You want blades that work well and last longer in hard places. Kryogen behandelte Scherenmesser are better than regular heat-treated blades.

- Cryogenic treatment makes blades 30% more durable.

- Blades resist wear better, so they last longer at work.

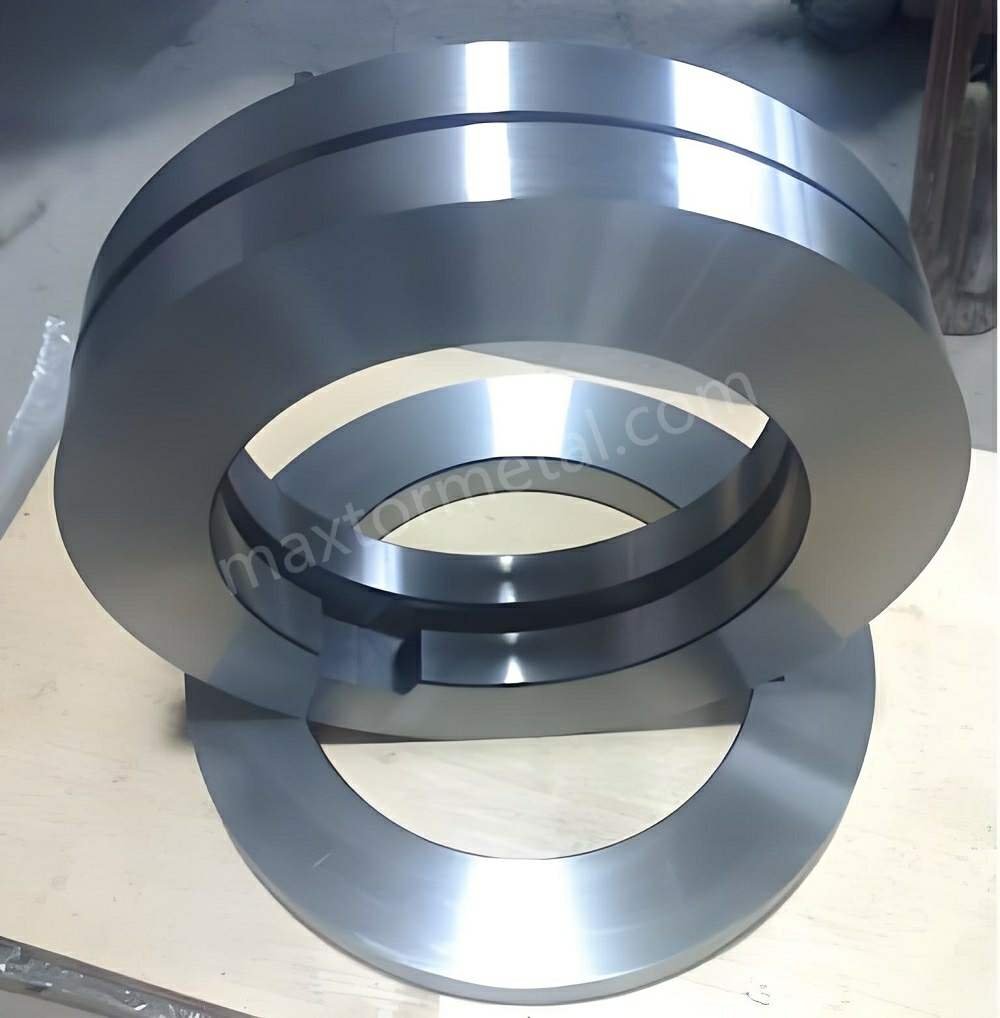

- Metal Industrial checks each blade for flatness, parallelism, and surface finish.

You get blades with new features and steady quality. This makes them a good pick for tough jobs.

Die wichtigsten Erkenntnisse

- Cryogenic treated shear blades last 30% longer than regular blades. This makes them a smart pick for hard jobs. The cryogenic process cools blades to very low temperatures. This makes the steel stronger and helps the blades last longer. These blades fight off wear and rust better. This means you have less downtime and need fewer new blades. Cryogenic treated blades stay sharp up to 40% longer. This gives you cleaner cuts and keeps things safer. Buying cryogenic treated blades can save you money over time. You will spend less on fixing and replacing them. These blades are great for cutting hard things like metals and plastics. This makes them useful for many different jobs. You can also get custom options to fit your cutting needs. Picking cryogenic treated shear blades means less time fixing blades. You get more time to focus on your work.

Cryogenic Treated Shear Blades: Process and Principles

What Is Cryogenic Treatment

Cryogenic treatment is a special way to make shear blades stronger and last longer. First, the blade gets heated to a high temperature. This changes how the inside of the blade works. Next, the blade cools down to room temperature. After that, the blade gets even colder, down to minus 300 degrees Fahrenheit. This super cold step helps change the steel inside the blade. It makes the blade harder and more stable. Then, the blade is heated again to a medium temperature. This locks in the changes. Here are the main steps:

- Heat the blade to over 200 degrees Fahrenheit.

- Cool the blade to room temperature.

- Lower the temperature to minus 300-310 degrees Fahrenheit for cryogenic treatment.

- Heat the blade again to plus 300-700 degrees Fahrenheit to make it stable.

- Cool the blade back to room temperature.

This process helps blades fight wear and stay sharp for a long time. If you need blades made for your job, you can learn about custom options Hier.

How It Differs from Heat Treatment

Cryogenic treated shear blades use a different process than regular heat treatment. Regular heat treatment uses only high heat to make blades hard and tough. Cryogenic treatment adds a step with very cold temperatures. This extra step changes the steel inside the blade in ways heat alone cannot.

| Verfahren | Temperatur | Duration | Equipment Used |

|---|---|---|---|

| Kryogene Behandlung | Below -150°C | Kurz | Specialized cryogenic chambers |

| Conventional Heat Treatment | High temperatures | Länger | Furnaces or kilns |

- Cryogenic treatment cools blades to very low temperatures. This makes blades better at fighting wear and fatigue.

- Regular heat treatment uses only high heat. It makes blades hard and bendable but does not keep the edge as well.

Cryogenic treated shear blades have been used in aerospace for more than 30 years. This process helps steel parts last longer, especially when they get worn out a lot.

Nanjing Metal Industrial’s advanced manufacturing and quality control make sure every blade is flat, parallel, and smooth.

Why It Matters for Industrial Blades

You want blades that work hard and stay sharp. Cryogenic treated shear blades give big benefits for tough jobs. Studies show these blades have up to 50% less stress inside than blades treated with heat only. This means they break less and keep their shape.

- Cryogenic treated blades fight rust better. One study found a 30% lower rust rate in saltwater.

- These blades keep their hardness for over two years. Regular blades start to lose hardness after six months.

- You get sharper edges for longer. Reports show cryogenic treated blades stay up to 40% sharper, even after lots of use.

When you pick cryogenic treated shear blades, you get tools that last longer and work better. This means less time fixing things and fewer replacements. Metal Industrial’s focus on quality and new ideas helps you get the most from every blade.

Scientific Mechanism: Metallurgical Changes

Austenite to Martensite Transformation

Cryogenic treated shear blades have a special change inside. The steel starts with austenite. Cold temperatures help turn austenite into martensite. This makes the blade stronger and more stable.

- Deep cryogenic processing finishes the change from austenite to martensite.

- The steel gets harder and does not bend or break easily.

- Blades keep their shape and work better under stress.

Here is a table that shows how cryogenic treatment changes the steel:

| Beweisbeschreibung | Wichtigste Ergebnisse |

|---|---|

| Effect of DCT on microstructure | DCT makes martensite tighter and more stressed. |

| Aging treatment effects | Elements move faster, making steel more even and strong. |

Hardness and Stability Gains

Blades need to stay hard and stable. Cryogenic treatment makes steel harder. Martensite gets tighter, so the blade can handle more force. The blade does not wear out fast and keeps its edge longer.

Tip: More martensite means blades last longer and need less sharpening.

Fine Carbide Precipitation

Cryogenic treated shear blades get stronger from tiny carbides. These carbides form inside the steel during cold treatment. They spread out and make the blade tougher.

| Beweisbeschreibung | Wichtigste Ergebnisse |

|---|---|

| Fine carbide precipitation boosts microhardness and wear resistance. | More hardness stops damage and reduces wear. |

| Uniform dispersion of fine carbides blocks dislocation movement. | Spread-out carbides increase wear resistance of the material. |

| Cryogenic treatment increases carbide precipitation and spreading. | More carbides in treated samples, which boosts wear resistance. |

| Dispersed ultrafine carbides form on martensite. | This helps carbides spread out, making blades resist wear better. |

Verbesserte Verschleißfestigkeit

Blades need to fight wear. Fine carbides in cryogenic treated blades act like shields. They stop damage from spreading and keep blades strong. Carbides also help blades stay sharp after many cuts.

Note: More carbides mean less wear and longer blade life.

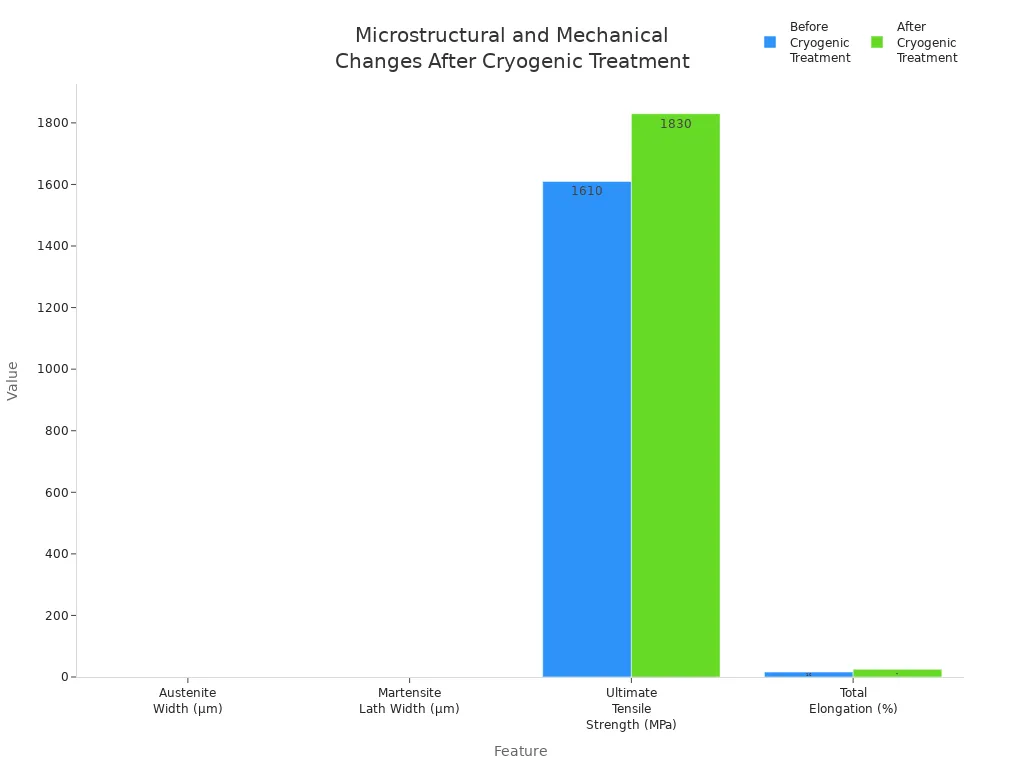

Mikrostrukturverfeinerung

Cryogenic treatment makes steel inside blades smoother and more even. Tiny parts like austenite and martensite get smaller and pack closer together. This gives you a blade that is stronger and stretches more before breaking.

| Microstructural Feature | Before Cryogenic Treatment | After Cryogenic Treatment | Change |

|---|---|---|---|

| Austenite Width (μm) | 0.20 | 0.15 | Refined |

| Martensite Lath Width (μm) | 0.18 | 0.13 | Refined |

| Austenite Content (vol.%) | N / A | Decreased by 12% | Decrease |

| Dislocation Density | N / A | Increased | Increase |

| Streckgrenze (MPa) | N / A | Increased by 200 MPa | Increase |

| Ultimate Tensile Strength (MPa) | 1610 | 1830 | Increase |

| Total Elongation (%) | 16 | 25 | Increase |

Blades are not just harder but also stretch more before breaking. This means blades can handle tough jobs without snapping. Steel inside gets more even, so blades cut smoothly and last longer.

Remember: Microstructure refinement makes blades tough, flexible, and reliable.

Cryogenic treated shear blades use these changes to work better and last longer. You get blades that fight wear, stay sharp, and work well in hard places.

Performance Comparison: Cryogenic vs. Heat-Treated Blades

Wear and Fatigue Resistance

You want blades that last a long time and work hard. Cryogenic treated shear blades fight wear and fatigue better than heat-treated blades. The cryogenic process cools steel below the Mf point after quenching. This step turns more austenite into martensite. Blades have less leftover austenite. This means they are harder and more stable. These blades do not wear out or get tired fast. You spend less time changing blades. They last longer in tough places.

Tip: Blades with less leftover austenite stay strong and work well, even after lots of use.

Edge Retention and Sharpness

Sharp blades cut better and are safer to use. You can see a big difference in how long the edge stays sharp between cryogenic treated and heat-treated blades. The table below shows how each blade type works:

| Besonderheit | Cryogenic Treated Blades | Standard Heat-Treated Blades |

|---|---|---|

| Kantenbeständigkeit | Much better | Okay |

| Schärfe | Improved | Normal |

| Verschleißfestigkeit | 150-200% higher | Normal |

| Zähigkeit | Besser | Focus on hardness |

Cryogenic treated shear blades keep their edge for more cuts. You do not need to sharpen them as often. The blades stay sharp and tough, even after many uses.

Service Life Data

You want blades that last and help you save money. Cryogenic treated shear blades last much longer than heat-treated blades. Here are some facts:

- Cryogenic treated shear blades can last over 200% longer than heat-treated blades.

- The cryogenic process makes the blade stronger at the smallest level. Blades become tougher and fight wear for a longer time.

- Blades treated with cryogenics keep their strength longer. This means you spend less on fixing and replacing blades.

You can see the difference in real numbers. The table below compares how long blades last and how much they cost each year:

| Klingentyp | Lifespan (Months) | Cost per Year ($) |

|---|---|---|

| Unbehandelte Klingen | 3 | 273 |

| Kryogen behandelte Klingen | 24 | 57 |

You get blades that last longer and cost less to take care of. This means you have more time working and less time changing blades.

Note: Picking blades that last longer helps you save money and keeps your work going without stops.

Cryogenic treated shear blades give you better wear resistance, sharper edges, and longer life. You see these good things in how they work and how much they cost.

Application Suitability: Where Cryogenic Treated Shear Blades Excel

High-Abrasion Cutting Tasks

Cryogenic treated shear blades are great for cutting tough things many times. They work best when you cut metals, plastics, or other hard stuff that wears out normal blades fast. These blades are harder and more stable inside. You get smoother cuts and the blades do not wear out as quickly. This means you do not have to change blades as often. You can spend more time working.

Metal, Plastics, and More

You can use these blades to cut steel sheets, aluminum, copper, and tough plastics. The cryogenic process makes the blades strong for sharp edges and thick things. Your cuts look better and smoother. This helps when you need clean edges for your products. If you use blades that get dull fast, you will see a big difference.

Tip: If you need a blade for a special job, you can ask for custom options.

Industry Use Cases

Many industries use cryogenic treated shear blades for better results and longer life. These blades are used where tools get used a lot and must stay sharp.

Automotive, Aerospace, Recycling, Construction

- Automobilindustrie: You cut strong steel and aluminum for car parts. These blades help you get clean cuts and change tools less.

- Luft- und Raumfahrt: You work with special alloys and composites. The blades give you better cuts and last longer, even with hard materials.

- Recycling: You cut scrap metal, wires, and plastics. The blades do not wear out fast and keep working, even with dirty stuff.

- Konstruktion: You cut rebar, sheet metal, and panels. The blades stay sharp and strong, so you finish jobs faster.

Studies show cryogenic treatment makes tools last longer and cuts look better. For example, treated tungsten carbide tools wear out less and make smoother cuts. In farming, rotavator blades made this way last longer and fight wear better. These good things happen because the steel inside the blade changes. The blades get harder and more stable, so they work better in tough jobs.

Nanjing Metal Industrial lets you pick custom blades for your work. You can choose the right material, shape, and edge for your job. The company works with you to make sure you get the best blade. Here is how they help:

| Anpassungsaspekt | Beschreibung |

|---|---|

| Materialauswahl | Pick the best steel for your job |

| Custom Geometries | Get the right shape and size for your machine |

| Edge Preparations | Choose special edges for better cutting |

| Heat Treatment Protocols | Use the best process for your application |

| Oberflächenbehandlungen und Beschichtungen | Add coatings for more durability |

| Collaboration with Customers | Work with engineers to solve your cutting problems |

| Typical Projects | Automotive, electronics, and more |

| Multi-Stage Heat Treatment | Make blades harder and last longer |

| Kryogene Behandlung | Change the steel for better performance |

Limitations and Marginal Benefits

Cryogenic treated shear blades have many good points, but you should know where they work best.

- You see the biggest gains with high carbon and chromium steels, like D2 and CPM S90V.

- Some steels do not get much better with this process.

- Not all materials can handle cryogenic treatment.

- You need special tools and skilled workers to do it right.

- If not done well, blades can bend or crack.

- The process can cost more, especially for small batches.

You get blades that last longer, stay sharp, and need less fixing. You also spend less time on repairs and changing blades. These benefits help you work faster and save money over time.

Note: Always check if your material and job are right for cryogenic treated shear blades before you choose them.

Cost Analysis: Investment vs. Long-Term Savings

When you choose cryogenic treated shear blades, you make an investment that pays off over time. These blades cost more at first, but you save money in the long run. You spend less on repairs, replacements, and downtime. Let’s look at how the process works and why it matters for your budget.

Process Timing in Manufacturing

Cryogenic treatment fits into the manufacturing process after quenching and before tempering. This timing is important. The process changes the steel at a deep level, making the blades stronger and more reliable. You can see the steps in the table below:

| Schritt | Temperatur | Duration |

|---|---|---|

| Austenitization | ~1100°C | – |

| Abschrecken | Room temperature | – |

| Cryogenic treatment | -196°C | 24 to 36 hours |

| Controlled cooling | -196°C | ~1 to 2°C per minute |

| Soaking | -196°C | 20-24 hours |

| Gradual reheating | Room temperature | ~0.5 to 1°C per minute |

| Temperieren | 150-200°C | 1-2 hours |

You see that cryogenic treatment happens after the blade cools from quenching. The blade stays at -196°C for up to 36 hours. This step helps the steel become harder and more stable. After this, the blade gets reheated for tempering. This careful timing gives you a blade that lasts longer and works better.

After Quench, Before Temper

You get the best results when you treat the blade right after quenching and before tempering. This order locks in the changes from the cold treatment. The steel forms more martensite and fine carbides. These changes make the blade tough and resistant to wear. You end up with a shear blade that keeps its edge and shape, even after many uses.

Reduced Maintenance and Downtime

Cryogenic treated shear blades help you cut down on maintenance and keep your machines running. Here’s how these blades make your work easier:

- The blades last longer because the steel is stronger and more even inside.

- You sharpen and replace the blades less often. This means you spend less time on maintenance.

- The blades keep their sharpness, so you do not need to polish or grind them as much.

- You avoid long stops in production. Your machines stay busy, and you finish jobs faster.

- You save money on labor and spare parts because you do not need to fix or change blades as often.

Tip: Fewer maintenance cycles mean you get more work done and lose less time.

Gesamtbetriebskosten

When you look at the total cost, cryogenic treated shear blades give you real savings. You pay more at first, but you spend less over time. Here’s why:

- The blades last much longer than regular blades. You do not need to buy new ones as often.

- You save money on repairs and sharpening. The blades keep working well for a long time.

- Your machines run more because you do not stop for blade changes. This means you make more products and meet deadlines.

- You use less energy and fewer resources because you do not need to make or ship as many replacement blades.

| Kostenfaktor | Standardklingen | Cryogenic Treated Shear Blades |

|---|---|---|

| Initial Purchase Price | Untere | Höher |

| Austauschhäufigkeit | Hoch | Niedrig |

| Maintenance Cost | Hoch | Niedrig |

| Downtime Cost | Hoch | Niedrig |

| Total Cost Over 2 Years | Höher | Untere |

You see the benefits add up. Cryogenic treated shear blades help you save money, reduce waste, and keep your work moving. You get better value for your investment and more reliable performance in your cutting tasks.

Note: Choosing the right blade can change your whole operation. Think about the long-term savings, not just the price you pay today.

Making the Choice: Are Cryogenic Treated Shear Blades Right for You?

Buyer Considerations

You want blades that last a long time and work well. Cryogenic treated shear blades are stronger and fight wear better. These blades stay sharp and tough, even after lots of use. Think about how often you change blades and how much time you lose when machines stop. If you cut hard things often, cryogenic treatment helps a lot.

Cryogenic treatment also stops rust from forming on the blade. This keeps blades strong and stops them from getting weak. Your blades keep working well for a long time. If you work where there is water or chemicals, this helps your blades last.

Stellen Sie sich diese Fragen:

- Do you need blades that fight wear and last longer?

- Do you cut hard things like metal or plastic?

- Is rust a problem for your blades?

- Do you want to spend less on fixing and changing blades?

If you say yes to these, cryogenic treated shear blades might be good for you.

Supplier Questions

When you pick a supplier for cryogenic treated shear blades, you need clear answers. You want blades that fit your needs and work in your machines. Here are some questions to ask:

- What steel do you use for cryogenic treated shear blades?

- Can you show how long the blades last and how well they work?

- How do you check blade quality when making them?

- Do you make custom blades for special jobs?

- How long does it take to get cryogenic treated blades?

- How do you help with blade care and support?

Tip: Good suppliers give you lots of details and help you choose the best blade for your job.

Decision Checklist

Use this checklist to see if cryogenic treated shear blades are right for you:

| Entscheidungspunkt | Ja | NEIN |

|---|---|---|

| Need blades with higher wear resistance? | ✅ | |

| Want longer blade lifespan? | ✅ | |

| Cut tough or abrasive materials? | ✅ | |

| Work in environments with moisture? | ✅ | |

| Want to lower maintenance costs? | ✅ | |

| Need custom blade options? | ✅ | |

| Require reliable supplier support? | ✅ |

If you check most boxes in the “Yes” column, cryogenic treated shear blades will help you. These blades help you work faster, save money, and keep machines running.

Remember: Picking the right blade helps your work and saves money. Cryogenic treated shear blades are great for hard jobs.

Cryogenic treated shear blades give you longer life, better performance, and real savings. Many people think this process replaces heat treatment or is easy to do, but it actually builds on heat treatment and needs special skills. You get blades that last longer, need less care, and work with many metals.

- You see less downtime and more cutting power.

- You use blades that fit tough jobs in many industries.

Ready to improve your cutting process? Reach out to our sales engineers Hier to find the right solution for your needs.

Häufig gestellte Fragen

What are cryogenic treated shear blades?

Cryogenic treated shear blades go through a special cold process. This treatment makes the blades harder and more durable. You get blades that last longer and stay sharp after many uses.

How do cryogenic treated shear blades differ from regular blades?

You get more wear resistance with cryogenic treated shear blades. The deep cold treatment changes the steel inside. Regular blades only use heat. Cryogenic blades keep their edge and shape for a longer time.

Can I use cryogenic treated shear blades for cutting plastics?

Yes, you can use cryogenic treated shear blades for plastics. These blades work well with metals, plastics, and other tough materials. You get smooth, clean cuts and less blade wear.

How often do I need to replace cryogenic treated shear blades?

You replace cryogenic treated shear blades less often than standard blades. The special treatment helps them last up to 200% longer. You save time and money on replacements.

Are cryogenic treated shear blades rust-resistant?

Cryogenic treated shear blades resist rust better than untreated blades. The process makes the steel structure tighter. You get blades that stay strong, even in wet or harsh environments.

Do cryogenic treated shear blades need special care?

You do not need special care for cryogenic treated shear blades. Clean and store them as you would with any quality blade. Regular checks help you keep them in top shape.

What industries use cryogenic treated shear blades?

Many industries use cryogenic treated shear blades. You see them in automotive, aerospace, recycling, and construction. These blades handle tough jobs and keep working longer.

Can I get custom cryogenic treated shear blades?

Yes, you can order custom cryogenic treated shear blades. You choose the size, shape, and material to fit your needs. Custom blades help you get the best results for your job.

Siehe auch

Der ultimative Einkaufsführer für Industriescherenklingen: 7 Qualitätsprüfungen vor dem Kauf

Scherenmesser Wie ein Profi Schärfen: Vermeidung Häufiger Schleiffehler und Verlängerung der TCO

H13 Warmarbeits-Scherenmesser: Meisterung des Hochtemperatur-Metallschneidens und Knüppelschneidens

Erzielen von Gratfreien Schnitten mit Präzisions-Guillotine-Scherenmessern