Have you tried to cut rubber and ended up with rough edges or wasted pieces? You’re not alone! Choosing the right rubber cutting blade is crucial for a clean cut. Before you start, consider the type and thickness of your rubber. Also, think about your specific cutting needs. Even small variations in your rubber can affect how you should cut it and impact your results. For example, take a look at this table:

| Applied Normal Force | Carbon Black Structure | Compound Behavior | Effect on Cut and Chip Wear |

|---|---|---|---|

| Low Force | High Structure | Stiffer compound, less deflection | Minimizes wear by stiffening the compound |

| High Force | Low Structure | Softer compound, enables strain-induced crystallization | Minimizes wear by allowing crystallization |

Selecting the right blade and rubber combination can improve your work quality and reduce errors.

Die wichtigsten Erkenntnisse

- First, know your rubber type, how hard it is, how bendy it is, and how thick it is before you pick a blade. This helps you get clean and smooth cuts.

- Choose the right blade type. It can be straight, serrated, circular, or custom. Pick based on your rubber and how you need to cut it. This gives you better results.

- Find a good balance between being exact and being fast. Pick blades and settings that match your project goals and how much work you have.

- Look at important blade features like tooth count, hook angle, kerf width, and size. These help you cut better and make your blade last longer.

- Always use sharp blades. Follow safety steps like wearing protective gear. This helps you cut rubber safely and keeps you from getting hurt.

Know Your Rubber Material

Types of Rubber

Before you pick a blade, you need to know what kind of rubber you have. Rubber comes in many forms. You might work with natural rubber, which feels soft and stretchy. Some projects use synthetic rubber, like neoprene or EPDM. These types can handle heat, oil, or weather better than natural rubber. Silicone rubber is another option. It stays flexible even in extreme temperatures. Each type reacts differently when you cut it. If you use the wrong blade, you might get jagged edges or waste material.

Tipp: Check the label or ask your supplier about the rubber type. This helps you choose the best cutting tool.

Hardness and Flexibility

Rubber hardness and flexibility matter a lot when you cut. Hardness means how firm the rubber feels. Flexibility shows how much it bends. Research shows that softer rubber lets you make deeper marks and shapes, but it can tear more easily. Harder rubber gives you cleaner, shallower cuts and holds its shape better. The way rubber stretches (its elasticity) also changes how a blade works. Two rubbers with the same hardness can still act differently if one is more flexible. If you want a balance, some products use a double-layer design—a soft inside and a hard outside. This mix helps you get both strength and flexibility in your cuts.

Dicke

Rubber thickness changes everything. Thin sheets cut easily with a sharp blade. Thick or reinforced rubber needs a stronger, sharper tool. If you try to use a small blade on thick rubber, you might end up with rough edges or even damage your blade. Always measure your rubber before you start. For very thick or tough materials, you may need a specialty blade or even a custom solution.

Remember: Knowing your rubber’s type, hardness, flexibility, and thickness helps you get smooth, clean cuts every time.

Rubber Cutting Blade Types

Choosing the right rubber cutting blade can make your project much easier. You will find several types of blades, each with its own strengths. Let’s look at the main options and see how they work for different rubber materials and jobs.

Gerade Klingen

Gängige Materialien

- High-carbon steel: This material gives you a sharp edge and lasts a long time. It works well for clean, straight cuts.

- Stainless steel: If you need to cut rubber in wet or harsh places, stainless steel resists rust and stays sharp.

- Tungsten carbide: This material is very hard and keeps its edge even when you cut tough or thick rubber.

Typische Anwendungen

You will use straight blades when you want a neat, straight cut in soft or medium-hard rubber sheets. These blades work in both hand tools and machines. If you need to cut rubber for gaskets, flooring, or seals, a straight blade is a good choice.

Researchers have tested straight blades by measuring how sharpness and blade shape affect cutting. They found that a sharper tip and the right wedge angle help you get a cleaner cut. The tests also showed that the way rubber stretches and grips the blade changes how much force you need. So, if you want reliable and smooth cuts, pay attention to the blade’s shape and sharpness.

Tipp: Always check your blade for sharpness before starting. A dull blade can tear the rubber and leave rough edges.

Gezackte Klingen

Gängige Materialien

- High-carbon steel: Serrated blades made from this material have strong, sharp teeth. They cut through tough or fibrous rubber easily.

- Stainless steel: This material helps prevent rust, which is helpful if you work in damp or industrial settings.

- Tungsten carbide: Serrated blades with tungsten carbide teeth stay sharp longer, even when you cut abrasive or reinforced rubber.

Typische Anwendungen

Serrated blades shine when you need to cut thick, textured, or reinforced rubber. The teeth grip the material and help reduce slipping. You might use these blades for cutting conveyor belts, rubber mats, or tires. The saw blade differences between straight and serrated types come down to how they handle tough materials. Serrated blades bite into the rubber, making it easier to cut through layers or fibers.

If you notice your rubber slipping or bunching up, try a serrated blade for better control.

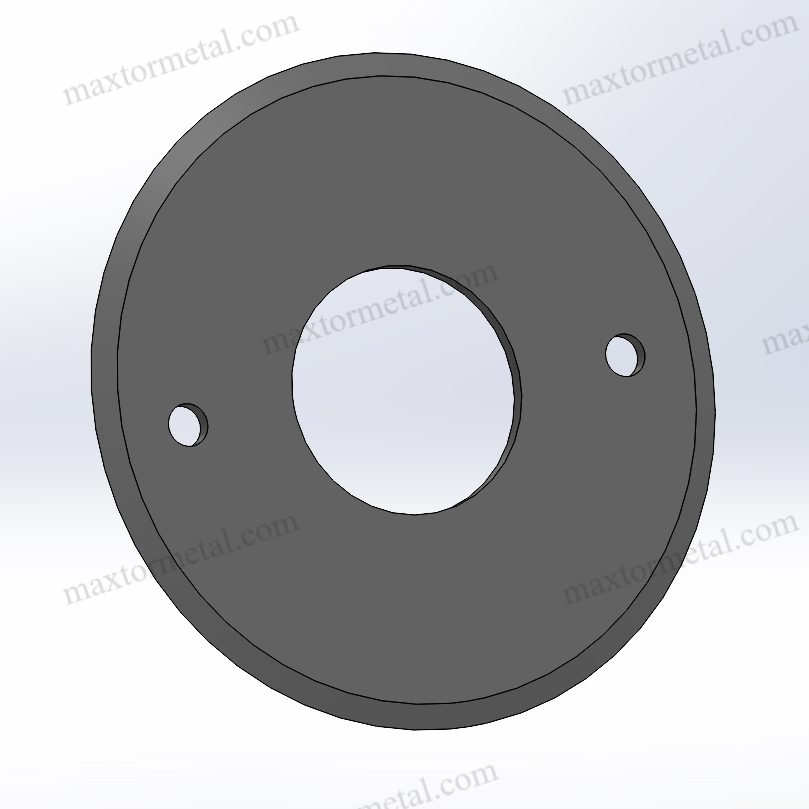

Kreissägeblätter

Gängige Materialien

- High-carbon steel: This material balances cost and performance, making it a popular choice for general cutting.

- Stainless steel: Use this if you need to cut rubber in wet or food-safe environments.

- Tungsten carbide: Circular blades with this material handle high-speed, nonstop cutting and resist wear.

Typische Anwendungen

You will often see circular blades in machines that cut large rolls or sheets of rubber. These blades work best for continuous or high-volume jobs. Factories use them to make products like rubber flooring, seals, or strips.

Technical studies show that circular blades work well for nonstop cutting. When you pair them with a flexible rubber backing roll, the blade can cut fibers cleanly and last through thousands of cuts. The backing roll supports the rubber and absorbs some of the cutting force. This setup keeps the blade sharp and helps you get smooth, even cuts every time.

Notiz: If you need to cut a lot of rubber quickly, a circular blade in a machine will save you time and effort.

Specialty and Custom Blades

Gängige Materialien

- High-carbon steel, stainless steel, tungsten carbide, and other special alloys: Custom blades use the best material for your job. You can choose what fits your needs.

Benefits and Necessity of Custom Blades

Sometimes, your project needs more than a standard rubber cutting blade. Maybe you work with a special type of rubber, or you need to cut a unique shape or thickness. Custom blades let you pick the right size, shape, and material. This helps you cut faster, safer, and with more accuracy. Industries like automotive, aerospace, or food processing often need custom blades to meet strict rules or handle tough jobs.

Custom blades can solve problems that standard blades cannot. If you keep running into trouble, a custom solution might be the answer.

Nanjing Metal as a Custom Blade Provider

If you need a custom rubber cutting blade, you want a manufacturer you can trust. Nanjing Metal stands out as a leading rubber cutting blade manufacturer with over 20 years of experience. Their team designs and makes blades for all kinds of industries. They use advanced tools and strict quality checks to make sure every blade meets your needs. Many customers around the world trust Nanjing Metal for their custom Blade projects.

Want to learn more or get a quote? Just contact a Nanjing Metal sales engineer. They can help you find the perfect blade for your project.

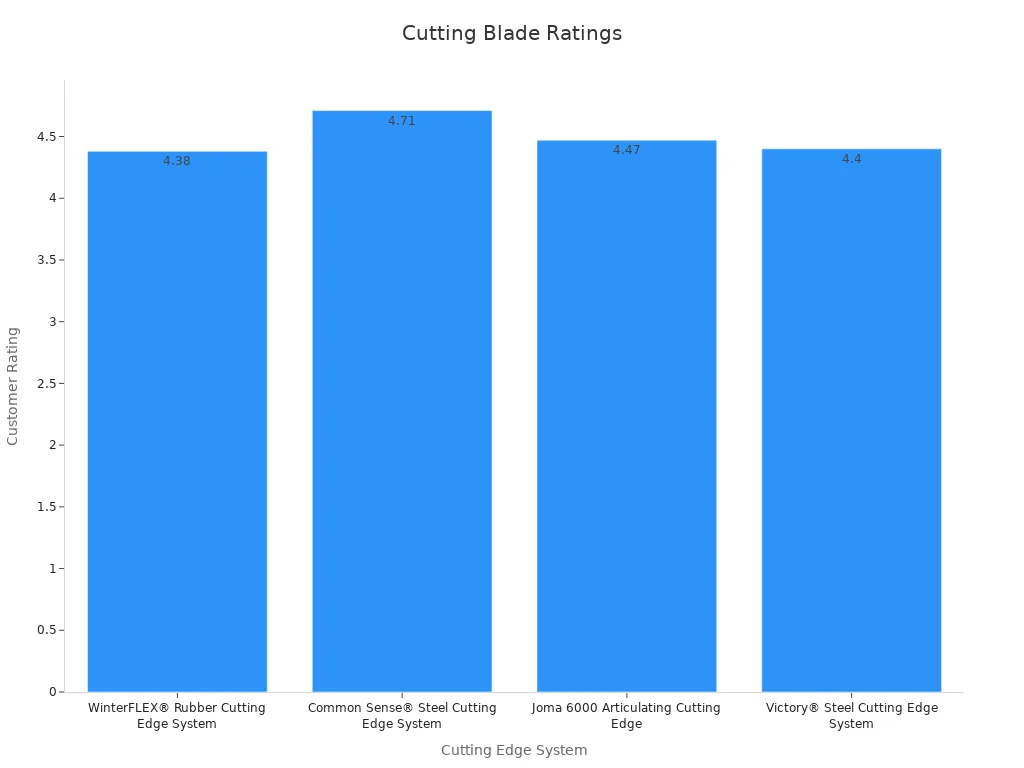

Choosing the Perfect Blade

Precision vs. Speed

When you start choosing the perfect blade, you need to think about what matters most for your project: precision or speed. If you want smooth, clean edges, you should focus on precision. If you need to finish a lot of work quickly, speed becomes more important.

When to Prioritize Precision

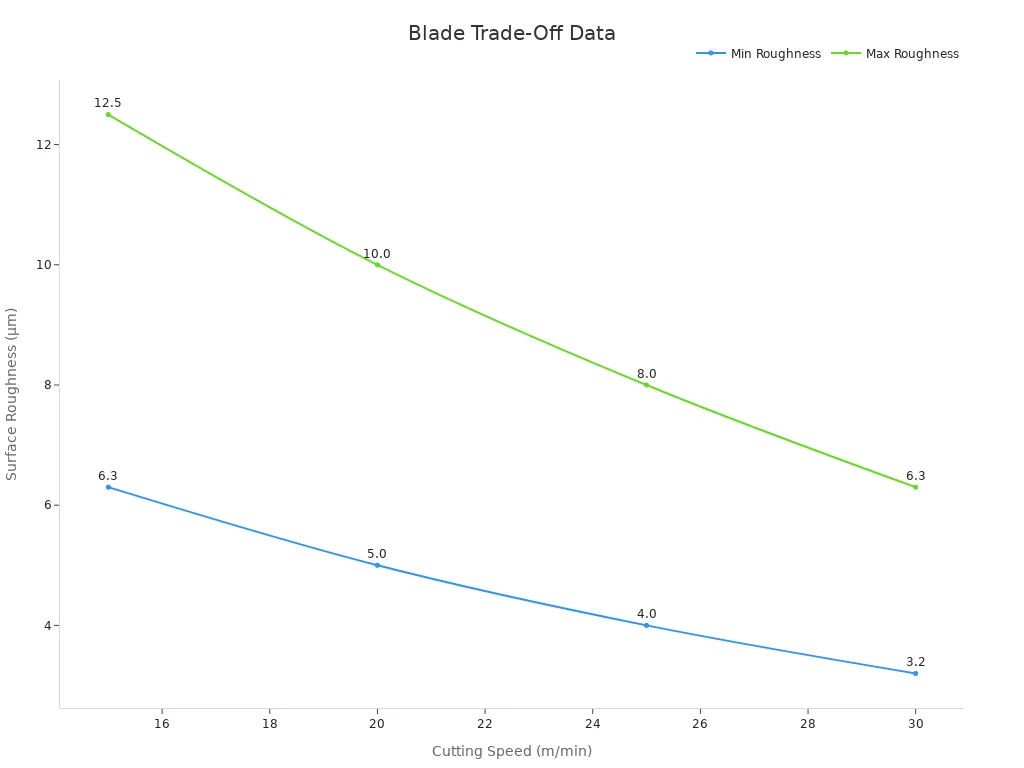

You should choose precision when your project needs tight tolerances or a perfect finish. For example, if you cut rubber gaskets for engines, a rough edge can cause leaks. Take a look at this table to see how different cutting speeds affect surface quality:

| Steel Grade | Surface Roughness (μm) | Schnittgeschwindigkeit (m/min) | Saw Type | Feed (mm/tooth) |

|---|---|---|---|---|

| Low Carbon Steel | 3.2 – 6.3 | 30 | Band saw | 0.2 |

| Medium Carbon Steel | 4.0 – 8.0 | 25 | Circular saw | 0.15 |

| Legierter Stahl | 5.0 – 10.0 | 20 | Band saw | 0.1 |

| Werkzeugstahl | 6.3 – 12.5 | 15 | Circular saw | 0.08 |

Higher speed can mean rougher cuts, especially with harder materials.

When to Prioritize Speed

Speed matters when you have a lot of material to cut and less need for perfect edges. For example, if you cut rubber mats for playgrounds, you might want to finish quickly. Just remember, faster cutting can wear out your blade faster and lower the quality of your cuts.

Balancing Both for Your Project

You can balance speed and precision by testing different blades and settings. Sometimes, using a hybrid blade or adjusting your machine helps you get both good speed and decent quality.

Manual vs. Machine Cutting

Blade Selection for Manual Cutting

Manual cutting works best for small jobs or when you need to make custom shapes. You should pick a blade that feels comfortable and stays sharp. Straight or serrated blades are common choices.

Blade Selection for Machine Cutting

Machines can cut faster and more accurately. They use circular or specialty blades for high-volume work. A sealing gasket company found that switching to machine cutting cut their production time in half and gave them smoother edges.

| Gasket Type | Dicke | Machine Speed (mm/s) | Manual Speed (mm/s) | Labor (people) |

|---|---|---|---|---|

| Rubber Gasket | 3 mm | 200 | 50 | 3 |

| Rubber Gasket | 10 mm | 50 | ≤10 | 4 |

Safety and Efficiency Considerations

Machine cutting is safer and more efficient for big jobs. Manual cutting needs more skill and can be tiring. Always wear safety gear and keep your blades sharp.

Volume of Work

Low-Volume Projects

If you only cut rubber once in a while, your blade will last longer. You will not need to sharpen or replace it often.

High-Volume or Industrial Projects

Cutting rubber every day wears out blades faster. In factories, blades may need replacing every few months. The table below shows how work volume affects blade life:

| Usage Context | Expected Lifespan | Wartungsbedarf |

|---|---|---|

| Home Kitchen | 12 to 24 months | Less frequent maintenance |

| Industrial Use | 6 to 18 months | Frequent sharpening and replacement |

Cost and Maintenance Implications

More cutting means higher costs for new blades and more time spent on maintenance. You can save money by storing blades properly and using the right blade for your job.

Key Blade Features

When you pick a rubber cutting blade, you want to look at more than just the shape. Each feature changes how your blade performs and how clean your cuts turn out. Let’s break down the most important features you should know.

Tooth Configuration

Tooth configuration means the way the teeth are arranged on your blade. The tooth count, spacing, and shape all matter. A higher tooth count gives you smoother cuts, but it can slow you down. Fewer teeth cut faster, but you might see rougher edges. The tooth geometry, or the shape of each tooth, also affects how the blade slices through rubber. If you work with thick or tough rubber, you might want a blade with fewer, larger teeth. For thin or soft rubber, a higher tooth count helps you get a cleaner edge.

Material Removal Rate (MRR) shows how fast you can cut. It depends on feed rate, tooth count, and how deep you cut. If you want to balance speed and quality, try different tooth counts to see what works best for your project.

Hook Angle

The hook angle is the tilt of the blade’s teeth. A positive hook angle pulls the rubber into the blade, making cutting easier and faster. A negative hook angle pushes the material away, which can help you get more control and a smoother finish. Some wood blades with a negative hook angle actually work well for certain rubber types, especially if you want to avoid tearing or slipping. Always check the hook angle before you start, because it changes how the blade grabs the rubber.

Kerf Width

Kerf width is the thickness of the cut your blade makes. A narrow kerf means less material wasted and more precise cuts. A wider kerf can handle thicker or tougher rubber but may leave a bigger gap. Studies show that smaller kerf widths lead to less heat damage and smoother edges, especially when cutting soft or flexible rubber. If you need tight tolerances, always measure the kerf width before you begin.

Blade Size and Diameter

Blade size and diameter decide how deep and wide you can cut. Bigger blades cut deeper, but they need more power. Smaller blades work well for thin sheets or detailed work. Always match your blade size to your rubber’s thickness and your cutting tool.

Durability and Maintenance

A durable blade saves you time and money. Look for blades made from strong materials like high-carbon steel or tungsten carbide. Sharpness matters, too. Tests like the BESS Score and CATRA metrics measure how sharp a blade is and how long it stays sharp. You can use high-tech tools like SEM or AFM to check for tiny defects or dull spots. Keep your blade clean and sharpen it often. Regular maintenance helps your blade last longer and keeps your cuts smooth.

Tip: If you notice your blade getting dull or your cuts looking rough, it’s time for some maintenance. A well-cared-for blade makes every project easier.

How to Cut Rubber Safely

Best Tool to Cut Rubber

You want clean, easy cuts when you work with rubber. Picking the best tool to cut rubber makes a huge difference. Many users say anvil pruners, like the Craftsman Edge, and the Ronan Multi-Cut tool give the best results. These tools help you avoid rough edges and wasted material. People who switched from scrapers or scissors to these tools noticed they stopped ruining cuts. The Ronan Multi-Cut tool stands out as the best tool to cut rubber for most jobs, even though it costs more. It gives you smooth, straight cuts every time.

If you need to cut thick or tough rubber, you might want to try waterjet cutting. This method works well for big projects and gives you high precision. Here’s a quick look at how different cutting methods compare:

| Besonderheit | Waterjet Cutting | Die Cutting | Laserschneiden | Knife Cutting |

|---|---|---|---|---|

| Präzision | ±0.005 in | ±0.010 in | ±0.003 in | ±0.020 in |

| Max Thickness | Up to 12 in | Up to 2 in | Up to 1 in | Up to 4 in |

| Geschwindigkeit | Medium-Fast | Very Fast | Schnell | Langsam |

| Kosten | Hoch | Medium | Hoch | Niedrig |

You can see that waterjet and laser cutting give you the best accuracy, but hand tools like the Ronan Multi-Cut are perfect for smaller jobs.

Safety Tips

When you learn how to cut rubber, safety should always come first. Many accidents happen because people skip safety steps or use the wrong tools. Always wear cut-resistant gloves, safety glasses, and sturdy boots. If you use power tools, check that everything works before you start. Keep your work area clean and free of clutter.

Tip: The Logger Safety Initiative recommends using sharp, well-maintained tools and wearing proper protective gear. They also suggest having a first aid kit nearby and working with others when possible.

A study in rubber sawmills found that most injuries happen to hands and feet. You can avoid these by using the right tools and following safe cutting techniques.

Common Mistakes

You might wonder how to cut rubber without making mistakes. Many people run into trouble because they rush or skip steps. Here are some common mistakes:

- Using dull blades or the wrong tool for the job.

- Not measuring or marking the rubber before cutting.

- Skipping safety gear like gloves or goggles.

- Ignoring tool maintenance, which leads to accidents.

- Applying uneven pressure, causing jagged or uneven cuts.

- Overheating the rubber or using too much force.

- Not checking for defects in the rubber before starting.

Incident analysis shows that fixing these mistakes can reduce defects by over 80%. If you want to cut rubber properly, take your time, use the best tool to cut rubber, and always follow safety steps.

Choosing the right rubber cutting blade starts with knowing your material and project goals. You should look at blade materials, shapes, and coatings to match your needs.

- Different blades work best for different types of rubber and cutting jobs.

- Coatings like Titanium Nitride help blades last longer.

- Custom blades give you the best results for tricky projects.

If you want to master how to cut rubber, always check your blade and stay safe. For unique jobs, custom blades from a trusted manufacturer like Nanjing Metal can make how to cut rubber easier and more precise. Don’t forget to keep your tools sharp and Kontakt their sales engineer if you need expert help.

Häufig gestellte Fragen

What is the best blade for cutting thick rubber?

You should use a heavy-duty blade, like a tungsten carbide or serrated blade. These blades stay sharp and handle tough, thick rubber without tearing.

Can I use a wood blade to cut rubber?

Some wood blades with a negative hook angle work for certain rubber types. Always check the blade’s sharpness and test on a scrap piece first.

How do I keep my cutting blade sharp?

Clean your blade after each use. Store it in a dry place. Sharpen it regularly with the right tool. A sharp blade gives you smoother cuts and lasts longer.

Do I need a custom blade for my project?

If you work with unique rubber materials or need special shapes, a custom blade helps you get better results. Custom options fit your exact needs and improve efficiency.

Where can I get expert help with custom blades?

You can contact a Nanjing Metal sales engineer for advice. They have years of experience as a leading industrial blade manufacturer and can help you find the perfect solution for your project.

Siehe auch

Der ultimative Leitfaden zur Auswahl einer Gummi-Schneideklinge

Neueste Trends und Entwicklungen bei Gummireifen-Trimmklingen und Messern

Was sind Rundklingen und wie werden sie in der Industrie eingesetzt?

So wählen Sie die richtigen Kreisschneiderklingen für lang anhaltende Leistung