You need strong tools to shape tricky metal profiles. More than 80% of metal projects use press brake tooling for complex metal profiles to achieve good and steady results. Special and custom tools help you get better accuracy and make work faster.

Nanjing Metal يوفر press brake tooling for complex metal profiles that adhere to tough industry standards.

| تكنولوجيا | Impact on Metalworking |

|---|---|

| المواد المتقدمة | Make tools last longer and work better. |

| Lightweight Composites | Make production go faster. |

| أتمتة | Help make more and better products. |

النقاط الرئيسية

- Press brake tooling helps shape metal profiles well and fast.

- Special tooling is needed for thick or hard metal shapes. It works better than regular tools.

- Picking the right tooling, like V-punches or gooseneck punches, is important. It helps you get the bends and shapes you want.

- Keeping press brake tooling clean and checked often makes it last longer. It also helps it work better.

- Custom press brake tooling can make projects more exact and quick. It saves time and cuts down on waste.

- Tooling must be lined up right to stop mistakes. This keeps results the same for hard shapes.

- Choosing a good supplier gives you strong tooling and ways to customize.

- Storing tooling the right way keeps it safe from harm. It also helps keep your workspace neat.

Press Brake Tooling Basics

ما هي أداة مكابح الضغط

Press brake tooling helps shape metal sheets into many forms. The tooling has punches, dies, holders, and adapters. Each part does something important. Punches push into the metal to make bends. Dies set the angle and curve of each bend. Holders keep the tools steady and lined up. Adapters let you change between different tools.

Here is a simple table about the main parts وماذا يفعلون:

| Component | وظيفة |

|---|---|

| Ram | Pushes down on the metal to bend it. |

| Die | Gives the metal its shape during bending. |

| Back Gauge | Helps put the metal in the right spot. |

| Bed | Holds the metal and keeps the bottom tools in place. |

| نظام التحكم | Makes sure the press brake works the right way. |

Nanjing Metal makes press brake tooling for many types of work. You can find these tools in cars, planes, buildings, electronics, and furniture. They help make car panels, airplane skins, and special metal parts. The tools use strong 42CrMo alloy steel. This makes them last longer and stay correct.

Why Use Specialized Tooling

Specialized tooling is needed for thick or tricky metal shapes. Regular tools are good for easy bends and thin metal. Special tools are better for hard jobs and odd shapes. They help you work faster and get better results.

Here is a table to compare regular and special tooling:

| ميزة | لكمة عنق الإوزة | لكمة قياسية |

|---|---|---|

| Neck Angle | 42°-45° outward neck | 86° sharp angle |

| Effective Height | Varies, but usually the same | 120mm standard height |

| تطبيق | Deep U-shaped parts, big boxes | Simple bends, car parts |

| التوافق المادي | Thick metal, hard shapes | Normal metal, thin to medium |

| Performance Pressure | Good for high-pressure bends | Works up to 300T/m |

| Sidewall Clearance | More than 8cm | Not much space |

| متانة | Very strong with extra support | Strong, but not for deep bends |

| الصناعات النموذجية | Cars, planes, buildings | Cars, metalwork, buildings |

Special tools let you make deep U-shapes and big boxes. You can bend thick metal and make hard shapes. These tools last a long time and work well for tough jobs.

Complex Metal Profiles

Complex metal profiles need careful bends and shapes. Press brake tooling helps make these special profiles. Special tools help you make Z-shapes, deep channels, and sharp angles. You need the right tools to avoid mistakes and keep your work the same every time.

You can pick V-punches, gooseneck punches, or custom tools. These tools help you meet strict rules in car and plane work. You get good bends and strong parts.

Tip: Always use the right press brake tooling for your metal and shape. This helps you get the best results and saves material.

Types of Press Brake Tooling

الأدوات القياسية

Standard press brake tools are used for most easy bending jobs. These tools work best for simple shapes and normal metal thickness. Standard tooling has common punches and dies that fit many machines. There are two main types: American Precision Style and European Precision Style. American Precision Style tools are quick to change and simple to use. European Precision Style tools give more accuracy and a bigger clamping area.

Here is a table that shows the main styles and what they do:

| أسلوب الأدوات | صفات | التطبيقات النموذجية |

|---|---|---|

| أسلوب الدقة الأمريكية | Easy to use, small clamp, fast tool changes | General metal work |

| النمط الأوروبي الدقيق | Very accurate, big clamp, better precision | Car and airplane making |

| أسلوب ويلا ترامبف | Uses hydraulics, lines up tools by itself, saves time | Big factories |

| Mate Tooling | Strong and reliable, works with many materials | Jobs with many bend types |

| Precitools | Can be changed for special projects | Hard metal jobs |

| WILA | Very precise, uses new technology, helps make more parts | Fast and careful factories |

Standard tooling is a good choice for most jobs. You get steady results with easy bends and normal shapes.

Specialized Tooling

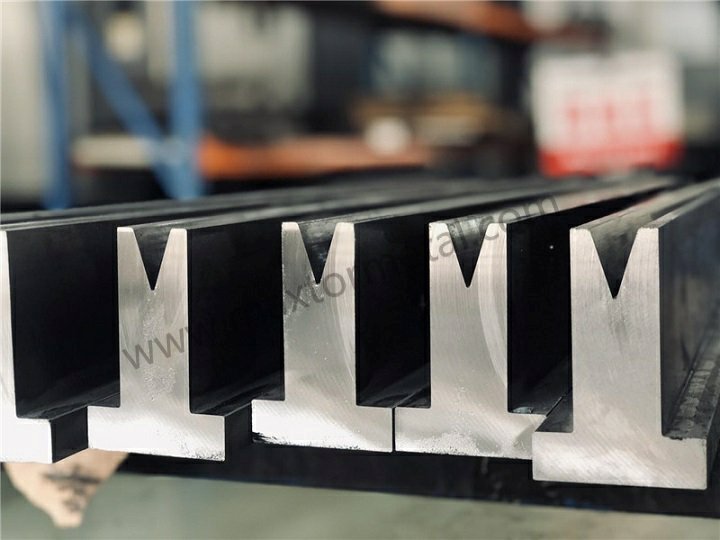

Specialized press brake tools are needed for thick metal or hard shapes. These tools help you make deep bends, sharp corners, and special profiles. Specialized tooling has gooseneck punches, offset dies, and tall punches. Gooseneck punches help you bend deep U-shapes and boxes. Offset dies let you make Z-shapes and steps. Tall punches and thick dies give more space and power for tough jobs.

Specialized tooling often uses precision tooling for better bends. You see these tools in car and airplane factories. Every bend must be perfect. Using the right specialized tools means better work and less waste.

Here is a table that compares custom and specialized tooling:

| وجه | أدوات مخصصة | Specialized Tooling |

|---|---|---|

| Design Focus | Made for one part shape | Made for certain jobs or industries |

| تقنيات التصنيع | Uses CNC machines, wire EDM, and lasers | May use these but not as custom |

| اختيار المواد | Uses strong steel and tough materials | Depends on what is needed |

Specialized tooling fixes problems that regular tools cannot. You get more control and better bends with precision tooling.

أدوات مكبس الفرامل المخصصة

Custom press brake tools are picked when you need a special shape or tight fit. Custom tooling is made just for your job. You work with experts to pick the shape, size, and material. Custom press brake tooling uses new machines like CNC and lasers. You get tools that fit your needs exactly.

Custom blades and dies help you make tricky metal shapes. If you need a special blade, you can look for custom solutions هنا. Custom tooling gives you more choices and better results for small batches.

Here is a table that shows why custom tooling is good:

| ميزة | وصف |

|---|---|

| دقة محسنة | Custom tools are very accurate, good for hard shapes. |

| زيادة الكفاءة | Makes work faster with fewer tool changes and less moving parts. |

| المرونة | Good for small jobs with many shapes and materials. |

| Long-term Cost Savings | Less waste and fixing mistakes, saves money over time. |

Custom press brake tools help you get better accuracy and work faster. You always have the right tool, so you waste less and make better parts.

Tip: Always use the right press brake tools for your job. Precision tooling keeps your work steady and your parts strong.

Tooling for Complex Metal Profiles

When you work with complex metal profiles, you need special press brake tooling. These profiles often have sharp angles, deep channels, or multiple bends. Standard tools cannot always handle these shapes. You must choose the right tooling to get accurate results and avoid mistakes.

You can find several shapes of press brake tooling for complex profiles. Here are some common options:

- V-punches: These tools help you make simple and sharp bends. You use them for most basic shapes.

- Gooseneck punches: These punches let you form deep boxes or channels. The curved neck gives extra space for tall sidewalls.

- Offset dies: You use these dies to create Z-shaped bends or steps in the metal. They help you make two bends in one stroke.

- Taller punches and thicker die profiles: These tools give you more clearance and strength. You need them for thick metal or deep bends.

- Custom tooling: Sometimes, your project needs a unique shape. Custom press brake tooling matches your exact design.

نصيحة: Always check your metal thickness and bend angle before picking your tooling. The wrong tool can cause cracks or uneven bends.

Here is a table to help you match tooling to complex profiles:

| نوع الأدوات | الأفضل لـ | Example Profile |

|---|---|---|

| V-punch | Simple bends | L-shape |

| Gooseneck punch | Deep channels, tall boxes | U-shape, hat channel |

| Offset die | Z-bends, step bends | Z-profile |

| Tall punch/thick die | Thick metal, deep bends | Heavy-duty brackets |

| Custom tooling | Unique or irregular shapes | Special enclosures |

You must also think about the material you use. Harder metals need stronger tooling. If you work with stainless steel or thick aluminum, you should pick tools made from tough alloys. This helps your press brake tooling last longer.

Complex metal profiles often need more than one bend. You may need to change tools during production. Quick-change systems can help you save time. Some press brake tooling uses special adapters or holders. These parts let you switch tools fast and keep your work accurate.

You should always align your tooling before you start. Even a small mistake can ruin a complex profile. Use shims or risers if you need to adjust the height. Check your setup with a test piece before you run a full batch.

ملحوظة: Good press brake tooling makes complex profiles easier to produce. You get better results and less scrap.

When you choose the right tooling, you can make almost any metal profile. You improve your production speed and keep your parts consistent. Press brake tooling for complex metal profiles gives you the flexibility to take on new projects and meet strict quality standards.

المواد والتصميم

Tooling Materials

You need to know what your press brake tooling is made of. The right material makes tools strong and last longer. Most good tools use special steels or alloys. 42CrMo alloy steel is a popular choice. This steel does not wear out fast and keeps its shape after many bends. High-speed steel and tool steel are also used in press brake tooling. These materials make tools tough for hard jobs.

Here is a table that shows common materials and how they help tools work:

| نوع المادة | ملكيات | التأثير على الأداء |

|---|---|---|

| الفولاذ عالي السرعة | Very strong, does not wear out, stays hard when hot | Makes tools last longer and bend metal better |

| أداة الفولاذ | Hard, tough, does not wear out (D2, A2, S7) | Helps tools last longer and shape metal well |

| Polymers | Light, does not rust | Good for jobs that need flexible tools |

Tip: Always check what your tooling is made of before you start. The right material gives you better results and saves money.

ميزات التصميم

The way your press brake tooling is made changes how well it bends metal. You want tools that fit your machine and your job. Some tools have special coatings to stop rust and wear. These coatings help tools last longer. Some tools have special shapes, like gooseneck punches or offset dies. These shapes help you make tricky bends. Quick-change systems let you swap tools fast and save time.

A good design helps you bend metal more accurately. You get cleaner bends and make fewer mistakes. Always pick tools that match your metal’s thickness and type.

المتانة ومقاومة التآكل

Durability means your tools last a long time without breaking. Wear resistance means your tools keep their shape after many uses. The material you choose is very important. Chromium molybdenum steel, like 42CrMo, is very strong and tough. High-speed steel and cemented carbide are even better for hard jobs.

Here is a table that shows how different materials help tools last longer:

| نوع المادة | الخصائص الرئيسية | Influence on Durability and Wear Resistance |

|---|---|---|

| Chromium Molybdenum Steel | Very strong, tough, does not rust | Lasts longer and does not wear out easily |

| الفولاذ عالي السرعة (HSS) | Hard, does not wear out, very strong | Works well for jobs that need high accuracy |

| كربيد الأسمنت | Very hard, does not wear out, can break if hit | Best for tough jobs, stays sharp for a long time |

| High Carbon High Chromium Tool Steels | Strong, tough, keeps its shape | Good for hard jobs, stays hard and keeps its shape |

Note: If you want your tools to last, pick materials that are strong and do not wear out. This helps your shop run better.

When you know about materials and design, you can pick the best press brake tooling for your shop. This helps you get the most from your tools and keeps your work neat and fast.

Compatibility and Setup

تركيب آلي

You must check if your press brake tooling fits your machine. If it does not fit, you might get bad bends or break your machine. Always look at your press brake’s size and type before picking tooling. Think about these things:

- What material you want to bend

- How thick the material is

- How long your workpiece is

- What bend angle you need

- What bend radius you want

- The shape you want to make

- Which bending process you will use

- How much money you can spend

- The tooling brand and if it fits your machine

- How many parts you need to make

- If your press brake works with the tooling

- How much weight your press brake can handle

When your tooling matches your machine, you get better bends and safer work.

Hydraulic vs. Mechanical

There are two main kinds of press brakes: hydraulic and mechanical. Each kind works best with certain tooling. Hydraulic press brakes use fluid to move the ram. These machines give you more control and can bend thicker metal. You can change the speed and pressure for each job. Hydraulic systems work well with advanced tooling, especially for tricky metal shapes.

Mechanical press brakes use gears and flywheels. These machines move fast and are good for simple bends. They do not let you control pressure and speed as much. You should use standard tooling with mechanical machines. If you need deep or hard bends, hydraulic machines and special tooling work better.

Tip: Always know your machine type before buying new tooling. The right match helps you avoid problems and keeps your tools safe.

CNC Integration

CNC integration changes how you use press brake tooling. CNC means Computer Numerical Control. This lets you program your press brake for each job. You can save bend steps and set exact angles. CNC helps you make the same part again and again with high accuracy.

With CNC, you get these benefits:

- Automated bending means fewer mistakes

- You can save and use complex bend steps

- You can adjust bends while working

- Pressure control makes each bend right

- You get the same results every time

CNC press brakes work best with precision tooling. You can switch jobs fast and keep working. If you want to make tricky metal shapes, CNC gives you the control you need.

Note: Always line up your tooling before starting a new job. Use shims or risers if you need to change the height. Good setup helps you get clean bends and less waste.

محاذاة الأدوات

Getting tool alignment right is very important. You need to do this step carefully when using press brake tooling for complex geometries. If you skip it or do it wrong, you might get uneven bends. You could also see angle mistakes or damage your material. Every bend should match your design. This is extra important for complex geometries that need high precision.

Here are some best ways to align your press brake tooling for complex geometries:

- Understand Why Alignment Matters

Good alignment keeps bends accurate. Small mistakes can ruin a part with complex geometries. - Gather the Right Tools

Get measuring tools like dial indicators and shims before you start. These help you check and fix your setup for complex geometries. - Prepare Your Press Brake

Turn off the machine first. Remove anything in the way. A clean workspace helps you focus on details for complex geometries. - Inspect Your Tooling

Look at all punches and dies for damage or wear. Replace any bad parts. Good tooling is needed for bending complex geometries. - Set Up Alignment Tools

Use a dial indicator to see if your tooling is straight. This tool helps you find small problems that can affect complex geometries. - Align Upper and Lower Dies

Adjust the dies so they are even. Even dies make each bend the same. This is important for complex geometries. - Check Ram Parallelism

Use your dial indicator to check if the ram is even with the bed. This helps you avoid angle mistakes in complex geometries. - Verify Angular Alignment

Use an angle gauge to check the tooling angle. This is needed for complex geometries with sharp or many bends. - Perform Test Bends

Try a test bend on scrap metal. Look at the results and fix any problems. Test bends help you find issues before working on complex geometries. - Document Your Settings

Write down your alignment settings. This helps you do the same thing next time with similar complex geometries. - Train Operators and Maintain Tools

Teach your team why alignment is important. Keep up with maintenance and training for good results with complex geometries. - Keep Improving

Check and fix your alignment often. Always try to get better at handling complex geometries.

نصيحة: Use shims or risers to adjust your tool height. Small changes can help a lot when working with complex geometries.

Proper tool alignment helps you do any project, even hard ones with complex geometries. You get cleaner bends, less waste, and better results every time.

Selecting Press Brake Tooling for Complex Metal Profiles

Picking the right press brake tooling for complex metal profiles helps you make good bends. It also helps you waste less metal and keep your work moving. You need to think about what your project needs, what metal you use, and if the supplier can give you good and custom tools.

تقييم الاحتياجات

Project Requirement Analysis

First, look at what your project needs. You should know the shape and size of each part. Think about what each part does. Check what tolerances you need and what rules your industry has. If you plan well, you can stop mistakes and save money.

Here is a table to help you list your project needs:

| معايير | وصف |

|---|---|

| مراقبة الجودة | Make sure your work meets all rules and sizes. |

| التسامحات | Set size limits to save money and make parts fit. |

| اختيار المواد | Pick the best material for your project. |

| Production Methods | Choose how you will make the parts and what machines you need. |

| Prioritization of Requirements | Decide which part features are most important. |

| Conflict Resolution | Fix any problems between different needs. |

| Quality Control Documentation | Keep notes about your checks and how you make things. |

Workpiece Complexity Assessment

The shape of your workpiece changes what tools you need. Complex profiles need special care. You should check:

- How many bends and angles your part has.

- How deep and sharp each bend is.

- If the metal might crack or bend the wrong way.

If your workpiece is tricky, you need special press brake tooling for complex metal profiles. You might need gooseneck punches, offset dies, or custom tools to get the right shape and not hurt the metal.

- Hard shapes need the right tools for good bends.

- Special tools help you not damage tough shapes.

- The right tooling makes your work better and faster.

You should also think about how thick and what kind of metal you use. Thick metal needs wider dies. Thin sheets need tighter dies so they do not get messed up.

Production Volume and Precision Needs

Think about how many parts you need and how exact each bend must be. If you make a lot, quick-change tools and strong materials help. If you need very exact bends, use precision-ground tools. For small jobs or test parts, custom press brake tooling for complex metal profiles gives you more choices and better results.

Matching Tooling to Material

You must match your press brake tooling for complex metal profiles to your metal. The type, thickness, and strength of your metal matter. For example, aluminum bends easier than carbon steel. You need less force and can use smaller dies. Stainless steel needs stronger tools and more force.

Here is a table to help you pick:

| عامل | وصف |

|---|---|

| Type of Metal | Each metal, like carbon steel or aluminum, needs special tool changes. |

| سماكة | Thick metal needs wider dies and stronger punches. |

| قوة الشد | Stronger metals need more force and tougher tools. |

| Tooling Types | Pick punches and dies that fit your metal and thickness. |

| Tonnage Requirements | Check your press brake’s power for your metal’s needs. |

Always check the thickness, length, and any coatings on your metal. These details help you pick the right press brake tooling for complex metal profiles and stop tool damage or bad bends.

نصيحة: Always try your setup with a test piece before making lots of parts. This helps you find problems early.

تقييم الموردين

Nanjing Metal vs. Other Suppliers

Not all suppliers give the same quality or custom choices. You want a company that knows what you need and gives you good press brake tooling for complex metal profiles. Here is a table to help you compare:

| ميزة | Nanjing Metal | Other Suppliers |

|---|---|---|

| خيارات التخصيص | Yes, many OEM/ODM services | Changes by supplier |

| Quality Certification | ISO9001 Quality System Certification | May not have it |

| Focus on Continuous Improvement | Strong R&D and quality focus | Changes by supplier |

| Product Range | Many types, like V-punches, gooseneck, custom | May have fewer choices |

| Import Service | Easy, one-stop import help | Not always offered |

Nanjing Metal gives OEM and ODM custom services. You can work with their team to design tools that fit your job. Their quality checks and certificates help you trust every tool you get.

Key Evaluation Criteria

When you pick a supplier for press brake tooling for complex metal profiles, look at these things:

| معايير | وصف |

|---|---|

| التوافق المادي | Make sure the tooling works with your metals, like stainless steel or aluminum. |

| Tooling Configuration | Look for special shapes or coatings that help your work. |

| Accuracy and Precision | Pick suppliers with precision-ground tools for better bends. |

| المتانة وطول العمر | Choose strong materials that last in tough jobs. |

| ميزات السلامة | Check for safety systems to keep your team safe. |

| التخصيص | Find suppliers who help you design custom tools. |

| سمعة المورد والدعم | Pick companies with a good history and helpful service. |

🛠️ ملحوظة: A good supplier helps you fix problems, not just sell tools. Always ask about help, custom options, and quality checks before you buy.

If you follow these steps, you can pick the best press brake tooling for complex metal profiles. You will get better parts, save time, and keep your work on track.

أدوات مكبس الفرامل المخصصة

When to Customize

You need custom press brake tooling for special projects. Standard tools work for easy bends. Complex shapes and tight rules need custom solutions. You may have problems with material type or thickness. Bend angles can be hard to get right. Sometimes, you must make big curves in one step. You might add gussets to metal parts. Hemming jobs need special hem tooling. Making lots of parts can make custom press brake tooling worth it. You get better results and save time.

Here is a table that shows when custom press brake tooling is needed:

| عامل | وصف |

|---|---|

| نوع المادة | Different metals need special tooling for good bends. |

| سماكة | Thick metals often need custom press brake tooling for best results. |

| زاوية الانحناء | Special bend angles need custom press brake tooling for accuracy. |

| Geometry | Hard shapes may not work with standard tools. |

| دقة | High precision needs custom press brake tooling. |

| حجم الإنتاج | Big batches make custom press brake tooling a smart choice. |

| التكلفة مقابل الأداء | Balancing cost and results leads to custom press brake tooling. |

You should pick custom press brake tooling if you want to:

- Bend thick or tough metals.

- Make special angles or shapes.

- Meet strict precision rules.

- Make parts faster for big orders.

- Balance cost and results for your project.

Tip: If you need a special blade, check the صفحة الشفرات المخصصة.

Design Process

Custom press brake tooling uses a clear design process. You work with experts to turn your idea into a finished tool. Each step helps you get the best results.

Step 1 – Requirement Collection

You start by sharing your project details. Tell the team about the metal type, thickness, bend angles, and shape. For example, if you need a Z-shape with tight rules, give all the details.

Step 2 – Feasibility Analysis

Engineers look at your needs. They check if the shape can be made with the right materials and machines. They find problems and offer solutions. If you need special features, they talk about custom press brake tooling.

Step 3 – Design & Engineering

The design team makes drawings and 3D models of your custom press brake tooling. They make the design accurate and strong. You see how your tool will look and work before making it. The team picks strong materials like tool steel or carbide so your custom press brake tooling lasts.

Step 4 – Prototype & Testing

A sample of your custom press brake tooling is made. The team tests it on metal to see if it works. They look for problems and fix them. Testing helps you avoid mistakes in full production.

Step 5 – Customer Review & Feedback

You check the sample results. You give feedback on bends, angles, and how it works. If you want changes, the team updates the design. Your ideas make sure the custom press brake tooling fits your needs.

Step 6 – Final Production & Delivery

After you approve the sample, the team starts making the final tool. They check quality and inspect each part.

دراسات الحالة

Custom press brake tooling helps many industries solve tough problems. You can see how different fields use these tools for better results.

| صناعة | التطبيقات الشائعة | سمك المادة | نوع الأدوات | Solution Series |

|---|---|---|---|---|

| السيارات | Chassis, Brackets | 1-6mm | Precision V-dies | AutoPro Series |

| الفضاء الجوي | Rib Components | 0.8-3mm | Radius Punches | AeroForm Series |

| HVAC | Duct Fittings | 0.5-2mm | Hemming Tools | AirFlow Series |

| بناء | Structural Angles | 3-12mm | Heavy-Duty Dies | BuildStrong Series |

| الالكترونيات | Enclosures | 0.5-1.5mm | Micro-Bending Tools | ElexPress Series |

Here are some real examples of custom press brake tooling:

- Car makers use advanced custom press brake tooling to make bodies faster and more accurate.

- Plane companies get perfect bends in aircraft aluminum for better flight and strength.

- Builders use strong machines with custom press brake tooling to make steel beams for big buildings.

Tip: Custom press brake tooling helps you start new projects and meet strict rules in any field.

Custom press brake tooling lets you make special metal shapes. You get better accuracy, faster work, and less waste. You can work with experts to design tools that fit your needs. If you want to see custom options, visit the صفحة الشفرات المخصصة لمزيد من الخيارات.

Setup and Maintenance

تثبيت

You must install press brake tooling the right way for good results. First, turn off your press brake and clean the area. Put punches and dies into the holders. Use adapters if your machine needs them. Make sure each tool fits tight and lines up with the bed. If you skip this, you might get bad bends or break your tools.

Use this checklist to help you:

- Clean the press brake and take away old dirt.

- Check punches and dies for any damage.

- Lock each tool in place so it does not move.

- Check the alignment before you start.

When you install tools the right way, you avoid mistakes and keep your work fast.

معايرة

Calibration keeps your press brake tooling working right. Follow the maker’s rules for how often to calibrate. Most shops do quick checks every day and bigger checks every month or three months. This helps you keep bends sharp and parts the same.

| تردد الصيانة | المهام |

|---|---|

| يوميًا | Clean the machine, check the back gauge, look for wear, check for leaks |

| شهريا | Clean hydraulic parts, check wires, let out air pressure |

| ربع سنوي | Do full checks and calibrations |

You can use dial indicators and angle gauges to check if things line up. Always test with scrap metal before a big job. Regular calibration helps you stop mistakes and keeps your work steady.

Tip: Stick to a regular calibration plan. This helps you find problems early and keeps your press brake working well.

نصائح الصيانة

Good maintenance makes your press brake tooling last longer and keeps your shop running well. Clean your tools every day to stop dirt from building up. Oil moving parts as the maker says. Check your tools for wear, cracks, or if they are not lined up. Change broken parts right away.

Here are some best ways to care for your tools:

- Clean often to stop dirt from building up

- Oil parts the way the maker says

- Take care of the hydraulic system

- Check for wear, damage, and if things line up

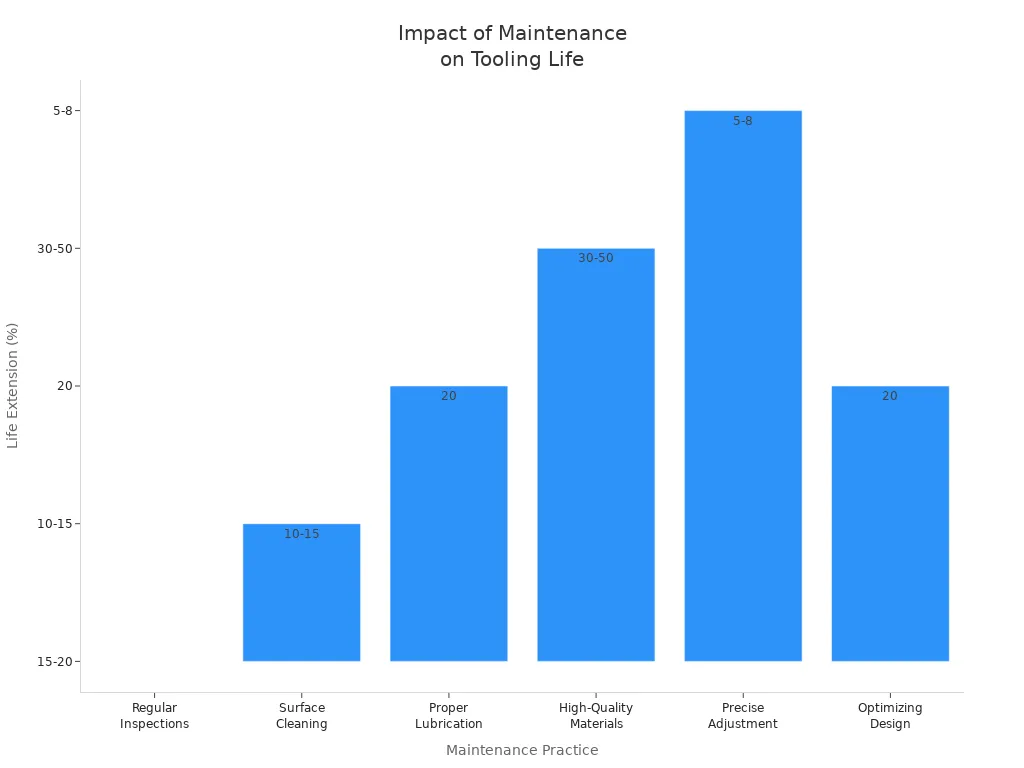

| ممارسة الصيانة | Impact on Tooling Life |

|---|---|

| التفتيشات الدورية | Tools last 15% to 20% longer |

| تنظيف السطح | Less wear by 10% to 15% |

| التزييت المناسب | Less wear by 20% |

| Use of High-Quality Materials | Tools last 30% to 50% longer |

| Precise Adjustment of Parameters | Less wear by 5% to 8% for each 10% more pressure |

| Optimizing Tooling Design | Tools last 20% longer |

Checking and cleaning your tools often helps you find problems early. When you care for your tools, you stop damage and bad bends. This keeps your work fast and stops delays.

🛠️ Note: Good maintenance is the key to long-lasting tools and smooth work. Make it a daily habit to get the best results.

تخزين

Storing your press brake tooling for complex metal profiles the right way keeps your tools safe and ready to use. Good storage stops damage, saves time, and helps you work faster. You want your tools to last as long as possible, so you need to protect them from wear, rust, and accidents.

You can use several smart storage solutions in your workshop:

- Tool racks keep your punches and dies off the floor. You can see each tool and grab what you need fast.

- Drawer systems protect tools from dust and bumps. Each drawer can hold a different type or size of tooling.

- Steel or heavy-duty plastic cabinets give strong protection. These cabinets last a long time and stand up to busy shop life.

- Dedicated storage near your press brake saves steps. You do not waste time walking across the shop to find your tools.

- Vertical storage uses less floor space. You can fit more tools in a small area and keep your shop tidy.

- Custom or modular storage lets you change the setup as your needs grow. You can add more racks or drawers when you get new tooling.

A well-organized storage area helps you find the right press brake tooling for complex metal profiles quickly. You spend less time searching and more time working. Logical organization, like grouping tools by size or shape, makes your workflow smoother.

Temperature and humidity matter, too. Keep your storage area dry and cool. Moisture can cause rust and damage your tools. You can use dehumidifiers or silica gel packs in cabinets to keep the air dry.

Ergonomic design helps you lift and move tools safely. Heavy tools should stay at waist height. This lowers the risk of dropping them or hurting yourself. Safety features, like soft edges or locking drawers, also prevent accidents.

Regular cleaning and inspection of your storage area keep your press brake tooling in top shape. Wipe down racks and drawers. Check for dust, oil, or metal shavings. Clean tools before putting them away to stop dirt from spreading.

🛠️ نصيحة: Always return each tool to its spot after use. This habit keeps your shop organized and your press brake tooling for complex metal profiles safe from damage.

A good storage system protects your investment. You get longer tool life, fewer mistakes, and a safer, more efficient workshop.

كفاءة الإنتاج

Optimizing Performance

You want your metal shop to work well. Using special press brake tooling helps you get better results. The right tools make your bends cleaner and save time. You can set up your press brake for each job. This keeps your work moving without stops. Quick-change systems let you switch tools fast. This helps your production line keep going.

Always pick tooling that fits your metal and shape. Gooseneck punches help with deep channels. Offset dies are good for Z-bends. These tools help you avoid mistakes. You get better parts and fewer errors. CNC controls let you program each bend step. You can repeat bends with high accuracy. This makes your work more precise and efficient.

Tip: Keep your tools clean and check them often. Good care helps you get sharp bends and keeps your projects on track.

Reducing Scrap

Scrap wastes money and slows your work. You can make less scrap by using smart steps. Use special tooling for hard shapes. This helps you avoid problems and keeps bends right. Make sure flange width is at least four times the thickness plus bend radius. This stops cracks and keeps parts strong.

Match punch tip radius to material thickness. This stops stress and damage when bending. Keep the metal touching the tooling all the way. You get better parts and fewer mistakes. Know how your metal bends back after pressure. Change the bend angle to fix springback. You can program a deeper stroke if you expect springback. Pick metals that bend easily for better results. Use punches with bigger nose radii to lower stress.

- Flange width should be at least four times the thickness plus bend radius.

- Match punch tip radius to thickness.

- Keep full contact between metal and tooling.

- Change bend angle for springback.

- Use special tooling for hard shapes.

- Program deeper stroke for springback.

- Pick metals that bend easily.

- Use punches with bigger nose radii.

These steps help you make less scrap and better parts. Your shop saves money and works faster.

مراقبة الجودة

Quality control helps your projects stay the same every time. You need to check your work often to meet your standards. Use precision tools to measure bend angles. Check sizes with calipers or CMMs. Try test bends on scrap metal to check your settings. Repeatability tests show if your press brake gives the same results. Bend test pieces to check if your machine is accurate.

| مقياس مراقبة الجودة | وصف |

|---|---|

| صيانة دورية | Keeps your tools working right and stops big mistakes. |

| Proper Tooling Selection | Picking the right punch and die helps you get good bends for each metal. |

| Accurate Workpiece Positioning | Putting the metal in the right spot helps you get the same results every time. |

| التكنولوجيا المتقدمة | Laser-guided systems help you get more precise bends. |

Always use the right tooling for your metal and shape. Put your metal in the right place for repeatable results. Laser-guided systems help you get better accuracy. Regular care stops mistakes and keeps your jobs on track.

🛠️ Note: Quality control is not just checking parts. It means always working with care and trying to be precise and efficient in every step.

Cost and ROI

Investment vs. Savings

When you pick press brake tooling for complex metal profiles, you spend money to help your shop. The right tooling might cost more at first, but you save money later. Many shops get their money back in one or two years. This happens because custom or special tooling lets you work faster and make more parts. You also waste less metal and spend less time fixing mistakes.

- Custom or special press brake tooling can pay for itself in 1–2 years.

- You can make more parts in less time.

- Good tooling means less scrap and fewer mistakes.

If you want your shop to grow, buying good tooling helps you do harder jobs. You can take on new work and meet higher standards.

💡 نصيحة: Think about how much time and metal you save with better tooling, not just the price you pay at first.

Quality vs. Budget

You might wonder how to pick between quality and price when buying press brake tooling for complex metal profiles. High-quality tooling costs more at first, but it lasts longer and works better. Cheap tools can break fast or mess up your bends.

- Initial Cost: Good tooling costs more at the start, but saves money later because it lasts longer.

- التكلفة على المدى الطويل: You should think about all costs, like repairs, lost time, and slow work.

- Consideration: Look at both the starting price and the costs over time to make the best choice for your shop.

A smart choice means you spend less fixing or replacing tools. You also keep your shop running without stops.

| عامل | High-Quality Tooling | Low-Cost Tooling |

|---|---|---|

| Upfront Price | أعلى | أدنى |

| متانة | Lasts longer | يتآكل بشكل أسرع |

| صيانة | Less needed | أكثر تواترا |

| Total Savings | Greater over time | Less over time |

Sourcing Tips

Finding a good supplier for press brake tooling for complex metal profiles helps you save money and avoid trouble. Look for companies that give you both good tools and good help. Nanjing Metal makes it easy to get the tooling you need with simple import service.

- Check if the supplier can make custom tools for your shapes.

- Ask if they have quality certificates and test their tools.

- Compare prices, but also check support and delivery speed.

- Pick suppliers who help you fix problems, not just sell tools.

🛠️ ملحوظة: A good supplier helps you get the most from your money. Good service and strong support keep your shop working and your projects on time.

Press brake tooling for complex metal profiles helps you make accurate bends and strong parts. Custom solutions let you handle unique shapes and boost your shop’s efficiency. You get better results and save time with the right tools. Always check your needs and choose quality tooling for your projects. If you want expert advice or need custom press brake tooling, contact a sales engineer للبدء.

التعليمات

What is a press brake and how does it work?

A press brake is a machine that bends sheet metal. You place the metal between a punch and a die. The press brake pushes the punch down. The metal bends along the die shape. You can make many shapes with the right tooling.

Why do I need special tooling for a press brake?

Special tooling lets you bend complex shapes. You use it when standard tools cannot make the bends you want. With the right tooling, your press brake can handle thick metal, sharp angles, and deep channels.

How do I choose the right press brake tooling?

You look at your project needs. Check the metal type, thickness, and shape. Match your press brake tooling to your machine. Test with scrap metal first. Good tooling helps you get clean bends and less waste.

Can I use the same tooling for all press brake jobs?

No, you cannot. Each press brake job may need different tooling. Some jobs need V-dies. Others need gooseneck punches or offset dies. Always pick tooling that fits your metal and the shape you want.

How often should I check or replace press brake tooling?

You should check your press brake tooling every day. Look for wear, cracks, or damage. Clean your tooling after each use. Replace tooling when you see problems. Good care keeps your press brake working well.

What safety tips should I follow when using a press brake?

Always wear safety gear. Keep your hands away from moving parts. Make sure your press brake tooling is locked in place. Never use damaged tooling. Follow your shop’s safety rules every time you use the press brake.

Can I use CNC with my press brake and tooling?

Yes, you can. CNC helps you program your press brake for each job. You get more accurate bends. CNC works best with precision tooling. You can save bend steps and repeat jobs with the same results.

How do I store press brake tooling to keep it in good shape?

Store your press brake tooling in a dry, clean place. Use racks or drawers to keep tools safe. Wipe off oil and dust before storage. Keep heavy tooling at waist height. Good storage helps your tooling last longer.

انظر أيضا

الثني في الهواء مقابل الثني باللمس: اختيار أداة مكبس الفرامل المناسبة لمشروعك

أدوات مكبس الفرامل على الطراز الأوروبي مقابل الأمريكي: أيهما مناسب لورشة عملك؟

اختيار أفضل أدوات مكبس الفرامل للفولاذ المقاوم للصدأ

إتقان استخدام مكبس الثني: كيفية تحديد وإصلاح التآكل الناتج عن الثقب والقوالب

كيف تؤثر الدقة في قوالب مكابس الضغط على نتائج الانحناء: دليل لتحقيق الانحناءات المثالية