| Andere Namen | Gezahnte Klinge für Gelee, gezahnte Klinge für Milchtee |

|---|---|

| Herkunftsort | China |

| Anwendung | Lebensmittelverpackung |

| Material | Edelstahl |

| Modell-Nr | GP-JP |

| OEM-Service | Verfügbar |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Paket | Kartonschachtel, in Holzkisten |

| Lieferzeit | 7-20 Tage |

Teilen mit:

The term “Tooth Punch Blades” refers to a specific type of punch blade characterized by a cutting edge that features a series of teeth or serrations. Unlike punch blades with a continuous, smooth cutting edge, Tooth Punch Blades are designed to create holes or perforations with a specific edge profile or to facilitate tearing or separation of the material being punched. The teeth can vary in size, shape, and spacing depending on the intended application and the desired effect. Tooth Punch Blades are particularly useful for processing materials where a clean, shear-like cut is not always desired, or where a specific texture or tear initiation point is needed around the punched feature. These blades operate in punching machines or presses, similar to other punch blades. Tooth Punch Blades are also sometimes referred to as “serrated punch blades,” “perforating punch blades” (if the teeth are small and closely spaced), “notching punch blades” (if used to create edge notches), or “tear-off punch blades,” depending on the specific application and the resulting hole or cut.

Tooth Punch Blades are used in various industrial and craft applications where a toothed or perforated edge is required in the punched material. Key uses and application scenarios include:

The specific size, shape, and spacing of the teeth on the Tooth Punch Blade are critical to achieving the desired perforation or tear characteristics in the punched material.

The materials used to manufacture Tooth Punch Blades are chosen for their ability to maintain the sharp edges of the teeth under repeated impact and to resist wear. Common materials include:

The selection of the appropriate material depends on the material being punched, the required precision and durability of the teeth, and the production volume. Proper heat treatment is essential to ensure the teeth have the necessary hardness and toughness to perform effectively.

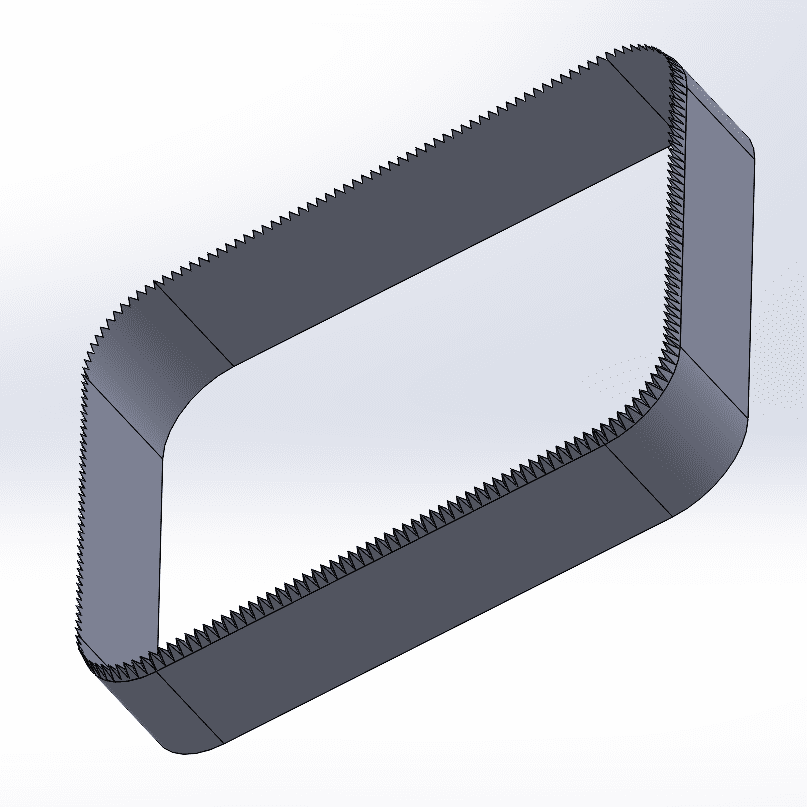

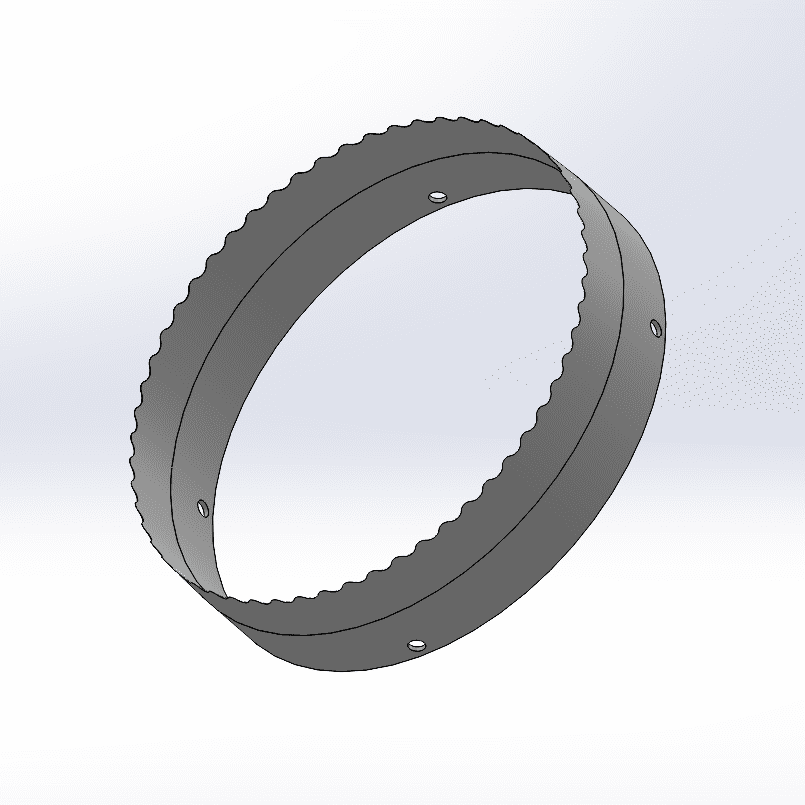

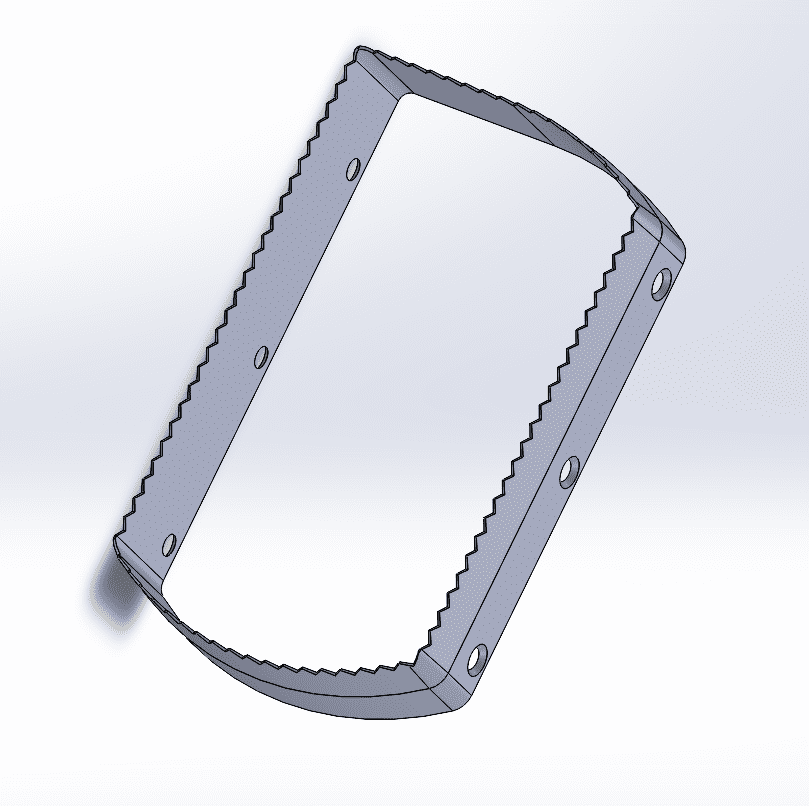

The defining characteristic is the toothed cutting edge. Beyond this, Tooth Punch Blades can have various overall shapes and tooth configurations:

The design of the teeth (size, shape, pitch, angle) is critical and is tailored to the specific material being punched and the desired outcome of the perforation or tear. Precision manufacturing is essential to ensure the teeth function correctly and consistently.

Sollten Sie die gewünschte Klinge nicht finden, können wir sie auch individuell anpassen. Sehen Sie sich unsere „Kundenspezifische Klingen„ um zu erfahren wie! Willkommen bei Anfragen!

Genießen Sie den Komfort des Imports. Vom Transport bis zur Zollabfertigung kümmern wir uns um den gesamten Prozess. Sie müssen nur die Mehrwertsteuer zahlen und warten, bis die Waren beim Unternehmen eintreffen.

Wir haben gesehen, wie seine Klingen in unzähligen Anwendungen eingesetzt wurden, und sind bereit, jedes Projekt zu bewältigen, das Sie uns stellen – mit Genauigkeit, Haltbarkeit und unübertroffen wettbewerbsfähigen Preisen.

Ob Sie Zeichnungen, Skizzen oder Muster liefern, wir können für Sie zeichnen und fertigen. Wir können Ihnen auch dabei helfen, bestehende Designs und Spezifikationen zu ändern, um nahezu jede industrielle Werkzeuganwendung zu verbessern. Bitte kontaktieren Sie unser engagiertes Vertriebsteam, um Ihre spezifischen Anforderungen zu besprechen.

Zur Kontrolle der Qualität werden eine Reihe von Tests und Kontrollen durchgeführt, darunter die Erstmusterprüfung, die Prüfung eingehender Materialien und zertifizierter Materialien, die Qualitätskontrolle während des Prozesses und die Endqualitätsprüfung.

Egal, ob Sie Importeur, Händler, Großhändler oder Endverbraucher sind, Sie sind bei uns herzlich willkommen – mit minimaler Mindestbestellmenge, ohne lästige Anfragen und mit mehr Freiheit beim Einkauf.

Werden Sie Ihr exklusiver Monitor und übertragen Sie regelmäßig alle wichtigen Knoten in der Produktionslinie, egal wie weit sie entfernt sind. So haben Sie den Produktfortschritt so weit wie möglich im Blick!

Nanjing Metal Industrial CO., Limited

Mingjue-Industriepark, Lishui, Nanjing, Jiangsu, China

Bleiben Sie mit unseren neuesten Nachrichten auf dem Laufenden.