If you see uneven perforation or lines that are not the same length, it can change your finished product a lot. Every step needs to be exact, especially when you use Perforationsklingen or a micro-perforating machine. Research shows that companies using exact micro-perforating blades have fewer mistakes and work faster. When micro-perforating is steady, you get holes without burrs and even pressure, which gives better results.

Die wichtigsten Erkenntnisse

- Blades need to be sharp and lined up right for good cuts and even lines.

- Clean and take care of blades and machines often to stop bad cuts and help blades last longer.

- The kind of material and how fast you feed it can change how well it cuts; always test new stuff before making a lot.

- Pick the right blade shape and type for your material and cutting job to get better results.

- Look at blades often and change them if they are dull, chipped, or broken so you do not get bad cuts.

- Keep machine parts like the anvil and rollers in good shape and set right so cutting goes smoothly.

- Teach workers often so they can find problems early and take care of machines the right way for steady work.

- Getting custom blades and using good materials can help you waste less, stop delays, and make better products.

Causes of Uneven Perforation

Klingenverschleiß

You need sharp blades to make clean cuts. Over time, the edge of your perforating blade knife gets dull. When this happens, you might see uneven perforations or lines that do not match in length. Dull blades need more force to cut. This can make the material tear instead of cutting smoothly. Your finished product will not look as good.

Strong materials help blades stay sharp and last longer. They also help the cutting edge stay strong. You should check your blades often for signs of damage. If you see nicks, chips, or a dull edge, change the blade. This keeps your cuts neat and accurate.

Alignment Issues

Blades must be lined up right for good cuts. If your perforating blade knife is not lined up with the anvil or support, you may get uneven perforations and lines that are not the same length. Bad alignment can also put stress on the edges of the perforation. This stress can change how the material breaks. It can make your results look uneven and lower the quality.

Tip: Always check if your blades are lined up before you start a new job. Use guides or tools to make sure the blade matches the support surface. This helps you get the best cuts every time.

Studien zeigen, dass stress around perforation edges can change the material. These changes can make the surface harder and more brittle. This can make the perforation less even. Keeping your blades lined up helps stop these problems. It also makes your cutting process better.

Material Variability

The kind of material you use can change how well you cut. Some materials, like certain plastics or cements, have different densities or porosity. These differences can change how the material acts when you cut or perforate it. For example, materials with high porosity may not handle pressure well. This can cause uneven perforations.

In packaging, the design and placement of the perforation pattern matter more than the type of cardboard. But with other materials like calcium silicate-based cements, things like powder-to-liquid ratio and temperature can change how the material acts. This can make the material break unevenly when you cut it.

You should always test new materials before starting a big job. Change your blade shape and cutting pressure to fit the material. This helps you keep your cuts neat and get the best results.

Note: Changing perforation cluster spacing and controlling hole friction can help lower stress and make your cuts more even.

Reinigung und Wartung

You need to keep your perforating blade knives clean if you want the best results. Dirt, dust, and leftover material can build up on the blades. This buildup can cause the blades to cut unevenly. When you do not clean your blades, you may see irregular perforations on your finished product. Cleaning is not just about looks. It helps your blades last longer and work better.

You should set up a regular cleaning schedule. Here is a simple cleaning routine you can follow:

- Turn off the machine before you start cleaning. Safety comes first.

- Remove the blade from the holder. Use gloves to protect your hands.

- Wipe the blade with a soft, lint-free cloth. Remove any dust or debris.

- Use a mild solvent if you see sticky residue. Do not use harsh chemicals. They can damage the blade.

- Check the blade edge for any signs of rust or corrosion. If you see any, clean it gently with a fine abrasive pad.

- Dry the blade completely before putting it back. Moisture can cause rust.

- Reinstall the blade and make sure it is aligned correctly.

Tip: Always inspect the blade after cleaning. Look for chips, nicks, or dull spots. Replace the blade if you see damage.

Maintenance goes beyond cleaning. You should also check the blade holder and the anvil. Make sure there is no buildup or wear. Lubricate moving parts as needed. This keeps the machine running smoothly.

A clean and well-maintained blade cuts better. It also reduces the risk of machine breakdowns. You save time and money by avoiding costly repairs. You also get more consistent results.

You can keep a maintenance log. Write down each time you clean or check the blades. This helps you spot patterns. If you notice more frequent cleaning is needed, you may need to check your material or process.

Good materials resist rust and wear. This makes cleaning easier and keeps your blades sharp longer.

If you follow these steps, you will see fewer problems with your perforating blade knives. Clean blades help you avoid irregular perforations and keep your production line running smoothly.

Perforating Blade Knives: How They Work

Klingentypen

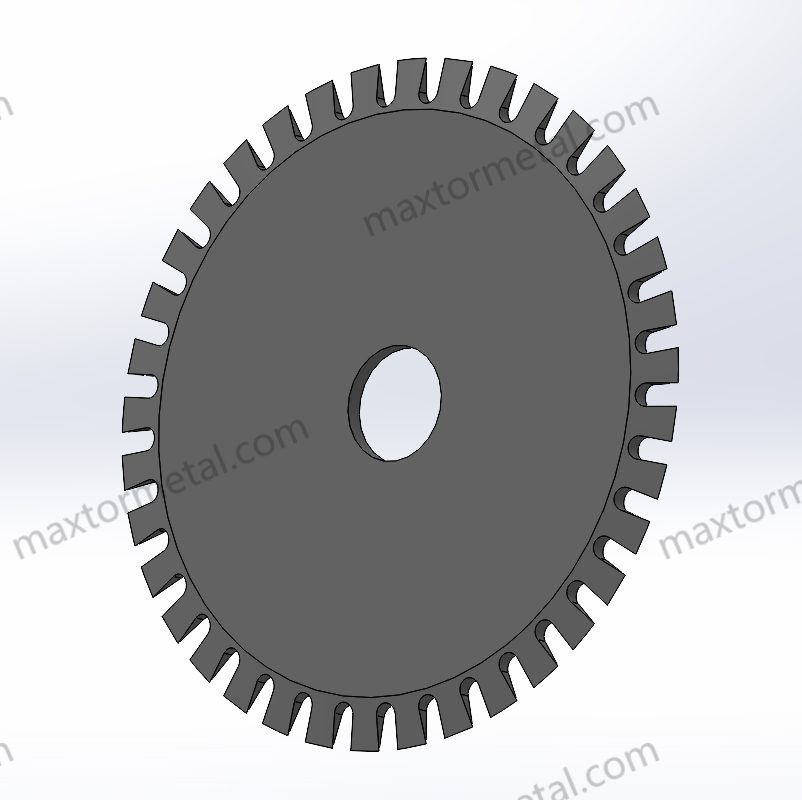

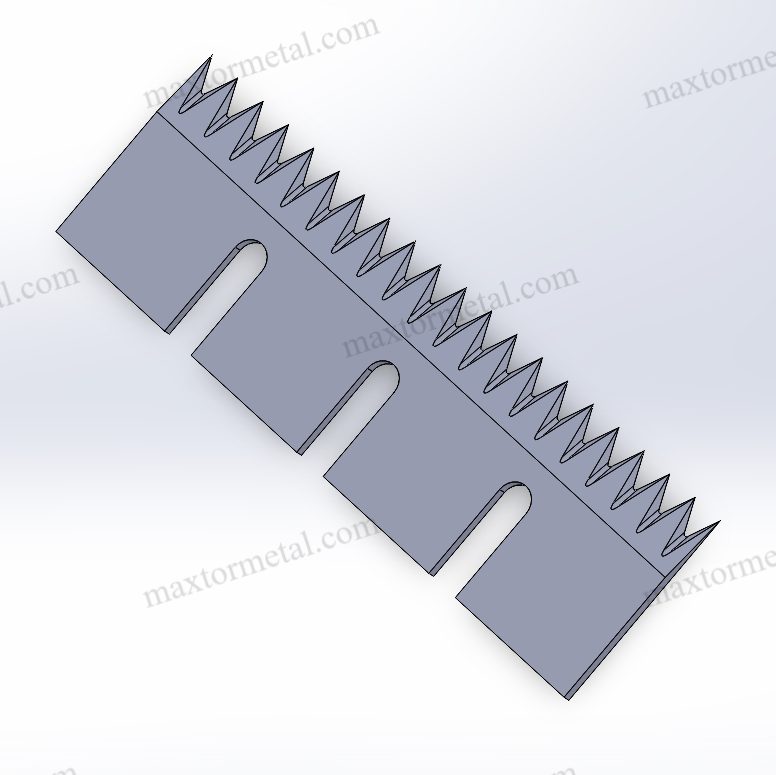

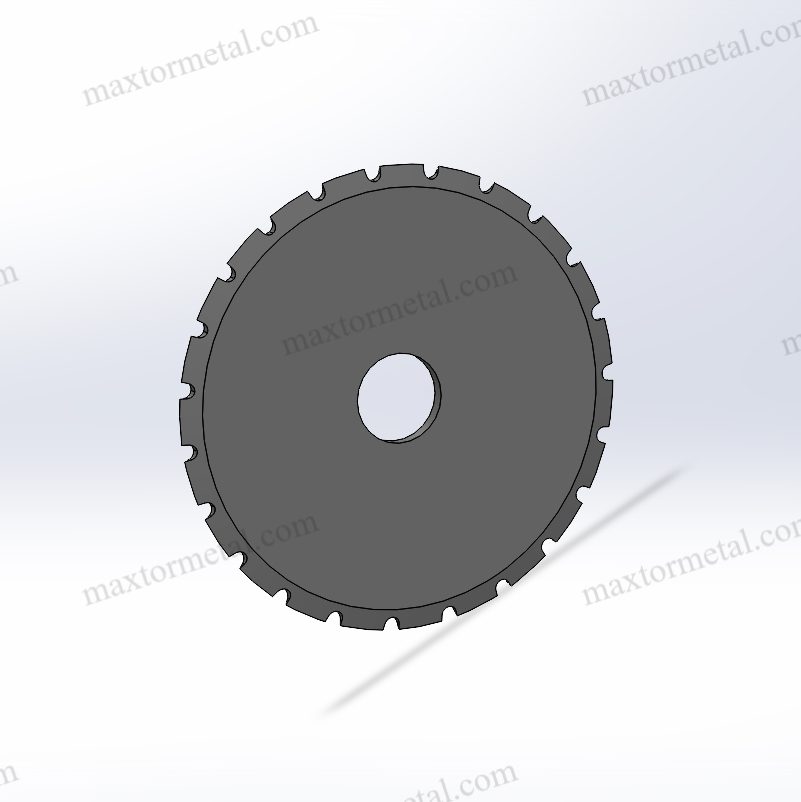

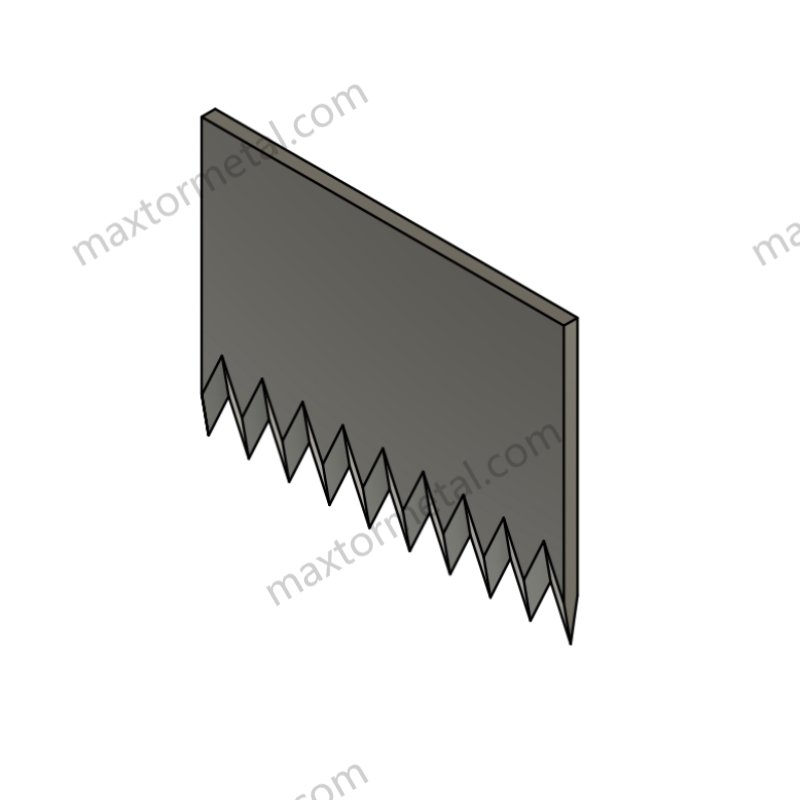

There are different perforating blade knives used in factories. Each one is made for a special kind of cut. Straight and cutoff perforating knives are good for quick, straight cuts. People use them for things like paper, packaging, and plastic. Circular perforating knives roll over the material to make long lines of holes. These are best for cutting things that need a long, straight tear, like food packaging or plastic wrap.

Maxtor Metal has many kinds of perforating blade knives. You can pick straight, rotary, toothed, or circular blades. Each type helps you cut with the right amount of accuracy. For example, a straight blade is good for toilet paper or napkins. A circular blade works well for bubble wrap or food packages. These blades help you make easy-tear lines, air holes, or safety seals.

| Type of Perforating Blade Knife | Beschreibung | Spezifische Anwendungen |

|---|---|---|

| Straight & Cutoff Perforating Knives | Straight knives for chop or fly-through perforations. Customizable tooth geometry and cut size. | Paper products, packaging materials, plastic wrap, tin foil, cardboard boxes |

| Circular Perforating Knives | Circular knives that roll over materials for lengthwise perforations. | Continuous cuts in paper, plastic, metal, food packaging |

Tip: You can change the blade’s material, tooth shape, and cut length to fit your job.

Klingengeometrie

Blade geometry is about the shape and angle of the blade. The edge angle, thickness, and tooth shape all change how the blade cuts. A small edge angle, like 10°–20°, makes the blade very sharp. This is good for soft or thin things. You get neat cuts, but the blade might get dull faster. A bigger edge angle, like 25°–40°, makes the blade stronger. You can cut harder things, but you need to push harder.

Tooth design is important too. Small tooth pitch, between 0.5–1.5 mm, helps cut soft things smoothly. Big tooth pitch, up to 8 mm, is better for tough things. The tooth shape, like triangle or scallop, changes how the blade grabs the material. Bigger spaces between teeth help clear away bits and keep the blade cool. This helps you get clean cuts and makes cutting easier.

Changing blade geometry can make your blade sharper and more exact. For example, making the bevel angle smaller by 5° makes the blade 38% sharper. Blades with fine teeth can lower surface tearing by 43%. These changes help you cut better and waste less material.

Anvil and Support

The anvil and support hold your material still while you cut. You need a flat, strong surface for even holes. If the anvil is not set up right, your cuts may look messy. Good support helps you cut better and keeps your blade working longer.

You should check the anvil for damage or wear. A smooth, clean anvil helps your blades work their best. When you match the blade shape to the support, you get better cuts and your blade lasts longer.

Note: Check your anvil and support often to stop cutting problems.

Troubleshooting Perforating Blade Knives

Identifying Issues

You need to spot problems with your perforating blade knives early to keep your cutting process smooth. Start by looking at the blades closely. Use a bright light and a magnifying glass to check for rust, cracks, chips, or bends. Run your finger gently along the edge to feel for dull spots. If you see or feel any damage, you should act right away.

Watch how the blade cuts. If you notice rough or uneven edges, or if the blade makes strange sounds or vibrations, these are signs of trouble. Sometimes, you will see the blade dragging or leaving jagged lines. This means the blade is not sharp enough or has the wrong blade geometry for the job.

Set up a regular inspection schedule. If you use the blades every day, check them daily or weekly. For lighter use, a monthly check works. Always clean the blades after each use. Wipe away dirt, glue, and debris with a soft cloth and mild soap. Dry the blade well to stop rust from forming.

Store your blades in a dry, shaded place. Use blade holders or covers to protect them from moisture and sunlight. Test the sharpness often by making a simple cut. If the blade does not cut smoothly, it may need sharpening or replacing.

Tip: Train your team to inspect and handle blades safely. Wear gloves and use the right grip to avoid accidents.

Schritte zur Fehlerbehebung

When you see uneven perforation or inconsistent line length, follow these troubleshooting steps to fix the problem:

- Inspect the Cutter Protection Strip

Look for gashes, gaps, or divots. This strip helps the blade move smoothly. If you find damage, replace the strip to restore cutting precision. - Check Blade Depth

Make sure the blade does not stick out more than the thickness of a credit card below the holder. Too much depth can cause incomplete or uneven cuts. - Adjust Cutting Force and Speed

Set the cutting force and speed to match the material. Use the manufacturer’s guide for the best settings. Run a test cut before starting full production. This helps you get the right blade geometry and cutting efficiency. - Examine Blade Geometry

Look at the edge angle, thickness, and tooth shape. If the blade geometry does not match the material, you may see rough or torn edges. Switch to a blade with the right geometry for your job. - Clean the Blade and Machine

Remove any dirt, glue, or debris from the blade and machine parts. A clean blade gives better cutting performance and helps maintain cutting efficiency. - Check Material Feed

Make sure the material moves at a steady rate. Irregular feed can cause uneven perforation and line length. - Adjust Pressure and Tension

Set the right pressure and tension for the material and blade. Too much or too little can affect the quality of the cut.

Note: Always follow the troubleshooting steps in order. This helps you find the cause quickly and keeps your production running smoothly.

Klingenwechsel

You should replace your blade when you see any of these signs:

- The cutting edge looks dull or rounded.

- You need more effort to cut the material.

- You hear squeaking or grinding noises during cutting.

- You see nicks, chips, or cracks on the blade edge.

- The cuts become inconsistent, uneven, or jagged.

- Rust or debris builds up and cleaning does not help.

- You switch to a new material that needs a sharper edge.

Follow the manufacturer’s replacement schedule if you have one. Regular cleaning and good maintenance can make your blades last longer, but you should always replace them based on how they look and perform, not just by time.

Tip: Keep spare blades ready. This way, you can replace them quickly and avoid delays in your production.

A sharp, well-chosen blade with the right blade geometry gives you better cutting precision and longer blade life. Using high-quality perforating blade knives from Maxtor Metal helps you keep your cutting process reliable and efficient.

Consistency Checks

Sie möchten Ihre Perforationsklingen to work the same way every time. Doing consistency checks helps you find problems early. This stops mistakes before they ruin your finished product. Adding these checks to your routine keeps your production line smooth.

Here are some ways to check for consistency in your perforation process:

- Regular Blade Testing

Try out your blades by making test cuts on the same material you use. Look at the cuts each time. If you see rough edges or uneven holes, you need to check for problems. - Reproducibility Checks

Run the same job more than once. Compare the results. If the perforations look the same, your process is steady. If not, check if the blade is dull, not lined up, or if the material feed changed. - Quality Control Tools

Use rulers or calipers to measure the length and spacing of the lines. You can also use digital tools to keep track of these numbers over time. This helps you notice small changes before they get worse. - Operator Checklists

Give your team a checklist for each shift. The list should include checking blade alignment, cleaning blades, and testing the material feed. A checklist helps everyone focus on doing a good job. - Machine Monitoring

Listen for new sounds or vibrations from the machine. These can be early signs of trouble. Some companies use sensors to watch the machine and warn you if something changes. - Dokumentation

Keep a log of all checks and fixes you do. Write down when you change blades, clean the machine, or change settings. This record helps you spot patterns and fix problems faster.

Tip: Use both your eyes and measuring tools. This gives you a better idea of how your process is working and helps you keep things consistent.

You can also use special tests to see if your process repeats well over time. Some factories use these tests to see if each run matches the last one. If you want to do more, you can use math tools to track your results and set clear rules for your team.

When you make consistency checks a habit, you find problems early. This saves time, cuts down on waste, and keeps your products looking great.

Troubleshooting Micro-Perforating Machine

When you use a micro-perforating machine, you want every hole to look the same. Sometimes, you might see problems like uneven lines or missing holes. You need to find these problems and fix them quickly. Troubleshooting helps your machine work well and keeps your line moving.

V-Shaped Grooves

V-shaped grooves can happen if the blade and anvil are not lined up. You may see these grooves along the cut line. They make the tear line weak and messy. If you spot V-shaped grooves, check if the blade and anvil match up. When they do not, the blade pushes harder on one side. This cuts deeper and leaves a groove.

Some machine parts can also cause trouble. Worn shaft bushings, bent shafts, or weak springs make the blade move up and down. The blade should stay steady. Watch the blade and anvil while the machine runs. If you see the blade move unevenly, stop and check the parts.

Tip: Set up your micro-perforating machine slowly. Start with no pressure. Add more pressure a little at a time. This helps you avoid mistakes and get better holes.

Maxtor Metal can make Kundenspezifische Klingen and setups. If your machine needs something special, you can get a blade that fits. Custom blades help you stop V-shaped grooves and get the best results.

Anvil Adjustment

You must adjust the anvil the right way to stop defects. The anvil holds the material while the blade makes holes. If the anvil is not set up right, you get bad cuts or uneven holes. Troubleshooting often starts with checking the anvil.

Here are some best ways to adjust the anvil:

- Set the shaft gap with the lowest pressure that still gives a clean cut.

- Check bushings, bearings, and shafts. Make sure they are not worn out. Bad parts make the blade wobble and wear out faster.

- Keep counter knives sharp. Dull knives make the blade wear out quickly.

- Clean all tool parts. Dirt on the blade holder or blade causes wobble and bad cuts.

- Use good parts that fit well. This stops rust and keeps your machine working.

- Test the holes in the final product. Make sure they work for your job.

- Write down each setup. This helps you do good jobs again and avoid mistakes.

| Schritt | Aktion | Warum es wichtig ist |

|---|---|---|

| 1 | Set minimum pressure | Stops damage to the material |

| 2 | Check moving parts | Stops wobble and uneven holes |

| 3 | Sharpen counter knives | Makes blades last longer |

| 4 | Clean parts | Helps the machine run smooth |

| 5 | Use good parts | Keeps the machine working well |

| 6 | Test final holes | Makes sure they fit your needs |

| 7 | Write down setups | Helps you repeat good work |

Note: Check your machine often and put it together the right way. This stops parts from getting loose or worn out. You get better results from your micro-perforating machine.

Synchronization

Synchronization means all parts of your machine work together at the same time. If the rollers and material feed do not match, holes end up in the wrong place or spaced unevenly. Troubleshooting often means checking if everything is in sync.

When you keep the machine parts in sync, you get neat and even holes. The holes line up right, even if you change the speed. This is important for jobs that need perfect lines for folding or tearing.

Laser micro-perforating machines need steady power and timing. If the power changes or a pulse is missed, the holes change size or shape. Closed-loop power control checks the laser and keeps it steady. If a pulse is missed, the machine stops to avoid mistakes.

Optical engineering helps keep the laser beam the same size. This makes every hole the same, even with many heads working. You get very exact results that meet tough rules.

Tip: Use real-time checks and feedback to keep your machine in sync. This helps you find problems fast and keep your work good.

Troubleshooting your micro-perforating machine takes careful checks, regular care, and setting up the machine just right. If you follow these steps, your machine will run well and make good holes every time.

Micro-Perforating Machine Consistency

To keep your micro-perforating machine working well, you need to focus on three things. These are material feed, pressure and tension, and quality control. If you pay attention to these, your machine will make better holes and your products will have fewer problems.

Material Feed

A steady material feed is very important for micro-perforating. If the material moves too fast or too slow, the holes will not look right. If the material jerks, the lines will not match up.

Ensuring Uniform Feed Rate

Your material should move at the same speed all the time. This helps every hole line up and keeps the lines even. Use rollers or belts that hold the material tightly. Check your feed system before each job. If your machine can track speed, use it to match the rollers and material. This stops the material from stretching or bunching.

Tip: Mark the start and end of a test strip. Run it through the machine and measure the marks. If the marks are not the same distance apart, change the feed rate.

Common Material Feed Issues

You might see these problems sometimes:

- The material slips or bunches up.

- The rollers leave marks or dents.

- The material stretches or shrinks as it moves.

- The holes do not line up from one end to the other.

These problems can happen if rollers are worn out, belts are dirty, or tension is wrong. If you use different materials, you may need to change the feed system for each one.

Solutions for Feed Irregularities

You can fix feed problems by doing these things:

- Clean and check rollers and belts often.

- Replace any parts that are worn or broken.

- Adjust roller pressure so it holds but does not crush the material.

- Use sensors to watch the feed rate and warn you about changes.

- Test each new material before you start a big job.

A steady feed rate helps your machine make clean and even holes every time.

Pressure and Tension

Pressure and tension decide how deep and neat your perforation lines are. If you set them wrong, you might get tears, weak spots, or lines that do not match.

Setting Optimal Pressure

Set the right pressure for your material. Many machines use air rollers or screws to change how deep the blades go. Some systems let you set air pressure up to 6 Bar and use small screws for fine changes. Start with low pressure and slowly increase it until you get a clean cut. Each material, like PE, PVC, or paper, needs its own setting. Always test on a sample before you run a big batch.

Monitoring and Adjusting Tension

Tension keeps the material flat and steady. Use idler rollers to help with tension. You can change how many rollers you use and where you put them. Watch for too much tension, which can stretch the material, or too little, which can cause wrinkles. Adjust the tension until the material is smooth but not stretched.

Note: Some machines use a special motor that tracks speed. This keeps the needle rotation in sync with the film speed. It helps stop stretching and keeps the perforation good.

Impact of Pressure and Tension on Perforation Quality

If pressure and tension are not set right, you might see:

- Film splitting or tearing at the perforation lines.

- Weak seals that break too easily.

- Holes that are uneven or not in the right place.

- Material that stretches or shrinks, making lines too long or short.

Check and adjust these settings often. Make sure machine parts are lined up and in good shape. Handle film rolls gently so you do not damage them.

Strenge Qualitätskontrolle

Quality control makes sure your micro-perforating results stay the same every time. You need to check your process at every step.

Regular Inspection Protocols

Make a schedule for checking your machine and products. Here is a simple table to help you:

| Inspektionstyp | Zweck | Recommended Frequency/Timing |

|---|---|---|

| Pre-Production Inspection | Check raw materials and parts before starting | Before production or with new suppliers |

| Initial Production Check | Inspect the first batch | At the start of mass production |

| During Production Inspection | Check quality during production | When 20% to 60% of production is complete |

| Final Product Inspection | Confirm quality before shipment | After production, before shipping |

| In-Line Inspection | Real-time checks at key stages | At critical points during production |

| Production Monitoring | Watch the process continuously | Throughout the entire production cycle |

Never skip inspections, even if you trust your supplier. If you see problems, check more often.

Real-Time Production Monitoring

Use sensors and cameras to watch your machine as it works. Real-time monitoring helps you spot problems fast. If a roller slips or a blade gets dull, you can fix it before you waste material. Some machines send updates to your phone or computer, so you always know how things are going.

Use checks during work, tests at the end, and real-time updates to keep machines working well. This helps you find problems early and keep your products good.

Documentation and Traceability

Write down every inspection, adjustment, and repair. Record when you change blades, clean rollers, or adjust tension. Good records help you find problems and fix them faster. If a customer asks, you can show what you did and when. This builds trust and shows you care about quality.

Tip: Use checklists for each shift. This helps your team remember every step and keeps your process steady.

If you follow these steps, your micro-perforating machine will work its best. You will get good results and have fewer surprises on your production line.

Optimization and Maintenance

Bedienerschulung

Operator training is very important for keeping machines working well. When you know how to find and fix problems, you help your team avoid mistakes. This keeps the production line moving. Good training helps you reach your goals and make better products.

You should join training programs often. These programs teach you new skills and tools. You learn how to do daily, weekly, monthly, and yearly maintenance. Following these routines helps stop problems before they happen.

Here is a simple list of things you learn in operator training:

- Clean machines and blades every day.

- Check safety systems and test motors.

- Look at hydraulic systems and tools.

- Lubricate moving parts to stop wear.

- Listen for odd sounds and check cables each week.

- Adjust belts, change filters, and check coolant every month.

- Inspect spindles, calibrate machines, and check grounding systems every year.

Tip: Doing these tasks on a schedule helps your machines work better and last longer.

Operator training covers many topics. You can find programs for waste management, electrical engineering, chemical engineering, and more. The table below shows some common training types and what they teach:

| Training Program Categories | Beschreibung |

|---|---|

| Abfallmanagement | Troubleshooting and fixing waste systems |

| Electrical Engineering | Electrical troubleshooting and fixing skills |

| Chemical Engineering | Chemical process troubleshooting and fixing |

| Instrument & Controls Engineer | Instrument and control systems troubleshooting |

| Maintenance Technician | Hands-on machinery and equipment fixing |

| Mechanical Engineering | Mechanical systems troubleshooting and fixing |

| Operations Management | Operational troubleshooting and making processes better |

| Plant Operations Engineer | Plant-wide troubleshooting and fixing |

| Refinery / Plant Operator | Refinery and plant operation troubleshooting and upkeep |

Pick training that fits your job and machines. Learning new skills helps you make your production line run smoothly. Well-trained operators find problems early, fix them quickly, and make sure every product is good.

Upgrades and Customization

You can make your perforating process better by using new blades and machines. High-quality blades give you cleaner cuts and last longer. Custom blades are made just for your job. You can pick the size, tooth shape, and material you need. This helps you keep up when products or markets change.

Here are some good things about upgrading and customizing your perforating blade knives:

- You get cuts that are more exact and neat.

- Blades stay sharp longer, so you do not change them as much.

- You save money by buying fewer blades and fixing less.

- Your machine works faster and can meet tight deadlines.

- You have less downtime and keep your line moving.

- You waste less material, which saves money and helps the planet.

- You can change blade designs fast for new products.

- You get help from experts who know about special materials and coatings.

Tip: Custom blades with smart coatings, like titanium, help blades last longer. Sensors can show when blades wear out, so you can fix them before problems happen.

Many companies do better after switching to custom blades. For example, a box factory cut downtime from 14 hours a month to less than 5 hours. Some businesses saved up to 28% on blade costs each year. You can also keep your product quality high, which is important for food, electronics, and medical packaging.

The table below shows how upgrades and custom blades help different industries:

| Industrie | Benefit of Custom Blades | Ergebnis |

|---|---|---|

| Verpackung | Exact cuts, less waste | Stronger seals, neat edges |

| Medizinische Industrie | Precise holes, safe materials | Reliable product quality |

| Kunststoffe | Faster, cleaner cuts | Lower downtime, less scrap |

| Non-woven | Flexible blade designs | Adapts to new products |

You can use upgrades to keep your process working well. Upgrading and customizing your blades and machines helps you stay ahead.

You can get better results with your perforating blade knives and micro-perforating machines if you follow some important steps. Doing regular maintenance and teaching operators helps you stop common problems. First, clean the machine and change old parts so it does not break down. Next, train workers so they make fewer mistakes and keep the machine running well. When you do both, your cuts look better and you spend less money.

Many companies do much better when they use strong, custom blades from Maxtor Metal. For example, a snack packaging company made cuts faster and wasted less material. A label company had less downtime and fewer mistakes after using custom blades. A steel plant worked faster and did not have to change blades as often.

Pick the best tools and keep your micro-perforating process working well with Maxtor Metal’s trusted solutions.

Häufig gestellte Fragen

What causes uneven perforation with perforating blade knives?

Uneven perforation can happen for a few reasons. If your blade is dull, it will not cut well. A blade that is not lined up right can also cause problems. Dirt on the blade makes cuts messy. If you use the wrong pressure, the cuts may not look good. Sometimes, the material changes and this affects the cut. Always check your perforating blade knives and machine before you start.

How often should you replace perforating blade knives?

Replace your perforating blade knives when you see dull edges or chips. If your cuts are uneven, it’s time to change the blade. If you use the blades frequently, check them every week. If you don’t use them much, check them once a month. Always have extra blades ready so you can change them fast.

Can you use one perforating blade knife for all materials?

You cannot use just one blade for everything. You need to pick the right blade type and shape for each material. Harder materials need stronger blades. Softer materials need blades with sharper edges. Using the right perforating blade knives helps you get better cuts and makes the blades last longer.

How do you keep perforating blade knives sharp?

Clean your blades after you use them. Store them in a dry place so they do not rust. Use a soft cloth and gentle cleaner to wipe them. If you see dull spots, sharpen or change the blade. Taking care of your perforating blade knives keeps them sharp.

Why do perforation lines sometimes vary in length?

Perforation lines can change if the material feed is not steady. If the blade is not lined up, the lines may be different lengths. Check your feed system and make sure the blade is in the right spot. Setting up your machine the same way each time helps make even lines.

What maintenance do perforating blade knives need?

You should clean, check, and oil your blades and machine parts often. Keep a log of when you do maintenance. Change blades that are worn out or broken right away. Good care helps your perforating blade knives last longer and cut better.

Siehe auch

So erzielen Sie die beste Leistung mit Ihrem Perforiermesser

So wählen Sie das richtige Perforiermesser für Ihr Material

Eine Antwort