Die Geflügelverarbeitungsindustrie ist ein riesiger globaler Markt. Im Jahr 2022 wurde der globale Markt für Geflügelfleisch auf über 15 Billionen Tonnen geschätzt, und Prognosen deuten auf ein anhaltendes Wachstum aufgrund der steigenden Nachfrage nach proteinreicher Nahrung hin. Die Industrie verarbeitet jährlich Milliarden von Vögeln und benötigt effiziente, präzise und schnelle Maschinen, um die Nachfrage zu decken.

Mit zunehmender Automatisierung in der Geflügelverarbeitung steigt der Bedarf an hochwertige Klingen für die industrielle Geflügelverarbeitung ist wichtiger denn je. Klingen und Messer für die Geflügelverarbeitung müssen saubere Schnitte, minimalen Abfall und eine hohe Haltbarkeit gewährleisten, was sich direkt auf die Betriebseffizienz auswirkt.

Nanjing Metal, mit 18 Jahren Erfahrung in der industriellen Klingenherstellung, bietet maßgeschneiderte und leistungsstarke Messer zugeschnitten auf die hohen Anforderungen von Geflügelverarbeitungsbetrieben. Ihre Expertise in der Präzisionstechnik gewährleistet optimale Schneidlösungen für jede Phase des Geflügelverarbeitungsablaufs.

1. Überblick über den Arbeitsablauf bei der Geflügelverarbeitung

Die Geflügelverarbeitung besteht aus mehreren klar definierten Schritten, die jeweils spezielle Schneidwerkzeuge erfordern. Die wichtige Schritte enthalten:

- Annahme und Schlachtung – Gewährleistung einer humanen Handhabung und eines präzisen Schnitts

- Federentfernung – Verwendung hocheffizienter Rupf- und Entfederungsklingen

- Ausnehmen und Trimmen – Präzisionsmesser entfernen unerwünschte Teile mit Genauigkeit

- Kühlen – Aufrechterhaltung der Lebensmittelsicherheit und Optimierung des Kühlprozesses

- Schneiden und Portionieren – Präzise Portionierung entsprechend den Marktanforderungen

- Verpackung – Endproduktvorbereitung mit sauberen, gleichmäßigen Schnitten

Jährlich werden weltweit über 70 Milliarden Hühner verarbeitet, wobei einige Fabriken über 55 Millionen Tiere pro Jahr verarbeiten. Die Effizienz industrieller Geflügelverarbeitungsklingen ist entscheidend für die Aufrechterhaltung schneller Produktionslinien und die Sicherstellung einer hohen Qualität.

2. Annahme und Schlachtung: Präzision, Effizienz und humane Verarbeitung

Die Bedeutung kontrollierter Schlachtung

Die Annahme und Schlachtung sind die ersten kritischen Schritte in der Geflügelverarbeitung. Die Sicherstellung einer humanen Behandlung und eines präzisen Schnitts in dieser Phase wirkt sich auf die Produktqualität, die Einhaltung von Vorschriften und die Betriebseffizienz aus.

Branchendaten und Trends

- Im Jahr 2023 verarbeitete die weltweite Geflügelschlachtindustrie über 70 Milliarden Vögel, wobei die Anforderungen an die Effizienz aufgrund von Arbeitskräftemangel und strengeren Tierschutzgesetzen steigen (USDA, 2023).

- Die Automatisierung der Geflügelschlachtung wird in den nächsten fünf Jahren voraussichtlich um 6,21 TP4T CAGR wachsen (Mordor Intelligence, 2024).

- Der Einsatz präzisionsgefertigter Klingen in automatisierten Schlachthöfen reduziert den Abfall im Vergleich zu herkömmlichen Methoden um bis zu 20%.

Gängige Betäubungs- und Schlachttechniken

Um den globalen Tierschutzstandards zu entsprechen, wird Geflügel vor der Schlachtung üblicherweise betäubt. Die beiden gängigsten Betäubungsmethoden sind:

- Elektrische Betäubung

- Dabei wird ein Niederspannungsstrom (normalerweise 100–200 mA pro Vogel) durch Wasserbäder geleitet.

- Vorteile: Sorgt für sofortige Bewusstlosigkeit und lindert so das Leiden.

- Nachteile: Eine falsche Kalibrierung kann zu einer schlechten Entblutungseffizienz und einer Minderung der Fleischqualität führen.

- Betäubung in kontrollierter Atmosphäre (CAS)

- Verwendet Kohlendioxid (CO₂), Stickstoff (N₂) oder Argon (Ar), um Vögel schrittweise zu betäuben.

- Vorteile: Minimiert Stress und verbessert die Zartheit des Fleisches.

- Nachteile: Höhere Gerätekosten.

Die Rolle von Schlachtklingen in der Präzisionsverarbeitung

Nach der Betäubung werden die Vögel mechanisch oder manuell geschlachtet. Die dabei verwendeten Klingen müssen mehrere wichtige Kriterien erfüllen:

✅ Extreme Schärfe: Sorgt für saubere, schnelle Schnitte, reduziert den Stress für den Vogel und verbessert die Entblutungseffizienz.

✅ Verschleißfestigkeit: Muss dem Dauerbetrieb auf Hochgeschwindigkeitsstrecken standhalten (Verarbeitung von über 10.000 Vögeln pro Stunde).

✅ Korrosionsbeständigkeit: Da die Klingen in einer Umgebung mit hoher Luftfeuchtigkeit und Bakterienbefall arbeiten, verhindern Edelstahl und beschichtete Legierungen eine Kontamination.

✅ Anpassung: Verschiedene Geflügelrassen erfordern für eine optimale Verarbeitung unterschiedliche Klingengeometrien.

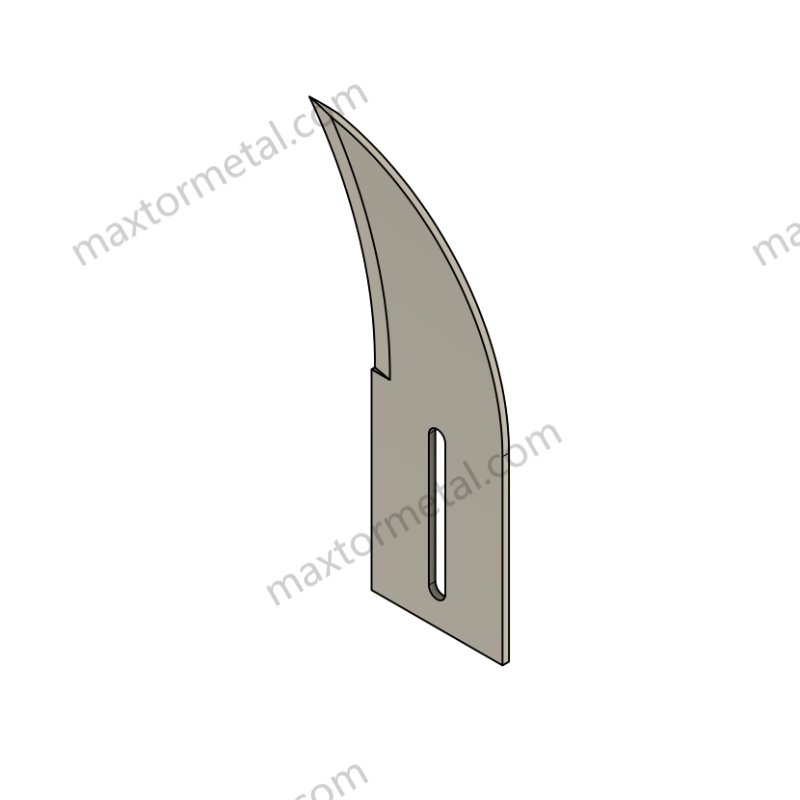

Die Schlachtklingen von Nanjing Metal:

🔹 Ultrafeine Kantenschärfung sorgt für höchste Schnittpräzision.

🔹 Behandlung verbessert die Härte und erhöht die Lebensdauer der Klinge um 30%.

🔹 Korrosionsschutzbeschichtungen Reduzieren Sie das Bakterienwachstum und gewährleisten Sie die Einhaltung der Vorschriften zur Lebensmittelsicherheit.

3. Federentfernung: Die Rolle der Klingen für Effizienz und Qualität

Die Wissenschaft hinter der Federentfernung

Nach der Schlachtung muss das Geflügel effizient entfedert, wobei die Hautintegrität und Produktqualität erhalten bleiben. Die beiden primären Methoden sind:

- Brühen und mechanisches Rupfen (am häufigsten)

- Die Vögel werden in heißes Wasser (54–65 °C) getaucht, um die Federn zu lösen.

- Mechanische Rupfmaschinen verwenden rotierende Gummifinger, um Federn schnell zu entfernen.

- Effizienz: Eine moderne Hochgeschwindigkeitsrupfmaschine kann 10.000 Vögel pro Stunde verarbeiten.

- Trockenzupfen und Wachsen (wird für Premium-Geflügel verwendet)

- Vögel werden manuell gerupft oder mit Wachs überzogen, das zusammen mit den Federn abgezogen wird.

- Verwendet in: Hochwertige Geflügelmärkte, in denen Hautschäden minimiert werden müssen.

Die Rolle von Messern beim Entfedern

Während Gummirupfgeräte die meisten Federn entfernen, werden hochpräzise Trimmmesser benötigt für:

✅ Letzte Ausbesserungen an Flügeln und Hälsen, wo die Rupfmaschinen verfehlen.

✅ Entfernen von Federkielen, die nach der mechanischen Bearbeitung zurückbleiben.

✅ Reduzierung des Kontaminationsrisikos durch Gewährleistung glatter Hautschnitte ohne übermäßiges Reißen.

Messer zum Entfernen von Federn von Nanjing Metal:

🔹 Kohlenstoffreicher Edelstahl sorgt für lang anhaltende Schärfe.

🔹 Ergonomische Griffdesigns verbessern die Arbeitseffizienz an manuellen Ausbesserungsstationen.

🔹 Speziell gezackte Kanten ermöglichen eine höhere Präzision beim Entfernen der Federkiele.

Brancheneinblick:

🔸 Die Effizienz der Federentfernung wirkt sich direkt auf Verarbeitungsgeschwindigkeit und Ausbeute aus. Studien zeigen, dass der Einsatz von präzisionsgefertigten Trimmmessern das Erscheinungsbild des Endprodukts um 15 % verbessern und so den Bedarf an Nachbearbeitung reduzieren kann.

4. Ausnehmen, Trimmen und Waschen: Maximierung des Ertrags mit Präzisionsklingen

Warum die Ausweidung hochpräzises Schneiden erfordert

Beim Ausnehmen werden innere Organe, Füße, Köpfe und alle nicht essbaren Teile entfernt. Dabei wird Folgendes sichergestellt:

1. Minimale Schäden an essbarem Fleisch

2. Hochgeschwindigkeits-Verarbeitungseffizienz

3. Einhaltung der Lebensmittelsicherheitsvorschriften

Dieser Prozess wird mit erstaunlicher Geschwindigkeit durchgeführt; moderne Geflügelfabriken verarbeiten 8.000 bis 12.000 Vögel pro Stunde.

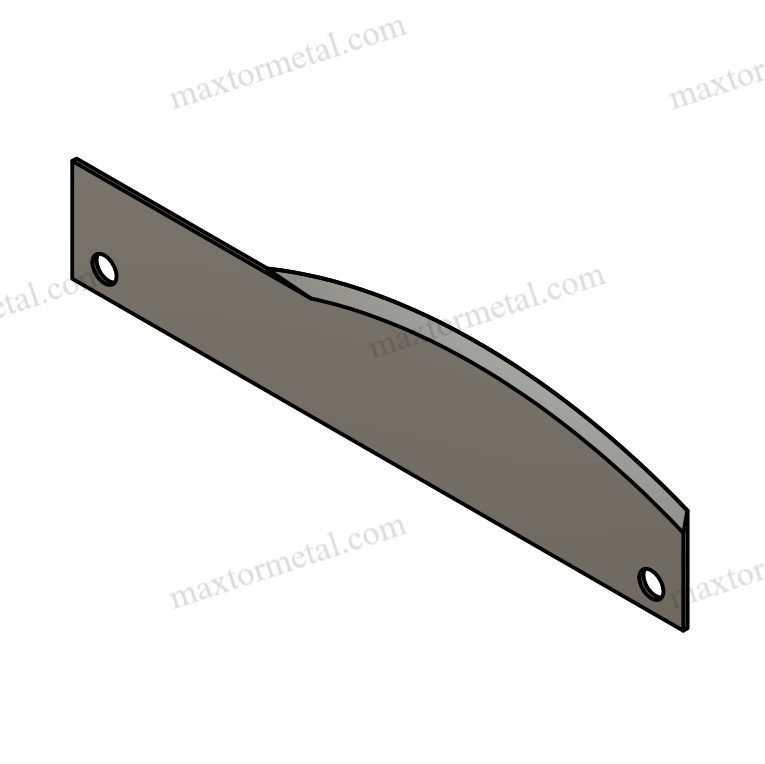

Wichtige Messer zum Ausnehmen und Trimmen

| Klingentyp | Funktion | Material und Beschichtung |

| Entlüftungsschneiderklingen | Schnitte rund um die Kloake für eine präzise Darmentnahme | Titanbeschichteter Edelstahl für Korrosionsbeständigkeit |

| Öffnungsmesser | Öffnet die Körperhöhle für die Darmentnahme | Kryogenisch behandelter Stahl für verbesserte Schärfe |

| Ausweidemesser | Entfernt saubere innere Organe | Antihaftbeschichtung verhindert Gewebeanhaftung |

| Bein- und Halstrimmer | Entfernt Beine und Hals zum Portionieren | Gezackte Kanten für effizientes Knochenschneiden |

Auswirkungen auf Klingenhaltbarkeit und Leistung

- Der Klingenverschleiß wirkt sich direkt auf die Verarbeitungseffizienz aus. Studien zeigen, dass stumpfe Messer die Verarbeitungszeit um 18 % verlängern und die Fleischausbeute verringern.

- Der Austausch von Standardklingen durch hochbeständige Legierungen (wie beispielsweise mit Wolframkarbid angereicherter Stahl) erhöht die Betriebseffizienz um 25%.

- Ein Geflügelverarbeitungsbetrieb, der die Bratklingen des Nanjing Metal verwendet, berichtete:

🔹 30% weniger Klingenwechsel pro Jahr

🔹 20% Reduzierung der schneidbedingten Ausfallzeiten

🔹 Gleichmäßigere Fleischstücke, weniger Schnittabfall

Hygiene und Compliance

Da die Ausweidung einen direkten Kontakt mit inneren Organen mit sich bringt, ist das Kontaminationsrisiko hoch. HACCP und USDA-Standards, Klingen müssen:

✅ Leicht zu reinigen, um Bakterienansammlungen vorzubeugen.

✅ Verfügen über antimikrobielle Beschichtungen, um das Risiko einer Kreuzkontamination zu verringern.

✅ Beständig gegen Rost und Abnutzung bei häufigem Waschen.

Lebensmittelsichere Klingenlösungen von Nanjing Metal:

🔹 Antimikrobieller Edelstahl zur Verhinderung von Bakterienwachstum.

🔹 Hitzebeständige Antihaftbeschichtungen für einfache Reinigung.

🔹 Präzise geschliffene Kanten reduzieren das Zerreißen des Fleisches und verbessern so die Gesamtausbeute.

5. Kühlphase: Verbesserung der Lebensmittelsicherheit und Produktintegrität

Warum Kühlen ein entscheidender Schritt ist

Das Kühlen ist eine der wichtigsten Phasen bei der Geflügelverarbeitung, da es:

✅ Verhindert Bakterienwachstum – Krankheitserreger wie Salmonellen und Campylobacter vermehren sich bei warmen Temperaturen schnell. Schnelles Abkühlen hemmt ihre Ausbreitung.

✅ Erhält die Fleischqualität – Durch richtiges Kühlen werden Feuchtigkeitsverlust, Verfärbungen und eine Verschlechterung der Textur verhindert.

✅ Gewährleistet die Einhaltung gesetzlicher Vorschriften – Lebensmittelsicherheitsbehörden wie USDA, FDA und EFSA schreiben strenge Kühlrichtlinien vor, um Verunreinigungen zu verhindern.

Gesetzliche Vorschriften schreiben vor, dass Geflügelkadaver innerhalb von vier Stunden nach der Schlachtung auf unter 4 °C (40 °F) abgekühlt werden müssen, um die Lebensmittelsicherheit zu gewährleisten (USDA Poultry Inspection Guidelines, 2023).

Drei Hauptkühlmethoden

| Kühlmethode | Verfahren | Vorteile | Nachteile |

| Kaltwasserimmersion | Vögel werden in aufgewühltes eiskaltes Wasser getaucht | Schnell und kostengünstig | Risiko einer Kreuzkontamination |

| Luftkühlung | Die Vögel werden durch kalte, zirkulierende Luft gekühlt | Bessere Produktintegrität, keine Wasseraufnahme | Dauert länger und benötigt mehr Platz |

| Verdunstungsluftkühlung | Eine Kombination aus kalter Luft und Wassernebel | Beschleunigt die Luftkühlung und reduziert gleichzeitig den Feuchtigkeitsverlust | Höherer Energieverbrauch |

Branchentrend:

🔹 Luftkühlung erfreut sich aufgrund strengerer Vorschriften zur Wassereinlagerung in Geflügelprodukten zunehmender Beliebtheit. Die EU hat die Immersionskühlung weitgehend verboten und bevorzugt die Luftkühlung aus Gründen der Lebensmittelsicherheit (Europäische Behörde für Lebensmittelsicherheit, 2023).

Wie Klingen die Kühleffizienz verbessern

Klingen für die industrielle Geflügelverarbeitung spielen vor und während des Kühlens eine entscheidende Rolle:

✅ Vortrimmen – Entfernen von überschüssigem Fett und Gewebe für eine gleichmäßige Kühlung.

✅ Portionieren vor dem Kühlen – Einige Verarbeitungsbetriebe schneiden Geflügel vor dem Kühlen in Stücke, wofür spezielle Klingen für präzises Schneiden erforderlich sind.

✅ Reduzierung des Kontaminationsrisikos – Hochwertige Edelstahlklingen mit antimikrobieller Beschichtung sorgen für sauberere Schnitte und reduzieren das Bakterienwachstum.

6. Schneiden und Portionieren: Ertrag maximieren und Abfall reduzieren

Präzision bei der Portionierung von Geflügel

Das Zerlegen und Portionieren von Geflügel bestimmt die Produktkonsistenz, den Ertrag und den Marktwert. Große Geflügelverarbeiter streben Folgendes an:

✅ Minimaler Abfall – Stellt sicher, dass bei jedem Schnitt das verwertbare Fleisch maximiert wird.

✅ Einheitliche Größen – Der Einzelhandel und die Gastronomie fordern standardisierte Portionen für eine effiziente Verpackung und Zubereitung.

✅ Höhere Geschwindigkeit und Genauigkeit – Verarbeitungslinien verarbeiten über 12.000 Vögel pro Stunde und erfordern langlebige, scharfe Messer.

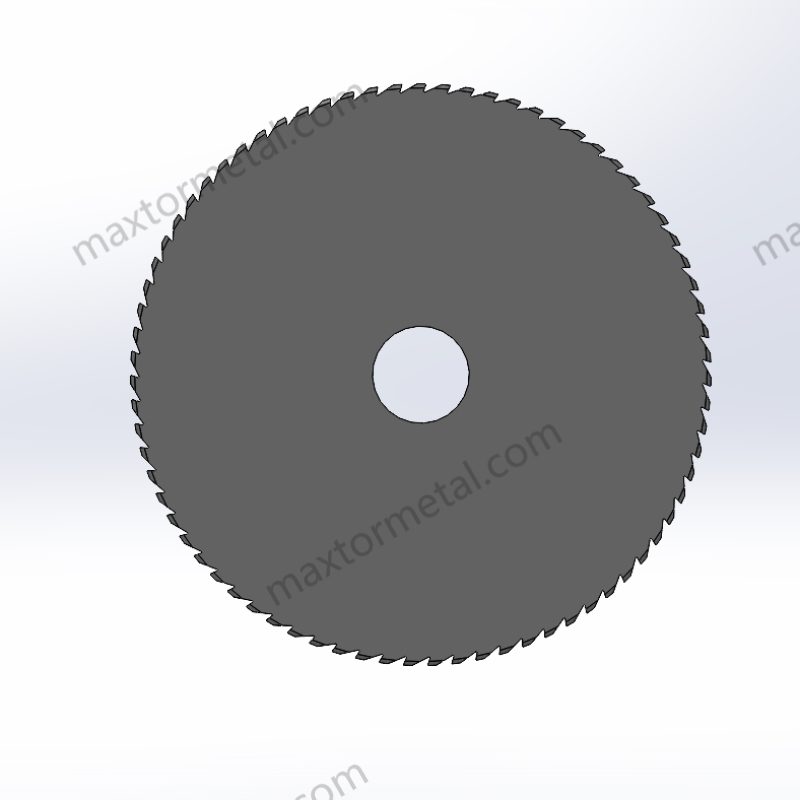

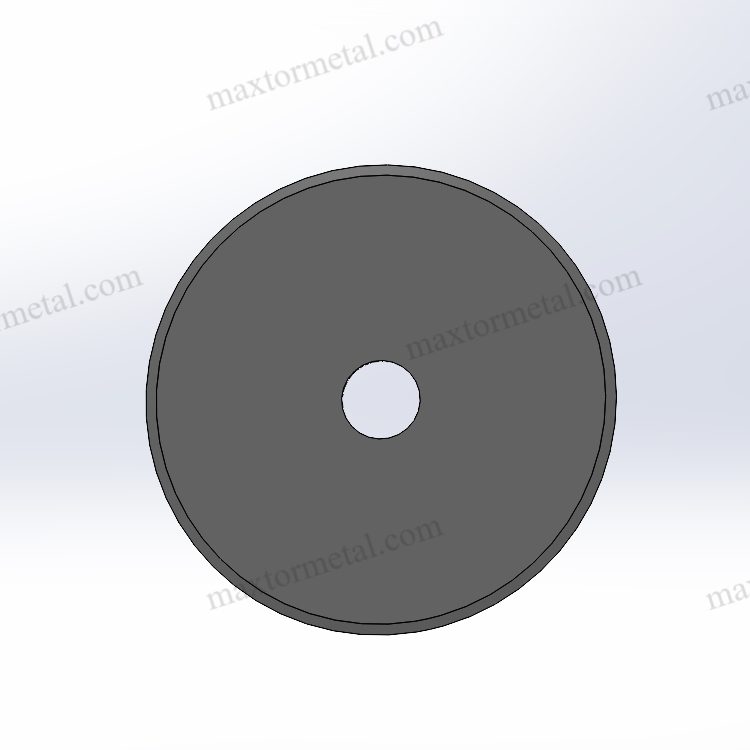

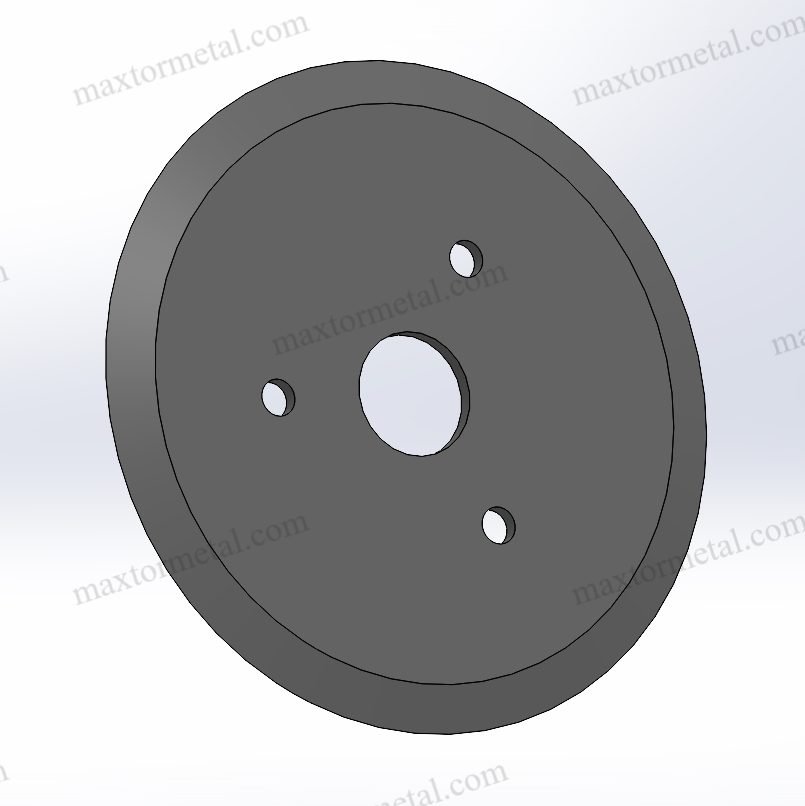

Arten von Geflügelschneide- und Portionierklingen

| Klingentyp | Anwendung | Material und Eigenschaften |

| Entbeinungsmesser | Fleisch vom Knochen lösen | Ultrascharfe Schneide mit flexiblem Design |

| Portioniermesser | Schneiden von Flügeln, Schenkeln, Brüsten und Keulen | Hochharter Stahl für Langlebigkeit |

| Kreissägeblätter | Automatisiertes Schneiden für gleichmäßige Schnitte | Titanbeschichteter Edelstahl |

| Bandsägeblätter | Großvolumige Schlachtkörperzerlegung | Hitzebeständig und korrosionsbeständig |

Herausforderungen bei der Geflügelportionierung

🔸 Problem: Knochenfragmente oder ungleichmäßige Schnitte führen zu Ineffizienzen bei der Verarbeitung.

🔹 Lösung: Die präzisionsgeschliffenen Messer des Nanjing Metal sorgen für saubere, gleichmäßige Schnitte, um Fleischverluste zu vermeiden und die Präsentation zu verbessern.

🔸 Problem: Klingen werden schnell stumpf, was die Wartungskosten erhöht.

🔹 Lösung: Mit Wolframkarbid angereicherte Schneidkanten verlängern die Lebensdauer der Klinge um 40% im Vergleich zu herkömmlichem Edelstahl.

🔸 Problem: Herkömmliche Blades haben Probleme mit der Automatisierungskompatibilität.

🔹 Lösung: Speziell entwickelte, roboterkompatible Schneidmesser gewährleisten eine nahtlose Integration in automatisierte Verarbeitungslinien.

7. Verpackung: Wie präzises Schneiden die Haltbarkeit verlängert

Die Rolle der Verpackung bei der Geflügelverarbeitung

Die richtige Verpackung ist entscheidend, um die Frische zu bewahren, Verunreinigungen zu vermeiden und die Haltbarkeit zu verlängern. Der globale Markt für Geflügelverpackungen wird voraussichtlich bis 2028 ein Volumen von 12,4 Milliarden TP5B erreichen, angetrieben durch die steigende Nachfrage nach vakuumversiegelten Verpackungen und Verpackungen mit modifizierter Atmosphäre (Mordor Intelligence, 2024).

Gängige Verpackungsmethoden für Geflügel

| Verpackungsart | Beschreibung | Vorteile | Häufige Anwendungen |

| Vakuumverpackung | Die Luft wird entfernt und der Kunststoff wird dicht um das Produkt herum versiegelt. | Verlängert die Haltbarkeit um 5–7 Tage, verhindert Oxidation. | Tiefgekühltes Geflügel, marinierte Produkte |

| Verpackung unter Schutzatmosphäre (MAP) | Um das Bakterienwachstum zu verlangsamen, wird die Luft durch Gase (CO₂, N₂) ersetzt. | Verlängert die Haltbarkeit und erhält gleichzeitig Farbe und Frische. | Vorgeschnittenes frisches Geflügel, Einzelhandelspackungen |

| Schrumpfverpackung | Geflügel wird in Plastikfolie eingewickelt und dann erhitzt, um eine dichte Versiegelung zu bilden. | Kostengünstig, schützt vor Gefrierbrand. | Ganze Hühner, Massenverarbeitung |

Wie Klingen die Geflügelverpackung optimieren

🔹 Präzises Schneiden gewährleistet die Einheitlichkeit der Verpackung und verhindert falsch ausgerichtete Siegel.

🔹 Spezialklingen reduzieren Produktabfälle, indem sie unregelmäßige Kanten beim Portionieren minimieren.

🔹 Automatisierte Schneidemesser optimieren die Hochgeschwindigkeitsverpackung, reduzieren Fehler und erhöhen die Leistung.

Der Beitrag von Nanjing Metal zur Effizienz der Geflügelverpackung

✅ Mikroverzahnte Verpackungsmesser sorgen für saubere Schnitte bei vakuumverpackten Produkten.

✅ Hitzebeständige und korrosionsbeständige Klingen halten auch rigorosen Reinigungen stand.

✅ Maßgeschneiderte Schneidwerkzeuge für automatisierte Verpackungssysteme.

Der Einfluss hochwertiger Klingen auf die Verpackungseffizienz

Ein Geflügelverarbeitungsunternehmen, das die Hochleistungs-Verpackungssägeblätter von Nanjing Metal verwendet, sah:

🔸 20%: Schnellere Verpackungsgeschwindigkeiten durch verbesserte Schnittpräzision.

🔸 Verbesserte Integrität der Verpackungsversiegelung, wodurch Verunreinigungen und Rücksendungen verhindert werden.

8. Bedeutung von Klingen für die industrielle Geflügelverarbeitung

Warum hochwertige Geflügelklingen wichtig sind

Die industrielle Geflügelverarbeitung ist ein Hochgeschwindigkeits- und Präzisionsprozess, bei dem die Klingenleistung direkten Einfluss auf Produktqualität, Ertrag und Betriebseffizienz hat. Der Unterschied zwischen einer scharfen, langlebigen Klinge und einer minderwertigen kann den Abfallanteil, die Ausfallzeiten und die Gesamtrentabilität bestimmen.

Hauptvorteile von Premium-Geflügelverarbeitungsklingen

| Nutzen | Auswirkungen auf die Produktion | Betriebliche Vorteile |

| Höhere Effizienz | Schnellere Schnitte bedeuten höheren Durchsatz | Erhöht die Verarbeitungsgeschwindigkeit um 15-20% |

| Weniger Abfall | Sauberere Schnitte reduzieren Schnittverlust und Verunreinigungen | Mehr Ertrag pro Tier, weniger Fleischabfall |

| Kosteneinsparungen | Langlebige Materialien halten länger und reduzieren so die Anzahl der Umrüstungen | Reduziert die Kosten für den Klingenaustausch um 40% |

| Verbesserte Sicherheit | Präzisionsschneiden verringert die Ermüdung des Arbeiters | Minimiert Verletzungen und verbessert die Genauigkeit |

| Einhaltung gesetzlicher Vorschriften | Saubere Schnitte helfen, HACCP- und USDA-Standards einzuhalten | Gewährleistet Produktintegrität und -sicherheit |

9. Zukünftige Trends bei Geflügelverarbeitungsklingen

1. Automatisierung und Robotik: Die Zukunft der Geflügelverarbeitung

Angesichts steigender Arbeitskosten und verschärfter Lebensmittelsicherheitsvorschriften nimmt die Automatisierung in der Geflügelverarbeitung rasant zu. Der globale Markt für Geflügelautomatisierung wird bis 2030 voraussichtlich um 7,11 Milliarden Tonnen pro Jahr wachsen (Research & Markets, 2024).

So passen sich Blades an die Automatisierung an:

🔸 Selbsteinstellende Schneidsysteme – Klingen, die den Winkel für unterschiedliche Fleischtexturen optimieren.

🔸 KI-gesteuerte Roboterschneider – Intelligente Sensoren passen Klingengeschwindigkeit und Druck an die Fleischdichte an.

🔸 Langlebigere, hitzebeständige Klingen – Unverzichtbar für Robotersysteme im Dauereinsatz.

2. Selbstschärfende Klingen: Reduzierung von Ausfallzeiten und Wartungsaufwand

Eine der größten Ineffizienzen bei der Geflügelverarbeitung ist das Abstumpfen der Klingen. Traditionell müssen die Arbeiter die Klingen alle paar Stunden manuell austauschen oder schärfen.

🔹 Die in Verarbeitungsmaschinen integrierte Selbstschärfentechnologie kann den Klingenverschleiß reduzieren und die Nutzungsdauer um bis zu 50% verlängern.

3. Nachhaltige und umweltfreundliche Klingenmaterialien

Die Zukunft der Rotorblattherstellung bewegt sich in Richtung umweltbewusster Produktion:

♻ Recycelbare Klingenmaterialien – Neue Legierungen mit geringerem CO2-Fußabdruck.

♻ Wassereffiziente Herstellung – Reduzierung des Ressourcenverbrauchs bei der Rotorblattproduktion.

♻ Biologisch abbaubare Schutzbeschichtungen – Als Ersatz für synthetische, nicht abbaubare Schmiermittel.

Industrielle Geflügelverarbeitungsklingen sind für Effizienz, Präzision und Wirtschaftlichkeit in modernen Geflügelverarbeitungsbetrieben unerlässlich. Von der Schlachtung bis zur Verpackung sorgt die richtige Klinge für höhere Erträge, weniger Abfall und bessere Produktqualität.

Für hochwertige Klingen zur industriellen Geflügelverarbeitung, Kontaktieren Sie uns noch heute! Optimieren wir Ihre Verarbeitungseffizienz mit maßgeschneiderte, leistungsstarke Lösungen.