Zusammenfassung

Industrielle Recyclingklingen sind wichtige Werkzeuge, um Abfall in wertvolle Ressourcen umzuwandeln. Dieser Artikel untersucht, wie diese Klingen die Recyclingeffizienz steigern, die Umweltbelastung verringern und die Nachhaltigkeit unterstützen. Von Designmerkmalen bis hin zu praktischen Vorteilen – entdecken Sie, warum industrielle Recyclingklingen sind für moderne Abfallwirtschaftssysteme unverzichtbar.

Einführung

Da die weltweite Abfallproduktion weiter zunimmt, ist eine effiziente Abfallbewirtschaftung für Industrie und Regierungen gleichermaßen zur obersten Priorität geworden. Recycling hat sich als Eckpfeiler der Nachhaltigkeit herausgestellt und ermöglicht die Umwandlung von Abfällen in wiederverwendbare Materialien. Im Mittelpunkt dieses Prozesses stehen industrielle Recyclingklingen, Werkzeuge zum effektiven Zerkleinern und Verarbeiten von Abfällen. Diese Klingen verbessern nicht nur die Recyclingeffizienz, sondern tragen auch erheblich zur Reduzierung der Umweltbelastung bei.

Dieser Artikel befasst sich mit der wesentlichen Rolle industrieller Recyclingklingen in der Abfallwirtschaft und bietet Einblicke in deren Design, Vorteile und Zukunftspotenzial.

1. Das wachsende Bedürfnis nach Nachhaltigkeit in der Abfallwirtschaft

1.1 Globale Abfallprobleme

Die Welt erzeugt über 2,01 Milliarden Tonnen fester Abfall jährlich, mit nur 19% weltweit recycelt, so die Weltbank. Unwirksames Abfallmanagement trägt zur Umweltverschmutzung, zu Treibhausgasemissionen und zur Erschöpfung der Ressourcen bei.

| Abfallart | Jährliche Erzeugung (Millionen Tonnen) | Recyclingquote (%) |

| Kunststoffe | 300 | 9 |

| Metals | 400 | 34 |

| Elektronik | 53 | 17 |

Diese Daten unterstreichen den dringenden Bedarf an innovativen Abfallbewirtschaftungsstrategien.

1.2 Der Wandel hin zu Recycling und Kreislaufwirtschaft

Die Kreislaufwirtschaft zielt darauf ab, Abfall durch Wiederverwendung, Recycling und Rückgewinnung von Ressourcen zu minimieren. Recycling steht bei diesem Wandel im Vordergrund, wobei industrielle Recyclingklingen ein präzises Zerkleinern und Trennen von Materialien ermöglichen. Dies gewährleistet eine hohe Qualität der Ergebnisse und unterstützt die Nachhaltigkeitsziele der Industrie.

Bleiben Sie dran, um zu erfahren, wie das Recycling von Klingen zu dieser Transformation beiträgt.

2. Was sind industrielle Recyclingklingen?

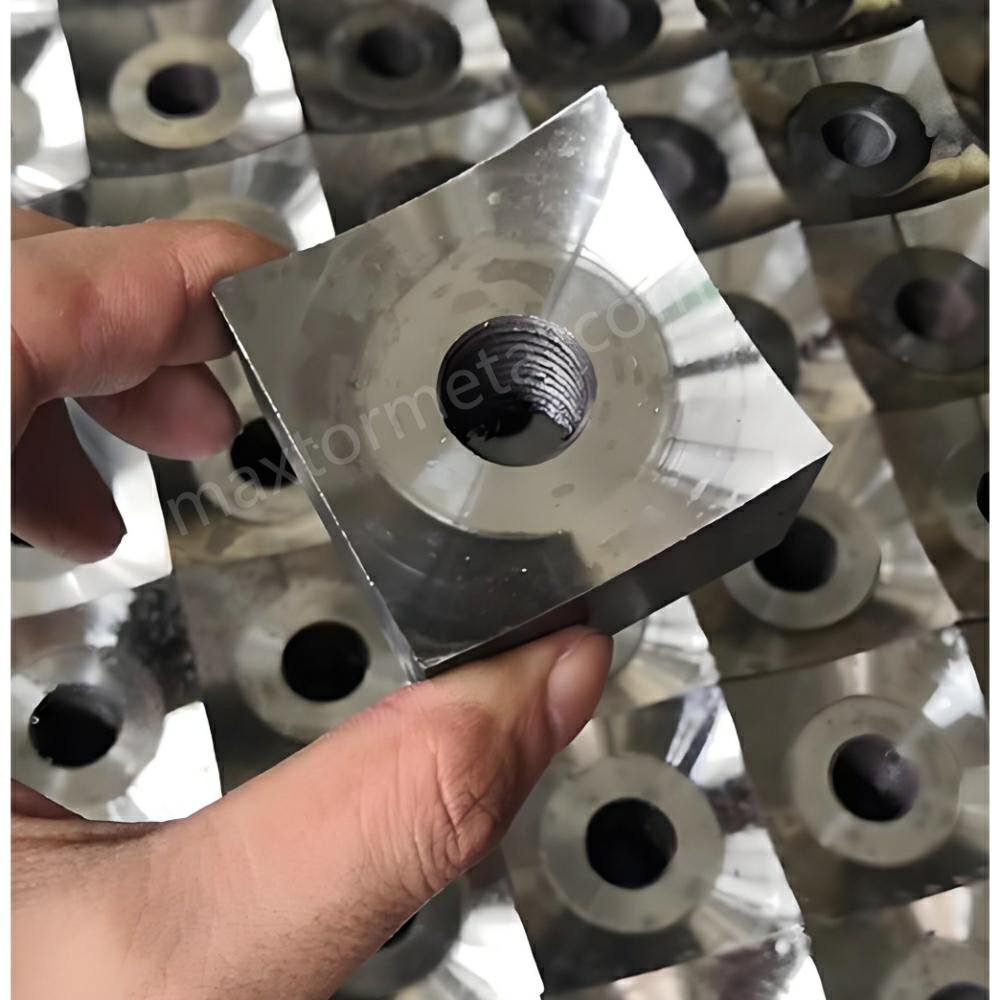

2.1 Funktion und Aufbau

Industrielle Recyclingklingen sind präzisionsgefertigte Komponenten, die es Abfallzerkleinerern ermöglichen, Materialien in kleinere, handliche Stücke zu zerlegen. Ihr Hauptzweck besteht darin, den Recyclingprozess zu erleichtern, indem sie den Abfall gleichmäßiger machen und seine Weiterverarbeitung erleichtern. Diese Klingen sind aus robusten Materialien wie hochlegierter Stahl, Werkzeugstahl, Und Wolframcarbid, von denen jedes spezifische Vorteile hinsichtlich Haltbarkeit, Schärfe und Verschleißfestigkeit bietet.

Kernfunktionen von industriellen Recyclingklingen

- Scharfe Kanten: Präzisionsschneiden sorgen für einen sauberen und effizienten Materialzerkleinerer.

- Verschleißfestigkeit: Fortschrittliche Materialien und Wärmebehandlungen verlängern die Lebensdauer der Klinge, selbst bei hoher Arbeitsbelastung.

- Kundenspezifisches Design: Klingen können auf bestimmte Anwendungen zugeschnitten werden, beispielsweise zum Schneiden von Kunststoffen, Metallen oder Verbundwerkstoffen.

Zum Beispiel Shredder-Verarbeitung Elektroschrott profitieren von Klingen mit hoher Zugfestigkeit, um metallische Komponenten zu durchtrennen, während beim Kunststoffrecycling ultrascharfe Kanten für eine saubere Trennung erforderlich sind. Diese Eigenschaften machen industrielle Recyclingklingen zu vielseitigen Werkzeugen für unterschiedliche Anwendungen.

2.2 Arten von Materialien, die mit industriellen Recyclingklingen verarbeitet werden

Recyclingklingen verarbeiten eine Vielzahl von Materialien und sind daher wichtige Werkzeuge in der Abfallwirtschaft. Im Folgenden sind die am häufigsten verarbeiteten Materialien aufgeführt:

Kunststoffe

Die Klingen zerkleinern Kunststoffe effizient in kleine, gleichmäßige Stücke, die dann zu Pellets für die Herstellung verarbeitet werden. Da die globale Kunststoffproduktion 390 Millionen Tonnen jährlichUm Abfall zu reduzieren, ist effizientes Schreddern unerlässlich.

Metals

Industrielle Klingen schneiden durch Metalle wie Aluminium, Stahl und Kupfer. Recycelte Metalle machen über 40% der weltweiten Metallproduktion und verdeutlichen ihre Rolle bei der Erhaltung natürlicher Ressourcen.

Elektronischer Abfall (E-Waste)

Elektroschrott enthält wertvolle Materialien wie Gold, Silber und Palladium. Industrielle Recyclingklingen sorgen für eine präzise Zerkleinerung und erleichtern so die Rückgewinnung dieser Materialien. Laut einem Bericht aus dem Jahr 2022 17% des weltweiten Elektroschrotts werden jährlich recycelt und die Nachfrage nach besserer Schreddertechnologie wächst.

Bauschutt

Die Rotorblätter verarbeiten Holz, Beton und andere Abfälle zu wiederverwendbaren Aggregaten. Allein in den USA erzeugt der Bausektor über 600 Millionen Tonnen Abfall jährlich, was die Bedeutung eines effektiven Recyclings unterstreicht.

Durch die Anpassung des Rotorblattdesigns an bestimmte Materialien können Hersteller die Effizienz und Ausgabequalität maximieren.

3. Die Rolle von Industrielle Recyclingklingen in der Abfallwirtschaft

3.1 Effizienzsteigerung in der Abfallbehandlung

Industrielle Recyclingklingen steigern die Betriebseffizienz erheblich. Hochleistungsklingen ermöglichen es Schreddern, Abfälle schneller zu verarbeiten und dabei eine gleichbleibende Qualität beizubehalten. Zum Beispiel:

- Eine Abfallentsorgungsanlage, die Wolframkarbidklingen verwendet, meldete einen 25% Reduzierung der Verarbeitungszeit durch verbesserte Schnittgeschwindigkeit.

- Die für einen wartungsarmen Betrieb konzipierten Rotorblätter reduzierten ungeplante Ausfallzeiten um 15% in einer großen Recyclinganlage.

Eine effiziente Zerkleinerung wirkt sich unmittelbar auf die Produktivität aus und ermöglicht es den Betrieben, ihre Recyclingziele effektiver zu erreichen.

3.2 Verbesserung der Recyclingqualität

Die Qualität des Recyclingmaterials hängt in hohem Maße von der Präzision des Zerkleinerungsprozesses ab. Scharfe Klingen sorgen für gleichmäßige Materialgrößen, was die nachfolgende Sortierung und Wiederaufbereitung vereinfacht. Zum Beispiel:

- Geschreddertes Kunststoffgranulat mit gleichmäßigen Abmessungen erreicht eine 30% höhere Recyclingquote als schlecht verarbeitete Materialien.

- In kleine, saubere Stücke zerkleinerte Metals reduzieren den Energieverbrauch beim Schmelzen um bis zu 20%, so Branchenstudien.

Durch präzises Zerkleinern wird sichergestellt, dass recycelbare Materialien ihren Wert behalten und in neuen Produkten verwendet werden können.

3.3 Reduzierung der Umweltbelastung

Durch die Optimierung der Zerkleinerungseffizienz verringern industrielle Recyclingklingen den ökologischen Fußabdruck von Recyclinganlagen. Zu den wichtigsten Beiträgen gehören:

- Energieeinsparungen: Effiziente Messer senken den Energieverbrauch von Aktenvernichtern und senken so Betriebskosten und Emissionen.

- Abfallreduzierung: Durch ordnungsgemäßes Zerkleinern wird der Müllanteil verringert. So reduzierten beispielsweise Klingen, die gemischten Abfall verarbeiten, das Deponievolumen um 35% in Pilotprojekten.

Diese Vorteile unterstreichen die Bedeutung moderner Rotorblatttechnologie für das Erreichen von Nachhaltigkeitszielen.

4. Nachhaltigkeitsvorteile durch die Verwendung recycelbarer und langlebiger Zerkleinerungsklingen

4.1 Langlebigkeit und Haltbarkeit

Hochwertige Industrieklingen sind für anspruchsvolle Arbeitsbelastungen ausgelegt. Hartmetallklingen zum Beispiel halten 10–15 mal länger als herkömmliche Stahlklingen, sodass sie seltener ausgetauscht werden müssen.

Vergleich der Klingenlebensdauer

| Klingenmaterial | Typische Lebensdauer (Stunden) | Austauschhäufigkeit (jährlich) |

| Standardstahl | 200–400 | 5–10 |

| Hochlegierter Stahl | 800–1.000 | 2–3 |

| Wolframkarbid | 3,000+ | 0–1 |

Diese Haltbarkeit senkt die Betriebskosten und minimiert gleichzeitig die Umweltauswirkungen bei der Herstellung neuer Rotorblätter.

4.2 Umwandlung von Abfall in Ressourcen

Industrieklingen spielen eine Schlüsselrolle bei der Umwandlung von Abfall in wertvolle Ressourcen.

- Kunststoffe: Zerkleinerte Kunststoffe können zu Baumaterialien, Textilien und Verpackungen weiterverarbeitet werden. Eine Anlage in Europa hat 85% seines geschredderten Plastikmülls in neue Produkte.

- Metals: Fast 95% der Materialien in Altgeräten können durch die Verarbeitung mit präzisen Zerkleinerungsklingen wiederverwertet werden.

Diese Transformationen zeigen, wie Klingen es der Industrie ermöglichen, den maximalen Wert aus Abfall zu gewinnen.

5. So wählen Sie die richtigen industriellen Recyclingklingen aus

5.1 Zu berücksichtigende Faktoren

Die Auswahl der richtigen Klinge hängt von mehreren wichtigen Faktoren ab:

- Materialzusammensetzung: Für anspruchsvolle Anwendungen bietet Wolframkarbid überlegene Festigkeit und Langlebigkeit.

- Aktenvernichter-Kompatibilität: Um einen ordnungsgemäßen Betrieb zu gewährleisten, müssen die Klingen zum Aktenvernichtertyp und zur Aktenvernichtergröße passen.

- Spezifische Anwendungen: Unterschiedliche Materialien erfordern spezielle Klingengeometrien für optimale Ergebnisse.

5.2 Partnerschaft mit zuverlässigen Lieferanten

Zuverlässige Lieferanten bieten maßgeschneiderte Lösungen für einzigartige Recyclingherausforderungen. Suchen Sie nach Anbietern mit:

- Benutzerdefinierte Designfunktionen: Stellt sicher, dass die Klingen für Ihre spezifischen Anforderungen optimiert sind.

- Umfassende Unterstützung: Beinhaltet Wartungsdienste und technisches Fachwissen.

Die Zusammenarbeit mit einem vertrauenswürdigen Lieferanten maximiert die Leistung und minimiert Ausfallzeiten.

6. Die Zukunft industrieller Recyclingklingen in der Abfallwirtschaft

6.1 Technologischer Fortschritt

Neue Technologien revolutionieren die Leistung von Rotorblättern. Zu den Innovationen zählen:

- Intelligente Klingen: Ausgestattet mit IoT-Sensoren zur Überwachung des Verschleißes und Optimierung der Leistung.

- Fortschrittliche Materialien: Klingen mit Nanotechnologie widerstehen Verschleiß wirksamer.

Diese Fortschritte werden voraussichtlich die Anzahl der Rotorblattwechsel um 20–30% im kommenden Jahrzehnt.

6.2 Erweiterte Rollen in neu entstehenden Abfallströmen

Neue Abfallarten erfordern anpassbare Recyclinglösungen. Zum Beispiel:

- Elektroschrott: Klingen mit ultraharten Kanten können empfindliche Schaltkreise verarbeiten, ohne wertvolle Komponenten zu beschädigen.

- Biologisch abbaubare Kunststoffe: Spezielle Klingen zerkleinern diese Materialien für die Kompostierung und entsprechen damit umweltfreundlichen Praktiken.

Mit der fortschreitenden Innovation in der Industrie wird die Nachfrage nach Hochleistungsklingen weiter steigen.

Schlussfolgerung

Industrielle Recyclingklingen sind für eine effiziente und nachhaltige Abfallwirtschaft unverzichtbar. Sie steigern die Verarbeitungseffizienz, verbessern die Recyclingqualität und reduzieren die Umweltbelastung. Unternehmen können von der Investition in hochwertige Klingen, die auf ihre spezifischen Anforderungen zugeschnitten sind, erheblich profitieren.

Sind Sie bereit, Ihren Recyclingbetrieb umzugestalten? Kontaktieren Sie uns Entdecken Sie noch heute die hochwertigen Recyclingklingen für die Industrie, die auf Nachhaltigkeit und Effizienz ausgelegt sind.

Eine Antwort