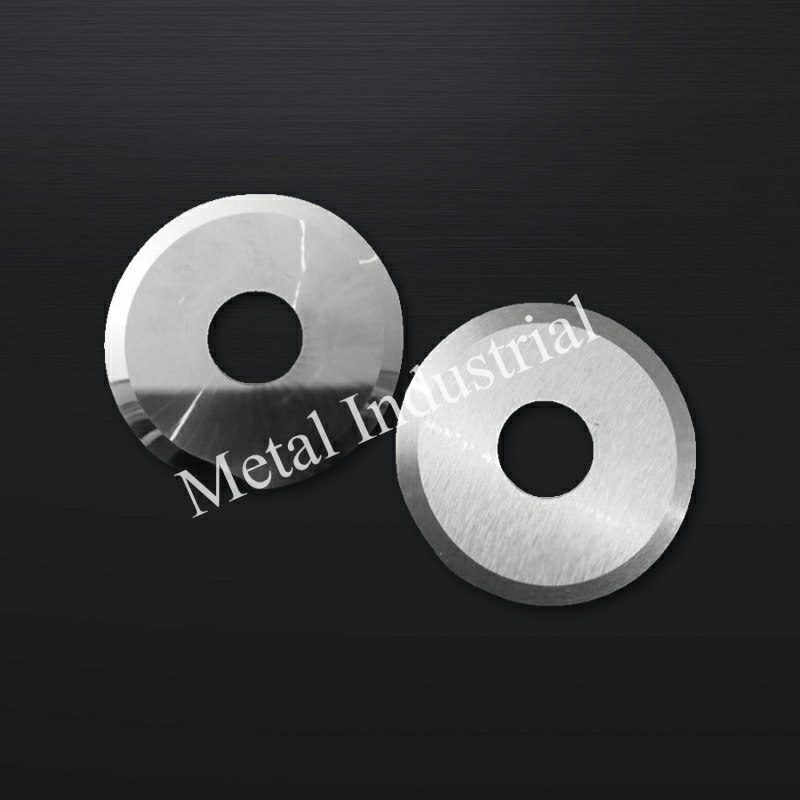

You need high precision rotary slitter blades for your work. These blades help your machines run well and not break down. Sharp and balanced rotary slitter blades make clean cuts. They also help you use less material and waste less. This tool cuts wide rolls into smaller pieces with exact sizes. It helps you keep your products good and your work fast. Good blade shapes give you smooth edges with no rough spots. You do not need extra work to fix the edges, so you save money. Custom slitter blades made from strong materials help you get good results every time.

Key Takeaways

- High precision rotary slitter blades make clean cuts. This helps reduce waste and saves money.

- Blades with high concentricity give steady cuts. This is important for sensitive materials.

- Sharp blades help machines work without stopping. This lets them run smoothly and fast.

- Taking care of blades makes them last longer. You will need fewer replacements, which saves money.

- Picking the right blade material is important. It helps cut different materials well.

- High precision blades help meet strict rules. This keeps product quality high.

- Custom blades can fit specific needs. This makes work easier and faster.

- Good blades make machines safer. They also lower the chance of machine problems.

Precision and Consistency with High Precision Rotary Slitter Blades

Uniform Cutting for Sensitive Materials

If you use thin films or foils, you need rotary slitter blades that cut the same way every time. High precision rotary slitter blades help you make cuts that match your needs. This means every piece looks just like you want. You do not get rough edges, so your products look neat.

Tight Tolerances

Rotary slitter blades with high concentricity spin smoothly. This helps you get the same cut even when working fast. You notice this when you cut sensitive materials. The blade stays steady and does not move off track. Every piece comes out just right.

| Feature | Description |

|---|---|

| Customization | Special sizes and angles make blades work better |

| Clean Cuts | Helps you use more material and waste less |

| High-Speed Operation | Works well for thin films and foils |

Tip: Pick rotary slitter blades with high concentricity to waste less and get better edges.

Edge Quality

You want blades that make smooth edges without rough spots. High precision rotary slitter blades give you clean cuts. You do not need to fix the edges much. This saves you time and keeps delicate materials safe. The right blade helps you avoid mistakes in your products.

Maintaining Product Standards

You need to follow strict rules to keep your products good. Rotary slitter blades with high concentricity help you do this. You get steady results and good performance. This is important for industries with tough standards.

Industry Specifications

Rotary slitter blades must meet certain rules to work well. High concentricity makes sure the blade spins evenly. This gives you exact cuts. Quality certifications like ISO 9001 show your blades are tested and trusted. Precision control technology helps your machines run without problems.

| Specification | Impact on Compliance and Consistency | Benefits of Compliance |

|---|---|---|

| Concentricity | Makes blades spin evenly for exact cuts | Less waste and better products |

| Quality Certifications | Shows blades follow strict quality rules | You can trust the blades and the process |

| Precision Control Tech | Keeps machines working well and lined up | Faster production and less stopping |

Reducing Rejects

You want fewer bad pieces in your work. High precision rotary slitter blades help you do this. Better cuts mean fewer mistakes. Less wasted material helps you work faster. Strong blades last longer, so you change them less often. You spend more time making good products.

- Better cuts mean fewer mistakes.

- Less wasted material helps you work faster.

- Strong blades last longer and need fewer changes.

- High precision blades help machines work better.

- Shock absorption design uses less power.

- Better production means fewer bad pieces.

Note: Using rotary slitter blades with high concentricity and strong materials helps you follow rules and waste less.

Efficiency and Productivity in Rotary Slitter Blades

Using rotary slitter blades with high precision helps you work better. These blades keep machines working well. They cut materials quickly. You spend less time fixing or adjusting things.

Minimizing Downtime

Downtime slows your whole line. You want to stop less and keep machines working. Good rotary slitter blades make switching and fixing fast and easy.

Fast Changeovers

You need to change blades fast when you switch jobs. Many rotary slitter blades have quick-change features. These let you swap blades in less time. Your machines start working again sooner. You wait less and make more products.

| Feature | Benefit |

|---|---|

| Quick-change mechanisms | Cuts downtime when you change products |

| Intelligent detection systems | Stops damage and keeps things running smoothly |

| Advanced diagnostic systems | Tells you when to fix things before they break |

IoT monitoring shows you how blades are working right now. This helps you plan fixes before problems happen. You avoid sudden stops.

Less Adjustment

You want blades that need fewer fixes while working. High precision rotary slitter blades stay sharp and balanced longer. You do not stop the machine often to adjust. Automation helps you keep things moving fast and steady.

Tip: Less downtime helps you finish on time and keep customers happy.

High-Speed Cutting Performance

You need blades that work well at fast speeds. High precision rotary slitter blades give clean, exact cuts even when working quickly.

Consistent Output

When machines run fast, you want every cut to look good. These blades make clean cuts and waste less material. They keep working well for a long time. Their strong design helps them last even when you use them a lot.

- Clean cuts mean less waste.

- Steady work helps you reach your goals.

- Strong blades need fewer replacements.

Operator Efficiency

Workers do better with good blades. Checking and sharpening blades keeps them working well. Sharp blades make work easier. Operators fix fewer problems and keep things moving.

| Metric | Description |

|---|---|

| Blade Sharpness | Tested by how well blades cut and how smooth the surface is. |

| Frequency of Re-sharpening | Shows how often blades need fixing, which affects downtime. |

| Metric | Description |

|---|---|

| Throughput | Went up by 20% after using better blades, showing more work done. |

| Scrap Material | Went down by 25%, meaning less waste and saving money. |

| Energy Consumption | Dropped by 15%, showing machines work easier with sharp blades. |

You get more work done, waste less, and use less energy. Your team can focus on doing a good job and working fast, not fixing blade problems.

Note: Picking the right rotary slitter blades helps you cut faster, waste less, and keep machines working longer.

Cost Savings and Material Waste Reduction

Accurate Cuts, Less Scrap

You want your work to be fast and cheap. High precision rotary slitter blades help you cut things right every time. Blades with high concentricity make smooth edges and even sizes. This means you throw away less material and have less scrap.

Maximizing Yield

You get more good pieces when blades stay sharp and spin evenly. Every cut matches what you need, so you use more of your material. You waste less. Studies show sharp blades can make work better by 25%. If blades are dull, you might get 15% more bad pieces. One metal plant saved $100,000 a year by using sharp blades that cut well.

- Sharp blades help you use more material.

- High concentricity keeps every cut accurate.

- You get fewer defective products.

- You save money by reducing scrap.

Lower Disposal Costs

Less scrap means you pay less to get rid of waste. Blades with high concentricity make fewer pieces you have to throw away. Companies that keep blades sharp work up to 30% better. One report said new slitting tools cut waste by 20%.

Tip: Less scrap and fewer bad pieces help you spend less on waste and save more money.

Operational Cost Control

You save money when you use blades that spin evenly and are made well. These blades last longer and you do not need to buy new ones often. You also spend less time fixing things.

Fewer Replacements

High precision rotary slitter blades with high concentricity stay sharp longer. You do not need to change them as much. This saves you money and keeps machines working well.

| Benefit | Description |

|---|---|

| Longer Lifespan | High precision rotary slitter blades last longer, reducing the frequency of replacements. |

| Reduced Downtime | These blades minimize production interruptions, leading to increased efficiency. |

| Lower Maintenance Costs | They require less frequent maintenance, further decreasing operational expenses. |

Reduced Maintenance

You fix and adjust machines less when blades spin evenly. Blades that work well mean you do not stop as much. Your team can make more products and spend less time on repairs.

| Feature | Benefit |

|---|---|

| Consistent Performance | Maintains sharpness for longer, ensuring high cutting efficiency. |

| Reduced Downtime | Fewer changeovers lead to lower maintenance costs and improved efficiency. |

Note: Picking slitter blades with high concentricity and strong materials helps you save money and keep your work running well.

Safety and Equipment Longevity with Slitter Blades

Lower Machine Wear

Smooth Operation

You want your machines to work well every day. High precision rotary slitter blades with high concentricity help with this. When blades spin evenly, machines feel less stress. You hear less noise and feel fewer shakes. This helps your machines last longer and need fewer repairs.

- High-speed steel blades are hard and tough, so machines wear out slower.

- Carbide-tipped blades cut rough materials and protect your machines.

- Ceramic blades are great at not wearing down, so they work well for careful jobs.

New blade materials like tungsten carbide and ceramic composites help blades last longer. Special coatings keep blades sharp for more time. These changes mean you do not need to replace blades as often. You also spend less money fixing things.

| Aspect | Sharp Blade Impact | Dull Blade Impact |

|---|---|---|

| Machine Wear | Less stress on machine, extending lifespan | More wear and tear, so you fix machines more often |

Component Protection

Blades with high concentricity help protect your machine parts. Clean, straight cuts stop jams and misfeeds from happening. Smooth edges keep rollers and guides safe from harm. If the blade tip wears out, the cut gets worse and can hurt your machine. This can change how the blade cuts and make it pull instead of slice, which is bad for your machine. Using blades that stay even helps your machines last longer.

- Clean cuts meet rules and keep machines working well.

- Smooth edges stop problems and protect important parts.

- Less stress on machines means they break down less.

One car parts company made slitting work better by 20% after using tungsten carbide blades. They also changed blades 20% less, so machines stopped less and lasted longer.

Enhanced Operator Safety

Fewer Failures

Your team stays safer with high precision rotary slitter blades. Fewer failures mean machines stop less and accidents are less likely. Blades that stay even make clean, straight cuts and smooth edges. This means less waste and a neater workspace.

- Fewer stops help you avoid sudden dangers.

- Less waste keeps floors safe and clear.

- Better cuts mean fewer sharp scraps.

Machines and blades last longer, so everyone works in a safer place.

Accident Prevention

You lower accident risks by picking blades made for safety. Many slitter blades have blade guards and shutoff systems. These keep workers safe during blade changes or if something goes wrong.

- Blade guards keep hands safe from sharp edges.

- Shutoff systems stop machines fast if there is a problem.

Safe work starts with good equipment. Blades that work the same every time and stay even help stop accidents before they happen.

Tip: Check your blades and safety tools often to keep your work safe and smooth.

Risks of Low-Quality Rotary Slitter Blades

If you pick low-quality rotary slitter blades, you can have big problems. These problems can hurt your work, cost you more money, and make your business look bad. Knowing about these risks helps you choose better for your company.

Increased Waste and Quality Issues

Blades that are not good do not cut clean or right. You might see more waste and more products that get thrown out. This can make you lose money and slow down your work.

High Reject Rates

You want every roll to be just right. If blades do not cut the same way, you get more pieces that fail checks. More bad pieces mean you throw away more and spend more time fixing things. Even small mistakes in trim width or slit width can cause big losses.

| Aspect | Impact on Waste | Notes |

|---|---|---|

| Trim Width | 1.2–2.5 cm | Too much trim can make up to 3% waste, especially in small machines. |

| Slit Width Variations | Increased waste | Changes in width can make rolls too wide or narrow, so they get rejected. |

| Environmental Factors | Quality issues | Hard to control the air or temperature can change sizes after making the rolls. |

Note: Even a little more waste can cost you a lot of money each year.

Inconsistent Dimensions

You need every cut to be the right size. Bad blades often make rolls with different widths. This means your products might not fit what you or your customers want. You may need to fix or throw away these rolls, which wastes time and money. Bad size control also makes it hard to meet rules for your industry.

More Downtime and Repairs

Using bad blades makes your machines stop more. You spend more time changing blades and fixing things. This extra stopping makes you work slower and costs you more.

Blade Breakage

Blades that are not strong or sharp break faster. When a blade breaks, you must stop and put in a new one. Changing blades a lot slows your work and makes your team tired. Dull or broken blades also make rough cuts, which can hurt your materials and machines.

- More broken blades mean more stops.

- Every stop means you make less.

- Broken blades can damage your machine parts.

Emergency Maintenance

Bad rotary slitter blades can break without warning. You might need to fix things fast if a blade fails while working. These surprise stops mess up your plans and can make orders late. Your repair team has to hurry to fix things, which costs more and adds stress.

Taking care of slitter blades is important to keep your work running well. Bad blades mean you change and fix them more, which makes you stop more and pay more for repairs. Dull blades cut badly, so you have to fix or change them more often.

Tip: Buying better blades helps you avoid expensive repairs and keeps your machines working well.

You keep your work safe when you pick blades that always work well. Stay away from bad blades to keep your line fast and steady.

High Concentricity and Quality Control in Slitter Blades

You want slitter blades that work the same every time. High concentricity and strong quality checks help with this. If you pick blades with tight concentricity, you get smoother cuts. You also waste less material and your machines last longer. Let’s see how top companies like Nanjing Metal Industrial set high standards for blade performance.

Blade Manufacturing Standards

Material Selection

The material you pick for slitter blades matters a lot. Nanjing Metal Industrial has many choices. These include tungsten carbide, high-speed steel, carbon steel, tool steel, and powder metallurgy. Each material has its own good points. Tungsten carbide is very hard and does not wear out fast. High-speed steel is tough and keeps its edge well. You can pick what fits your job best, like cutting paper, film, foil, or rubber.

- Tungsten carbide: Great for long jobs and rough materials.

- High-speed steel: Good for lots of cutting and general use.

- Tool steel and carbon steel: Work well for normal jobs.

- Powder metallurgy: Best for hard and tricky tasks.

You can also make your blades special. Nanjing Metal Industrial lets you order blades using your own drawings or samples. You can change blade shape, edge angle, and thickness to fit your needs.

Inspection Protocols

Quality control starts with picking good materials. It keeps going through every step of making blades. Makers use strict checks to make sure blades have high concentricity and work well. Here’s how they test each blade:

| Inspection Parameter | Description |

|---|---|

| Hardness Testing | Rockwell or Vickers tests check blade hardness. |

| Dimensional Accuracy | CMM and laser tools check thickness and size within ±0.002 mm. |

| Runout and Concentricity | Measured to keep wobble low, usually less than 0.005 mm. |

| Surface Finish | Lapping and polishing make smooth surfaces for less friction. |

| Edge Integrity | Microscopes check for sharp, clean edges. |

You get blades that meet strict concentricity rules. This means your machines run better and your cuts stay neat.

Performance and Reliability

Certification

You want proof your blades meet industry rules. Top suppliers give certifications like ISO 9001:2015 and AS9100D. These show every blade passes tough checks. Nanjing Metal Industrial follows these rules to give you reliable, high precision rotary slitter blades.

| Certification Type | Description |

|---|---|

| ISO 9001:2015 | Makes sure blades are made with strong quality systems. |

| AS9100D | Meets tough aerospace reliability and quality needs. |

You can ask for special packaging to keep blades safe. Waterproof and strong packaging keeps blades in good shape until you use them.

Supplier Support

Good performance is more than just the blade. You need a supplier who helps before and after you buy. Nanjing Metal Industrial gives technical help, training, and quick answers if you have problems. You can get help with setup, use, and fixing issues. You can also pick blade sizes and thickness from 0.01mm to 0.05mm, so you always get the right blade.

- Help with installing and using blades

- Fast answers to your questions

- Training for your team to use blades safely and well

Tip: Pick a supplier who gives high concentricity and strong support. This helps your line run well and your products stay the same.

Blade Manufacturing Standards Table

| Feature | Description |

|---|---|

| Materials | Best alloy tool steels and forged steel, including tungsten carbide and high-speed steel. |

| Hardening Process | Hardened and tempered for even blade hardness. |

| Tolerances | Thickness tolerances better than +/- 0.000040”. |

| Surface Finish | Lapped and polished for smooth cutting. |

| Mechanical Properties | Heat-treated for top slitting results. |

| Special Applications | Custom orders for specific needs. |

| Tooling Tolerance Levels | Made to different tolerance levels for tough jobs. |

Every detail matters. From picking materials to final checks, each step makes sure your blades meet high standards for concentricity and reliability.

Performance Metrics Table

| Performance Metric | Description |

|---|---|

| Maintenance | Regular checks and oil keep knife holders working well. |

| Material Selection | The right material makes blades last longer. |

| Coating Technologies | PVD and CVD coatings help blades resist wear and work better. |

When you use high precision rotary slitter blades with high concentricity, you get better results. Your machines last longer, your cuts stay sharp, and your team works more safely.

Selecting the Right High Precision Rotary Slitter Blade

Picking high precision rotary slitter blades takes careful thought. You need blades that fit your materials and machines. The right blade helps you work faster and waste less. It also keeps your products looking the same.

Application Requirements

Material and Thickness

First, figure out what material you want to cut. You also need to know how thick it is. Softer things like paper or plastic films use high carbon steel or stainless steel blades. Harder things like metal sheets or rubber need tool steel or tungsten carbide blades. Thick materials need blades that are harder and last longer. If you cut many kinds of materials, you might need different blades for each job.

- The kind of material changes which blade you pick and how long it lasts.

- How thick the material is tells you how strong the blade should be and what edge it needs.

Tip: If you have special materials or thicknesses, look at custom blade choices.

Cut Quality

You want every cut to be neat and meet your needs. High precision rotary slitter blades should make smooth edges and straight lines. They should also make little dust. You can check cut quality in different ways:

| Criteria | Description |

|---|---|

| Visual Inspection | Edges should look clean with no fraying or tiny defects. |

| Edge Straightness | Most jobs need edges within ±0.5mm per meter; some need even tighter cuts. |

| Measurement Techniques | Optical scanners can find edge changes as small as 0.01mm. |

| Dust Count Measurements | Normal jobs allow 50-100 dust bits per cm²; medical jobs need less than 10 bits per cm². |

If you need very exact cuts for things like medicine or packaging, pick blades that give smooth edges and tight cuts.

Supplier Partnership

Technical Expertise

It helps to work with suppliers who know a lot about high precision rotary slitter blades. Skilled teams help you pick the right blade, material, and edge shape. They give tips on how to fit blades to your machines and make them last longer. Custom blades let you do special jobs and make sure blades fit your machines.

- Custom blades fit your work needs.

- Expert help makes it easier to fix problems.

Service and Support

Good service helps your work go smoothly. Trusted suppliers give fast help after you buy, like quick shipping and fixing problems. They also help you keep things running well. You can expect:

| Feature | Description |

|---|---|

| Unmatched Quality | Blades made from top materials for steady work. |

| Custom Solutions | Blades made to fit your needs and machines. |

| Ready to Ship | Popular blades can be sent quickly. |

| Expert Support | Skilled staff help you pick, install, and care for blades. |

Note: Working with a supplier who knows a lot and helps fast makes sure your high precision rotary slitter blades work well.

Picking the right blade helps you get better cuts, waste less, and keep your work smooth. Take time to match your blade to your material, cut needs, and supplier help for the best results.

When you pick high precision rotary slitter blades, your work gets better. These blades help you cut things faster and waste less. They also help keep your team safe. You get good results by choosing the right blades. You can also make slitter blades fit your needs. Strong quality checks make sure every blade is up to your standards.

| Benefit Category | Description |

|---|---|

| Sustainability and Eco-Friendly Products | Eco-friendly blades help you reach your green goals. |

| Demand for High-Precision Solutions | Special blades fit your process needs. |

| Focus on Cost Efficiency | Tough blades help you save money over time. |

| Shift Toward Automation-Ready Products | Automation-ready blades work well with fast machines. |

| Brand Trust and Quality Assurance | Trusted blades give steady results and keep you safe. |

Look at your blades now. If you want to make more products, talk to our sales engineers here.

FAQ

What makes high precision rotary slitter blades different from regular blades?

High precision rotary slitter blades use tighter rules and better materials. You get cleaner cuts and less waste. These blades help you follow strict rules and make your products better.

How do I choose the right blade material for my application?

Pick blade material that matches what you cut. Use high carbon steel for soft things. Use tungsten carbide or tool steel for hard or rough things. Ask your supplier for help with your needs.

How often should I replace high precision rotary slitter blades?

Change blades when you see dull edges or rough cuts. If you notice more waste, check your blades. Look at blades often to find problems early. High precision rotary slitter blades last longer, so you change them less.

Can high precision rotary slitter blades reduce material waste?

Yes, these blades help you waste less material. They make accurate cuts and smooth edges. You get more good pieces and spend less on trash.

What maintenance do high precision rotary slitter blades require?

Clean blades often and check for damage. Lubricate moving parts and look at blade holders. Good care keeps blades sharp and machines working well.

Are high precision rotary slitter blades suitable for automated production lines?

You can use these blades in automated lines. They work well and last long. You get fewer stops and better results.

How do I know if my blades meet industry standards?

Look for certifications like ISO 9001. Ask your supplier for reports and papers. Trusted blades meet strict rules.

Can I customize high precision rotary slitter blades for my equipment?

You can order custom blades for your machine. Give drawings or details to your supplier. Custom blades help you get the best results.

See Also

Top Mistakes in Rotary Slitter Blade Troubleshooting and How to Fix Them

Extend Your Blade’s Life: The Complete Guide to Rotary Slitter Blade Sharpening

High-Precision Rotary Slitter Blades for Film and Foil Slitting

The Best Rotary Slitter Blades for Metal Slitting

How to Achieve Perfect Cuts with Rotary Slitter Blades for Paper