You should look at seven important things before buying industrial shear blades. These things are blade material, application match, manufacturing tolerances, edge design, equipment compatibility, supplier reputation, and total cost. If you do not check these, your machine may stop working. You could face safety problems and spend more money. Use the Buying guide for Industrial shear blades to help you choose well. Good brands like Metal Industrial give you strong and good blades. Always use this checklist before you buy anything.

Key Takeaways

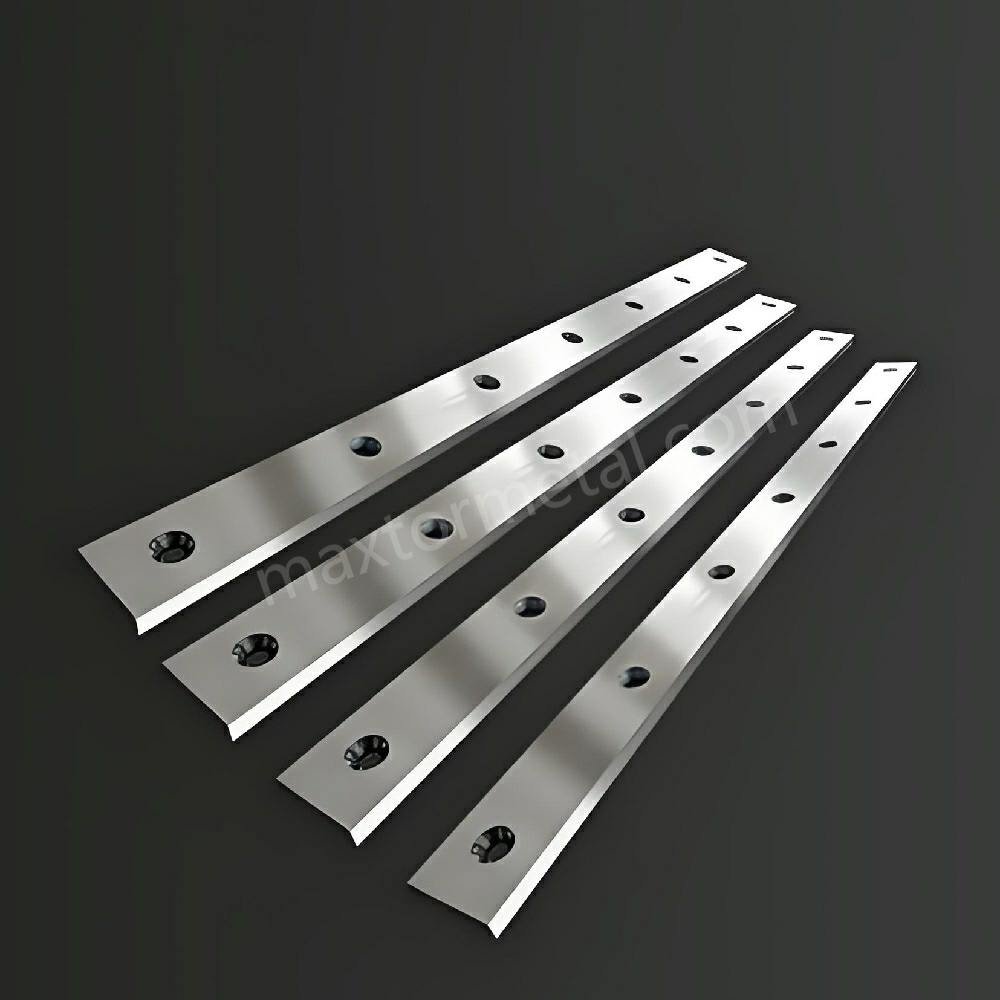

- Always look at the blade material before you buy. Good materials like D2 or H13 make blades last longer and work better.

- Pick a blade that fits your job. The right blade keeps you safe and helps you cut faster.

- Check how flat and even the blade is made. Blades with tight tolerances cut better and last longer.

- Look at the edge shape and any coatings. The right edge and coating help the blade cut fast and wear out less.

- Make sure the blades fit your shears. If they do not fit, they can break or cause accidents.

- Check if the supplier is well known. Good brands give you better products and help when you need it.

- Think about all the costs, not just the price to buy. Add up every cost to see what is the best deal.

- Use a checklist before you buy. A checklist helps you avoid mistakes and make smart choices.

Why Quality Checks Matter in Industrial Shears

Buying industrial shear blades is a big decision. Your choice can change how your whole team works. Each quality check in the buying guide helps you avoid trouble. These checks stop problems that slow down your work. They also help keep your team safe. If you skip these checks, you might have more downtime. You could spend more money and face safety issues. Picking blades carefully protects your machines and your workers. It also saves your company money.

Impact on Performance and Safety

Quality checks help your shears work their best. Good blades cut better and last longer. They also make your workplace safer. The right blades lower the chance of accidents. This means fewer injuries. The table below shows how blade quality helps your work:

| Impact Area | Description |

|---|---|

| Cutting Performance | Good blades keep cutting well. This means less downtime and better work. |

| Replacement Frequency | Strong blades last longer. You do not need to replace them as often. |

| Equipment Lifespan | The right blades are easier on your machines. This helps your equipment last longer and stay safe. |

| Cutting Precision | Good blades make cleaner cuts. This helps your work look better. |

| Downtime Reduction | Quality blades break less. This means your machines stop less often. |

| Accident Risk Minimization | Better blades break less and are safer to use. |

| Ergonomics Improvement | The right blades are easier to use. This helps workers stay safe and comfortable. |

Cost and Downtime Risks

If you pick the wrong blades, you might pay more for repairs. Bad blades break and wear out fast. This means your machines stop more often. You lose time and money. Bad blades can also hurt your machines. Fixing them can cost a lot. Checking each blade before you buy saves money. It also helps your machines last longer.

Application-Specific Needs

Not every blade works for every job. You must pick the right blade for your work. Using the wrong blade can cause problems. Here are some risks if you do not match blades to the job:

- The blade might act in strange ways and hurt someone.

- Blades not made for some materials can break, especially with hard metals.

- The wrong blade can make bad cuts and mistakes.

Always check if your blade fits your job. This step helps you avoid problems. It keeps your work safe and smooth. When you follow these steps, your blades work better. Your workplace runs well and stays safe.

Blade Material & Metallurgy in Metal Shear Blades

Picking the right blade material is very important. The material and how it is made affect how long blades last. It also affects how well they cut. You should learn about the different blade materials. Each one works best for certain jobs.

Tool Steel Grades and Purity

There are many tool steel grades for metal shear blades. Each grade has special features for different jobs. The table below lists common grades and what they do best:

| Tool Steel Grade | Key Features | Applications |

|---|---|---|

| A-Series (A2, A6) | Hardened by air cooling, good wear resistance and toughness, high dimensional stability | Shear blades, molding dies, forming tools |

| D-Series (D2, D3) | Very high wear resistance, moderate toughness, retains hardness up to 425°C | Punches, industrial knives, cold extrusion tools |

| M-Series (M2, M42) | Excellent cutting performance at high speeds, good red hardness | End mills, drill bits, gear cutters |

| H-Series (H11, H13, H21) | Good toughness and heat resistance, high thermal fatigue strength | Die casting dies, hot extrusion tools |

| O-Series (O1, O2) | Good wear resistance and toughness, easy to machine | Gears, punches, knives |

| S-Series (S1, S7) | Exceptional toughness and impact resistance | Impact tools, dies for drop forging |

| T-Series (T1, T15) | Outstanding red hardness, very high wear resistance | Heavy-duty cutting tools, industrial machining |

| W-Series (W1, W2) | High hardness and good wear resistance | Hand tools, woodworking tools |

If you want blades that last a long time, look for D2, H13, or powdered metal. These grades are good for cutting tough metals. They are also good for hard jobs. If you need a special blade, you can check out custom blade options to fit your needs.

Heat Treatment and Hardness

Heat treatment makes blades strong and tough. When you pick blades, find out how the maker treats the steel. Nanjing Metal Industrial uses special forging and heat treatment. This helps blades stay sharp and last longer.

- Heat treatment methods like quenching and carburizing make steel harder.

- Harder blades last longer and need fewer replacements.

- Good hardness means less downtime and lower maintenance costs.

- Strong blades help your work run smoothly and safely.

Always check how the blade was treated before you buy. This helps you get the most out of your metal shear blades.

Material Certification and Verification

You want to know your blades meet industry standards. Good suppliers check every batch to make sure it is right. Here are some ways they do this:

- Hardness testing at different steps in production.

- ISO 9001 certification for regular quality checks.

- Traceability for each batch, so you know the hardness and source.

- Custom hardness checks if you have specific needs.

- Quality certificates that show the results of all tests.

When you buy from a trusted brand, you get blades that pass all the right tests.

Tip: Always ask for material certificates and test results before you buy. This helps you avoid problems and keeps your work safe.

Application Matching: Buying Guide for Industrial Shear Blades

Identifying Your Cutting Material

You must know what you are cutting before picking blades. The kind of metal, its thickness, and your machine’s speed matter a lot. Think about how much you use your shears. Notice if you have problems like chipping or blades wearing out fast. Here are some questions to help you decide:

- What material do you need to cut?

- How thick is the metal?

- What speed does your machine cut at?

- Do you see chipping or fast blade wear?

- What kind of machine do you use?

- How many hours do you use your shears each day?

When you answer these, you can find the right blade for your job. Hardness, toughness, and heat treatment are important. These things help blades last longer and work better. D2 steel is good for wear resistance. H13 is better if you need more toughness. M2 is best for jobs needing very high wear resistance. If you want to save money, 42CrMo is a good choice.

Tip: Always pick a blade that matches your cutting material and job. This helps you avoid problems and keeps your work safe.

Decision Matrix for Blade Selection

A decision matrix can help you choose the best blade. This tool lets you compare different blades by what matters most, like cost or wear resistance. Here are some ways to do this:

| Method | Type | Description |

|---|---|---|

| COPRAS | Multi-attribute decision-making | Looks at many things to rank materials. |

| EVAMIX | Multi-attribute decision-making | Helps pick materials using different types of data. |

| TOPSIS | Multi-attribute decision-making | Ranks choices by how close they are to the best option. |

| AHP | Multi-attribute decision-making | Compares materials in pairs to see which is better. |

| VIKOR | Multi-criteria decision-making | Ranks and picks from choices that have different needs. |

These methods help you look at all your needs and pick the right blade. You can also ask suppliers for help if you need a custom blade. Metal Industrial has many choices, so you can get blades that fit your needs.

Common Application Mistakes

People often make mistakes when picking blades for shears. Some use blades in high heat, which makes them wear out much faster. Others forget to clean their blades often. Cleaning blades every week helps them last longer. Picking the wrong blade for the job is another mistake. For very tough jobs, you might need a tungsten carbide blade.

| Mistake Type | Evidence |

|---|---|

| High Temperature Usage | Using blades in high heat makes them wear out up to 50% faster. |

| Irregular Maintenance | Blades cleaned every week last 30% longer than those not cleaned often. |

| Material Selection | For tough jobs, picking a tungsten carbide blade is best. |

You can avoid these mistakes by following the buying guide for industrial shear blades. Always check your job, keep up with cleaning, and pick the right blade. Metal Industrial has both standard and custom blades, so you can find the best one for your work.

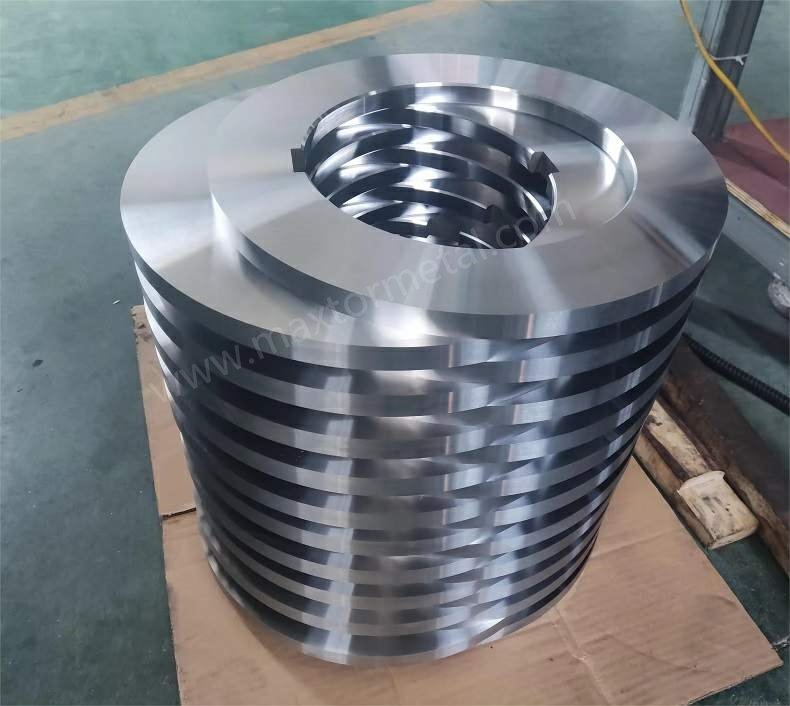

Manufacturing Tolerances in Industrial Shear Blades

Manufacturing tolerances are very important for shear blades. Tight tolerances help blades cut better and last longer. If tolerances are not good, cuts can be uneven. Blades may wear out faster and stop working more often. You want your blades to work well and be safe every day.

Flatness and Parallelism

Flatness and parallelism are two things to check on blades. Flatness means the blade surface is even. Parallelism means both sides of the blade are straight and match. These checks help you get clean cuts every time. If a blade is not flat or parallel, it can wobble. This can hurt your machine or make bad cuts.

Here is a table that shows what these checks mean:

| Parameter | What It Measures | Why It Matters |

|---|---|---|

| Flatness | The difference from a perfect flat surface. | Stops wobbling and keeps contact even. |

| Parallelism | How straight both sides of the blade are. | Keeps blade thickness and cut width the same. |

If flatness is poor, the cut width can change. Warped blades can move and cut in the wrong place. In busy factories, these problems make work harder and less exact.

Surface Finish Standards

Surface finish is also important for blade quality. A smooth blade slides through metal easily. It stops metal from sticking to the blade. This helps you get cleaner cuts and less extra work. A rough blade can drag, get hot, and wear out fast. Always look at the surface finish before buying blades.

Inspection and Quality Control

Good inspection and quality control keep blades working right. Makers use special tools to check every blade. They look at flatness, parallelism, and surface finish during and after making blades. Workers measure each blade to make sure it is correct. They set up machines with back gages and clamps to keep blades in place.

Quality teams check every blade before sending it out. They look for problems or mistakes. This helps you get blades that fit and last longer. Metal Industrial uses strong quality checks for every blade. When you buy from a good supplier, you can trust your blades and worry less.

Tip: Always ask how blades are checked before you buy. This helps you avoid mistakes and keeps your machines working well.

Edge Design & Wear Resistance: Tips for Buying Shears

Edge Profiles and Geometric Angles

The shape and angle of a blade edge affect how your shears work. You should choose the right edge profile for your job. Some blades have more teeth, which make smoother cuts. Blades with fewer teeth cut faster but are less exact. Thin blades are good for small, detailed cuts. Thick blades are better for heavy jobs. The blade’s design is important too. A smart design helps you cut safely and quickly.

| Feature | Impact on Efficiency and Safety |

|---|---|

| Tooth Configuration | Fewer teeth cut faster but are less exact. More teeth make smoother cuts. |

| Thickness and Width | Thin blades are for detail work. Thick blades last longer for tough jobs. |

| Blade Geometry and Design | Knowing these types helps you pick the best blade. |

Metal Industrial uses special edge shapes and angles. These features help you get clean cuts fast and keep your work safe.

Coatings and Surface Treatments

Coatings and treatments help blades last longer. They also help blades stay sharp and resist wear. Here are some coatings and treatments you might see:

- Titanium Nitride (TiN): Makes blades harder and lowers friction.

- Titanium Aluminum Nitride (TiAlN): Helps blades handle heat and last longer.

- Diamond-Like Carbon (DLC): Makes blades harder and lowers friction, good for soft metals.

- Nitriding: Adds nitrogen to the blade’s surface for better wear resistance.

- Boriding: Adds boron to help blades resist wear.

- PVD (Physical Vapor Deposition): Makes blades harder and protects against wear and rust.

- CVD (Chemical Vapor Deposition): Like PVD, helps blades last longer.

- Polished Surface Treatment: Lowers friction, stops sticking, and helps prevent rust.

These coatings can make blades last up to 50% longer in some jobs. If you pick blades with the right coating, you get better cuts and less downtime.

Assessing Wear Resistance

You need to know how well your blades can resist wear. Labs use tests to check this. Each test shows how blades handle different types of stress and abrasion.

| Test Method | Type of Abrasion | Stress Level |

|---|---|---|

| Dry-sand, rubber-wheel | Three-body abrasion | Low-stress |

| Pin-on-drum | Two-body abrasion | High-stress |

| Jaw crusher | Gouging-abrasion | High-stress |

| High-speed, impeller–tumbler | Impact-abrasion | High-stress |

You can ask your supplier about these tests. Good results mean your blades will last longer and work better.

Tip: Always check the edge design, coating, and wear resistance before you buy. This helps you get the best results and keeps your work safe.

Equipment Compatibility in Industrial Shears

You need to make sure your blades fit your shears. If you do not check, you could have problems. Blades that do not fit can wear out fast or break your machine. The right blades help your machine work well and keep everyone safe.

OEM vs. Aftermarket Blades

You can choose OEM blades or aftermarket blades. OEM blades are made by the same company as your shears. These blades usually fit well and work like the old ones. Aftermarket blades are made by other companies. Some aftermarket blades are good and cost less. But you must check their size and shape. Not all aftermarket blades fit every machine. Always look at the size, thickness, and holes before you buy.

Note: Metal Industrial sells both regular and custom blades. You can get blades that fit your machine, no matter what kind you need.

Fit, Installation, and Maintenance

Blades must fit right for your shears to work well. If a blade is not the right size, it can cut wrong or break your machine. You should do these things:

- Check blades every day for sharpness and chips.

- Change or sharpen dull blades right away.

- Make sure blades are lined up and balanced.

- Use only parts the maker says are okay.

- Watch how well your shears cut and how long it takes.

- Keep a schedule to check and fix your shears.

Doing these checks helps you stop big problems. Using the right parts and fixing things on time makes your machine last longer.

Fixed vs. Replaceable Blades

Some shears have blades that stay in place. Others let you change just the cutting part. Fixed blades need to be replaced all at once when they wear out. Replaceable blades let you change only the edge. This saves time and money. You should know what kind your machine uses before you buy. Replaceable blades are easier to take care of and help you work faster. Fixed blades can be better for tough jobs.

Tip: Metal Industrial lets you order blades that fit your machine. You can get fixed or replaceable blades, whatever you need.

Checking if blades fit before you buy is smart. You get better cuts, safer work, and your machine lasts longer.

Supplier Reputation & Support for Industrial Shear Blades

Picking the right supplier helps your work every day. A trusted company stops problems and keeps things running well. You want a supplier that stands by its products. They should help you when you need it. Brands like Nanjing Metal Industrial are known for good quality and care.

Evaluating Brand Reliability

There are many things to check when picking a brand. A good brand does more than sell strong blades. It brings new ideas and listens to what you need. It also delivers orders on time. The table below shows what to look for when you compare suppliers:

| Criteria | Description |

|---|---|

| Product Performance | Cutting precision, speed, and durability matter most. |

| Technology & Innovation | Look for new features like automation or smart controls. |

| Customization & Flexibility | The ability to make custom blades for your job is important. |

| Price & Cost-Effectiveness | Fair prices and long-term value help your business. |

| Customer Support & Service | Good support and fast answers make your work easier. |

| Reputation & Track Record | Brands with a history of happy customers are safer choices. |

| Compliance & Certifications | Meeting industry standards keeps your work safe. |

| Supply Chain & Delivery | Fast and steady delivery keeps your production on track. |

If you pick a supplier with these good points, you lower your risk. You get better results from your industrial shears.

Technical Support and Warranty

Good technical support and clear warranty rules protect your money. You want help if something breaks or goes wrong. Top suppliers offer different warranties and support. Here are some common choices:

- 5 Year Parts Warranty: Covers main parts like cylinders, motors, and structural items.

- 1 Year Warranty: Covers shear blades, dies, controls, and related accessories.

- Optional 7 Year Extended Warranty: Adds more years for parts, controls, and some labor.

- Lifetime Guarantee: Some brands offer lifetime coverage for defects in materials or workmanship.

- Six Month Warranty: Covers sharpeners or other small tools.

Always ask what the warranty covers before you buy. Good support helps you fix problems fast and keeps your shears working.

Regrinding and After-Sales Service

After-sales service like regrinding helps blades last longer. Professional sharpening costs more at first but saves money later. You use blades longer and buy fewer replacements. This lowers your total cost over time. A supplier with good after-sales help gives you spare parts, advice, and quick repairs.

When you pick a supplier with a good name and strong support, you protect your blades. You make sure your shears stay ready for every job.

Cost, Value & TCO in Metal Shear Blades

Price vs. Performance

You want to spend your money wisely when buying blades. Price and performance do not always match up. Sometimes, expensive blades have better technology and last longer. Other times, you pay more for things you do not need. The table below shows what changes price and performance:

| Factor | Description |

|---|---|

| Technological Innovation | New materials and machines help blades work better and last longer. |

| Regulatory Environment | Rules can make blades cost more but also improve quality. |

| Pricing and Cost Pressures | Problems with supplies can change prices and affect performance. |

| Enhanced Value Focus | Many buyers look at total cost, not just the first price. |

| Demand for Innovation | Safety and efficiency features are more important now. |

You should check what you pay and what you get. Look for blades that work well and keep you safe. Metal Industrial has blades with new features and fair prices.

Calculating Total Cost of Ownership

Total cost of ownership means you think about all costs, not just the first price. You need to add up everything you spend while using your blades. Here is what you should count:

- The first price you pay for blades.

- Money spent on fixing and sharpening blades.

- How often you need new blades.

- Time lost when dull blades slow down your work.

- Costs from injuries if blades do not work well.

- Insurance and money for accidents.

- Premium blades last much longer than cheap ones.

If you buy cheap blades, you may spend more on repairs and replacements. Dull blades can slow your work and lower your profits. Good blades help you cut more and keep your team safe.

Tip: Always add up all costs, not just the first price. This helps you see which blades give you the best value.

Negotiating Value-Added Services

You can save money by asking for extra help when you buy blades. Many suppliers offer help with installing, training, or fast delivery. Some give free sharpening or longer warranties. Metal Industrial offers flexible buying options and quick delivery. You can ask for custom blades for special jobs.

Here are ways to get more value:

- Ask for free or cheaper maintenance.

- Request training for your team on blade care.

- Look for suppliers who ship fast.

- See if you can get a longer warranty.

- Ask about custom blades for special jobs.

You get better results when suppliers help you after you buy. These services help your blades last longer and work better.

Note: Always check what services come with your purchase. This helps you get the most out of your investment.

Quick Checklist: Tips for Buying Shears

If you want to pick the best blades, you need a plan. This checklist helps you choose the right blades and avoid mistakes. The buying guide for industrial shear blades shows you what to do before you buy.

7-Step Pre-Purchase List

- Check Blade Material

Find out what the blades are made of. High-speed steel, alloy steel, and tungsten carbide are good for different jobs. - Match Blade to Application

Think about what you need to cut. Pick blades that work for your job and the material you use. - Inspect Manufacturing Tolerances

Look for blades with tight tolerances. This gives you better cuts and helps blades last longer. - Review Edge Design and Coating

Choose blades with the right edge shape and special coatings. These help you cut faster and keep blades sharp. - Confirm Equipment Compatibility

Make sure the blades fit your shears. Check the size, thickness, and holes. - Evaluate Supplier Reputation

Pick a supplier with a good history. Trusted companies give you better blades and support. - Calculate Total Cost

Look at the price, but also think about how long blades last and how much you spend on care.

Tip: Keep this checklist close. It helps you make smart choices and keeps your work running well.

Common Pitfalls to Avoid

Many people make the same mistakes when buying new blades. You can avoid these problems by following these tips for buying shears:

- Low-quality blades can hurt your work and damage your machines.

- If you ignore blade material, your blades may not work well. Always pick the right blade material for your job.

- If you skip checking the supplier’s reputation, you might get bad blades and poor help.

- If you forget to check if blades fit, you could have trouble installing them or working safely.

- If you do not look at edge design and coatings, blades may wear out fast and need more changes.

- If you only look at price, you might spend more later.

- If you do not ask for certificates or test results, you may get blades that do not meet standards.

Remember: Careful planning and checking details help you avoid these mistakes. Good choices keep your shears working well and your team safe.

If you follow all seven quality checks, you protect your money. These steps help you avoid big mistakes and make blades last longer. Good materials, the right blade shape, and a trusted supplier help your machines work better. This means less time fixing things and better products.

Buying good blades means fewer problems and less fixing. You save money over time and your machines work well.

Always use the checklist when you buy new blades. If you want tips to keep blades working longer or need special blades, talk to our sales engineers here.

FAQ

What materials work best for industrial shear blades?

Pick tool steels like D2, H13, or powdered metal. These materials make blades strong. They help blades last longer and cut better.

How often should you replace industrial shear blades?

Check your blades often. Replace them if you see chips or dull spots. Uneven cuts mean it is time for new blades. Regular checks stop machine damage.

Can you sharpen industrial shear blades yourself?

You can sharpen blades if you have the right tools. You also need training to do it safely. Many people send blades to experts for sharpening.

What is the difference between OEM and aftermarket blades?

OEM blades are made by your machine’s company. Aftermarket blades come from other companies. Always check size and fit before you buy aftermarket blades.

How do you know if a blade fits your machine?

Measure the blade’s length, thickness, and hole spots. Look in your machine’s manual for the right size. Check these things before you buy new blades.

Why do coatings matter on industrial shear blades?

Coatings like TiN or DLC help blades last longer. They keep blades sharp and lower friction. These coatings also help blades cut better.

What is the most important quality check before buying?

Make sure the blade matches your cutting job. This step helps you avoid problems. It keeps your work safe and running well.

See Also

Achieving Zero-Burr Cuts with Precision Guillotine Shear Blades

D2 Shear Blades: Why D2 Steel is King for Cold Metal Cutting

Guillotine vs. Shear Blades: What’s the Difference and Which is Best for Your Job?

Shear Blade Material Guide: D2 vs. A2 vs. 5160 vs. Carbide — What’s the Best Choice?

How to Troubleshoot Common Issues with Hydraulic Scrap Shear Blades in 2025

One Response