Cuchillas de Corte de Cerámica Son excepcionalmente afiladas y resistentes a la oxidación, lo que las hace ideales para cortes limpios y precisos. Muchos usuarios valoran su ligereza y su durabilidad en comparación con las hojas de acero tradicionales.

Puntos clave

- Las hojas de corte de cerámica conservan su filo por más tiempo que las de acero. Esto les permite realizar cortes muy limpios y prolijos.

- No se oxidan ni se dañan con productos químicos, lo que los hace fáciles de lavar y aptos para trabajos en alimentos, medicina y laboratorio.

- Las cuchillas de cerámica son ligeras y seguras para usar cerca de aparatos electrónicos. No producen chispas ni conducen electricidad.

- Estas cuchillas pueden romperse o astillarse si se caen. Debe manipularlas con cuidado y usar herramientas especiales para afilarlas.

- Las cuchillas de cerámica personalizadas de empresas de confianza como Nanjing Metal se adaptan a trabajos de corte especiales. Además, ayudan a trabajar más rápido y mejor.

Ventajas de las hojas de corte de cerámica

Nitidez y retención de bordes

Afilado inicial excepcional para tareas de corte precisas

Cuchillas de Corte de Cerámica Son muy afiladas cuando son nuevas. Utilizan materiales especiales como zirconio o alúmina, lo que les confiere un filo muy fino. Estas hojas pueden cortar objetos con gran precisión. Son ideales para trabajos que requieren cortes precisos, como en la industria alimentaria, la electrónica o los laboratorios. Las hojas de cerámica son más utilizadas para trabajos que requieren poco esfuerzo y alta precisión.

Mantiene el filo por mucho más tiempo que el acero, reduciendo la frecuencia de reemplazo.

Las hojas de cerámica mantienen su filo durante mucho tiempo. Las hojas de acero necesitan afilarse con más frecuencia. Las hojas de cerámica no necesitan cambiarse con tanta frecuencia. Esto significa que se pierde menos tiempo cambiándolas en el trabajo. Algunas pruebas demuestran que las hojas de cerámica se mantienen afiladas hasta diez veces más que las de acero. Esto las convierte en una opción inteligente para trabajos que requieren muchos cortes.

Corrosión y resistencia química

Completamente resistente al óxido y la oxidación, incluso en ambientes húmedos o ácidos.

Las hojas de corte de cerámica no se oxidan ni se corroen. Se mantienen resistentes incluso en ambientes húmedos o ácidos. Su superficie lisa impide la adhesión de manchas y olores. Esto es importante en entornos como la industria alimentaria o médica. Gracias a su resistencia a la oxidación, las hojas de cerámica conservan su buen aspecto y funcionan bien durante mucho tiempo.

Químicamente inerte: no reacciona con la mayoría de las sustancias, ideal para aplicaciones sensibles.

Las hojas de cerámica no reaccionan con la mayoría de los productos químicos. Esto las hace seguras para lugares con muchos químicos. Ayudan a mantener la limpieza y la seguridad en laboratorios y fábricas de alimentos. zirconia y alúmina hace que estas hojas sean resistentes y resistentes a los químicos.

Bajo mantenimiento

No requiere engrase ni lubricación.

Las hojas de corte de cerámica son fáciles de cuidar. Las hojas de acero necesitan aceite para evitar la oxidación, pero las de cerámica no. La siguiente tabla muestra las diferencias entre las hojas de cerámica y las de acero:

| Característica | Cuchillas Cerámicas | Cuchillas de acero |

|---|---|---|

| Resistencia a la corrosión | Naturalmente resistente a la oxidación, no se oxida. | Propenso a oxidarse, requiere lubricación. |

| Porosidad de la superficie | No poroso, resistente a manchas y olores. | Poroso, absorbe aceites y olores. |

| Requisitos de mantenimiento | Bajo mantenimiento, no necesita aceite. | Alto mantenimiento, lubricación regular. |

| Retención de nitidez | Mantiene el filo por más tiempo, afilado menos frecuente | Se desafila más rápido y necesita un afilado regular. |

| Durabilidad | Frágil, propenso a astillarse | Más flexible y duradero |

Las cuchillas de cerámica solo necesitan limpiarse y almacenarse de forma segura. Esto las hace perfectas para lugares de trabajo con mucha actividad.

Fácil de limpiar y esterilizar, adecuado para industrias donde la higiene es crítica.

Las cuchillas de cerámica son suaves y no absorben la suciedad. Son fáciles de lavar y mantener limpias. Esto ayuda a prevenir la propagación de gérmenes. A los trabajadores de la alimentación y la salud les gusta porque garantiza la seguridad y cumple con las normas más estrictas.

Ligero y no magnético

Significativamente más ligeras que las hojas de metal, lo que reduce la fatiga del operador.

Las cuchillas de corte de cerámica pesan menos que las de acero. Esto facilita su uso durante mucho tiempo. Los trabajadores se cansan menos al usarlas. Los estudios demuestran que las cuchillas de cerámica pueden reducir el cansancio hasta en un 30%Su ligereza y filo afilado evitan la necesidad de presionar con fuerza. Esto permite trabajar con mayor rapidez y seguridad.

No magnético y antichispas, seguro para usar en entornos electrónicos y peligrosos.

Las hojas de cerámica no son magnéticas ni producen chispas. Esto las hace seguras cerca de aparatos electrónicos y en lugares peligrosos. Además, no conducen electricidad, lo que contribuye a la seguridad de los trabajadores.

Consejo: Si necesita hojas afiladas, seguras y fáciles de usar, las hojas de corte de cerámica son una excelente opción.

Ventajas y desventajas de las cuchillas de cerámica

Principales ventajas

Las hojas de cerámica tienen muchas ventajas. Se utilizan en muchos trabajos. Estas son las principales razones por las que a la gente le gustan:

- Nitidez excepcionalLas hojas de cerámica cortan con mucha limpieza y facilidad. Utilizan materiales especiales como zirconio y alúmina. Esto les permite conservar el filo durante mucho tiempo. La mayoría de las personas observan que las hojas de cerámica se mantienen afiladas durante más tiempo que las de acero.

- Retención de bordes de larga duraciónEstas cuchillas no necesitan afilarse con frecuencia. Tampoco es necesario cambiarlas con tanta frecuencia. Algunos informes indican que las cuchillas de cerámica duran hasta diez veces más que las de acero. Esto ahorra dinero y tiempo en el trabajo.

- Resistencia a la corrosión y a los productos químicosLas cuchillas de cerámica no se oxidan ni reaccionan con la mayoría de los productos químicos. Su superficie lisa evita manchas y olores. Esto las hace ideales para trabajos con alimentos, médicos y de laboratorio.

- Higiénico y fácil de limpiar.Las cuchillas de cerámica son suaves y no se ensucian fácilmente. Los trabajadores pueden limpiarlas y esterilizarlas rápidamente. Esto ayuda a mantener la seguridad y la limpieza en trabajos importantes.

- Diseño ligeroLas hojas de cerámica son más ligeras que las de metal. Esto facilita su uso durante más tiempo. Las personas se cansan menos y se sienten mejor en el trabajo. Los estudios demuestran que las herramientas ligeras ayudan a los trabajadores a mantenerse seguros y a rendir más.

- No magnético y no produce chispasLas hojas de cerámica no conducen electricidad ni producen chispas. Esto garantiza la seguridad de las personas en lugares con aparatos electrónicos o materiales peligrosos.

- Beneficios ambientalesLas hojas de cerámica duran mucho tiempo. Esto significa que se desechan menos. Algunos dicen que ayudan al planeta al generar menos residuos.

Nota: Muchas empresas y trabajadores afirman que ahorran dinero y trabajan más rápido con cuchillas de cerámica. Por ejemplo, una fábrica de automóviles trabajaba... 50% más rápido y ahorró 30% en costos.

Desventajas principales

Las cuchillas de cerámica no son perfectas. También presentan algunos problemas. Estos son los principales aspectos a tener en cuenta:

- FragilidadLas hojas de cerámica son duras, pero pueden romperse o astillarse si se caen. No resisten golpes ni torceduras tan bien como las hojas de acero.

- Uso intensivo limitadoEstas hojas no son buenas para cortar objetos muy duros. Funcionan mejor para trabajos pequeños y cuidadosos.

- Costo más altoLas hojas de cerámica son más caras al principio que las de acero. Los materiales especiales y su fabricación las hacen más caras.

- Difícil de afilarNecesita herramientas de diamante especiales para afilar las hojas de cerámica. Si se astillan o se desafilan, podría necesitar un profesional para repararlas o reemplazarlas.

- Sensible a la suciedad y los residuos.Incluso la suciedad más pequeña puede dañar el filo de la cuchilla. Es importante mantener limpias las cuchillas de cerámica y manipularlas con cuidado para evitar daños.

- Mala resistencia al choque térmicoLos cambios bruscos de temperatura pueden romper las hojas de cerámica. A veces, es necesario enfriarlas para evitar grietas.

- Curva de aprendizaje para nuevos usuariosQuienes cambian de hojas de acero a hojas de cerámica necesitan tiempo para aprender. Cuidarlas es importante para obtener buenos resultados.

⚠️ Consejo: Guarde siempre las cuchillas de cerámica en un lugar seguro y límpielas después de usarlas. No las deje caer ni las doble para que duren más.

Cuchillas de cerámica vs. de acero

Actuación

Nitidez y precisión de corte

Las hojas de cerámica son conocidas por ser muy precisas. Su El borde es súper fino, de solo 1 a 2 micrones de ancho.Esto les ayuda a realizar cortes muy limpios y precisos. Las hojas de acero son útiles para muchas cosas, pero su filo suele ser más ancho. No siempre son tan afiladas como las de cerámica. En sectores como las fábricas de alimentos o la industria electrónica, esto es fundamental. Se traduce en cortes más suaves y menos desperdicio de material.

| Métrica | Cuchillas Cerámicas | Cuchillas de acero |

|---|---|---|

| Dureza de Mohs | 8.2 (Óxido de circonio) | 4-6 |

| Retención de bordes | Nitidez hasta 10 veces mayor | Menor duración de la nitidez |

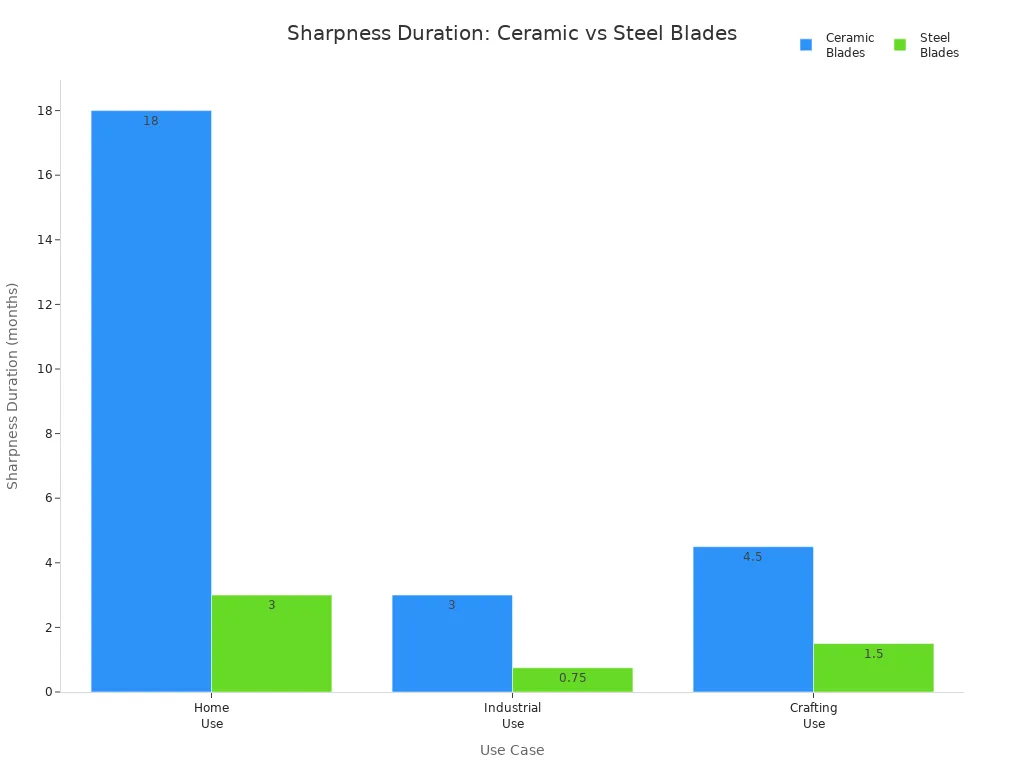

| Duración de la nitidez (uso doméstico) | 12-24 meses o más | 2-4 meses |

| Duración de la nitidez (uso industrial) | Varios meses | Semanas a 1 mes |

| Duración de la nitidez (uso en la elaboración) | 3-6 meses | 1-2 meses |

Las hojas de cerámica se mantienen afiladas y precisas por mucho más tiempo que las de acero. Esto las hace ideales para trabajos que requieren los mismos resultados siempre.

Afilado inicial del filo: las hojas de cerámica suelen estar más afiladas al salir de fábrica, mientras que las hojas de acero se pueden reafilar fácilmente.

Al principio, las hojas de cerámica son más afiladas que la mayoría de las de acero. Esta agudeza permite cortar con facilidad y precisión. Las hojas de acero se pueden afilar repetidamente con herramientas normales. Esto es ideal para quienes prefieren reparar sus propias hojas.

Consistencia de corte: la cerámica mantiene la precisión por más tiempo, el acero puede desafilarse más rápido pero se puede restaurar

Las hojas de cerámica cortan bien durante mucho tiempo. Obtendrás el mismo corte de calidad de principio a fin. Las hojas de acero se desafilan más rápido, pero puedes afilarlas para que funcionen como nuevas.

Durabilidad

Resistencia al desgaste: la cerámica es muy resistente a la abrasión, el acero se desgasta más rápidamente.

Las hojas de cerámica son muy resistentes al desgaste. Su superficie dura no se raya fácilmente. Permanecen afiladas después de muchos usos. Las hojas de acero son resistentes, pero se desgastan más rápido. Hay que cambiarlas o afilarlas con más frecuencia.

| Atributo | Cuchillas Cerámicas | Cuchillas de acero |

|---|---|---|

| Dureza (Mohs) | 8.2 (óxido de circonio, muy duro) | 5-6 (varía según el tipo de acero) |

| Retención de bordes | Mantiene la nitidez hasta 10 veces más tiempo | Requiere afilado frecuente |

| Resistencia al desgaste | Excelente, resiste el desgaste y la corrosión. | Propenso al desgaste y a perder brillo |

| Fragilidad | Alto, propenso a astillarse o agrietarse. | Bajo, flexible y resistente al impacto. |

| Resistencia al impacto | Bajo, puede astillarse bajo fuerza lateral | Alto, durable bajo uso intensivo. |

| Resistencia al óxido | 100% a prueba de óxido, sin oxidación | Puede oxidarse a menos que sea de acero inoxidable. |

| Herramientas de afilado | Requiere afilador de diamantes | Se puede afilar con herramientas estándar. |

| Mejor caso de uso | Corte de precisión, nitidez sostenida | Corte resistente, tenacidad. |

Fragilidad vs. tenacidad: la cerámica es frágil y propensa a astillarse, el acero es más resistente y soporta el impacto.

Las hojas de cerámica pueden astillarse o romperse si se caen o se tuercen. Las hojas de acero son más resistentes y pueden doblarse o resistir golpes sin romperse. Esto hace que el acero sea más adecuado para trabajos duros o difíciles.

Idoneidad para tareas pesadas: se prefiere el acero para aplicaciones exigentes o de alto impacto

Las hojas de acero son ideales para cortar objetos gruesos o duros. Son flexibles y resistentes, por lo que no se rompen fácilmente. Las hojas de cerámica son ideales para trabajos precisos y cuidadosos, no para trabajos pesados.

Mantenimiento

Limpieza y cuidado: las hojas de cerámica requieren un mantenimiento mínimo, el acero puede necesitar lubricación para evitar la oxidación.

Las hojas de cerámica son fáciles de cuidar.Simplemente se enjuagan y no necesitan aceite. Las hojas de acero deben limpiarse y engrasarse con frecuencia para evitar la oxidación, sobre todo si se mojan.

- Las hojas de cerámica son fáciles de limpiar y rara vez necesitan afilarse.

- Las hojas de cerámica no necesitan aceite y no se oxidan.

- Las hojas de acero necesitan afilarse y engrasarse con frecuencia.

- Las hojas de acero deben limpiarse mucho para eliminar la suciedad.

Afilado: la cerámica requiere herramientas y experiencia especializada, el acero se puede afilar con equipos estándar.

Para afilar cuchillas de cerámica, se necesitan herramientas de diamante especiales y habilidad. La mayoría de la gente simplemente compra una nueva cuando se desafila. Las cuchillas de acero se pueden afilar en casa con herramientas comunes, por lo que es más fácil para la mayoría mantenerlas afiladas.

Resistencia a la corrosión: la cerámica es inmune al óxido, el acero es susceptible a menos que sea inoxidable o esté recubierto.

Las hojas de cerámica nunca se oxidan, incluso si se mojan o se exponen a ácido. Las hojas de acero pueden oxidarse, a menos que sean de acero inoxidable o tengan un recubrimiento especial. Esto hace que las hojas de cerámica sean más adecuadas para trabajos que requieren una limpieza constante.

Costo

Precio de compra inicial: las hojas de cerámica suelen ser más caras que las de acero.

Las hojas de cerámica son más caras al principio. Son aproximadamente cinco veces más caras que las de acero. Esto se debe a que utilizan materiales especiales y son más difíciles de fabricar.

| Aspecto | Cuchillas Cerámicas | Cuchillas de acero |

|---|---|---|

| Costo | Aproximadamente 5 veces más caro | Rentable, aproximadamente 5 veces más barato. |

| Esperanza de vida | Dura aproximadamente 10-11 veces más | Se desafila más rápido y requiere reemplazo frecuente |

| Seguridad | Reduce las lesiones por laceración en 70% | Mayor riesgo de lesiones por laceración |

| Resistencia a la corrosión | No se oxida | Puede oxidarse |

| Durabilidad contra roturas | Más frágil, puede astillarse si se cae. | Más duradero, resistente a la rotura. |

Valor a largo plazo: la cerámica dura más entre reemplazos, el acero puede generar costos de reemplazo más frecuentes

Aunque las hojas de cerámica son más caras, duran mucho más. En las fábricas, las hojas de cerámica pueden funcionar de 6 a 18 meses. Las hojas de acero pueden necesitar ser reemplazadas o afiladas cada pocos meses. Con el tiempo, las hojas de cerámica pueden ahorrar dinero a quienes buscan hojas duraderas.

Costos de afilado y mantenimiento: la cerámica tiene costos de afilado más altos, el acero es más económico de mantener

Afilar cuchillas de cerámica es más caro porque se necesitan herramientas especiales. La mayoría de la gente simplemente compra una cuchilla nueva. Las cuchillas de acero son más económicas de afilar y mantener, por lo que son una buena opción para ahorrar dinero.

Nota: La elección entre hojas de cerámica y de acero depende del trabajo. Las hojas de cerámica son mejores para trabajos precisos y cuidadosos, y duran mucho tiempo. Las hojas de acero son mejores para trabajos difíciles y son fáciles de reparar y mantener.

Aplicaciones de las cuchillas de cerámica

Procesamiento de alimentos

Corte sin contaminación para carnes, verduras y productos de panadería.

Las cuchillas de cerámica son importantes en las fábricas de alimentos. Su superficie lisa impide la adhesión de gérmenes y suciedad, lo que ayuda a mantener el área limpia. Muchos trabajadores de alimentos eligen cuchillas de cerámica porque no se oxidan. Tampoco se rompen, incluso con mucha agua o alimentos ácidos. Esto mantiene cada corte limpio y seguro, y ayuda a cumplir con las más altas normas de seguridad alimentaria.

La superficie no reactiva evita la transferencia de sabor y el crecimiento bacteriano.

Las cuchillas de cerámica no se mezclan con los ácidos ni los jugos de los alimentos. Esto conserva el auténtico sabor de la carne, las verduras y el pan. Los chefs y los fabricantes de alimentos utilizan cuchillas de cerámica para eliminar los sabores metálicos. También ayudan a prevenir la propagación de gérmenes. resistencia química Mantiene alejadas las bacterias. Esto las hace ideales para lugares que deben mantenerse muy limpios.

Fácil esterilización y cumplimiento de las normas de seguridad alimentaria.

Las cuchillas de cerámica son fáciles de limpiar. Su superficie lisa permite lavarlas y desinfectarlas rápidamente. A las plantas de alimentos les gusta esto porque les ayuda a seguir estrictas normas de limpieza. Las cuchillas de cerámica se pueden lavar muchas veces y se mantienen afiladas. Esto las convierte en la mejor opción para trabajos de alta complejidad alimentaria.

Nota: Las cuchillas de cerámica ayudan a las máquinas a cortar los alimentos con precisión. Reducen los desperdicios y los costos. Además, mejoran el aspecto y el sabor de los alimentos.

| Aspecto | Detalles |

|---|---|

| Materiales utilizados | Acero inoxidable, acero al carbono, cerámica, otros |

| Razones para el uso de cuchillas de cerámica | Durabilidad, protección contra la oxidación, higiene, seguridad alimentaria, mantenimiento del filo, respeto al medio ambiente, automatización. |

| Impulsores del mercado | Demanda de alimentos procesados, enfoque en la higiene, corte de precisión, expansión de la industria. |

Médica y de laboratorio

Biocompatible y no corrosivo para instrumental quirúrgico y de laboratorio.

Los médicos y el personal de laboratorio necesitan herramientas seguras. Las hojas de cerámica son seguras para las personas y no se oxidan. Cirujanos y científicos las usan cuando no se permite el metal. Su resistencia química significa que no reaccionan con partes del cuerpo ni con líquidos de laboratorio.

Corte de precisión para muestras de tejido y dispositivos médicos

En laboratorios y hospitales, el corte debe ser preciso. Las cuchillas de cerámica realizan cortes limpios y precisos para tejidos y herramientas pequeñas. Su filo fino facilita el trabajo minucioso. Los laboratorios confían en las cuchillas de cerámica para trabajos que requieren el mismo corte en todo momento.

Resistente a productos químicos de esterilización agresivos y al autoclave repetido.

Las cuchillas de cerámica son resistentes a limpiadores fuertes y vapor caliente. Su resistencia química impide que se debiliten o pierdan el filo después de muchas limpiezas. Esto las convierte en una opción inteligente y segura para hospitales y laboratorios.

Las hojas de cerámica gozan de gran confianza en la medicina y los laboratorios. Son seguras, resistentes y facilitan el trabajo.

Electrónica

Cuchillas no conductoras para una manipulación segura de componentes electrónicos sensibles

La electrónica requiere herramientas que no dañen los circuitos. Las cuchillas de cerámica no conducen electricidad. Esto previene cortocircuitos y mantiene las piezas seguras. Los trabajadores las utilizan para cortar cables y placas sin riesgo.

Propiedades no magnéticas y antichispas, ideales para montaje y reparación.

Las hojas de cerámica no producen chispas ni son magnéticas. Esto las mantiene seguras cerca de imanes y en lugares con riesgo de chispas. Los técnicos las utilizan para trabajos cuidadosos que requieren seguridad.

Cortes limpios y sin rebabas para placas de circuitos, cables y películas.

En electrónica, el corte debe ser preciso. Las cuchillas de cerámica realizan cortes suaves y sin asperezas. Su filo dura mucho tiempo, lo cual es ideal para trabajos grandes.

| Característica | Cuchillas Cerámicas | Cuchillas tradicionales Metal (acero inoxidable) |

|---|---|---|

| Nitidez | Filo más fino, más afilado y más duradero. | Requiere afilado frecuente |

| Seguridad eléctrica | No conductor, evita cortocircuitos. | Conductor, riesgo de cortocircuitos. |

| Interferencia magnética | No magnético, sin interferencias. | Metallic, interferencia potencial |

| Idoneidad | Ideal para cortes precisos y delicados en la fabricación de productos electrónicos. | Más versátil para tareas pesadas. |

Textiles y papel

Proporciona cortes limpios y sin deshilachado para telas, telas no tejidas y productos de papel.

Las cuchillas de cerámica son ideales para cortar tela y papel. Realizan cortes suaves sin deshilacharse. Su fina construcción ayuda a cortar materiales blandos como seda y papel fino. Los fabricantes obtienen mejores productos con menos errores.

Alta resistencia al desgaste para operaciones de corte industrial continuo

Las fábricas necesitan herramientas duraderas. Las hojas de cerámica mantienen su filo, por lo que no es necesario cambiarlas con frecuencia. Esto ayuda a los trabajadores a rendir más y a mantenerse seguros.

Reduce el tiempo de inactividad y el mantenimiento en líneas de procesamiento de textiles y papel.

Las hojas de cerámica no se oxidan ni se deterioran con los productos químicos. Cortan bien durante mucho tiempo. Su peso ligero evita que los trabajadores se cansen. Además, no conducen electricidad, lo que las hace más seguras cerca de las máquinas.

- Las hojas muy afiladas ayudan a cortar bien cosas blandas.

- Un filo duradero significa menos cambios de hoja.

- La resistencia al óxido mantiene las cuchillas fuertes en muchos lugares.

- El peso ligero ayuda a que los trabajadores los utilicen durante más tiempo.

Las hojas de cerámica son mejores para trabajos que necesitan cortes limpios, seguridad y menos trabajo.

Personalización

Cuchillas de cerámica personalizadas

Las cuchillas de corte de cerámica personalizadas son importantes para trabajos especiales. Muchas fábricas necesitan cuchillas con formas y tamaños específicos. Esto les ayuda a obtener los mejores resultados. Los fabricantes utilizan máquinas como CNC y láseres para dar forma a las cuchillas. Estas herramientas permiten crear cuchillas de diversas formas, como redondas, rotativas u octogonales. Algunas cuchillas cuentan con recubrimientos especiales, como nitruro de titanio o carbonitruro de titanio. Estos recubrimientos endurecen las cuchillas y prolongan su vida útil. También contribuyen a que las cuchillas funcionen bien en entornos difíciles, como fábricas de alimentos o plantas de envasado.

Los clientes piden cuchillas que corten mejor y se mantengan afiladas por más tiempo. Algunos prefieren logotipos, orificios especiales o mangos fáciles de sujetar. Los materiales de buena calidad, como el dióxido de circonio, garantizan un buen rendimiento y una larga vida útil de las cuchillas. Estas cuchillas personalizadas ayudan a las empresas a ahorrar dinero y a evitar retrasos en el trabajo. También son útiles cuando se requieren cortes intensos.

Las hojas de cerámica personalizadas facilitan la realización de trabajos especiales. Cortan bien, son duraderas y se pueden fabricar para múltiples usos.

Servicios de Nanjing Metal

Nanjing Metal es un fabricante líder de cuchillas de cerámica. Cuenta con más de 20 años de experiencia. La empresa fabrica cuchillas personalizadas para diversos tipos de trabajo. Su equipo puede diseñar cuchillas en diversos tamaños y formas. También se encarga de que las cuchillas se adapten a diferentes máquinas.

Nanjing Metal verifica la calidad en cada paso. Seleccionan materiales de alta calidad y supervisan el trabajo de cerca. Prueban las cuchillas para garantizar su resistencia y resistencia a la oxidación. Su trabajo cumple con las normas de la FDA e ISO 9001, lo que significa que se preocupan por la seguridad y la calidad. Los clientes obtienen buenos precios, ayuda de expertos y respuestas rápidas. Muchos dicen que trabajan más rápido y cambian menos cuchillas gracias a Nanjing Metal.

Elegir la mejor cuchilla de corte depende de lo que necesite cortar, de cuánto dinero esté dispuesto a invertir y del trabajo que desee realizar para su mantenimiento. La siguiente tabla muestra lo que ofrece y lo que sacrifica con cada opción:

| Ventaja | Desventaja |

|---|---|

| Se mantiene afilado por mucho más tiempo | Frágil, puede astillarse si se cae. |

| Resistente a la oxidación y fácil de limpiar. | Más difícil de afilar, mayor coste inicial |

| Ligero, reduce la fatiga. | No apto para tareas pesadas |

Las hojas de cerámica son ideales para trabajos que requieren cortes precisos y limpios. Muchos trabajos especiales utilizan hojas personalizadas para obtener los mejores resultados. Nanjing Metal es una empresa de confianza que fabrica hojas de cerámica para diferentes necesidades. Pueden fabricar hojas a su medida. Si necesita ayuda, puede... póngase en contacto con Un ingeniero de ventas para obtener asesoramiento.

Preguntas frecuentes

¿Qué materiales utilizan las hojas de corte de cerámica?

Las hojas de corte de cerámica están fabricadas con materiales resistentes como el zirconio o la alúmina. Estos materiales son muy resistentes y duraderos. Ayudan a que la hoja se mantenga afilada y no se oxide, incluso en entornos difíciles.

¿Pueden las hojas de cerámica cortar metal o materiales muy duros?

Las hojas de cerámica son mejores para materiales blandos o de dureza media. Funcionan bien con alimentos, telas y aparatos electrónicos. No son adecuadas para cortar metal grueso ni piedra.

¿Cómo deben los usuarios limpiar y almacenar las hojas de cerámica?

Lave las cuchillas de cerámica con agua y jabón suave. Séquelas completamente antes de guardarlas. Guárdelas en un estuche o soporte seguro para que no se astillen ni se rompan.

¿Es seguro utilizar cuchillas de cerámica en el procesamiento de alimentos?

Sí. Las cuchillas de cerámica no se oxidan ni reaccionan con los químicos. Su superficie lisa ayuda a prevenir la propagación de gérmenes. Muchas personas que trabajan en el sector alimentario las usan para mantener la limpieza.

Ver también

Comprensión de las cuchillas perforantes y sus aplicaciones prácticas

Hoja de cerámica vs. hoja de acero: Análisis del rendimiento de corte