Die Wahl des richtigen Biegewerkzeuge und -stempel helps fix press brake problems. It also stops bending defects from happening. Nanjing Metal gives you press brake tooling for good results. Their tools last a long time. In factories, you might see problems like:

- Springback, when the metal moves back after bending

- Overbending or underbending, which change the angle

- Cracks along the bend line

- Wrinkles or wavy edges

- Scratches or marks from the tools

Using the right tools helps you stop these problems. It keeps your sheet metal projects working well.

Die wichtigsten Erkenntnisse

- Picking the right bending dies and punches stops common problems like springback, cracking, and wrinkling.

- There are different bending methods, like air bending and coining. These methods change how accurate your bends are. Choose the method that fits your project best.

- Checking and taking care of your tools often helps you avoid problems. It also keeps your tools working well.

- Custom tooling solutions can help with specific needs. They also lower the mistakes in your finished parts.

- Try bending a sample before making many parts. This helps you find problems early. It saves time and materials.

- Using protective films on metal stops surface damage during bending. This keeps your parts looking nice.

- Setting up and lining up dies and punches the right way is very important. It helps you get accurate bends and stops problems.

- Always match your tooling to the type and thickness of your material. This gives you better results and fewer mistakes.

Importance of Bending Dies and Punches

Tooling and Bend Accuracy

When you work with sheet metal, the choice of bending dies and punches shapes the final result. The right tools help you get the angle and shape you want every time. If you want to improve press brake accuracy, you need to match your tooling to the job. Different bending methods give different results:

- Air bending lets you create many angles and works well for prototypes. You may notice less accuracy because of springback.

- Bottom bending uses more force and special dies. This method gives you more consistent angles and better press brake accuracy.

- Prägung presses the metal hard into the die. You get the most precise bends with almost no springback. This is best when you need tight tolerances.

You should always pick press brake tooling that matches your material type, thickness, and the bend angle you need. High-quality tools last longer and help you keep your machine running smoothly. If you need a special shape or size, you can look for Kundenspezifische Klingen to fit your project.

Role in Preventing Defects

Using the correct bending dies and punches does more than improve accuracy. It also helps you avoid common bending problems. You can prevent issues like cracking, wrinkling, or uneven bends by choosing the right tool for each job.

Tipp: Customized tooling solutions help you meet special needs and reduce defects in your finished parts.

Here are some ways the right tooling helps you prevent defects:

- Custom dies and punches fit your material and design, so you get fewer mistakes.

- Regular inspection and maintenance of your tools stop problems like cracks or wrinkles before they start.

- Advanced press brake technology gives you better control, so your bends stay accurate and reliable.

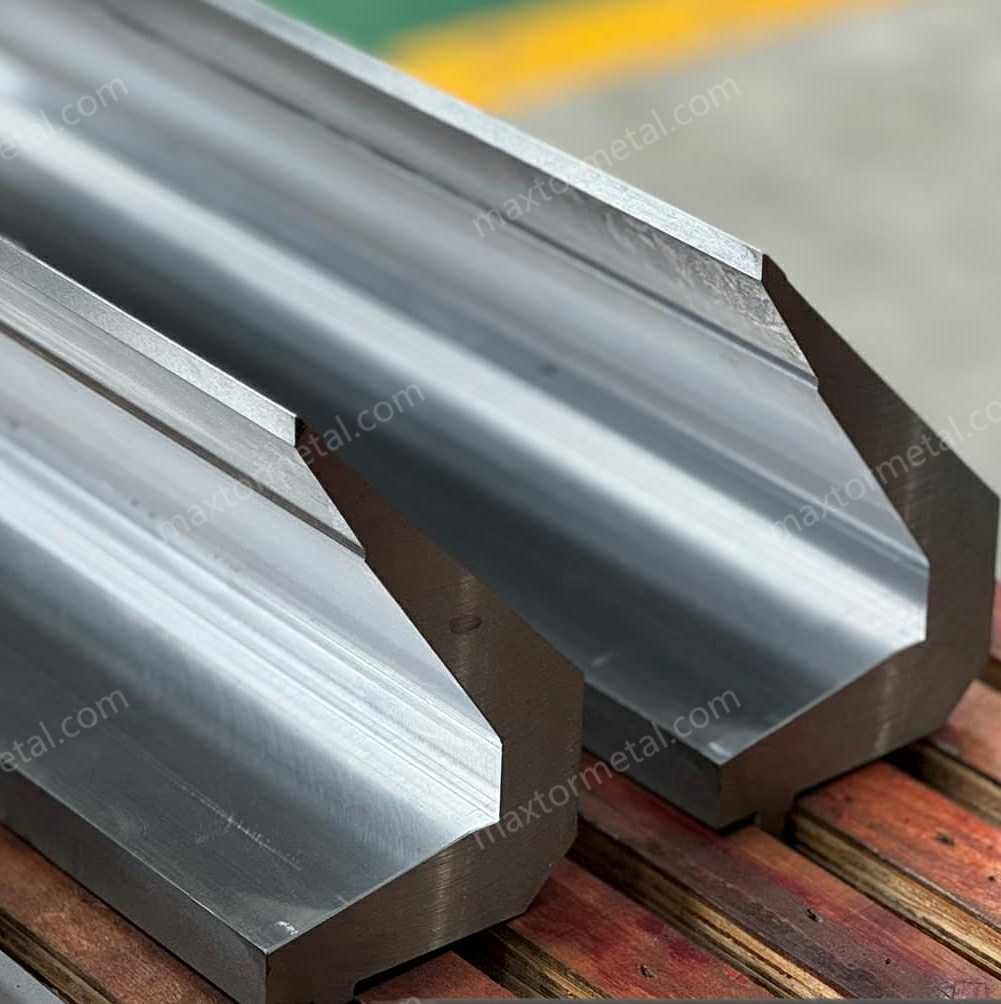

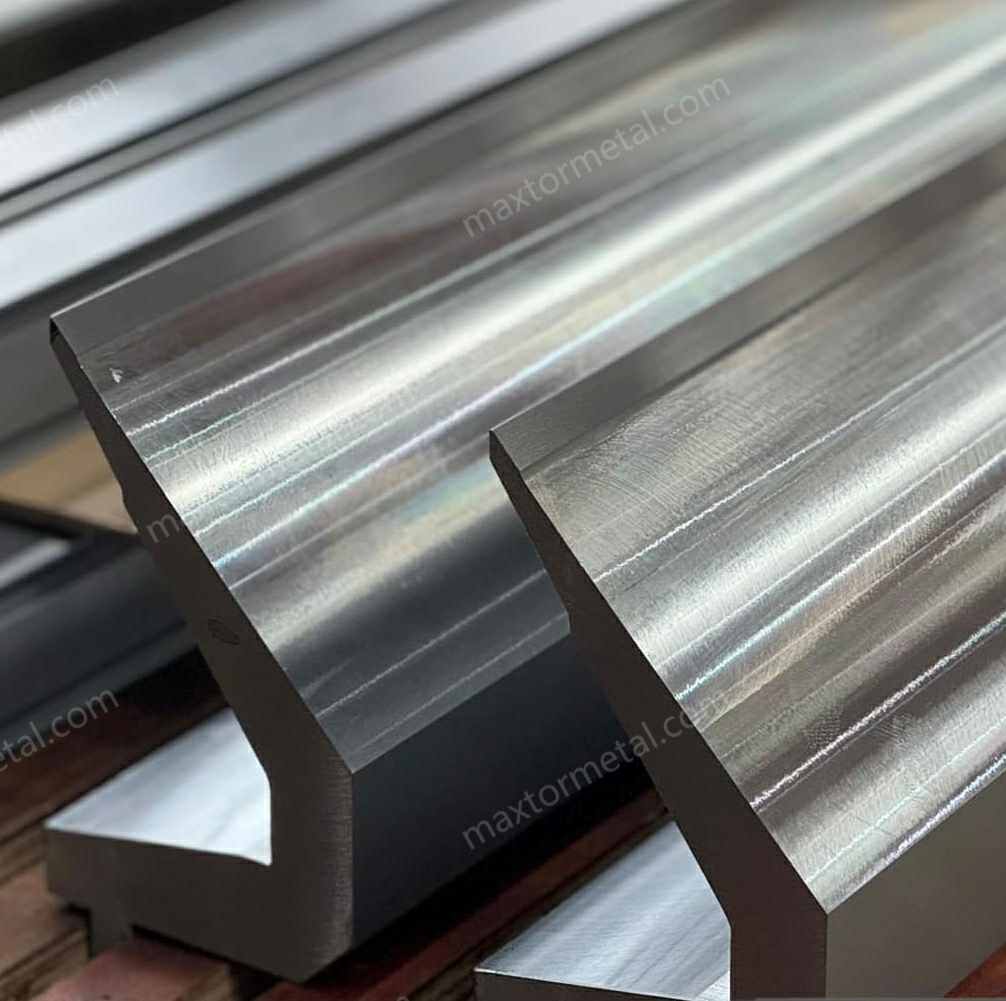

Nanjing Metal uses strong materials like 42CrMo alloy steel for their tools. This means your dies and punches resist wear and keep their shape, even after many uses. If you want to avoid downtime and keep your production line moving, choose tools that match your needs. You can always ask for custom options to make sure your press brake accuracy stays high.

Common Bending Defects

Springback

Springback is one of the most common bending defects you will face in sheet metal bending. After you bend the metal, it tries to return to its original shape. This happens because the metal has elastic properties. You may notice that the angle you get is not the angle you set on your press brake. This can cause problems with part fit and assembly.

Several factors affect springback:

- The elastic modulus and yield strength of the material

- The thickness of the sheet

- The ratio of the bending radius to the thickness

- The design of the die, including the upper die fillet radius and lower die groove width

- The amount of force you apply and how long you hold it during bending

If you want to reduce springback, you need to choose the right die and punch. Adjusting the die opening and using a punch with the correct radius can help you control this defect. You should always check your process and make small changes to get the best results.

Tip: Always test a sample bend before starting a large batch. This helps you spot springback early and adjust your setup.

Knacken

Cracking is a severe defect that can ruin your part. You will see cracks or splits along the outer surface of the bend. This usually happens when the material cannot stretch enough during bending. Cracking is also called splitting in some cases.

The main causes of cracking include:

- High material hardness, which makes the metal less ductile

- Increased thickness, which needs more force to bend and can lead to splitting

- A heat-affected zone from cutting, which makes the metal more brittle

You can prevent cracking by matching your tooling to the material. Use a larger die opening for thicker or harder materials. Make sure you do not use a punch with too small a radius, as this increases the risk of splitting. Always inspect your material for signs of brittleness before bending.

Wrinkling

Wrinkling is another common bending defect. You will see wave-like patterns or folds on the inside of the bend. This defect makes the part look bad and can weaken its structure.

Many process variables can cause wrinkling. The table below shows how each factor contributes:

| Process Variable | Contribution to Wrinkling |

|---|---|

| Punch and Die Radii | Affects how the material flows and stress spreads. |

| Punch to Die Clearance | Changes the space for the metal to move. |

| Press Speed | Alters how fast the metal bends. |

| Schmierung | Reduces friction and changes material movement. |

| Blank Holding Force | Controls the flow and helps stop wrinkling. |

To fix wrinkling, you should check your punch and die radii. Make sure the clearance between the punch and die matches your material. Adjust the press speed and use enough blank holding force to keep the metal flat. Good lubrication can also help the material move smoothly and prevent folds.

Note: Wrinkling often signals that your setup needs adjustment. Always review your process if you see this defect.

Overbending

Overbending is when you bend metal too far. This means the angle is more than you want. It happens a lot in factories that use press brakes. Most of the time, overbending comes from setting up the tools wrong. Sometimes, it happens because the machine program is not right. If you overbend, you might have to throw away parts. This mistake can make your work cost more and take longer.

- Overbending happens often in factory work.

- Setting up tools wrong can cause overbending.

- Bad programming can also make overbending happen.

- Overbending leads to wasted parts and higher costs.

To fix overbending, check your press brake settings first. Make sure you pick the right dies and punches for your metal. Always try a test bend before you start a big job. If you see overbending, change your tools or program right away. This helps you save material and keeps your work moving.

Tip: Try a sample bend to check your angle before making many parts. This easy step helps you find bending problems early.

Underbending

Underbending is when the metal does not bend enough. The angle is less than you need. This can happen if your tools do not match your metal. It can also happen if you do not use enough force. Underbending can make your parts not fit right. This can cause trouble when you put things together.

The table below shows what can cause underbending in sheet metal work:

| Faktor | Beschreibung |

|---|---|

| Metal Type | Different metals bend in different ways. For example, aluminum can crack if you bend it too much. |

| Yield Strength | This tells you how much force the metal can take before it bends for good. |

| Duktilität | Ductility shows how much the metal can stretch before it breaks. |

You can fix underbending by picking dies and punches that fit your metal. Check your press brake to make sure it is set right. Use enough force to bend the metal. Always look at your parts after bending to spot underbending early. If you see this problem, change your tools or settings before making more parts.

Note: Underbending means your tool setup may need work. Check your process if you see this problem.

Oberflächenschäden

Surface damage is a problem you see after bending metal. You might notice scratches, dents, or marks on the metal. These problems can make your parts look bad. They can also cause rust or make it hard to put parts together.

Surface damage can happen for many reasons:

- Scratches or marks during bending

- Clamping too hard or using too much pressure

- Picking the wrong tools for your metal

- Tools that are dirty, rough, or worn out

- Not using enough lubrication

- Handling the metal the wrong way

You can stop surface damage by using a film to protect your metal. Clean or change your tools often to keep them smooth. Use softer dies or lined tools for soft or shiny metals. Always keep your tools clean and handle metal with care to stop bending problems.

Tip: If your parts need to look nice, always check your tools and use protection. This helps you stop surface damage and keeps your products looking good.

Fix Common Press Brake Problems

When you use press brakes, you may see problems like springback, cracking, and wrinkling. You can fix these problems by picking the right bending dies and punches. You should also follow steps that help you solve these issues. This part will show you how to fix press brake problems and get better results.

Springback Solutions

Springback is when metal tries to go back to its old shape after bending. You need to stop springback if you want your bends to be right. Here are some ways to help with this problem:

Die Opening Adjustments

You can change the die opening to help with springback. Try these ideas:

- Use rotary bending tooling instead of flange wipe dies. Rotary tooling lets you change the angle more easily.

- If you use flange wipe dies, bend the part a little more than needed. Pick die radii that are smaller than the part radius. Add back relief to both the die and punch.

- Make your part’s cross section so you can over-bend it. This helps stop sidewall curl and makes springback less of a problem.

- Add more forming steps. These steps help fix parts that have sprung back, so they are closer to the right size.

- Try forming in more than one stage. This makes your bends more accurate and cuts down on springback.

Tip: Always bend a test piece before making many parts. This helps you see springback early and change your setup if needed.

If you need special shapes or want to make your work better, you can look at Kundenspezifische Klingen for your press brake.

Punch Radius Selection

The punch radius changes how much the metal springs back. You can make springback less by picking the right punch radius. A smaller punch radius puts more force on the bend, which helps set the angle. Always think about springback when you design your parts. Use bend allowances or bend deductions to make sure your part is the right size after bending.

You can also pick punches and dies based on your metal type, thickness, and bend angle. Using special coatings on your tools, like nitriding, can make them last longer and lower friction. This helps you fix press brake problems and keeps your bends the same every time.

Cracking Prevention

Cracking is a big problem. You need to stop cracking so you do not waste parts or money. Here are some ways to help:

Material and Tooling Match

- Use materials with the right strength and ductility. This makes cracking less likely.

- Clean and treat the metal before bending. Dirt or rust can make the metal crack.

- Use data and computer programs to guess how your metal will bend. Change your bend angles if you need to.

- Make sure your workers know what to do and keep your machine in good shape. Taking care of your machine helps stop cracking.

- Use safety devices and two-hand controls. Keep your hands away from the die and lock the ram before you put in tools.

Note: Always check your metal and tools before you start bending. This helps you avoid mistakes and keeps you safe.

Die Width Choice

- Make sure your press brake has enough open height for your parts.

- Use the tallest tools you can to help with bending.

- Leave enough space between punches and dies. This makes moving parts easier and lowers the chance of cracking.

Wrinkling Fixes

Wrinkling makes your parts look bad and weak. You need to stop wrinkling to get smooth, strong bends. Here are some ways to help:

Die Geometry

- Use different blank holder pressure. This helps stop wrinkling in deep-drawn parts.

- Try an NC die cushion. It lets you change the pressure and makes the die cavity deeper, which helps stop defects.

- Make your die design better and change binder pressure. This can cut down on wrinkling a lot.

- Change the binder drawbead angle. This changes the pulling force and helps control how the metal moves.

- Use pre-bulging. This lowers stress and helps stop wrinkles.

- Support the flange area when you bend. This helps stop flange wrinkling in roll forming.

- Raise the cavity pressure in hydrodynamic deep drawing. This makes the metal more stable and stops wrinkling.

Tip: Good binder design and pressure can cut wrinkling by up to 40% in hard parts.

Punch Shape

The punch shape also changes wrinkling. Pick a punch that fits your metal and bend needs. A good punch helps control how the metal moves and stops wrinkles. If you see wrinkling, check your punch and die and make changes if needed.

You can fix press brake problems like wrinkling by using the right dies and punches and keeping your tools in good shape.

Overbending Corrections

Overbending is when metal bends too far. You want a certain angle, but the bend goes past it. You can fix this by picking the right tools. You also need to make careful changes to your setup.

Large-Radius Punches

Large-radius punches help control overbending. These punches spread force over more space. The bend becomes smoother and not as sharp. A punch with a bigger radius bends metal gently. This helps you get closer to the angle you want. Large-radius punches work best for thick sheets and tough metals.

Benefits of large-radius punches:

- Make bends less sharp

- Lower chance of cracking

- Help you get the right angle

Tip: Match the punch radius to your metal thickness. This helps you avoid bending problems. It also keeps your parts the same.

Manual Adjustments

Manual adjustments let you change your bending process. You can change press brake settings or move the die and punch. If you see overbending, stop and check your setup. Make small changes to the angle or pressure. Test a sample piece before making many parts.

Steps for manual adjustments:

- Check the angle after each bend.

- Change the ram depth or back gauge.

- Use a protractor or angle gauge to measure.

- Repeat until you get the angle you want.

Note: Manual adjustments give you more control. You can fix press brake problems fast. This helps you save material.

Underbending Solutions

Underbending means the metal does not bend enough. You can fix this by checking your machine and setup.

Calibration Tips

Calibration helps you get the right bend every time. You need to check your press brake often. Make sure the machine settings match your metal and tools. Use laser tools or digital gauges for better accuracy.

Calibration checklist:

- Look for wear or damage on the press brake

- Set the ram depth right

- Line up the die and punch

- Test with a sample bend

Tip: Calibrate often to stop underbending. This keeps your bends the same.

Die and Punch Setup

How you set up your die and punch changes the bend angle. Pick the right die opening and punch radius for your metal. Make sure the die and punch are clean and not damaged. Put the metal in the right spot before bending.

Die and punch setup tips:

- Match die opening to sheet thickness

- Use a punch with the right radius

- Check alignment

- Hold the metal in place

Note: Good setup helps you fix press brake problems. It also makes your bends better.

Surface Damage Prevention

Surface damage can make your parts look bad. It can also hurt how they work. You can stop surface damage by using protective films and keeping tools clean.

Protective Films

Protective films keep metal safe from scratches and marks. Put a thin plastic film on the metal before bending. The film takes the pressure and stops marks from the tools.

Advantages of protective films:

- Stop scratches and dents

- Keep parts clean

- Easy to take off after bending

Tip: Use protective films for shiny or painted metals. This helps you avoid bending problems. It also keeps your products looking nice.

Werkzeugwartung

Tool maintenance stops surface damage. Clean your dies and punches often. Look for wear or rough spots. Change any damaged tools right away. Lubricate moving parts to lower friction.

Tool maintenance steps:

- Clean dies and punches after each use

- Check for wear or damage

- Bewegliche Teile schmieren

- Change worn tools

Note: Good maintenance helps you fix press brake problems. It also makes your tools last longer.

Preventing Sheet Metal Bending Defects

Tool Selection Tips

Match Die and Punch to Material Type

You must pick dies and punches that fit your material. Aluminum, steel, and stainless steel all bend in different ways. Each metal needs special tools for good results. Aluminum bends easier than steel, so you may need a bigger die opening. Always check what metal you have before you start.

- Pick dies and punches that match the metal’s strength.

- Use special dies for thick or tough metals.

- Choose the right tools for big jobs or tricky shapes.

Consider Bend Radius and Thickness

Bend radius and thickness change which die and punch you need. If you use the wrong size, you might get cracks or wrinkles. Always measure your metal and pick a die opening that fits.

Tip: A bigger bend radius helps stop cracks in thick or hard metals.

Use Manufacturer Guidelines

Manufacturers give rules for matching dies and punches to metal type and thickness. These rules help you avoid mistakes and keep bends right. Mild steel may need 20% die clearance, but stainless steel may need 25%. Always follow these rules to lower the chance of defects.

| Materialtyp | Thickness Range (in.) | Recommended Die Clearance (%) |

|---|---|---|

| Weichstahl | 0.036 to 0.105 | 20% (change for thickness) |

| Edelstahl | 0.038 to 0.109 | 25% (change for thickness) |

| Aluminum/Brass | 0.032 to 0.081 | 15% (change for thickness) |

Setup and Alignment

Ensure Proper Tool Installation

Putting dies and punches in the right way helps stop bending defects. Tighten the tools so they do not move. Adjust the space between punch and die to fit your metal.

Check Material Positioning

Put your sheet metal in the right spot every time. Loading it wrong can cause burrs or size mistakes. Use the back gauge and check with measuring tools.

Use Alignment Tools and Gauges

Use alignment tools and gauges to check your setup. Dial gauges, digital protractors, and laser systems help you check angles and straightness. These tools help you find problems before you bend.

| Werkzeugtyp | Zweck |

|---|---|

| Dial gauge or test indicator | Checks if things are lined up |

| Digital protractor | Measures bend angles fast |

| Laser alignment system | Makes sure things are straight and square |

Maintenance and Inspection

Regularly Inspect Dies and Punches

Check your dies and punches often to find damage early. Look for cracks, chips, or uneven spots. Finding problems early keeps bends good and stops delays.

Clean and Lubricate Tooling

Clean and oil your dies and punches to keep them working well. Dirt or rust can cause defects. Use safe lubricants to protect your tools.

Replace Worn or Damaged Parts

Change any dies or punches that are worn or broken right away. This step helps your tools last longer and keeps bends good. Taking care of your tools and replacing bad parts quickly helps you get better results.

Note: Stopping sheet metal bending defects starts with picking good tools, setting up carefully, and doing regular maintenance. These steps help you get great results every time you bend sheet metal.

Choosing Bending Dies and Punches

Checklist for Tooling Selection

Picking the right tooling helps you bend metal the right way. It also helps you stop mistakes. You need to think about a few things before you choose dies and punches. The table below shows common tooling styles and what they are good for:

| Werkzeugstil | Force Application | Hauptmerkmale | Vorteile | Anwendungsfall |

|---|---|---|---|---|

| American Style | Linear | Segmented, easy punch reversal | Flexible, available | Custom production runs |

| European Style | Offset | Slim profile, quick changes | Efficient, versatile | Großserienproduktion |

| Wila Trumpf Style | Linear/Offset | Hardened, quick-change system | Durable, precise | Thick plates, strong metals |

Check what the die is made of before you start. Tool steel and carbide last longer and work well for hard jobs. For aluminum, use dies with nitriding treatment. These dies do not wear out fast and keep the metal smooth. Always match the die to your press brake’s tonnage. Softer metals like aluminum need less force. Harder or thicker metals need more force. Make sure your press brake can do the job.

When you pick an aluminum alloy, look at its strength and hardness. Some alloys bend easier than others. Pick the best alloy for your project to get good results.

Tip: Use this checklist every time you start a new job. It helps you stop mistakes and keeps your bending work easy.

Anpassungsoptionen

Sometimes you need special tooling for tricky shapes or hard projects. Custom press brake tooling gives you more control. It also helps you get better bends. Nanjing Metal lets you order tooling made just for you.

| Werkzeugstil | Vorteile |

|---|---|

| American Precision Style | Simple design, easy to use |

| European Precision Style | High precision, secure locking for CNC machines |

| Wila Trumpf Style | Auto-clamping for fast tool changes and accurate bends |

| Bevel Tang Style | Fits newer Amada press brakes with angled punch tang |

| Kundenspezifische Werkzeuge | Matches your specifications, improves flexibility and efficiency |

Custom tools help you work faster and make fewer mistakes. You get better bends every time. You spend less time setting up and waste less metal. Fewer tool changes mean fewer errors and smoother work.

Take care of your dies and punches to keep them working well. Clean and oil your tools often. Store them in a dry place so they do not rust. Check for damage before each job. Good care makes your tools last longer and keeps your bends safe and even.

Note: Custom tools and good care help you stop mistakes and keep your press brake tooling working great.

Picking the right bending dies and punches for each job helps you fix press brake problems. It also stops bending defects from happening. You get better bends when you know your tools and use the ones that fit your metal. If you take care of your equipment and check it often, it works well and you make fewer mistakes. When you follow good steps, your bends are more exact, you waste less metal, and you finish your work faster.

| Quick-Reference Checklist | Warum es wichtig ist |

|---|---|

| Pick the right tools | Makes your work better and more exact |

| Check and adjust tools often | Stops problems and keeps things working |

| Set up tools and metal the right way | Gives you good bends every time |

If you need help or want special tools, talk to a Nanjing Metal sales engineer.

Häufig gestellte Fragen

What are bending dies and punches?

Bending dies and punches are special tools you use in a press brake. They help you shape and bend sheet metal into different angles and forms. You need the right set for each job to get accurate results.

How do I choose the right bending dies and punches?

You should match the die and punch to your material type, thickness, and bend angle. Always check manufacturer guidelines. Using the correct tooling helps you avoid common bending defects and improves your finished parts.

Why do I see cracks or wrinkles after bending?

Cracks or wrinkles often happen when you use the wrong bending dies and punches. Sometimes, the material is too hard or the die opening is too small. Check your setup and try different tooling to fix these problems.

How often should I inspect my bending dies and punches?

You should inspect your bending dies and punches before every job. Look for wear, cracks, or dirt. Clean and replace damaged tools right away. Regular checks help you prevent bending defects and keep your tools working longer.

Can I use the same tooling for all metals?

No, you cannot use the same bending dies and punches for every metal. Different metals need different die openings and punch radii. Always choose tooling that matches your material for the best results.

What should I do if my bends are not accurate?

Check your press brake calibration and make sure your bending dies and punches are set up correctly. Use alignment tools and gauges. Test with a sample piece before starting a large batch.

How can I prevent surface damage during bending?

Use protective films on your sheet metal. Keep your bending dies and punches clean and smooth. Handle materials with care. These steps help you avoid scratches and dents on your finished parts.

Do I need custom bending dies and punches for special shapes?

Yes, you may need custom bending dies and punches for unique shapes or complex bends. Custom tooling helps you get precise results and reduces the risk of bending defects.

Siehe auch

Freies Biegen vs. Prägen: Die richtige Abkantpressen-Werkzeuge für Ihr Projekt auswählen

Abkantpressen-Werkzeuge im europäischen vs. amerikanischen Stil: Was ist das Richtige für Ihre Werkstatt?

Auswahl der besten Abkantpressen-Werkzeuge für Edelstahl

Beherrschung von Abkantwerkzeugen: So erkennen und beheben Sie Stempel- und Matrizenverschleiß