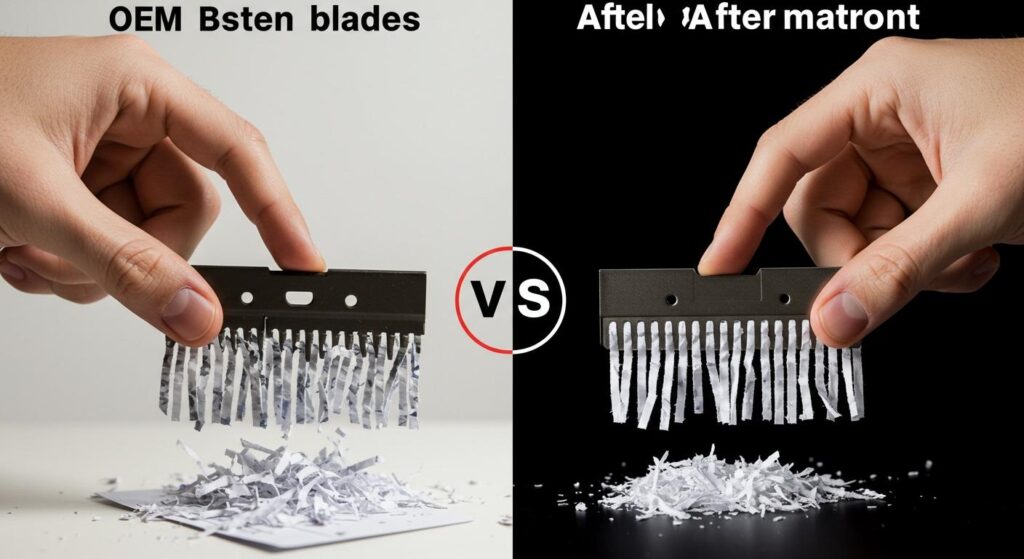

When you compare شفرات المفرمة OEM and aftermarket shredder blades, you want the best for your shredder. Most people see that OEM shredder blades have better quality, sharper edges, and work more reliably. The best choice depends on what you need. You should think about:

- Material properties, like high-speed steel or tungsten carbide, which change how your blades work.

- The kind of shredder and what you use it for.

- Customization choices that help your blades last longer.

- What you want your blades to do.

Nanjing Metal sells OEM shredder blades that can fit your needs, especially if you want the best quality and long-lasting blades.

النقاط الرئيسية

- OEM shredder blades have better quality and fit. They help your shredder work well and last longer. Aftermarket blades usually cost less but can be different in quality. Always check the details before you buy them. The blade material, like high-speed steel or tungsten carbide, affects how well they work and how long they last. OEM blades often come with a strong warranty. This gives you help and comfort if something goes wrong. Remember to plan for wait times when you order blades. This helps you avoid stopping your work. Taking care of your blades and checking them often makes them last longer. It also helps your shredder work better. You can get custom blades from both OEM and aftermarket brands. This helps you meet special shredding needs. Think about how much you shred and what you shred. This helps you pick the best blades and save money.

شفرات المفرمة OEM

تعريف

When you look at OEM shredder blades, you see blades made just for your shredder. These blades come from the original equipment manufacturer. They fit your machine perfectly and work well with all the parts. OEM shredder blades are not like regular blades you find in a store. They are built for tough jobs in industrial shredders. You can use them for cutting plastic, metal, or even rubber. Some types have serrated or hook-shaped edges. These special shapes help with tearing and shearing solid waste. You will also find single shaft shredder blades, which are great for many shredding jobs. If you need blades for a single shaft shredder, OEM blades give you the right fit and performance.

مزايا

التوافق

You want blades that fit your shredder without problems. OEM shredder blades match your machine’s size and shape. You do not have to worry about the blade being too loose or too tight. This is important for single shaft shredder blades and other types. When you use the right blade, your shredder works better and lasts longer. You also avoid damage to your machine. If you ever need custom blades, you can get them made to fit your needs.

جودة

Quality matters when you choose blades. OEM shredder blades use strong materials like high-speed steel or tungsten carbide blades. These materials help the blades stay sharp and last longer. You get better blade sharpness and smoother cutting. Nanjing Metal uses strict quality checks to make sure every blade meets high standards. Here is how they check for quality:

| مقياس مراقبة الجودة | وصف |

|---|---|

| First Article Inspection | Checks the first blade made. |

| Incoming Material Inspection | Looks at the materials before making blades. |

| In-Process Quality Inspection | Checks blades during the making process. |

| Final Quality Inspection | Looks at blades before sending them to you. |

You can trust that your blades will work well and keep your shredder running smoothly. The quality of OEM blades means you spend less time fixing your machine and more time shredding.

ضمان

When you buy OEM shredder blades, you get a warranty. This warranty gives you peace of mind. If something goes wrong, you can get help or a replacement. You know you are covered if there is a problem. The warranty and support also show that the company stands behind their product. You can focus on your work and not worry about your blades.

سلبيات

يكلف

شفرات المفرمة OEM cost more than some other types. You pay for better quality, fit, and warranty. Sometimes, special features or custom designs can add to the price. Here is a quick look at the cost and other disadvantages:

| Disadvantage | وصف |

|---|---|

| Time to manufacture | Custom blades take more time to make. |

| Cost of special features | Special features can cost extra money. |

Lead time

You may need to wait a bit longer for OEM blades, especially if you order custom blades. The usual lead time for OEM shredder blades is about 4 to 7 days for making the blades, plus 3 to 5 days for shipping. This is faster than some aftermarket blades, which can take up to 40 days. If you plan ahead, you can avoid delays and keep your shredder working.

Tip: When sourcing shredder blades, always check the lead time and plan your orders early. This helps you avoid downtime and keeps your operation running.

OEM shredder blades give you the best mix of quality, fit, and warranty. They work well for single shaft shredder blades and other types. If you want blades that last, cut well, and come with strong warranty and support, OEM blades are a smart choice. You also get the benefit of advanced shredder blade design features and many types of single shaft shredder blades to fit your needs. This helps lower your total cost of ownership over time.

Aftermarket shredder blades

تعريف

Aftermarket shredder blades are a common choice for upgrades or replacements. These blades are not made by the original equipment manufacturer. Third-party companies make them for many shredders. You can get blades for single shaft, double shaft, or multi-shaft shredders. Aftermarket blades fit lots of machines, but you must check the specs first. If you want to try new shredder blade design features, aftermarket blades give you more choices.

الايجابيات

سعر

Many people want to save money on shredder blades. Aftermarket blades usually cost less than OEM shredder blades. Lower prices help you spend less, especially if you change blades often. You can buy standard blades for normal jobs or get custom blades for special materials.

التوفر

Aftermarket blades are easy to find in stores or online. Many suppliers keep popular types ready to ship. If your shredder breaks, you can get new blades fast. The modular design lets you swap out parts quickly. Here are the main advantages:

| ميزة | وصف |

|---|---|

| التخصيص | Aftermarket shredder blades can be made to fit your needs. This helps you get the best performance for the materials you shred. |

| التوفر | The modular design means you can find parts easily. You can replace or adjust blades fast when you need to. |

التخصيص

You can order aftermarket blades in special shapes, sizes, or with coatings. If you shred tough materials, you might want blades with nitriding or titanium coatings. These features help blades last longer and cut better. Some suppliers offer single shaft shredder blades with extra claws or serrations for stronger shredding.

سلبيات

Quality variation

Aftermarket blades do not always have the same quality as OEM shredder blades. You may see big differences in how long they last. Standard blades last about 10 days in recycling, but custom blades can last over 40 days. Tungsten carbide makes blades last three times longer than high-speed steel. Surface treatments can make blades last 40-50% longer. If you pick low-quality blades, you may have more downtime and higher costs.

| نوع الشفرة | Wear Resistance / Lifespan | مزايا إضافية |

|---|---|---|

| الشفرات القياسية | Last about 10 days in recycling | More downtime (about 16 hours/month), higher replacement costs ($25,000/year) |

| شفرات مخصصة | Last over 40 days (4x longer) | Downtime drops to about 5 hours/month, replacement costs go down to $9,500/year; tungsten carbide makes blades last about 3x longer than high-speed steel; surface treatments (nitriding, titanium coatings) make blades last 40-50% longer; fewer jams and repairs help keep work safe and productive |

Compatibility issues

You must check if aftermarket blades fit your shredder. Some blades may not match your machine’s specs. A bad fit can cause jams or damage. Always check the size and mounting style before you buy. If you use special blades, like multi-shaft or claw blades, double-check that they fit.

Limited warranty

Aftermarket blades often have a limited warranty and less support. You may not get the same coverage as OEM shredder blades. If a blade breaks, you might pay for repairs or new blades. Always ask about the warranty before you buy. A good warranty helps protect your shredder and your money.

Tip: Always compare quality, warranty, and fit before you buy aftermarket blades. This helps you avoid problems and keeps your shredder working well.

Blade quality and efficiency

When you pick shredder blades, you want good quality and efficiency. The right blades can help your shredder work better. You might ask how OEM shredder blades and aftermarket shredder blades compare. Let’s look at the details so you can choose what works best for you.

مادة

المواد الشائعة المستخدمة

Manufacturers use different kinds of steel to make shredder blades. Each steel type has its own strong points. Here are the main materials:

- Tool Steel (like D2, H13): This steel is tough and hard. It works well for shredding metals and plastics.

- Alloy Steel (such as CrMo or NiCrMo): These blades are strong and can handle shocks. They are good for mixed scrap.

- High-Speed Steel (HSS): This steel is very hard and lasts a long time. It costs more and can break easier.

- Cold Work Die Steel (like 9CrSi): This steel is hard and cheap. It works well for shredding cables.

You can pick the steel type based on what you need to shred. If you want special blades, you can look at شفرات مخصصة لمزيد من الخيارات.

مقارنة المواد

You may want to know how these steels compare. Here is a table that shows what each steel is good at and where it might not be as strong:

| Material Category | Key Strength(s) | Potential Weakness(es) |

|---|---|---|

| أداة الصلب | High Wear Resistance, Good Hardness | Moderate Toughness |

| خليط معدني | High Toughness, Shock Resistance | Lower Wear Resistance |

| حديدعالى السرعه | Superior Edge Retention, Hardness | Higher Cost, More Brittle |

| فولاذ العمل البارد | Good Wear Resistance, Cost-Effective | Needs quality heat treatment |

Hardness helps blades stay sharp longer. Wear resistance means blades do not wear out fast. Toughness keeps blades from breaking when they hit hard things. If you use single shaft shredder blades, you want blades that are hard, tough, and last long.

Special manufacturing steps, like careful machining and heat treatment, can make blades harder and tougher. Nanjing Metal uses these steps to make sure their blades are high quality.

متانة

Actual Service Life Comparison

You want blades that last a long time. How long blades last depends on the steel and how well they fit your shredder. OEM blades usually fit perfectly and help your shredder work well. Some aftermarket blades, like manganese hammers, can last about 20% longer than some OEM blades. If you buy from a good aftermarket supplier, you might get blades that last as long as OEM blades or even longer.

Here are things that help blades last:

- Using the right steel for your waste.

- Good hardness to stop wear.

- Special manufacturing for extra toughness.

- Regular care to keep blades sharp.

Blades that last longer save you money. You do not need to buy new blades or fix your shredder as often. Machines with good blades need less fixing. This helps you spend less over time. If you buy strong blades, your shredder works better and breaks down less.

أداء

You want your shredder to work quickly and cut well. Blade quality is very important for this. Studies show that OEM blades can help your shredder work over 30% better than regular aftermarket blades. Good steel and careful making help blades cut better, stop breakdowns, and lower repair costs.

If you pick good blades, you get sharper edges and smoother cuts. Your shredder works faster and can handle more stuff. You also get less waste left inside the machine. Here are some things to check:

| متري | وصف |

|---|---|

| Recycling Efficiency | Ratio of output mass of recycled PET plastic to input mass of PET plastic. |

| Retained Mass | Mass of PET plastic left uncut in the shredder; a low value means good shredding. |

| كفاءة التقطيع | Percentage of recyclable shredded PET plastic with area size ≤ 1 cm × 1 cm relative to total output. |

You can also check shredding efficiency, how much work gets done, and how long it takes. If you use single shaft shredder blades, you want blades that stay sharp and cut tough things. Good blades help you finish jobs faster.

Tip: If you want blades that fit your shredder and work well, always check the steel, how they are made, and the warranty. Blades with good warranty and support help you avoid problems and keep your shredder running.

Picking the right blades gives you better work, longer blade life, and lower costs. Whether you choose OEM shredder blades or aftermarket blades, always look for good quality, strong steel, and the right type for your job.

شفرات تقطيع البلاستيك

تطبيق

Plastic shredder blades help break down plastic waste. They turn big plastic pieces into small ones. This makes it easier to recycle or throw away plastic. You can find these blades in recycling plants and factories. Some workshops also use them. The right blades let your shredder cut bottles, containers, pipes, and large plastic parts.

It is important to pick the right plastic shredder blades. Good blades stay sharp and last a long time. If you choose the wrong blades, your shredder might jam or break. You need blades that can cut many types of plastic. Some plastics are soft, but others are hard or tough. The best blades can cut all these types without problems.

Here is a table that shows what to look for in plastic shredder blades:

| Characteristic/Material | وصف |

|---|---|

| High Hardness | Keeps blades sharp during cutting and stops early wear. |

| ارتداء المقاومة | Makes blades last longer, even with lots of use. |

| مقاومة الصدمات | Lets blades handle hits and pressure from tough plastic. |

| قابلية التصنيع | Makes it easy to shape blades for different shredder types. |

| أداة الصلب | Good for hardness and wear resistance. |

| Hard Alloy | Great for tough jobs, with high hardness and wear resistance. |

| كربيد التنغستن | Best for extreme hardness and wear resistance, but costs more. |

Tip: Always use plastic shredder blades that match the type of plastic you need to shred. This helps your shredder work well and last longer.

OEM vs. aftermarket

OEM shredder blades come from the company that made your shredder. These blades fit your machine just right. They work well for most plastic types. OEM blades use standard tool steels and give steady cutting.

Aftermarket blades are made by other companies. Some use better tool steels like D2 or SKD11. These blades are often stronger and tougher. Some aftermarket blades work better for hard plastic jobs. They can cut better and last longer with tough plastics.

فيما يلي جدول لمساعدتك في المقارنة:

| ميزة | OEM Blades | Aftermarket Blades |

|---|---|---|

| مادة | Standard tool steels | Premium tool steels (D2, SKD11) |

| تصميم | Original design | Enhanced for toughness |

| ملاءمة التطبيق | General use | Heavy-duty and special tasks |

| أداء | Standard cutting | Improved cutting |

You might want aftermarket blades if you need stronger replacement blades. Some are made in-house for better quality. These blades can cut big plastic items and handle strong impacts. Some have tough designs for hard jobs.

Nanjing Metal sells many kinds of plastic shredder blades. You can choose single shaft, double shaft, or multi-shaft blades. Each type is good for different shredding jobs. Some blades have special shapes, like claws or hooks, to help with tough plastic.

Note: Always check if your blades fit your shredder and match the plastic you want to shred. The right blades help your machine work better and keep you safe.

Maximizing efficiency

Selection tips

You want your shredder to work its best. The right selection of blades makes a big difference. When you look at plastic shredder blades, you should match the blade type to your material and machine. Here are some tips to help you with selection:

- Think about the material you need to shred. Hard plastics need tough blades. Softer plastics may need a different design.

- Check your production volume. If you shred a lot, you need blades with high durability.

- Plan your maintenance cycle. Some blades need sharpening more often. Others last longer between changes.

- Set your budget. Sometimes, spending more at first means you save money later because the blades last longer.

- Ask about heat treatment. Proper heat treatment helps blades stay sharp and strong.

You can find many types of plastic shredder blades. Some have special shapes for better cutting. Others use advanced materials for longer life. Always check if the blades fit your shredder. Good selection helps with maximizing efficiency and keeps your machine running smoothly.

صيانة

Keeping your blades in top shape is key for maximizing efficiency. Regular care helps your shredder last longer and work better. Here are some steps you can follow:

- Pick blades made from strong materials like alloy steel or carbide. These last longer and handle tough jobs.

- Inspect your blades often. Look for chips, dull edges, or cracks.

- Clean and lubricate your blades. This stops rust and keeps them moving smoothly.

- Use precision sharpening tools. Machines like CNC sharpeners make sure each blade edge is even.

- Follow the shredder’s guidelines. Running your machine the right way helps blades last.

- Try protective coatings. Coatings like titanium nitride can make blades resist wear.

- Watch the temperature. If your shredder gets too hot, blades can wear out faster.

- Check blade alignment. Misaligned blades can cause extra stress and wear.

- Buy from trusted brands. High-quality manufacturing means better blades.

- Train your team. When everyone knows how to spot problems, you catch issues early.

- Use new tech. Smart sensors can warn you when blades need care.

- Choose eco-friendly options. Green lubricants and materials help your blades and the planet.

If you follow these steps, your plastic shredder blades will last longer and keep your shredder working at its best.

التخصيص

Sometimes, standard blades do not fit your job. Customization can help you get the most from your shredder. When you choose custom plastic shredder blades, you can:

- Pick the perfect shape and size for your material.

- Choose blade thickness for the output you want. Thicker blades handle big pieces. Thinner blades make finer cuts.

- Select special cutting edges or tooth designs. Some teeth work better for certain plastics or reduce dust.

- Match the blade material to your needs. This helps with durability and efficiency.

- Reduce energy use by picking blades made for your machine and material.

Custom blades can boost your shredder’s efficiency and make your work easier. If you need help, companies like Nanjing Metal offer support and custom blades for many types of shredders. You can talk to their team to find the best fit for your operation.

Note: Customization is not just for big factories. Even small shops can benefit from blades made for their exact needs. The right plastic shredder blades help you save time, money, and effort.

Decision guide

ميزانية

When to choose OEM blades

You want your shredder to run smoothly and last a long time. If you have a bigger budget, OEM blades make sense. These blades cost more at first, but you get better quality and longer life. You spend less time fixing your shredder and more time working. OEM blades fit your machine perfectly, so you avoid jams and breakdowns. You also get a strong warranty, which means help if something goes wrong.

Here’s a table to help you see how the costs compare:

| نوع المادة | التكلفة الأولية | Cost-per-ton Processed | طول العمر | وقت التوقف |

|---|---|---|---|---|

| High-performance steels | أعلى | أدنى | أطول | أقل |

| 9CrSi (heat-treated) | معتدل | Competitive | Task-specific | يختلف |

If you process lots of plastic, metal, or rubber, OEM blades save you money over time. You get consistent quality and reliable cutting. You also avoid surprise costs from repairs or lost work.

When to choose aftermarket blades

If you want to save money right now, aftermarket blades might be the way to go. These blades cost less up front. You can find many types for different shredders, including single shaft shredder blades. Some aftermarket blades work well if you buy from a trusted supplier. You get more choices for plastic shredder blades and can pick special designs for your job.

وهنا بعض الأمور التي يجب التفكير فيها:

- Aftermarket blades offer cost savings and a wider selection.

- You can find blades for many shredder models.

- Performance can be strong if you choose reputable suppliers.

- Warranty may be limited, so check before you buy.

If you run a small shop or do light shredding, aftermarket blades can help you stay on budget. Just make sure you check the quality and fit before you buy.

Machine type

Compatibility with OEM blades

You want blades that match your shredder exactly. OEM blades are made for your machine. They fit perfectly and work with all the parts. You avoid problems like loose blades or jams. If you use single shaft shredder blades, OEM options give you the best fit and cutting action. You also get blades designed for your shredder’s speed and power.

OEM blades work well for machines with special designs or custom features. You get blades that match the size, shape, and mounting style. This helps your shredder run safely and efficiently.

Compatibility with aftermarket blades

Aftermarket blades fit many types of shredders. You can find blades for single shaft, double shaft, or multi-shaft machines. If your shredder uses standard parts, aftermarket blades may fit well. You get more choices for plastic shredder blades and can pick designs for different materials.

Before you buy, check the blade size and mounting style. Some aftermarket blades may not fit perfectly. A bad fit can cause jams or damage. Always ask the supplier about compatibility and warranty. If you use aftermarket blades, test them first to make sure they work with your shredder.

أداء

High-performance requirements

If you need your shredder to handle tough jobs, you want blades that deliver top performance. OEM blades use high-quality materials and advanced manufacturing. You get sharp edges and strong cutting power. These blades last longer and help your shredder work faster. You also get less downtime and fewer repairs.

For heavy-duty shredding, like processing large amounts of plastic, metal, or rubber, OEM blades are the best choice. You get blades that stay sharp and cut cleanly. You also get a strong warranty, so you can focus on your work.

Standard performance needs

If you do light shredding or work with softer materials, aftermarket blades may be enough. These blades cost less and can handle everyday jobs. You get more choices for plastic shredder blades and can pick designs for your needs. Some aftermarket blades work well for single shaft shredder blades and general cutting.

Just make sure you check the quality and fit. If you buy from a good supplier, aftermarket blades can give you solid performance. You may not get the same warranty or lifespan as OEM blades, but you save money and get the job done.

Tip: Always match your blades to your shredding needs. If you want high performance and long life, OEM blades are the way to go. For standard jobs and lower costs, aftermarket blades can work well.

تطبيق

Material type considerations

When you pick blades for your shredder, think about what you want to shred. Each material needs a different kind of blade. Plastic, metal, rubber, and wood all act differently in the shredder. Some are soft and easy to cut. Others are hard and need stronger blades.

Here are some things to remember: First, learn about blade materials. Tool steel is good for hard plastics and metals. Alloy steel is tougher and works for mixed scrap. High-speed steel lasts longer but can break more easily. Cold work die steel is best for cables and softer plastics. Next, match the steel to your job. Plastic shredder blades need to stay sharp and resist wear. For metal, you want blades that are extra tough. Rubber and wood need blades that can take hits and not chip.

Think about how much you use your shredder. If you use it all day, you need blades that last and do not need much care. Single shaft shredder blades are good for most jobs. If you shred big or bulky waste, you might need multi-shaft blades.

Also, check how strong your shredder is. Stronger shredders can use tougher blades and handle bigger loads. The right blade material helps your shredder work better and saves money over time.

Here’s a table to help you pick the right blade:

| المواد المعالجة | Recommended Blade Type | الخصائص الرئيسية |

|---|---|---|

| بلاستيك | شفرات تقطيع البلاستيك | High wear resistance, sharp cutting |

| المعدن | Alloy/tool steel blades | Toughness, impact resistance |

| أو صناعة المطاط | Hardened steel blades | Flexibility, durability |

| خشب | Carbide-tipped blades | Edge retention, strength |

Tip: Always check your blade specs before buying. The right blade keeps your shredder working well and helps you avoid repairs.

توصيات خاصة بالقطاع

Different industries need different blades. If you work in recycling, manufacturing, or waste management, you need blades that fit your job. Here are some examples:

- Plastic recycling plants: Use plastic shredder blades that stay sharp and last long. These blades help you cut bottles, containers, and pipes into small pieces.

- Metal processing facilities: Pick blades made from tough tool steel or alloy steel. These blades cut hard metals and last longer.

- Rubber and tire shredding: Use blades with high impact resistance. Hardened steel blades are best for thick rubber and tires.

- Wood processing: Carbide-tipped blades keep their edge and cut wood cleanly. These blades last longer and make smooth cuts.

If you shred a lot, OEM shredder blades are best for reliability and long life. They fit your machine and material, so you spend less time fixing things. For smaller jobs, good aftermarket blades work if you buy from a trusted seller.

Here’s a checklist to help you choose the right blades:

- Check what material you shred most.

- Match blade type to your shredder’s power and design.

- Look for blades with the right hardness and toughness.

- Ask about warranty and support.

- Test blades before buying a lot.

If you use single shaft shredder blades, make sure they fit your machine and your job. The right blades help you cut better and keep your work safe.

Note: Always check if the blades fit your shredder and what the warranty covers. This can save you time and money.

When you look at OEM shredder blades and aftermarket shredder blades, you notice big differences. OEM blades fit better and last longer. They also come with a strong warranty. Aftermarket blades cost less but you might need to change them more often. Here is a table that shows the main points:

| نوع الشفرة | التكلفة الأولية | عمر | تردد الاستبدال | المدخرات طويلة الأجل |

|---|---|---|---|---|

| شفرات منخفضة الجودة | قليل | قصير | عالي | قليل |

| شفرات عالية الجودة | أعلى | طويل | قليل | عالي |

You want blades that help your shredder work well. Good blades mean less time fixing your machine. You do not have to change blades as much. Many people say they get more work done with better blades.

Tip: Think about what you need, compare blade types, ask suppliers questions, and try different blades to see what works best.

Nanjing Metal is known for good quality and strong support. If you want blades you can trust, talk to a sales engineer هنا.

التعليمات

What are OEM shredder blades?

OEM shredder blades come from the company that made your shredder. You get blades that fit your machine perfectly. These blades help your shredder work smoothly and last longer.

Can aftermarket blades fit any shredder?

You can find aftermarket blades for many shredders. Sometimes, these blades do not fit as well as OEM blades. Always check the size and shape before you buy new blades for your shredder.

How do I choose the right blades for my shredder?

You should look at what you want to shred. Hard materials need strong blades. Softer materials need different blades. Check your shredder’s manual and ask for help if you are not sure.

Do aftermarket blades last as long as OEM blades?

Some aftermarket blades last a long time. Others wear out faster. You need to check the quality before you buy. Good blades help your shredder work better and save you money.

Why does my shredder jam with new blades?

Your shredder might jam if the blades do not fit right. Sometimes, blades are too loose or too tight. Make sure you pick blades made for your shredder to avoid problems.

Are there special blades for shredding plastic?

Yes, you can buy blades made for shredding plastic. These blades cut plastic into small pieces. You should match the blades to your shredder and the type of plastic you use.

كم مرة يجب علي استبدال شفرات التقطيع؟

You should check your blades often. If you see dull edges or chips, it is time to change them. Sharp blades help your shredder work faster and safer.

انظر أيضا

تعظيم إيرادات نفايات الخشب الخاصة بك باستخدام سكاكين المفرمة عالية الأداء للخشب

الميزات الأساسية لشفرات مفرمة النفايات الإلكترونية للتدمير الآمن

كيفية اختيار شفرات مفرمة البلاستيك لإعادة تدوير فعالة

الدليل الشامل لتصاميم شفرات المفرمة أحادية العمود

شفرات التقطيع: تحليل التصنيف واختيار المواد وعمر الخدمة وتقنيات التصميم

ردود 2

It is appropriate time to make some plans for the future and it is time to be happy.

I’ve read this post and if I could I want to suggest you few interesting things or tips.

Maybe you can write next articles referring to this article.

I desire to read even more things about it!

Thank you. You can search for it; there’s plenty more related content available.