Cuchilla Ranuradora para Cartón Corrugado are the main tools for cutting and shaping cardboard in packaging. The type and material of these blades are very important for how well they work and how good the boxes look. Nanjing Metal is a trusted company that makes corrugated carton slotter blades. They have been doing this for twenty years. They give new solutions for modern machines like the automatic flexo printer slotter.

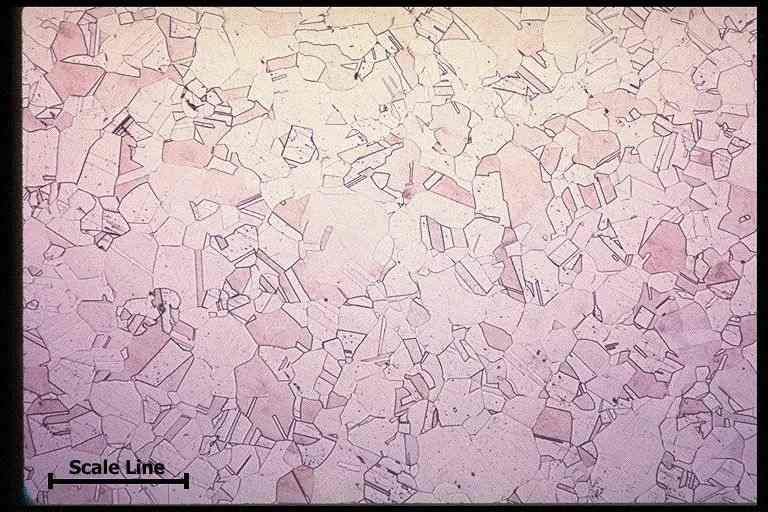

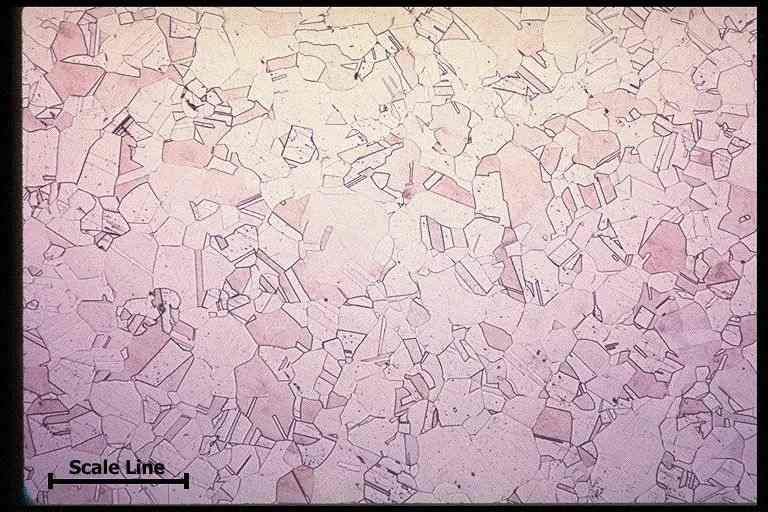

- How long slotter blades last depends on how hard the material is and how carbide particles are spread in the blade.

- Good materials like tungsten steel stop the edges from wearing out, make clean cuts, and help the blade last longer.

Using the right blade and making sure it fits the machine helps make perfect slots and great cartons.

Puntos clave

- Corrugated carton slotter blades cut and shape cardboard. They help make strong boxes with neat folds and slots.

- There are different blade types like male, female, trimming, and spacer. These blades work together to cut, crease, trim, and space slots well.

- Blade materials such as tungsten carbide and high-speed steel matter. They change how sharp, strong, and smooth the blades cut.

- Picking the right blade type and material helps cut better. It also lowers waste and makes boxes last longer.

- Blades need regular care like cleaning and sharpening. This keeps them sharp and stops rough cuts or machine jams.

- Custom and adjustable blades let factories change box sizes fast. This helps them work quicker and make more kinds of boxes.

- Nanjing Metal sells trusted, high-quality slotter blades. They also offer custom solutions for different machines and packaging needs.

- Using the right blades and taking care of them saves money. It cuts down on machine stops, repair bills, and wasted materials.

Corrugated Carton Slotter Blades Overview

What Are Slotter Blades

Slotter blades are special tools for cutting cardboard. People use them in the corrugated packaging industry. These blades cut, slot, and score cardboard sheets. This helps make boxes with the right shapes and sizes. Slotting blades work fast and make clean cuts. There are different types of slotter blades. Some are serrated slotter knives. Others are rotary slotter knives. Some blades are custom-made with different tooth shapes. Blades are made from high carbon steel, high-speed steel, or tungsten carbide. Each material has its own benefits. Some last longer. Others cut more precisely.

Tip: Picking the right slotting blades helps you work faster and makes better cartons.

Main Functions in Slotting

Carton slotter blades do many important jobs:

- Cutting and slotting: They make neat slots and cuts in cardboard. This helps the cardboard fold and fit together.

- Scoring and creasing: The blades make lines for folding the cardboard.

- Perforating: Some blades make small holes or tear lines. This makes boxes easier to open.

- High-speed operation: Slotting blades work in rotary slotter machines. These machines make lots of boxes quickly.

- Versatility: Different blade shapes do different jobs. Some cut straight lines. Others cut curves or waves.

Rotary slotter machines use these blades to make strong, neat carton edges. Machines with new controls can handle many cardboard sizes and thicknesses. This helps meet many packaging needs.

Key Roles in Carton Production

Carton slotter blades are very important for making strong boxes. Good blades, like those made from tungsten carbide, last a long time and cut well. Clean cuts keep the cardboard strong. This stops the box from getting weak. Good slotting helps the box fold easily. This makes the box look nice and last longer.

It is important to take care of slotting blades. Change them when they get dull. This stops problems like rough edges or jams. The design and material of the blades affect how well they work. Good blades help make boxes faster and look better. Trusted companies like Nanjing Metal make reliable blades. This helps businesses make good boxes every time.

Types of Carton Slotter Blades

Male Blades

Male blades are the main tools for cutting in slotting. These slotting knives have sharp, round, or special shapes. They cut through corrugated board very well. The shape of each male blade decides how wide and what shape the slot will be. Operators use these blades to make clean slots. This helps the carton fold and go together easily.

- Male blades work with female blades, which are called scoring anvils. This lets cutting and creasing happen at the same time.

- Makers use tool steel, high-speed steel, and carbide-tipped alloys for male blades. These materials make the blades last long and not wear out fast.

- Heat treatment and careful grinding make each blade sharp and strong.

- Male blades are important for making corrugated boxes, displays, special packaging, and inside dividers.

Straight and Shaped Edges

Male blades have two main edge types: straight and shaped.

- Straight edges make even, rectangle slots. These are used in normal cartons where straight cuts are needed.

- Shaped edges have curves, waves, or special patterns. These let you make different slot shapes for special packaging or custom cartons.

Choosing straight or shaped edges depends on the carton design and what kind of slot is needed. Straight edges are simple and fast. Shaped edges help make creative packaging.

Female Blades

Female blades are also called scoring rules or anvils. They work with male blades in slotting. Their main job is to hold the board and make creases for folding. They do not cut all the way through the board.

Steel and Polyurethane Options

Makers offer female blades in steel and polyurethane.

- Steel female blades are strong and last a long time. They keep their shape and do not wear out quickly.

- Polyurethane female blades are softer. This helps protect the male blade and stops damage to soft carton materials.

Operators pick the material based on the carton type and how long they want the blade to last. Both types make clean creases and good folding lines.

Cuchillas de recorte

Trimming blades are also called razor slitting blades. They do fine cutting and trim the edges of cartons. These blades are not like main slotting knives. They make thin, exact cuts.

Structure Features

Trimming blades are very sharp and thin. Makers use high-speed steel or tungsten carbide to keep them sharp during fast work. The design makes it easy to put them on and change them quickly. This helps the production line run well.

Escenarios de aplicación

Operators use trimming blades in many ways:

- Cutting thin, bendy materials like plastic films, tapes, and light laminates.

- Making narrow edge trims or many thin strips at once.

- Helping fast machines that make light film products.

- Used in flexible packaging, labels, and non-woven fabric work.

Trimming blades are best when you need clean, thin, and exact cuts. They are not good for thick or rough materials.

Ventajas y desventajas

| Ventajas | Desventajas |

|---|---|

| Makes clean, smooth cuts | Not good for thick materials |

| Funciona bien a altas velocidades. | Only for soft, bendy stuff |

| Easy to change and take care of | May need changing often if used on rough stuff |

Trimming blades help keep cartons looking nice by making smooth edges and the right size.

Spacer Blades

Structure Features

Spacer blades are important in the slotting process. These blades help set the space between cutting blades. Each spacer blade keeps a set gap. This gap controls how wide the slot will be. The design makes sure every slot is the right size. Spacer blades are flat, round, and simple in shape. They go between the main cutting blades on the shaft. Most spacer blades are made from strong tool steel or hard alloys. These materials help them last long and keep their shape.

Escenarios de aplicación

Operators use spacer blades in many carton factories. These blades help set the exact slot width for folding and putting boxes together. Getting the slot size right is important for strong boxes that fit well. Spacer blades keep the cutting steady and accurate. They stop the main blades from moving or shaking. This keeps the slots straight and even.

Common uses include:

- Fast automatic slotter machines that need exact slot widths.

- Production lines making cartons in many sizes and shapes.

- Jobs where slot width changes often for custom orders.

- Times when good slot quality is needed for strong, nice-looking boxes.

With spacer blades, workers can quickly change machines for new carton designs without changing the main blades.

Ventajas y desventajas

| Ventajas | Desventajas |

|---|---|

| Makes slots accurate and even | Adds more parts to handle |

| Lets you change slot width fast | Needs careful setup |

| Helps keep cutting steady | Wrong size can hurt quality |

| Lowers wear on main cutting blades | Must fit the machine exactly |

Tip: Spacer blades help the slotting process run well. They make it easy to switch between carton sizes and designs.

Slotting Process and Blade Configurations

Rotary and Arc-Shaped Blades

Structural Features

Rotary slotter blades are round and spin very fast. They are made from strong metals like tool steel or tungsten carbide. These blades stay sharp after many uses. Arc-shaped slotter blades have a curved edge. This curve matches the wavy part of corrugated cardboard. The special shape lets the blade follow the cardboard closely. Both blade types work in automatic flexo printer slotter machines. These machines need blades that cut quickly and exactly.

Escenarios de aplicación

Rotary slotter blades are used in busy factories. These factories make thousands of boxes each day. Arc-shaped blades are best for cutting wavy corrugated cardboard. The curved edge helps the blade move smoothly through the board. This is important when conveyor belts move fast. Many packaging plants pick these blades for their machines. They work well with different box sizes and shapes.

Impact on Slotting Quality

Arc-shaped slotter blades make cutting easier by lowering resistance by over 30%. The curved edge stops chipping and keeps the blade sharp longer. Machines can run faster than 120 meters per minute. The blades control groove depth with only ±0.1mm error. This means every box has neat, even slots. Rotary slotter blades also help make clean cuts. When used with advanced machines, they make strong, neat cartons that fold well and look good.

Tip: Picking the right rotary slotter blades helps factories work faster and spend less on repairs.

Serrated and Crescent Teeth

Structural Features

Serrated rotary slotter blades have a jagged edge like a saw. This helps them grip and cut tough, fibrous materials. Crescent teeth blades have a wavy, curved edge. The curve makes smooth, gentle cuts, good for soft materials. Both blade types use metals that do not rust, like 440C stainless steel. This helps them last longer and stay safe.

Escenarios de aplicación

- Serrated rotary slotter blades are best for cutting thick, fibrous cardboard. The jagged edge cuts through many layers.

- Crescent teeth blades are good for cutting curves in packaging. They work on cardboard and softer materials.

- Both blade types fit in automatic flexo printer slotter machines. This makes them popular in modern factories.

- Factories that need exact and flexible slotting often use these blades.

Impact on Slotting Quality

Serrated rotary slotter blades cut with high accuracy. The teeth hold the material and stop slipping. This makes straight, even cuts. Crescent teeth blades control slot depth and stop the material from getting stuck. Both blade types keep cutting smooth and exact. The ±0.1mm tolerance means every box meets high standards. Operators see fewer rough edges and less waste. This makes cartons look better and stay strong.

Compatibility with Automatic Flexo Printer Slotter Machines

Both serrated and crescent teeth rotary slotter blades work well in automatic flexo printer slotter machines. These machines need blades that can go fast and change for new box designs. The special blade designs help with quick changes and steady work. One big benefit is that these machines can use many blade types for different jobs. This helps factories handle new orders and keep quality high.

Upper and Lower Knife Combinations

Structural Features

Upper and lower knife combinations use two rotary slotter blades together. The upper blade cuts from the top. The lower blade supports from below. This makes a scissor-like action. The blades are made to fit each other perfectly. They often use hard steel or carbide tips to last longer. The close fit gives clean, exact cuts every time.

Escenarios de aplicación

Operators use upper and lower knife combinations for slotting and scoring. These blades are common in automatic flexo printer slotter machines. The setup works for both straight and curved slots. Factories that switch box styles often use this combination. The blades can cut thick cardboard or thin paperboard.

Impact on Slotting Quality

The scissor action gives smooth, even cuts. The tight fit stops tearing and keeps slot edges clean. This setup also lowers the chance of jams or crooked slots. Operators see fewer mistakes and less waste. The boxes fold easily and keep their shape. Good slotting and scoring make boxes stronger and look better.

Custom and Adjustable Heads

Structural Features

Custom and adjustable heads help carton makers control the slotting process better. These heads let workers move rotary slotter blades without stopping the machine. Operators can change the blade’s position, angle, or depth fast. Each head holds one or more rotary slotter blades. The heads can slide on a guide rail or turn to different angles. Some designs use quick clamps or digital controls for easy changes. The frame is made from strong steel and uses smooth bearings. This keeps the rotary slotter blades steady when running fast. Custom heads can hold special blade shapes or sizes. This is good for making unique packaging.

Escenarios de aplicación

Custom and adjustable heads are great for factories making many box types. Workers use these heads to switch jobs quickly. For example, a plant might make small cartons in the morning and big boxes later. Adjustable heads let workers change the setup in just a few minutes. This helps companies fill urgent orders and waste less time.

Factories with automatic flexo printer slotter machines get the most from these heads. The machines can use different rotary slotter blades for each job. Custom heads help make boxes with special slots, curves, or holes. Some plants use adjustable heads to try new packaging ideas before making lots of boxes. This saves time and cuts down on waste.

Note: Custom and adjustable heads help factories make many kinds of boxes in small amounts. This helps them keep up in a fast-changing market.

Impact on Slotting Quality

Custom and adjustable heads make slotting better in many ways. They keep rotary slotter blades in the right spot for clean cuts and neat slots. Operators can adjust the blades to match the cardboard’s thickness and type. This stops rough edges and keeps slots the right size.

When used with an automatic flexo printer slotter, these heads let workers make changes while the machine runs. The machine can swap rotary slotter blades or change settings right away. This keeps production smooth and makes sure every box is high quality. Custom heads also help blades last longer by lowering stress and wear.

Tip: Companies wanting to work faster and make better boxes should use custom and adjustable heads for their rotary slotter blades.

Quality and Performance Comparison

Precisión de corte

Factors Affecting Cutting Precision

Cutting precision is very important for making good cartons. Many things affect how well a slotter blade can cut. The sharpness of the blade edge matters a lot. The blade material is also important. The way the blade is lined up in the machine helps too. Operators need to think about how fast the machine goes. They also need to know what kind of material they are cutting. If the blade gets dull or is not lined up right, cuts can be rough or uneven. This makes the finished carton look worse.

Comparison of Blade Types (Male, Female, Trimming, Spacer)

Each blade type helps with cutting precision in its own way:

- Male blades do most of the cutting. They make straight or shaped slots. When sharp and lined up, they cut with high accuracy.

- Female blades act like anvils or scoring rules. They help make clean creases for folding. This helps the carton stay precise.

- Cuchillas de recorte are thin and sharp. They trim edges and make smooth, exact cuts on thin materials.

- Spacer blades keep the right space between cutting blades. This makes sure every slot is the right width and keeps the carton design the same.

Using the right mix of these blades helps operators get better slots and waste less material.

Impact of Material Quality on Precision

The quality of the blade material affects how well it cuts. The table below shows how different materials change performance:

| Aspecto | Evidence & Impact |

|---|---|

| Tipo de material | HSS blades bend and take hits well, good for soft materials. |

| Carbide blades (~90 HRC) are tough and last longer on hard stuff. | |

| Durabilidad | Carbide blades last up to 10 times longer than steel blades. |

| Precisión de corte | Carbide-tipped blades cut 15% more precisely than HSS blades. |

| Blade Sharpness & Wear | Worn blades make 25% more mistakes; keeping blades sharp is key. |

| Advanced Coatings | TiN and DLC coatings help blades stay sharp and last longer. |

| Manufacturing Tech | CNC and laser cutting make blades more exact, about 20% better. |

| Seguro de calidad | ISO 9001 suppliers make production 15% more accurate. |

Typical Issues and Solutions

Many things can hurt cutting precision in slotter blades. Operators often see problems like dull edges, chipping, cracking, and rust. Here are some common problems and fixes:

- Dull edges make cuts worse and slower. Sharpen blades often to keep the right angle.

- Chipping and cracking happen from stress or rough handling. Handle blades with care and run machines at the right speed.

- Rust makes blades weak. Use anti-rust coatings and store blades in dry places.

- Wrong feed rates and bad alignment cause rough cuts and wear. Follow the maker’s rules and check alignment often.

- Overheating can bend or break blades. Use coolants or let blades cool down.

- Using the wrong blade for the material wears it out faster. Always pick the right blade for the job.

Early warning signs are rough cuts, more noise, and visible wear. Check and care for blades often to keep them working well and cartons looking good.

Resistencia al desgaste

Material Hardness and Coating Technologies

Wear resistance helps blades work well and keep cartons strong. Hardness helps blades fight wear and stay sharp. Carbide-tipped slotter blades last longer than steel blades. Special coatings like DLC and TiN make blades harder and reduce friction. These coatings help blades last longer and need less sharpening. New ways of making blades, like CNC machining, also help blades last and cut better.

Blade Type Durability Comparison

- Carbide-tipped blades stay sharp longer and need fewer changes.

- High-speed steel (HSS) blades are tough and good for soft materials.

- Blades with special coatings last longer and resist wear better.

- Trimming blades are thin, so they may need changing more if used on rough stuff.

Picking the right blade for the material and speed helps blades last and keeps cartons good.

Maintenance Practices to Enhance Wear Resistance

Taking care of blades helps them last and cut well. Operators should:

- Clean blades after use to stop dirt and rust.

- Check blades often for wear, chips, or dullness.

- Sharpen blades with the right tools to keep the edge angle.

- Use coatings or oil as needed.

- Store blades in dry, safe places to stop rust and damage.

Good care means less downtime and steady carton making.

Signs of Wear and Replacement Indicators

Operators should look for these signs to know when to fix or change blades:

- Cuts are rough or jagged on the carton.

- The machine makes more noise or shakes more.

- You see rust, cracks, or chips on the blade edge.

- The blade does not cut well or jams more often.

Fix blades if the damage is small and cheap to repair. Change blades if they are unsafe or work badly.

Rentabilidad

Initial Investment vs. Long-Term Value

Buying good slotter blades costs more at first but saves money later. Strong blades need fewer changes and less fixing. Factories have less downtime and make more boxes, which helps them earn more.

Blade Lifespan and Replacement Frequency

Disc slitting blades last from weeks to months if used all the time. The material, machine speed, and care affect how long blades last. Good care, right alignment, and using the right blade for each job help blades last longer and keep cartons good.

Cost Comparison by Material and Type

- Carbide-tipped blades cost more but last up to 10 times longer than steel blades.

- HSS blades are cheaper but need changing more often.

- Blades with special coatings balance cost and lasting power.

- Picking the right blade for the job helps control costs and keeps cartons good.

Impact of Maintenance on Overall Cost

Regular care and changing worn blades help control costs. Factories that buy strong blades and take care of them spend less on repairs and have fewer delays. Changing blades too often means more downtime and higher costs. By picking good blades from a trusted maker, companies can work better and save money over time.

Suitability for Production Environments

Adaptability to High-Volume Production

Slotter blades need to work well in busy factories. These factories make lots of cartons every day. Machines run for many hours without stopping. Blades made from high-carbon steel or tungsten carbide stay sharp and strong. This means workers do not have to change blades often. Less downtime helps the factory keep making boxes fast. The right blade shape also helps cut waste and keeps carton edges neat. Many companies make blades for these busy places. Their long experience helps them make blades that work well and last long.

Performance in Different Carton Materials

Slotter blades must cut many kinds of cardboard. Some boxes use thick, double-wall board. Others use thin, single-wall board. Good slotter blades have special angles and tooth shapes. These features protect the flute inside the carton and keep it strong. Makers often change blades to fit the thickness and flute type of each box. This helps make smooth, clean cuts and better boxes. People who use these blades say they work well on all types of corrugated board. This helps with both normal and special packaging.

Compatibility with Modern Slotter Machines

Modern slotter machines, like automatic flexo printer slotters, need blades that fit just right. The blades must match the machine’s size and speed. Makers like Nanjing Metal design blades for many top machine brands. Their team uses new technology to make sure every blade is high quality. This makes it easy for workers to switch jobs fast and keep the machines running smoothly. Good blades help keep cartons looking nice, even when machines go fast or cut tricky shapes.

Environmental and Safety Considerations

Factories want to be safe and protect the environment. Good slotter blades make less dust and waste when cutting. Cleaner cuts mean less scrap and a safer place to work. Blades made from strong materials last longer, so workers do not need to replace them as much. This means less metal waste. Some makers use coatings that stop rust and do not give off bad chemicals.

Tip: Picking the right slotter blade makes better boxes, helps the factory work faster, and keeps everyone safe and healthy.

Choosing the Right Carton Slotter Blades

Assessing Production Needs

Picking the right slotter blade starts with knowing what your factory needs. Every packaging line is different and has its own needs. Operators must think about a few things before choosing a blade.

- Keep the plant at the right temperature. This helps the cardboard stay strong and form well.

- Watch the tension during production. This keeps cartons flat and stops them from bending.

- Control how much glue you use. This saves money and keeps cartons stable.

- Check the moisture in the paper and finished cartons. This stops problems like cartons getting too soft or too hard, which can hurt the final packaging.

Operators should also look at how fast the line runs. Fast lines need blades that stay sharp even with lots of use. Every carton needs to be cut with care so all the slots are the same size. This keeps products safe and cuts down on waste. If the line makes many carton sizes or uses different materials, it needs flexible blades. Blades that last longer and are easy to care for help keep the line running.

Matching Blade to Material and Volume

The blade type should fit the carton material and how many boxes you make. Thick or double-wall cartons need blades made from tool steel or cemented carbide. These blades do not wear out fast and stay sharp longer. If you make lots of boxes, pick blades with special coatings. These coatings help blades last longer and cut smoother. For lighter cartons or small jobs, high-speed steel blades can save money.

Operators also need to think about what kind of cut they want. Straight blades are good for normal cartons. Shaped or serrated blades are better for special packaging. Using the right blade for the carton material makes clean cuts and strong edges. This helps keep quality high for every box you make.

Tip: Always check if the blade works with your slotter machine. The right blade helps you waste less and work faster.

Maintenance and Replacement

Taking care of slotter blades helps them work well. Operators should clean blades after each shift to get rid of dust and glue. Look at the blades for dull spots or chips. Sharpen blades when needed to keep them cutting well. Change blades if they have cracks, rust, or cannot stay sharp.

Opciones de personalización

Every packaging factory has its own needs. Regular slotter blades do not always work best. Custom blades let factories pick features that fit their machines and box designs. Top makers like Nanjing Metal, also called Maxtor Metal, have helped the corrugated carton industry for 20 years by making special blades.

Nanjing Metal’s team works with customers to make blades that fit just right. They let you choose the blade’s material, shape, and size. This makes sure each blade works well in its job and meets high standards for quality and speed.

The table below shows how picking different blade features can help:

| Customization Aspect | Descripción | Production Benefit |

|---|---|---|

| Material de la Cuchilla | You can pick high carbon steel, stainless steel, alloy steel, or ceramic. | The right material helps the blade last longer and cut better for your boxes. |

| Geometría de la hoja | You can get straight, serrated, or angled edges, plus special shapes and sizes. | This helps the blade cut more accurately for different box types. |

| Blade Size | Blades can be made to fit your machine and box size. | This means less waste, fewer problems, and less time lost. |

| Material Selection Strategy | You can balance how sharp, strong, and costly the blade is for each job. | This helps the blade last longer and work better for your needs. |

Tip: Custom slotter blades help factories waste less, make better slots, and keep machines working well.

Nanjing Metal is a trusted corrugated carton slotter blade maker. They offer many cuchillas industriales personalizadas. Their team uses new technology and strict checks to make strong, reliable blades for any job. Customers can send in drawings or samples to get blades made for their own machines and box styles.

Custom blades also help factories change quickly for new box trends or rush orders. Workers can switch between box sizes or materials without losing speed or quality. This helps companies stay ahead in a fast market.

Applications in Automatic Flexo Printer Slotter

Compatibilidad de la máquina

Automatic flexo printer slotter machines need blades that fit just right. The slotter blades must match the machine’s size and speed. They also need to meet the machine’s specific needs. Makers design these blades for many types of automatic flexo printer slotter machines. This means factories can use the same good blades on different machines.

Some important things to check are:

- Blade material, like tungsten carbide or tungsten steel, makes blades strong and accurate.

- Blade size matters for making neat slots and folds in boxes.

- You can get regular or custom blades for special jobs.

- Blades should work smoothly with the machine for easy use.

Eficiencia de producción

Factories with automatic flexo printer slotter machines can make boxes fast and well. Slotter blades help by cutting cleanly and quickly. Good blades stop rough edges and tears, so there are fewer stops and less waste. Special coatings and strong materials, like high-grade alloy steel, help blades last longer and cut more boxes before changing.

Workers can change blades fast in new machines. This lets them switch between box sizes or styles quickly. It saves time and keeps the line moving. These machines can watch blade performance and control it closely. This means every slot and fold is neat, even when making lots of boxes.

Some big benefits of automatic flexo printer slotter machines are:

- Faster box making.

- Better looking cartons.

- Lower repair costs.

- Less wasted material.

Industry Trends

The corrugated packaging world is changing with new tech and green ideas. New slotter blade designs use eco-friendly materials and save energy. Some makers now use materials that are better for the planet. This helps companies follow green rules.

Smart systems and data tools are now common in factories. These let workers see how blades are doing at any time. Fast blade changes help workers handle new orders or box styles without waiting. New slotting and scoring blades cut more exactly, so boxes look better and there is less waste.

Picking the right slotter blade type, material, and setup helps make good cartons. When workers know about these choices, they get smoother cuts and work faster.

Preguntas frecuentes

What are corrugated carton slotter blades used for?

Corrugated carton slotter blades cut and crease cardboard sheets. These blades help make neat slots and folds. This makes boxes strong and shaped right for packaging.

How do I choose the right slotter blade material?

Operators pick blade material by carton thickness and speed. They also think about how long the blade should last. Tungsten carbide and high-speed steel stay sharp for big jobs.

Can slotter blades be customized for special machines?

Yes. Top makers like Nanjing Metal offer custom industrial blades. These blades fit special machines and packaging needs.

How often should slotter blades be replaced?

How often you change blades depends on use and care. Operators should check blades often. If a blade is dull or broken, replace it fast to keep cartons good.

What is the difference between male and female slotter blades?

Male blades do most of the cutting work. Female blades, called scoring rules, help with folding. Both blades work together for neat slots and creases.

How does blade maintenance affect production efficiency?

Cleaning, sharpening, and changing blades on time keeps them sharp. Good care helps machines run well and makes better cartons. This means less downtime and better results.

Ver también

La Guía Esencial de las Cuchillas Ranuradoras Rotativas en el Embalaje

Cómo Extender la Vida Útil de Sus Cuchillas Ranuradoras de Cartón: Consejos y Trucos de Expertos

Slotter Blades & Knives For Corrugated

Qué son las Cuchillas de Embalaje Corrugado y Sus Aplicaciones Industriales