng dụng – Ngành công nghiệp giấy

Trong ngành công nghiệp giấy, lưỡi dao sắc bén rất quan trọng. Cacbua Vonfram Lưỡi dao được sử dụng để cắt và rạch cuộn giấy. Lưỡi dao này sắc bén và giữ được hình dạng lâu hơn lưỡi dao thép tốc độ cao. Bạn sẽ không cần thay lưỡi dao thường xuyên. Điều này có nghĩa là máy của bạn có thể hoạt động nhiều hơn và ít bị dừng hơn. Bạn sẽ giảm thiểu thời gian chết và hoàn thành nhiều việc hơn.

Các nghiên cứu cho thấy lưỡi dao này cho đường cắt sạch hơn và chính xác hơn. Bạn sẽ thấy kết quả tốt hơn và chi phí sửa chữa thấp hơn. Độ sắc bén và khả năng chống mài mòn của chúng khiến chúng trở thành lựa chọn tốt nhất để cắt giấy và các công việc tương tự.

Tốc độ cắt và tuổi thọ dụng cụ

So sánh hiệu suất với HSS

Bạn muốn lưỡi dao cắt nhanh và bền lâu. Cacbua Vonfram Lưỡi dao có thể cắt nhanh hơn 4–7 lần so với lưỡi thép tốc độ cao. Ví dụ, chúng có thể cắt thép hợp kim với tốc độ khoảng 160 mét/phút. Lưỡi thép tốc độ cao hoạt động tốt nhất ở tốc độ khoảng 70 mét/phút.

| Tham số | Lưỡi thép tốc độ cao (HSS) | Lưỡi Dao Hợp Kim Tungsten Carbide |

|---|---|---|

| Cắt nhanh | ~70 m/phút (thép) | ~160 m/phút (thép hợp kim) |

| Tuổi thọ công cụ | Tốt, nhưng ngắn hơn | dài hơn 5–10 lần |

| Khả năng chịu nhiệt | Lên đến 500°C | Lên đến 1000°C |

Cacbua Vonfram Lưỡi dao cũng bền hơn nhiều. Chúng có thể bền hơn từ 5–10 lần so với lưỡi thép tốc độ cao. Điều này có nghĩa là bạn sẽ không cần thay lưỡi dao thường xuyên. Bạn tiết kiệm được thời gian và tiền bạc cho nhân công. Mặc dù ban đầu lưỡi dao này có giá cao hơn, nhưng về lâu dài, chúng sẽ giúp bạn tiết kiệm chi phí.

Ghi chú: Tuổi thọ dụng cụ dài hơn và tốc độ cắt nhanh hơn có nghĩa là máy móc của bạn hoạt động tốt hơn và bạn có thể hoàn thành nhiều việc hơn.

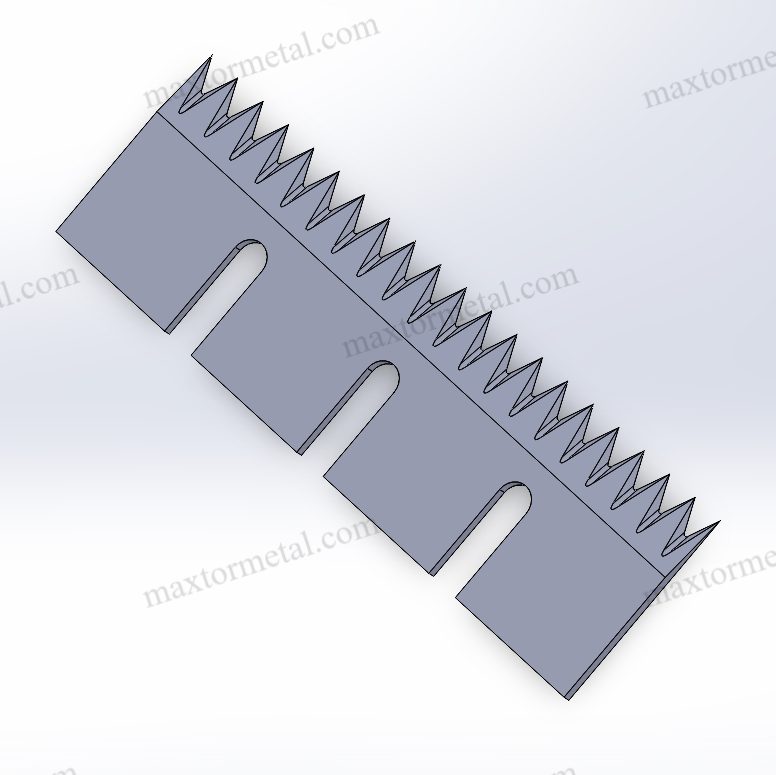

Các tình huống ứng dụng điển hình

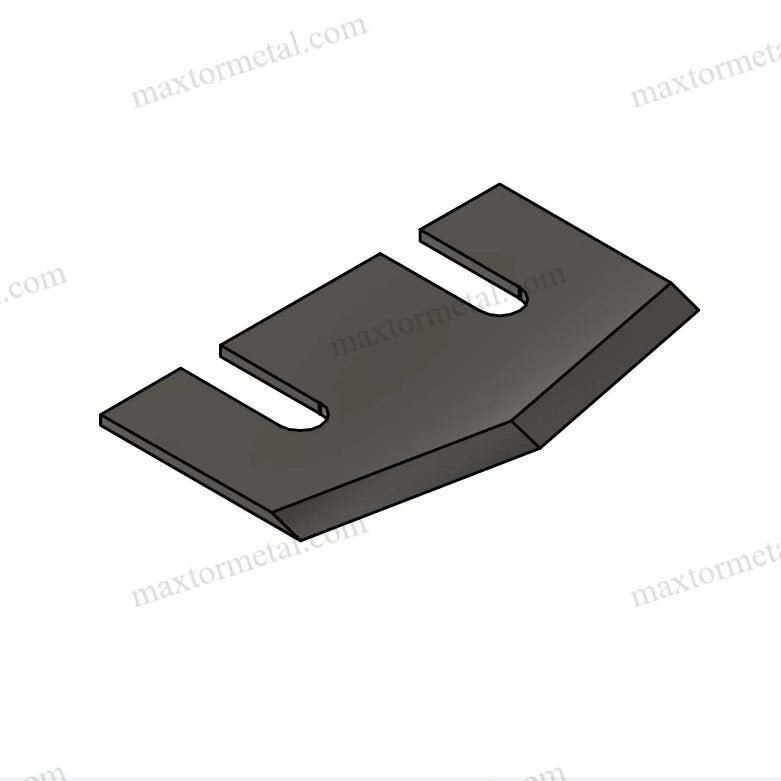

Cacbua Vonfram Lưỡi dao được sử dụng trong nhiều ngành công nghiệp đòi hỏi hiệu suất cao. Dưới đây là một số ứng dụng phổ biến:

- Cắt tấm kim loại, cao su dày, nhựa và vật liệu tổng hợp

- Chế tạo các bộ phận ô tô bằng cách cắt nhôm rất chính xác

- Cắt tỉa vật liệu composite và hợp kim trong máy bay

- Chế tạo dụng cụ y tế cần độ chính xác cao

- Thái thịt, rau và pho mát trong các nhà máy thực phẩm

Những lưỡi dao này phù hợp nhất cho những nơi sản xuất số lượng lớn sản phẩm liên tục. Bạn có thể tin tưởng vào hiệu suất cao và thời gian ngừng hoạt động ngắn của chúng. Chúng luôn sắc bén và chống mài mòn, vì vậy rất lý tưởng để cắt các vật liệu cứng hoặc thô. Bạn cũng sẽ thấy chúng trong chế biến gỗ, gia công kim loại và cắt giấy, những công việc đòi hỏi độ bền và chính xác cao.

Nếu bạn muốn một lưỡi dao luôn sắc bén, cắt nhanh và bền lâu, Cacbua Vonfram là sự lựa chọn tốt nhất cho nhu cầu cắt của bạn.

Thép tốc độ cao (HSS) trong lưỡi dao công nghiệp

Độ bền và khả năng chống va đập

Thép tốc độ cao nổi tiếng với độ bền và khả năng chịu va đập tốt. Lưỡi dao HSS không dễ gãy khi sử dụng. Chúng có thể uốn cong một chút nếu bị tác động mạnh, thay vì gãy. Điều này giúp chúng phù hợp cho các công việc thường xuyên bị va đập hoặc sốc đột ngột.

Ví dụ ứng dụng trong Metalworking và Woodworking

Bạn thường thấy lưỡi cưa HSS trong các xưởng gia công kim loại và gỗ. Trong gia công kim loại, lưỡi cưa HSS cắt kim loại mềm, khoan và tạo hình các chi tiết. Chúng được sử dụng để khoan lỗ trên dầm thép hoặc cắt tấm kim loại. Trong chế biến gỗ, lưỡi cưa HSS cắt gỗ cứng, gỗ mềm và gỗ dán. Chúng được sử dụng trong máy cưa, máy bào và máy phay. Lưỡi cưa HSS cũng dễ dàng cắt nhựa và các vật liệu mềm khác.

So sánh với cacbua vonfram

| Diện mạo | Thép tốc độ cao (HSS) | Cacbua Vonfram (WC/Co) |

|---|---|---|

| Các chế độ lỗi phổ biến | Nứt do va chạm hoặc căng thẳng | Nứt hoặc hư hỏng nghiêm trọng do va chạm đột ngột; mài mòn, bám dính và ăn mòn |

| độ dẻo dai | Độ dẻo dai và độ dai cao; khả năng chống nứt tốt hơn | Giòn hơn; dễ nứt do độ cứng và giòn |

| Hao mòn điện trở | Khả năng chống mài mòn vừa phải | Khả năng chống mài mòn và độ cứng vượt trội |

| Ứng dụng phù hợp | Môi trường năng động với tác động | Điều kiện cắt mài mòn, ổn định |

| Giảm thiểu rủi ro thất bại | Lựa chọn cấp độ và thiết kế phù hợp để tăng cường độ dẻo dai | Lựa chọn cấp độ phù hợp để cân bằng độ cứng và độ dẻo dai |

Lưỡi dao HSS chống nứt tốt hơn lưỡi dao cacbua vonfram. HSS có thể chịu được nhiều va đập hơn mà vẫn hoạt động tốt. Cacbua vonfram cứng hơn nhưng có thể gãy nếu bị rơi hoặc va đập quá mạnh. Nếu công việc của bạn có va chạm đột ngột hoặc tải trọng thay đổi, HSS an toàn và đáng tin cậy hơn.

Mẹo: Chọn lưỡi cưa HSS cho những công việc có nhiều rung động hoặc va đập. Chúng bền hơn trong những tình huống khắc nghiệt này.

Tính linh hoạt và chi phí

Lưỡi thép tốc độ cao linh hoạt và phù hợp với nhiều công việc. Bạn có thể sử dụng chúng trên nhiều vật liệu khác nhau. Lưỡi thép HSS có giá thành thấp hơn, vì vậy chúng là lựa chọn thông minh cho nhiều xưởng.

Khả năng tương thích và hiệu suất của vật liệu

- Lưỡi HSS có thể cắt gỗ, kim loại và nhựa dễ dàng.

- Bạn có thể sử dụng HSS cho các kim loại mềm hơn như nhôm và thép mềm.

- Lưỡi dao HSS hoạt động tốt với nhựa và vật liệu composite.

- Những lưỡi dao này xử lý quá trình phay thô và cắt nặng tốt hơn lưỡi dao cacbua vì chúng ít giòn hơn.

- Dụng cụ HSS hoạt động tốt khi thiết lập không ổn định hoặc phôi di chuyển.

- Bạn có thể sử dụng lưỡi HSS cho những công việc nhỏ và nhiều nhiệm vụ khác nhau.

Lưỡi dao cacbua vonfram phù hợp nhất với kim loại cứng, vật liệu mài mòn và sản xuất hàng loạt. Lưỡi dao giữ được độ sắc bén lâu hơn nhưng không chịu được va đập tốt bằng HSS.

Ghi chú: Lưỡi HSS dễ sử dụng hơn nếu máy của bạn không được thiết lập hoàn hảo hoặc nếu bạn chuyển đổi giữa các loại vật liệu.

Phạm vi giá thị trường

Lưỡi dao HSS có giá thành thấp hơn lưỡi dao cacbua vonfram. Chúng rẻ hơn vì dễ chế tạo hơn và sử dụng vật liệu rẻ tiền hơn. Điều này khiến HSS trở thành lựa chọn tốt nếu bạn muốn tiết kiệm chi phí hoặc cần nhiều lưỡi dao.

So sánh chi phí với cacbua vonfram

Lưỡi dao cacbua vonfram ban đầu có giá cao hơn do vật liệu đắt tiền và quy trình sản xuất phức tạp hơn. Tuy nhiên, chúng bền hơn và hoạt động tốt hơn cho những công việc khó khăn. Nếu bạn điều hành một nhà máy lớn hoặc cắt vật liệu cứng cả ngày, lưỡi dao cacbua có thể tiết kiệm chi phí theo thời gian nhờ ít phải thay thế hơn.

Đối với các cửa hàng nhỏ hoặc công việc không đòi hỏi độ cứng cao, lưỡi cưa HSS có giá thành thấp hơn. Bạn sẽ có được kết quả tốt với chi phí thấp hơn. Lưỡi cưa HSS dễ thay thế và mài, giúp bạn tiết kiệm chi phí bảo trì.

Bảng tóm tắt: Hiệu quả chi phí

| Loại ứng dụng | Lựa chọn tốt nhất | Tại sao? |

|---|---|---|

| Công việc khối lượng lớn, khó khăn | Cacbua Vonfram | Tuổi thọ cao hơn, thời gian chết ít hơn |

| Công việc đa dạng, khối lượng thấp | Thép tốc độ cao (HSS) | Chi phí thấp hơn, dễ thay thế và mài sắc |

Mẹo: Nếu bạn muốn tiết kiệm chi phí cắt gọt nói chung hoặc cần lưỡi dao cho nhiều công việc, HSS là một lựa chọn thông minh. Đối với công việc nặng nhọc, liên tục, hãy cân nhắc sử dụng cacbua để tiết kiệm lâu dài.

Các kịch bản ứng dụng

Khi nào nên sử dụng cacbua vonfram

Sản xuất liên tục, khối lượng lớn

Hãy chọn lưỡi dao Tungsten Carbide nếu nhà máy của bạn hoạt động cả ngày. Lưỡi dao này là lựa chọn tốt nhất để cắt nhiều vật liệu liên tục. Chúng bền bỉ hơn nhiều so với hầu hết các loại lưỡi dao khác. Bạn sẽ không cần phải thay lưỡi dao thường xuyên. Điều này giúp bạn hoàn thành nhiều công việc hơn. Các lớp hoàn thiện và xử lý cạnh đặc biệt giúp lưỡi dao này bền hơn. Những nâng cấp này giúp lưỡi dao bền hơn và không bị sứt mẻ. Điều này rất quan trọng khi máy móc hoạt động trong thời gian dài.

Cắt vật liệu cứng hoặc mài mòn

Sử dụng lưỡi dao cacbua vonfram để cắt vật liệu cứng hoặc có sạn. Lưỡi dao này có thể xử lý kim loại cứng và vật liệu thô rất tốt. Trong nông nghiệp, các dụng cụ làm từ vật liệu này bền hơn nhiều so với thép thông thườngNông dân sử dụng chúng để cày và thu hoạch. Họ không cần thay lưỡi dao thường xuyên và tiết kiệm chi phí. Các ngành công nghiệp khác cũng sử dụng những lưỡi dao này cho các công việc nặng nhọc hàng ngày.

Các ứng dụng yêu cầu thời gian ngừng hoạt động tối thiểu

Bạn muốn máy móc của mình hoạt động liên tục mà không bị gián đoạn. Lưỡi dao Tungsten Carbide giúp bạn làm được điều này. Chúng có tuổi thọ cao, vì vậy bạn không cần phải dừng lại để thay lưỡi dao. Lớp phủ đặc biệt giúp lưỡi dao này chịu nhiệt và mài mòn tốt hơn. Điều này giúp máy móc của bạn hoạt động liên tục và hoàn thành công việc đúng hạn.

Ngành công nghiệp: Chế biến gỗ, Chế biến giấy, Nhựa

Nhiều ngành công nghiệp sử dụng lưỡi dao này cho những công việc khó khăn nhất. Trong gia công kim loại, chúng dễ dàng cắt các tấm dày và kim loại cứng. Các xưởng chế biến gỗ sử dụng chúng để cắt mịn gỗ cứng. Ngành công nghiệp giấy sử dụng chúng để cắt và xẻ các cuộn lớn. Các nhà máy nhựa sử dụng chúng để cắt nhựa cứng. Nếu bạn cắt nhiều hoặc làm việc với vật liệu cứng, lưỡi dao này là một lựa chọn tốt.

Mẹo: Bạn muốn ít phải thay lưỡi dao hơn và có nhiều thời gian làm việc hơn? Hãy thử những lưỡi dao này cho những công việc khó khăn nhất của bạn.

Khi nào nên sử dụng HSS

Ứng dụng yêu cầu khả năng chống va đập cao

Chọn lưỡi thép tốc độ cao (HSS) cho những công việc va chạm đột ngột. Lưỡi thép này uốn cong thay vì gãy, do đó an toàn hơn. HSS hoạt động tốt khi bạn chạm vào các mắt gỗ hoặc các điểm cứng trên kim loại.

Thay đổi công cụ thường xuyên hoặc sản xuất ngắn hạn

Nếu bạn thường xuyên thay lưỡi dao hoặc làm những công việc ngắn, HSS là một lựa chọn thông minh. Lưỡi dao này dễ mài và thay thế. Bạn có thể tiết kiệm chi phí và làm được nhiều việc cùng lúc. Lưỡi dao HSS rất phù hợp cho các xưởng có nhiều công việc khác nhau.

Hoạt động có ý thức về ngân sách

Lưỡi cưa HSS có giá thành rẻ hơn lưỡi cưa carbide. Bạn sẽ có được kết quả tốt mà không tốn quá nhiều chi phí. Nếu bạn muốn tiết kiệm chi phí mà vẫn có được những đường cắt đẹp, HSS là một lựa chọn tốt. Lưỡi cưa này dễ dàng giữ được độ sắc bén, giúp bạn tiết kiệm chi phí.

Ngành nghề: Tổng hợp Metalworking, Chế biến gỗ, Xưởng bảo trì

Bạn thấy lưỡi cưa HSS trong nhiều xưởng kim loại và gỗ. Đội ngũ bảo trì sử dụng chúng để sửa chữa và khắc phục nhanh chóng. Lưỡi cưa này dùng được cho máy khoan, máy cưa và dụng cụ phay. Chúng cắt được nhiều loại vật liệu và vẫn sắc bén dưới tác động của nhiệt. Lưỡi cưa lưỡng kim, được làm từ HSS và thép lò xo, bền hơn và cắt thẳng hơn lưỡi cưa thép thông thường. Lưỡi cưa HSS không dễ bị mẻ hoặc cùn, ngay cả trong những công việc khó khăn. Nhiều người nói rằng họ có được những đường cắt sạch hơn và ít lãng phí hơn khi sử dụng lưỡi cưa HSS.

- HSS phù hợp nhất cho những công việc cần khả năng chịu nhiệt và độ bền.

- Bạn có thể sử dụng HSS để cắt, chế biến gỗ và sửa chữa cẩn thận.

- Những lưỡi dao này có độ bền và giá cả hợp lý nên được nhiều cửa hàng ưa chuộng.

Lưu ý: Nếu bạn muốn một lưỡi dao bền, dễ mài và không đắt tiền thì HSS là lựa chọn tốt cho nhiều công việc hàng ngày.

Lựa chọn vật liệu phù hợp

Vật liệu để cắt

Độ cứng và độ mài mòn của vật liệu

Khi chọn lưỡi dao, bạn cần xem xét mục đích cắt của mình. Một số vật liệu rất cứng hoặc thô ráp. Một số khác mềm hơn và dễ cắt hơn. Chất liệu lưỡi dao phù hợp sẽ giúp bạn đạt được kết quả tốt nhất và tiết kiệm chi phí.

- Vật liệu cứng, như thép cứng hoặc gốm sứ, cần lưỡi dao có thể sắc bén và chống mài mòn.

- Các vật liệu mài mòn như sợi thủy tinh hoặc vật liệu tổng hợp sẽ nhanh chóng làm cùn lưỡi dao thông thường.

- Những vật liệu mềm hơn, như thép mềm, gỗ hoặc nhựa, không làm mòn lưỡi dao nhanh như vậy.

- Nếu phôi của bạn có bề mặt gồ ghề hoặc chứa các hạt cứng, bạn cần một lưỡi dao có khả năng chống mài mòn cao.

Bạn cũng nên cân nhắc xem bạn muốn cắt nhanh đến mức nào và công việc đó có cần lưỡi dao cứng hay bền không.

Tính phù hợp của cacbua vonfram cho vật liệu cứng hoặc mài mòn

Lưỡi dao Tungsten Carbide hoạt động tốt nhất trên các vật liệu cứng hoặc mài mòn. Những lưỡi dao này có độ cứng và khả năng chống mài mòn vượt trội. Bạn có thể sử dụng chúng để cắt tốc độ cao và cho các công việc cần lưỡi dao sắc bén trong thời gian dài. Nếu bạn cắt các vật liệu như thép tôi, thủy tinh hoặc vật liệu composite mài mòn, vật liệu này mang lại đường cắt sạch sẽ và tuổi thọ dụng cụ cao. Kích thước hạt mịn và hàm lượng chất kết dính trong lưỡi dao giúp cân bằng độ cứng và độ bền. Điều này giúp lưỡi dao đủ mạnh mẽ cho các công việc khó khăn nhưng vẫn giữ được độ sắc bén.

Tính phù hợp của HSS đối với vật liệu mềm hơn hoặc ít mài mòn hơn

Lưỡi thép tốc độ cao (HSS) là lựa chọn tốt cho các vật liệu mềm hơn hoặc ít mài mòn hơn. Lưỡi dao này có độ bền cao và khả năng chống va đập. Bạn có thể sử dụng chúng để cắt gỗ, thép mềm hoặc nhựa. Lưỡi dao HSS xử lý các vết cắt đứt quãng và va chạm đột ngột tốt hơn lưỡi dao cứng hơn. Nếu công việc của bạn đòi hỏi phải thay đổi dụng cụ thường xuyên hoặc bạn cần một lưỡi dao có thể chịu được va đập, HSS là một lựa chọn thông minh. Bạn cũng tiết kiệm chi phí vì lưỡi dao này có giá thành thấp hơn và dễ mài.

Tần suất sử dụng

Sử dụng liên tục, khối lượng lớn

Nếu bạn vận hành máy móc cả ngày và cắt một lượng lớn vật liệu, bạn cần một lưỡi dao bền bỉ. Lưỡi dao Tungsten Carbide giữ được độ sắc bén lâu hơn nhiều so với lưỡi dao thép. Bạn không cần phải dừng máy thường xuyên để thay lưỡi dao. Điều này giúp bạn tiết kiệm thời gian và giảm thời gian chết. Những lưỡi dao này hoạt động tốt trong các nhà máy, nơi việc dừng dây chuyền tốn kém. Bạn có thể hoàn thành nhiều công việc hơn với ít gián đoạn hơn.

- Lưỡi dao bằng cacbua vonfram có tuổi thọ cao hơn trong điều kiện mài mòn.

- Bạn giảm chi phí bảo trì và thay thế.

- Bạn duy trì dây chuyền sản xuất của mình hoạt động trơn tru.

Sử dụng không liên tục hoặc khối lượng thấp

Nếu bạn chỉ thỉnh thoảng cắt vật liệu hoặc cắt theo mẻ nhỏ, lưỡi dao thép tốc độ cao có thể phù hợp hơn. Lưỡi dao này chịu được va đập và chấn động tốt. Bạn có thể sử dụng chúng cho những công việc thường xuyên phải dừng lại giữa chừng. Lưỡi dao HSS có giá thành thấp hơn, vì vậy bạn không phải tốn nhiều tiền cho những dụng cụ ít sử dụng. Chúng cũng dễ thay thế và mài, giúp bạn tiết kiệm chi phí.

- Lưỡi dao HSS hấp thụ lực va chạm tốt hơn.

- Bạn tiết kiệm được tiền mua dụng cụ cho những công việc nhỏ hoặc đa dạng.

- Bạn có thể thay đổi lưỡi dao nhanh chóng cho các nhiệm vụ khác nhau.

Ngân sách

Đầu tư ban đầu so với chi phí dài hạn

Bạn cần cân nhắc cả chi phí ban đầu và số tiền bạn chi tiêu theo thời gian. Lưỡi dao Tungsten Carbide có giá ban đầu cao hơn. Chúng bền hơn nhiều, vì vậy bạn mua ít lưỡi dao hơn và tiết kiệm chi phí thay thế. Lưỡi dao thép tốc độ cao có giá mua thấp hơn, nhưng bạn cần thay thế thường xuyên hơn.

| Nhân tố | Cacbua Vonfram | Thép tốc độ cao (HSS) |

|---|---|---|

| Chi phí vật liệu ban đầu | Cao | Thấp |

| Tuổi thọ công cụ | Dài | Ngắn |

| Quy trình sản xuất | Tổ hợp | Đơn giản |

| Lao động và Tự động hóa | Cao hơn lúc đầu, nhưng thấp hơn theo thời gian | Tổng thể thấp hơn |

| Chất thải và Hiệu quả | Ít chất thải hơn, hiệu quả hơn | Nhiều chất thải hơn, ít hiệu quả hơn |

Hiệu quả chi phí trong các tình huống khác nhau

Lưỡi dao Tungsten Carbide mang lại giá trị tối ưu cho những công việc khối lượng lớn và đòi hỏi khắt khe. Ban đầu, bạn sẽ tốn kém hơn, nhưng về lâu dài, bạn sẽ tiết kiệm được chi phí vì không cần thay lưỡi dao thường xuyên. Những lưỡi dao này cũng giúp máy móc của bạn hoạt động liên tục, đồng nghĩa với việc bạn có thể hoàn thành nhiều công việc hơn.

- Bạn sẽ có chi phí dài hạn thấp hơn ở những nhà máy bận rộn.

- Bạn giảm thời gian ngừng hoạt động và bảo trì.

- Bạn cải thiện hiệu quả và tiết kiệm nhân công.

Lưỡi thép tốc độ cao là lựa chọn tốt nếu bạn muốn tiết kiệm chi phí ngay hoặc không sử dụng lưỡi thường xuyên. Ban đầu, bạn sẽ tiết kiệm được chi phí, nhưng có thể tốn kém hơn cho việc thay thế và thời gian ngừng hoạt động. Loại lưỡi này là lựa chọn tốt cho các cửa hàng nhỏ hoặc công việc không yêu cầu độ cứng quá cao.

Mẹo: Hãy cân nhắc tần suất sử dụng lưỡi dao và mục đích cắt. Lựa chọn đúng đắn sẽ giúp bạn tiết kiệm chi phí và đạt được kết quả tốt hơn.

Lưỡi dao công nghiệp tùy chỉnh

Tại sao tùy chỉnh lại quan trọng

Mỗi công việc cắt gọt đều không giống nhau. Đôi khi, bạn cần lưỡi cắt vừa vặn với máy móc của mình. Một số công việc cần lưỡi cắt cho các vật liệu đặc biệt. Lưỡi cắt công nghiệp tùy chỉnh giúp bạn thực hiện những công việc này tốt hơn. Dưới đây là một số lý do tại sao lưỡi cắt tùy chỉnh lại quan trọng:

- Bạn có được những đường cắt chính xác, ngay cả với những vật liệu hoặc kích thước không đồng đều.

- Lưỡi dao tùy chỉnh phù hợp với nhu cầu của bạn và hoạt động tốt hơn với máy móc của bạn.

- Thiết kế và vật liệu lưỡi dao phù hợp giúp lưỡi dao bền hơn và ít cần thay thế hơn.

- Lưỡi dao tùy chỉnh giúp nơi làm việc của bạn an toàn hơn và giảm chi phí sửa chữa.

- Bạn có thể chọn góc cạnh, độ dày và chiều dài để phù hợp với công việc của mình và tránh bị chậm trễ.

- Những vật liệu đặc biệt như SKD11, D2 và 6CrW2Si giúp lưỡi dao cứng và bền.

- Lưỡi Dao Tùy Chỉnh hỗ trợ các ngành công nghiệp như hàng không vũ trụ, ô tô, điện tử và xây dựng bằng cách đáp ứng các nhu cầu cắt khắc nghiệt.

Lưỡi cắt được thiết kế riêng giúp bạn tiết kiệm thời gian và tiền bạc bằng cách ngăn chặn sự chậm trễ và giúp công việc nhanh hơn. Bạn cũng có được công việc an toàn hơn và kết quả tốt hơn với lưỡi cắt được thiết kế riêng cho công việc của mình.

Dịch vụ Nam Kinh Metal

Nam Kinh Metal là nhà sản xuất lưỡi dao công nghiệp tùy chỉnh uy tín. Họ có 20 năm kinh nghiệm và nổi tiếng với chất lượng và dịch vụ tốt. Bạn sẽ được hỗ trợ bởi đội ngũ lành nghề, am hiểu nhu cầu của bạn.

- Nanjing Metal sản xuất lưỡi dao tùy chỉnh và hỗ trợ thay đổi thiết kế để lưỡi dao hoạt động tốt hơn.

- Họ sử dụng máy CNC tiên tiến và in 3D để có chất lượng và độ chính xác cao.

- Bạn sẽ được kiểm tra chất lượng chặt chẽ ở mọi bước, từ khâu chọn vật liệu cho đến khâu kiểm tra cuối cùng.

- Nanjing Metal cung cấp cả dịch vụ ODM và OEM, sản xuất lưỡi dao theo bản vẽ hoặc mẫu của bạn.

- Họ xử lý việc vận chuyển và thủ tục hải quan, do đó việc nhập khẩu rất dễ dàng đối với bạn.

- Nhiều ngành công nghiệp như thực phẩm, bao bì, tái chế, cắt kim loại, nhựa, cao su, dệt may và in ấn sử dụng các dịch vụ này.

- Bạn sẽ có được lưỡi dao giúp bạn làm việc nhanh hơn, tiết kiệm tiền và hỗ trợ mục tiêu xanh của bạn.

Nếu bạn muốn biết thêm hoặc nói về nhu cầu của mình, hãy nhấp vào Liên Hệ để liên hệ với kỹ sư bán hàng. Hãy sở hữu lưỡi dao phù hợp cho công việc đặc biệt của bạn ngay hôm nay!

- Chọn Tungsten Carbide nếu bạn cắt nhiều và cần lưỡi dao bền.

- HSS phù hợp hơn cho những công việc đòi hỏi lưỡi dao phải cứng hoặc phải thay thường xuyên.

- Bạn nên chọn vật liệu lưỡi dao phù hợp với công việc, ngân sách và mục đích cắt của mình.

- Lưỡi dao tùy chỉnh có thể giúp bạn khắc phục các sự cố đặc biệt và làm việc nhanh hơn.

Câu hỏi thường gặp

Sự khác biệt chính giữa lưỡi dao Tungsten Carbide và HSS là gì?

Lưỡi dao Tungsten Carbide sắc bén lâu hơn và cắt được các vật liệu cứng hơn. Lưỡi dao HSS chịu va đập tốt hơn và giá thành thấp hơn. Bạn nên lựa chọn dựa trên nhu cầu cắt của mình.

Tôi có thể sử dụng lưỡi dao Tungsten Carbide cho mọi loại vật liệu không?

Bạn có thể sử dụng lưỡi dao Tungsten Carbide cho nhiều công việc khó khăn. Chúng hoạt động tốt nhất trên các vật liệu cứng hoặc mài mòn. Đối với các công việc nhẹ nhàng hơn hoặc ít đòi hỏi kỹ thuật hơn, lưỡi dao HSS có thể phù hợp hơn.

Làm sao để biết loại vật liệu lưỡi dao nào phù hợp với công việc của tôi?

Hãy cân nhắc về vật liệu cắt, tần suất cắt và ngân sách của bạn. Nếu bạn cần độ sắc bén lâu dài, hãy chọn Tungsten Carbide. Nếu bạn muốn độ linh hoạt và chi phí thấp hơn, hãy chọn HSS.

Xem thêm

Nắm vững nghệ thuật của lưỡi cacbua vonfram

Làm thế nào để kéo dài tuổi thọ của lưỡi tròn bằng thép vonfram một cách hiệu quả?

Top 10 Nhà Cung Cấp và Sản Xuất Lưỡi Dao Máy Tạo Hạt Bạn Cần Biết Trong Năm 2025

Top 10 Nhà Sản Xuất và Cung Cấp Dao Cắt Hạt Vòng Khí Hàng Đầu Năm 2025

Cách Thay Thế Lưỡi Dao Mặt Khuôn Máy Tạo Hạt An Toàn và Hiệu Quả

Tìm Kiếm Dao Tạo Hạt Hoàn Hảo cho Nhu Cầu Chế Biến Nhựa Của Bạn

2 bình luận