You use Lebensmittelgeeignete Kreismesser to cut and slice food. These knives help you portion food safely in kitchens and factories. They meet strict food grade rules to keep your food safe from germs. Stainless steel is the best choice for these knives because it does not rust. It is also easy to clean. The right coatings make your food grade circular knives work better and safer. Using the right application keeps your circular knives sharp and clean for every food grade job.

Die wichtigsten Erkenntnisse

- Food grade circular knives are made from stainless steel. This steel does not rust. It follows strict hygiene rules. These rules help keep food safe and clean.

- Picking the right steel grade and coating is important. Choices like 304L, 316L, or DLC make knives last longer. They help knives stay sharp. They also make cleaning easier.

- Non-stick and antimicrobial coatings are helpful. They stop food from sticking. They help clean up faster. They also lower the chance of germs spreading.

- Cleaning, drying, and storing knives the right way is important. This helps knives last longer. It also keeps food safe. Do not use harsh chemicals. Do not put knives in dishwashers.

- Training workers is important. Using the right blade shape and material for each food helps. This makes cutting better. It also helps stop injuries at work.

Food Grade Circular Knives in the Food Industry

Hygiene Standards

When you work with food, you must keep things very clean. Food grade circular knives have to follow special hygiene rules. This helps stop germs from getting into food. The table below lists what makes equipment safe and clean:

| Aspekt | Requirement/Standard |

|---|---|

| Material | Stainless steel (AISI 200, 300, or 400 series), minimum 16% chromium for food contact surfaces; 304 stainless steel is the standard for food service knives |

| Surface Characteristics | Smooth, non-porous, non-corrosive, free of cracks, seams, roughness, or pits to prevent microbial harborage |

| Design | Durable, maintain original characteristics, avoid injury hazards, no parts that can break off into food |

| Reinigungsverfahren | Multi-step: remove visible soil, wash in detergent at ≥110°F (43°C), rinse at ≥110°F, sanitize (hot water at 170°F or chemical sanitizer), air dry |

| Regulatory References | FDA Food Code §4-201.11, USDA FSIS §416.3, NSF Food Equipment Materials Standards |

| Additional Notes | Rough, scarred, or pitted surfaces do not meet FDA Food Code hygiene standards; knives must not impart odors, colors, or contaminants to food |

You need to use circular knives that meet these rules. This keeps your food safe and stops contamination.

Korrosionsbeständigkeit

You want your circular knives to last a long time. Stainless steel is the best choice because it does not rust. Chromium and nickel in the steel make a strong shield. This shield protects the blade after many washes. If you cut meat, fish, or dough, you need tough blades. These knives can handle salty or sour foods. Stainless steel circular knives from the 300 and 400 series work better than other types. They stay sharp and clean, even if you use them a lot.

Cleanability

You must clean your circular knives after every use. Good cleaning stops bacteria and keeps your knives working well. Wash your knives with warm water and mild soap. Dry them right away with a clean towel. Do not use strong chemicals or dishwashers. These can hurt the blade. Keep your knives in a dry place. This helps them stay clean and last longer. Regular cleaning and good storage keep your food safe.

Stainless Steel Knives: Materials & Standards

Common Grades (304L, 316L, 420J2)

You need to know about stainless steel grades for food knives. Each grade has its own good points for cutting and safety. Let’s check out the most used types.

304L Stainless Steel

304L stainless steel is used a lot in food work. It has at least 18% chromium and 8% nickel. This makes it resist rust and stains. It is great for places where you wash tools often. 304L has low carbon, so welding is easy. You see this steel in knives for cutting fruits, veggies, and bread. Its smooth surface helps you keep things clean and safe.

316L Stainless Steel

If you cut salty or sour foods, you may need 316L. This steel has molybdenum, which helps stop rust. 316L can handle strong cleaners and tough food jobs. You use it for knives that cut fish, cheese, or salty foods. It is easy to weld and shape because of low carbon. 316L is a good pick if you want extra rust protection.

420J2 Stainless Steel

420J2 stainless steel gives you a harder edge. This type can be heat treated to get very hard. It is good for blades that must stay sharp. You use 420J2 for knives that cut meat, dough, or sticky foods. It does not fight rust as well as 304L or 316L. But you can polish it to help it work better. If you want a blade that stays sharp longer, 420J2 is a strong choice.

Vergleichstabelle

Here’s a quick table to show how these steels compare:

| Stainless Steel Grade | Korrosionsbeständigkeit | Hardness (Annealed) | Typical Food Processing Use |

|---|---|---|---|

| 316L | Exzellent | Up to 217 HB | Salty, acidic, or harsh environments |

| 304L | Very Good | Up to 201 HB | General food processing, easy to clean |

| 420J2 | Mäßig | HRC 50+ (heat treated) | Meat, dough, sticky foods; high wear resistance |

Tip: Pick 316L for tough jobs, 304L for daily use, and 420J2 for a sharper blade.

Regulatory Compliance (FDA, NSF)

You must use knives that meet food safety rules. These rules keep your food and customers safe.

FDA Standards

The FDA has rules for knives that touch food. You need to use steel that does not let out bad stuff. Grades like 304 and 316 are safe for this. The FDA also wants you to keep records of your knife materials and steps. This helps you fix problems fast.

NSF Certification

NSF International checks and certifies food tools. If your knives have NSF marks, they passed tests for rust, cleaning, and safety. NSF/ANSI Standard 51 is the main rule for food tools. Look for this mark when you buy new knives.

EU Regulations (EC 1935/2004)

If you sell food in Europe, you must follow EU rules. Regulation (EC) No. 1935/2004 says your knives cannot let bad stuff get into food. EN 10088 lists safe steel grades like 304L and 316L. You also need papers to show your knives meet these rules.

| Regulatory Body | Relevant Standard | Key Requirements for Stainless Steel Knives |

|---|---|---|

| FDA (USA) | 21 CFR § 177.2600 | No harmful leaching, corrosion resistance, traceability |

| NSF International | NSF/ANSI Standard 51 | Food safety, sanitation, corrosion resistance |

| European Union | EC 1935/2004, EN 10088 | No transfer of harmful substances, approved grades |

| 3-A Sanitary | 3-A Sanitary Standards | Hygienic design, easy cleaning |

Note: Good records and certified steel help you act fast if there is a food safety problem.

HSS and Other Options

You might see other blade materials in food work. Each one has good and bad points.

Schnellarbeitsstahl (HSS)

High-speed steel is very hard and lasts a long time. You use HSS knives for tough jobs, like cutting dough or sticky wraps. HSS stays sharp longer than many stainless steel knives. But it does not fight rust as well, so you must clean and dry it after use.

Kohlenstoffstahl

Carbon steel blades are the sharpest and keep their edge best. You can make them very pointy, which is good for careful cutting. But carbon steel rusts fast. You must dry and oil these blades to keep them safe for food. Most food factories use stainless steel knives because they are easier to care for.

Other Alloys (Ceramic, Titanium)

Ceramic and titanium blades are used in some food lines. Ceramic blades stay sharp and do not rust, but they can break if dropped. Titanium blades are light and do not rust, but they cost more and are not as hard as HSS or 420J2. Most food plants use stainless steel or HSS for their knives.

Material Comparison

Here’s a table to help you compare blade materials for your needs:

| Material | Kosten | Bearbeitbarkeit | Food Safety & Corrosion Resistance | Typical Use Cases |

|---|---|---|---|---|

| Edelstahl | Höher | Moderate to Hard | Excellent; easy to clean, non-reactive | Most food processing, general use |

| Kohlenstoffstahl | Untere | Easy | Needs maintenance; prone to rust | Precision cutting, less common in food |

| HSS | Hoch | Hard to machine | Good wear resistance; moderate corrosion | High wear, sticky or tough materials |

| Keramik | Hoch | Not machinable | Excellent; brittle | Specialty, light-duty applications |

| Titanium | Sehr hoch | Mäßig | Good; lightweight, less hard | Specialty, where weight matters |

When you pick blade materials, think about your food, cleaning, and how much you use your knives.

Coatings and Surface Treatments

Food grade circular knives need more than just strong steel. Coatings and treatments help your knives last longer and cut better. These coatings make knives safer and easier to use in food work. You can pick from different food-safe coatings and finishes for your needs.

Food Safe Coatings (Teflon, DLC)

Teflon Coatings

Teflon, also called PTFE, is a common coating for these knives. Teflon gives blades a non-stick surface. Food slides off, so you get cleaner cuts and less waste. Teflon also stands up to chemicals and heat. This coating meets FDA and EU food safety rules. You can trust it in kitchens and factories. Teflon-coated knives are used for bread, cheese, and deli meats. Cleaning these knives is easy because food washes off fast.

DLC (Diamond-Like Carbon) Coatings

DLC coatings make your knives very hard and smooth. These coatings give great wear resistance and high hardness. DLC also keeps blades safe from rust and corrosion. This coating helps knives last much longer, even with tough jobs. You can use DLC-coated knives for sticky or rough foods. The super-smooth surface means you use less force to cut. This gives better cutting and keeps blades sharp. DLC coatings are FDA-approved, so they are safe for food work.

Performance Comparison: Teflon vs. DLC

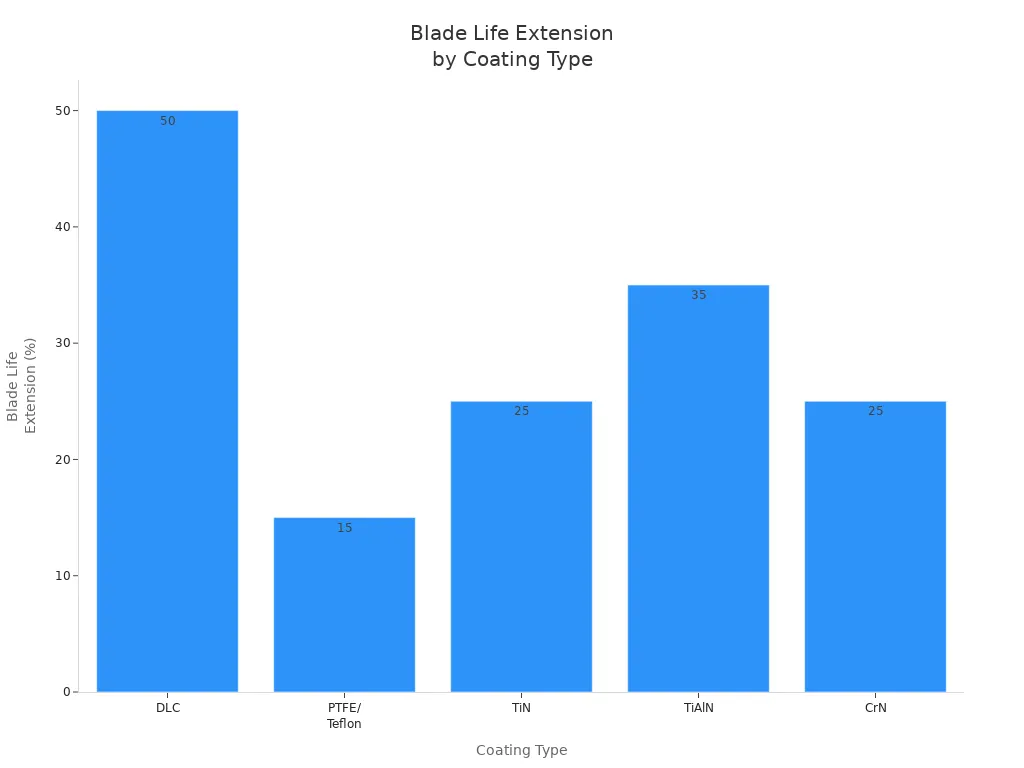

You might wonder which coating is best for you. The table below shows how Teflon and DLC compare with other coatings:

| Beschichtungstyp | Verschleißfestigkeit | Corrosion Protection | Reibungsreduzierung | Verlängerung der Klingenlebensdauer |

|---|---|---|---|---|

| DLC | Außergewöhnlich | Hoch | Sehr hoch | Up to 50% |

| PTFE/Teflon | Mäßig | Hoch | Sehr hoch | 10-20% |

| Zinn | Hoch | Mäßig | Mäßig | 20-30% |

| TiAlN | Sehr hoch | Mäßig | Mäßig | Up to 35% |

| CrN | Hoch | Hoch | Hoch | 20-30% |

You can also see how long each coating helps your blade last in the chart below:

Tip: DLC coatings make blades last longest and resist wear best. Teflon coatings are best for non-stick and easy cleaning.

Application Scenarios

Pick your coating based on what you cut and how you use your knives:

- Use Teflon for sticky foods like cheese, dough, or baked goods. The non-stick surface keeps blades clean.

- Choose DLC for heavy-duty cutting, fast lines, or when you want blades to last longer.

- Both coatings work well for food packaging and film cutting, where you want to stop residue buildup.

Antimicrobial and Non-Stick Benefits

Antimicrobial Coatings in Food Processing

You want to keep food safe from germs. Antimicrobial coatings help with this. These coatings, like PTFE and titanium dioxide, stop bacteria from sticking to blades. They make it harder for germs to grow. You get a cleaner blade that is easier to sanitize. This lowers the risk of food getting contaminated.

Non-Stick Coatings: Reducing Product Waste and Cleaning Time

Non-stick coatings do more than stop food from sticking. They help save time and reduce waste. Less food stays on the blade, so you get cleaner cuts and more product. Cleaning knives is faster because food comes off easily. You spend less time cleaning and more time working.

Case Studies: Real-World Applications in Food Processing

Studies show antimicrobial and non-stick coatings help a lot. For example, Ni-P-PTFE coatings on dairy blades cut E. coli sticking by about 90%. Bacterial fouling dropped by over 96%. TiO2 coatings also lowered bacteria and improved corrosion resistance. In real factories, these coatings made cleaning faster and kept blades working longer. You get safer food and a better process.

Surface Finishing (Polishing, Electropolishing)

Polishing Process and Benefits

Polishing makes knife surfaces smoother. Mechanical polishing uses abrasives to remove rough spots. This lowers the Ra value and makes it harder for germs to hide. A polished blade is easier to clean and lasts longer. You often see a No. 4 brushed finish in food work.

Electropolishing Process and Benefits

Electropolishing uses electricity to remove a thin layer from the blade. This gives an ultra-smooth, shiny finish. Electropolished blades have a very low Ra value (≤0.4 µm). This means almost no place for bacteria to stick. You get better corrosion resistance and easier cleaning. Many food factories like electropolished knives for top hygiene.

Inspection and Testing Standards for Surface Finishing

You need to check blade surfaces to meet food safety rules. The most common test is the Ra value, which shows how smooth the surface is. In North America, you use Ra, but in Europe, you may see Rz. ASTM A480 gives the rules for surface finish. For food grade knives, you want a smooth, crevice-free surface to pass inspection. Visual checks and roughness tests help keep blades safe for food.

| Surface Finishing Technique | Beschreibung | Typical Surface Roughness (Ra) | Hygiene Improvement | Durability Improvement |

|---|---|---|---|---|

| Mechanical Polishing (No. 4 Brushed Finish) | Directional polish using abrasives | 0.6–1.2 µm | Reduces surface roughness to limit microorganism retention | Enhances cleanability and wear resistance |

| Bright Annealing (BA) | Annealing in inert gas producing a reflective finish | ~0.2–0.4 µm | Creates smoother surface reducing bacterial adhesion | Improves corrosion resistance |

| Electropolishing | Electrochemical removal of surface layer | ≤0.4 µm | Produces ultra-smooth, corrosion-resistant surface minimizing bacterial adhesion and facilitating cleaning | Increases corrosion resistance and mechanical wear resistance |

| Passivation Treatment | Acid treatment forming stable chromium oxide layer | N / A | Enhances corrosion resistance, preventing surface degradation that can harbor bacteria | Protects against corrosion and extends blade life |

Note: Always pick surface treatments that meet food safety rules and help keep your knives clean and strong.

Circular Knives for Food Grade Applications

Circular knives are important in food jobs. You use these blades to cut food neatly and evenly. The right blade material and coating help you keep things clean. They also make cutting faster and easier. Let’s see how you can pick the best circular knives for different food jobs.

Slicing and Dicing

You use circular knives to slice and dice fruits, veggies, and baked foods. These blades help you get even slices and waste less food. Stainless steel is best because it does not rust and keeps tools safe. Non-stick coatings like Teflon stop food from sticking to the blade. This gives you smoother cuts and makes cleaning faster. Blade shape and sharpness are important too. Thin, slanted blades are good for soft foods. Serrated blades work better for tough foods.

Meat, Fish, Cheese, Dough

When you cut meat, fish, cheese, or dough, you need sharp blades that do not rust. For these jobs, you often use 420J2 stainless steel or high-speed steel. These materials keep blades strong after many uses. Coatings like DLC or PTFE help blades slide better and stop sticky foods from building up. This means you get better cuts and cleaner results. Clean and sharpen your blades often to keep them ready.

Packaging and Film Cutting

In packaging, circular knives cut films, foils, and cardboard very well. You need blades that are hard and last a long time for these jobs. High-speed steel and tungsten carbide are good choices. Special coatings like TiN or DLC help blades last longer and cut smoother. Non-stick coatings stop packaging from sticking to the blade. This keeps your work fast and easy. Adjustable cutters help you cut different film thicknesses without trouble.

Tip: Always choose blade materials and coatings that fit your job. This helps you get the best cuts and makes your blades last longer.

Selection and Maintenance

Choosing the Right Knife

You want your circular knives to work well in food jobs. Pick the right steel, coating, and blade shape for your task. The table below shows what to think about:

| Criteria Aspect | Details |

|---|---|

| Stahlsorte | Stainless steel does not rust and is simple to clean. Carbon steel cuts well but needs a coating to stop rust. |

| Beschichtungen | Use FDA-approved coatings like Titanium Nitride or ceramic. These make blades last longer and cut smoother. |

| Blade Configuration | Choose the best edge shape. V-style and Hi/Low V edges work for many foods and help your tools last. |

| Additional Factors | Think about what you cut, how fast you cut, and the blade angle. These change how well and safely you cut. |

You should also remember these things:

- Circular knives can be made from stainless steel, high carbon steel, or ceramics.

- Edge shapes like Standard V, Hi/Low V, and Scalloped Tooth work for different foods.

- Custom blades can be made for your special food or packaging needs.

Maintenance and Cleaning

You keep your circular knives safe and sharp by cleaning them well. Follow these steps to protect your blades and food:

| Maintenance Aspect | Recommended Protocols |

|---|---|

| Cleaning Method | Wash by hand with mild soap and warm water. Do not soak or use dishwashers. |

| Drying | Dry right away with a soft cloth to stop rust. |

| Lagerung | Store in knife blocks, magnetic strips, or trays to keep blades sharp and safe. |

| Honing and Sharpening | Hone before or after use. Sharpen with a whetstone or get professional help when needed. |

| Avoid Abrasives | Do not use rough sponges or harsh cleaners. |

| Cutting Surfaces | Use wood or plastic boards. Avoid glass or stone. |

| Professional Servicing | Get help for chips, cracks, or loose handles. |

| Environmental Care | Use natural cleaners and reusable cloths. |

Here is a good routine:

- Always use a clean cutting board.

- Scrape off food, wash with warm soapy water, rinse, sanitize, and dry.

- Replace boards if they get grooves.

- Teach everyone how to clean and sanitize.

- Keep knives clean to stop germs and help them last longer.

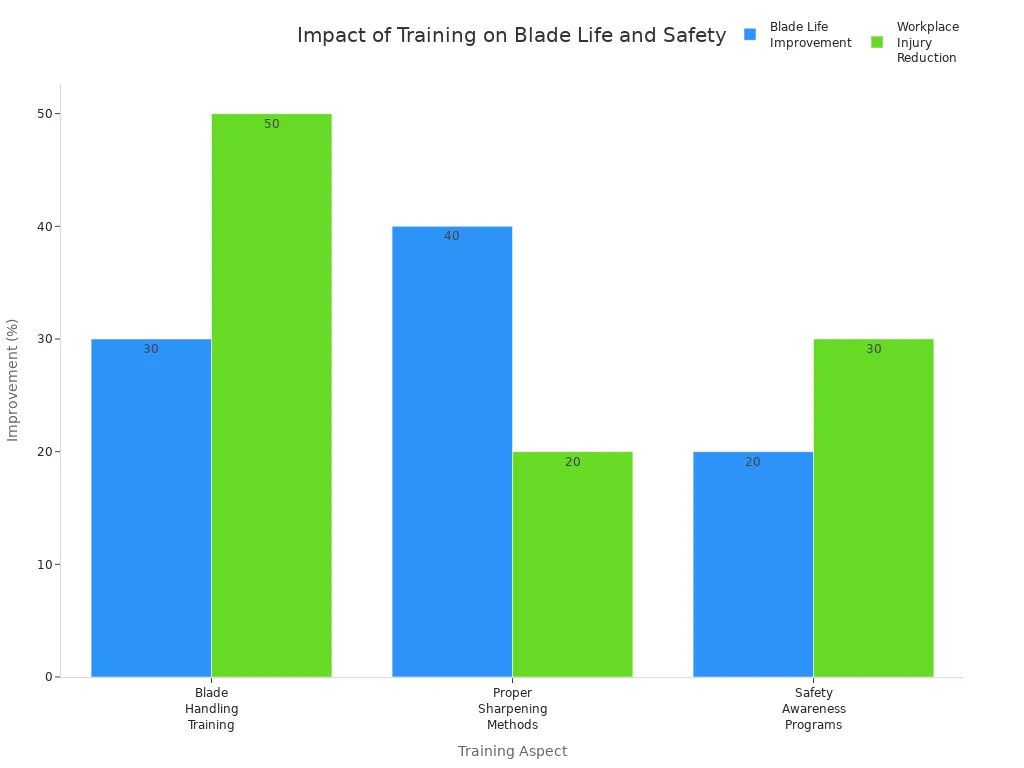

User Insights and Best Practices

You can make your knives safer and last longer with good habits. Training helps you and your team avoid injuries and keep blades working well. The table below shows how training helps:

| Training Aspect | Improvement in Blade Life (%) | Reduction in Workplace Injuries (%) |

|---|---|---|

| Blade Handling Training | 30% longer lifespan | 50% fewer injuries |

| Proper Sharpening Methods | 40% longer lifespan | 20% fewer accidents |

| Safety Awareness Programs | 20% longer lifespan | 30% fewer injuries |

Best practices are:

- Sharpen blades the right way and do not let them get too hot.

- Use blade guards and food-safe oils.

- Clean and store knives to stop rust.

- Do not use blades for more than they can handle.

- Hold training every month for everyone who uses circular knives.

You can make food jobs safer and easier by following these steps. If you want expert help or a benutzerdefinierte Klinge, contact Nanjing Metal’s sales engineers.

Picking the right food grade circular knives keeps your food safe. It also helps you cut better and save money. The table below shows how different materials change the total cost:

| Material | Vorabkosten | Wartungsbedarf | Long-Term Savings |

|---|---|---|---|

| Edelstahl | Hoch | Niedrig | Best for durability |

| Kohlenstoffstahl | Niedrig | Hoch | More replacements |

| Keramik | Highest | Very Low | Fewer replacements |

You should clean your blades often and check them for damage. Store them safely to help them last longer and cost less. New features like smart sensors and green coatings make your job safer and easier. For specific needs, Nanjing Metal makes custom industrial blades and is trusted in the industry. If you need help, contact Nanjing Metal’s sales engineers for advice.

Häufig gestellte Fragen

What makes a knife “food grade” in the food industry?

A food grade circular knife uses stainless steel that meets FDA or NSF standards. The blade resists rust, does not react with food, and has a smooth surface. You can clean it easily and keep your food safe.

How do food grade rotary knives pass safety checks?

You use food grade rotary knives made from metal that metal detectors can find. These knives have coatings that do not peel. The smooth surface helps you spot any damage fast and keeps your food line safe.

Can I use FDA food grade circular blades for sticky foods?

Yes, you can. FDA food grade circular blades with non-stick coatings like Teflon or DLC work well for sticky foods. These coatings help you cut cheese, dough, or candy without food sticking to the blade.

How do I choose the right food grade circular knife for my job?

You should match the blade material and coating to your food. Use stainless steel for most foods. Pick high-speed steel for tough jobs.

How do I keep my food grade circular knives clean and safe?

Wash your knives by hand with warm water and mild soap. Dry them right away. Store them in a dry place. Check for damage often. Clean blades help you keep your food safe and your knives sharp.

Siehe auch

5 schnelle Fakten zu lebensmittelechtem Stahl für sicherere Klingen