The top 10 Cuchillas Cortadoras de Granulador makers are the best in 2025. Picking a top blade maker helps companies get exact cuts. It also helps blades last longer and keeps work running well. These top suppliers care about good products and new ideas. They also give strong help to customers. Each maker has many pelletizer cutter blade choices. Some even make custom blades for specific needs. Many have important industry certificates. They send blades to many countries. For special help or big orders, readers can póngase en contacto con Un ingeniero de ventas hoy.

Puntos clave

- The best pelletizer cutter blade suppliers give strong, safe, and good blades. These blades help make better pellets and help machines work well.

- You should pick suppliers with good certifications like ISO 9001 and CE. These show the blades are high quality and safe to use.

- Many suppliers let you choose custom blades. You can pick different shapes, materials, and coatings for your machine and needs.

- Good suppliers tell you prices clearly and send orders quickly. They also help after you buy, with warranties and technical support.

- Taking care of blades and picking the right material and coating helps blades last longer. This also saves you money in the long run.

Tabla comparativa

Key Features Overview

Picking the best pelletizer cutter blade is important. You need to think about a few key things. Top companies make blades that last a long time. They also help stop resin from building up. These blades are safer for workers to use. Good features keep pellets high quality. They also help machines work without stopping a lot. The table below shows how top brands compare:

| Supplier/Brand | Vida útil de la cuchilla | Resin Build-up Reduction | Características de seguridad | Efficiency Improvements |

|---|---|---|---|---|

| Vecoplan, LLC | Up to 16x standard | Sí | Enhanced blade guards | High throughput, low downtime |

| Coperion GmbH | Up to 18x standard | Sí | Quick-change system | Consistent pellet size |

| Diamond America | Up to 15x standard | Sí | Ergonomic design | Reduced maintenance |

| MAAG Group | Up to 20x standard | Sí | Safety interlocks | Stable operation |

| American Cutting Edge | Up to 17x standard | Sí | Minimal exposure design | Reliable pellet uniformity |

| Baucor | Up to 16x standard | Sí | Tool-less replacement | Smooth pellet flow |

| Sollex | Up to 14x standard | Sí | Protective covers | Fast changeover |

| Nanjing Metal Industrial CO., Limited | Up to 18x standard | Sí | Operator-friendly design | Clean cuts, efficient output |

| Rowe Equipment, Inc. | Up to 15x standard | Sí | Safety handles | Consistent performance |

| Reduction Engineering Scheer, Inc. | Up to 19x standard | Sí | Blade lock system | High efficiency |

Note: How long a blade lasts and how well it works matter a lot. The best blades stay sharp and do not get sticky. They are also safe to change.

Locations and Certifications

Blade makers are in many different places. They have different certificates too. These things change how easy it is to get blades. They also show if the blades are good quality. The table below lists where each company is and what certificates they have:

| Supplier/Brand | Headquarters Location | Major Certifications | Global Supply Coverage |

|---|---|---|---|

| Vecoplan, LLC | USA, Germany | ISO 9001, CE | North America, Europe |

| Coperion GmbH | Alemania | ISO 9001, ISO 14001 | Worldwide |

| Diamond America | EE.UU | ISO 9001 | North America, Europe |

| MAAG Group | Switzerland | ISO 9001, CE | Global |

| American Cutting Edge | EE.UU | ISO 9001 | Americas, Europe |

| Baucor | USA, Germany, UK | ISO 9001, CE | Global |

| Sollex | Sweden | ISO 9001 | Europe, Asia |

| Nanjing Metal Industrial CO., Limited | China | ISO 9001, SGS | Asia, Europe, Americas |

| Rowe Equipment, Inc. | EE.UU | ISO 9001 | North America |

| Reduction Engineering Scheer, Inc. | EE.UU | ISO 9001, CE | Global |

Tip: Always look for ISO 9001 and CE certificates. These show the company cares about safety and quality.

If you want more info or a price, you can contact a sales engineer.

Top Manufacturers

Vecoplan, LLC

Descripción general

Vecoplan, LLC is a top company for industrial blades. They are known for making strong blades for cutting and recycling. Vecoplan works hard to make better blades with new ideas.

Main Pelletizer Cutter Blade Products

Vecoplan has many pelletizer cutter blade choices. They sell rotor knives, bed knives, and custom blades. These blades work for both plastic and wood pelletizing.

Unique Strengths

Vecoplan puts money into research to make blades cut better. They use strong tool steels and special heat treatments. Their blades help machines run longer with less stopping. Vecoplan also helps customers after they buy blades.

Contact Information

- Website: https://www.vecoplanllc.com

- Phone: +1 336-861-6070

- Email: [email protected]

Coperion GmbH

Descripción general

Coperion GmbH is one of the biggest blade makers in the world. They make blades for compounding and extrusion systems. Their blades work well in tough places.

Main Pelletizer Cutter Blade Products

Coperion makes blade sets for underwater, strand, and dry-cut pelletizers. Their blades help make pellets the same size and last longer.

Unique Strengths

Coperion uses special metals and coatings to make blades stronger. They have ISO 9001 and ISO 14001 certificates. Their team can make custom blades for special jobs.

Contact Information

- Website: https://www.coperion.com

- Phone: +49 711 897 0

- Email: [email protected]

Diamond America

Descripción general

Diamond America is good at making extrusion and pelletizing equipment. Their blades meet high quality rules.

Main Pelletizer Cutter Blade Products

Diamond America makes blade assemblies with rotary and stationary knives. Their blades fit many pelletizer types.

Unique Strengths

Diamond America designs blades that are easy to use and change. Their blades help workers stay safe and save time on repairs. They also make custom blades for different needs.

Contact Information

- Website: https://www.diamondamericacorp.com

- Phone: +1 330-535-3330

- Email: [email protected]

MAAG Group

Descripción general

MAAG Group is a big name for blades and pelletizing systems. They help the plastics, chemical, and food industries.

Main Pelletizer Cutter Blade Products

MAAG Group makes blades for underwater, strand, and dry-cut pelletizers. They offer both regular and custom blade options.

Unique Strengths

MAAG Group uses careful engineering and checks quality closely. Their blades help machines run smoothly and last a long time. MAAG also teaches customers and helps after sales.

Contact Information

- Website: https://www.maag.com

- Phone: +41 52 728 8000

- Email: [email protected]

American Cutting Edge

Descripción general

American Cutting Edge has been making blades for a long time. They sell blades for plastics, recycling, and food.

Main Pelletizer Cutter Blade Products

American Cutting Edge sells blade sets with rotary and bed knives. Their blades fit many pelletizer brands.

Unique Strengths

They use strong materials and special heat treatments. Their blades cut well and make even pellets. American Cutting Edge ships fast and answers customer questions quickly.

Contact Information

- Website: https://www.americancuttingedge.com

- Phone: +1 888-543-6860

- Email: [email protected]

Baucor

Descripción general

Baucor is a worldwide supplier of blades and custom tools. They help customers in plastics, packaging, and medical fields.

Main Pelletizer Cutter Blade Products

Baucor makes blades for strand, underwater, and hot-face pelletizers. Their blades come in many shapes and sizes.

Unique Strengths

Baucor grinds blades carefully and checks quality. They let you change blades without tools and fill custom orders fast. Baucor has ISO 9001 and CE certificates.

Contact Information

- Website: https://www.baucor.com

- Phone: +1 949-614-5830

- Email: [email protected]

Sollex

Descripción general

Sollex is a Swedish company that makes blades for plastics and film. They sell blades in Europe and Asia.

Main Pelletizer Cutter Blade Products

Sollex gives pelletizer cutter blade sets for granulators and pelletizing machines. Their blades are sharp and last a long time.

Unique Strengths

Sollex uses high-speed steel and special coatings to make blades last. They offer covers for safety and quick blade changes. Sollex can make both regular and custom blades.

Contact Information

- Website: https://www.sollex.se

- Phone: +46 35 15 75 00

- Email: [email protected]

Nanjing Metal Industrial CO., Limited

Descripción general

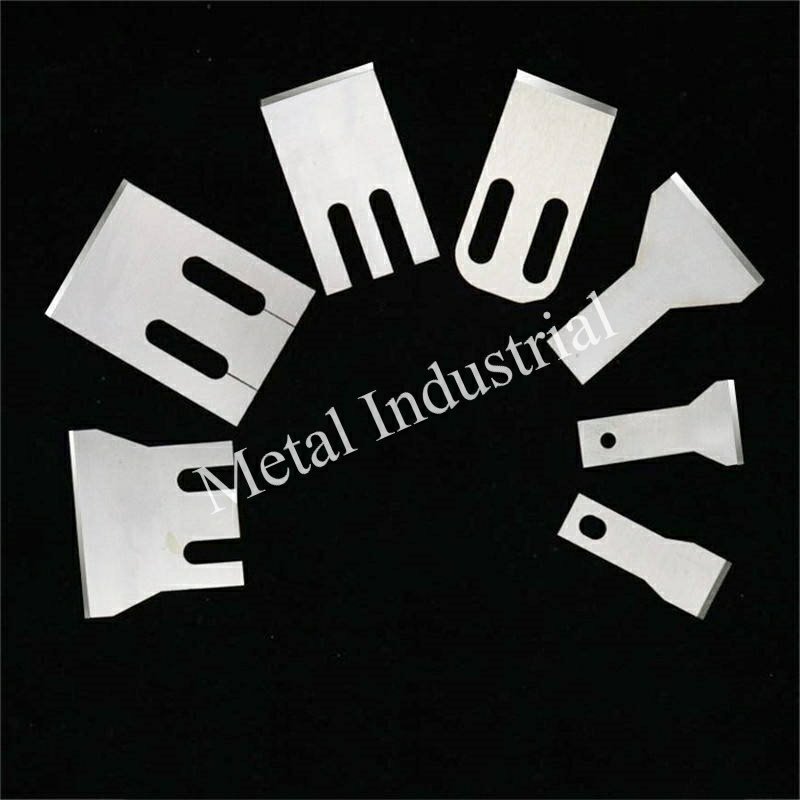

Nanjing Metal Industrial CO., Limited is a trusted blade supplier for plastic recycling and making. They help with pelletizing, compounding, and masterbatch jobs.

Main Pelletizer Cutter Blade Products

Nanjing Metal sells Plastic Pelletizer Blades for many machines. They have rotor knives, stator knives, and custom blades for special systems.

Unique Strengths

Nanjing Metal uses strong materials like SK2, HSS, M2, and SKD11. They heat treat blades to make them hard. Some blades have coatings to make them even tougher. Nanjing Metal lets customers order custom blades from drawings or samples. They check quality at every step. Customers get good prices, easy buying, and fast delivery in 7 to 20 days.

Note: Nanjing Metal Industrial CO., Limited has ISO 9001 and SGS certificates. This shows they care about quality and customers.

Contact Information

- Website: https://www.maxtormetal.com

- Correo electrónico: [email protected]

- Contact a sales engineer

Rowe Equipment, Inc.

Descripción general

Rowe Equipment, Inc. sells blades and parts for plastics and process companies. They focus on good quality and quick shipping.

Main Pelletizer Cutter Blade Products

Rowe Equipment sells blade sets with rotary and bed knives for many pelletizer models.

Unique Strengths

Rowe Equipment uses strong materials and careful machining. They add safety handles and make sure blades work well. Rowe Equipment gives advice and ships orders fast.

Contact Information

- Website: https://www.roweequipment.com

- Phone: +1 713-462-8406

- Email: [email protected]

Reduction Engineering Scheer, Inc.

Descripción general

Reduction Engineering Scheer, Inc. is a well-known name in pelletizing. They design and make blades for big jobs.

Main Pelletizer Cutter Blade Products

Reduction Engineering Scheer sells blade sets for underwater and strand pelletizers. Their blades work for both regular and custom uses.

Unique Strengths

They use special metals and blade lock systems for safety and speed. Reduction Engineering Scheer helps customers with support and service. Their blades work well and last a long time.

Contact Information

- Website: https://www.reductionengineering.com

- Phone: +1 330-665-2931

- Email: [email protected]

Experts say the best blades come from companies that care about design, materials, and control. These companies use new metals and coatings to make blades last longer. Their focus on quality and helping customers makes them stand out.

Want to learn more or get a price? Contact a sales engineer at Nanjing Metal Industrial CO., Limited for help.

How to Choose a Pelletizer Cutter Blade Supplier

Picking the right supplier is very important. It helps your pelletizing work run smoothly and reliably. Companies should look at a few things before choosing. This makes sure they get cutting tools that work well and last a long time.

Quality Standards

Industry Certifications and Compliance

Industry certifications show a supplier cares about safety and quality. Many top suppliers have ISO 9001 and SGS certificates. TUV and SGS certificates mean blades meet world rules. Suppliers use good materials like D2, 1.2379, and SKD11. They can also change how hard or exact the blades are. These steps make sure blades cut well and last long.

Raw Materials and Manufacturing Processes

The materials used in blades matter a lot. Good suppliers use high-speed steel, tool steel, and strong alloys. They heat treat blades and add special coatings. This helps blades last longer and cut better. They check quality during every step. This makes sure each blade works well for tough jobs. Suppliers who use new ways to make blades keep them sharp and strong.

Product Testing and Quality Assurance

Quality checks happen at every step. Suppliers look at materials, watch the making process, and test finished blades. They check if blades are hard and the right size. This makes sure blades cut well every time. Companies that give test reports and follow world rules care about quality.

Reputation and Customer Feedback

A supplier’s reputation shows if they are reliable. High ratings and good reviews mean customers are happy. Some suppliers have store ratings over 4.7 out of 5. They also deliver on time more than 97% of the time. These numbers help buyers find good partners for custom industrial blades.

Pricing and Value

Transparent Pricing Structure

Clear prices help buyers plan and avoid surprises. Good suppliers give quotes that show material, treatments, and extra costs. Being open about prices builds trust and helps long-term deals.

Costo vs. Valor a largo plazo

The cheapest blade is not always best. Buyers should think about how long blades last and how well they cut. Good blades may cost more at first but save money later. They need less fixing and fewer replacements. This gives better value over time.

Bulk Order Discounts and Payment Terms

Many suppliers give discounts for big orders. They also offer easy ways to pay. These choices help buyers save money, especially for custom industrial blades used all the time.

Price Comparison with Competitors

Looking at prices from different suppliers helps buyers get good deals. Buyers should check not just price but also what comes with it. Things like quality checks and help after buying matter too.

Lead Time and Delivery

Standard Production and Delivery Times

Good suppliers tell you how long making and shipping will take. Most orders take one to three weeks, depending on size and custom needs. Knowing this helps companies plan their work.

Flexibility for Urgent or Custom Orders

Sometimes, companies need blades fast or in special shapes. Top suppliers can rush orders and ship quickly. They also make custom industrial blades for special machines or jobs.

Shipping Methods and Logistics Support

Good shipping means blades arrive safe and on time. Suppliers often help with customs and give tracking numbers. This makes buying easier and avoids delays.

On-Time Delivery Record

Suppliers with high on-time delivery rates are reliable. They help customers avoid problems and keep work going.

Opciones de personalización

Availability of Non-Standard Sizes and Shapes

Pelletizer cutter blades come in many shapes and sizes. Suppliers offer straight, slanted, V-shaped, round, and custom blades. This lets buyers pick what fits their machines best.

Material and Coating Customization

Buyers can pick from high-speed steel, SKD11, carbide, and other steels. Coatings like titanium nitride, chromium, and diamond-like carbon make blades harder and stop rust. These choices help custom industrial blades work better.

Engineering and Technical Support for Custom Projects

Suppliers help with custom projects. They look at drawings, samples, or needs to design the right blade. This makes sure cutting tools fit the job.

Minimum Order Quantities for Customization

Some suppliers need a minimum order for custom industrial blades. Buyers should check this before ordering to make sure their needs are met.

Customization Table:

| Customization Aspect | Available Options / Details |

|---|---|

| Blade Shapes | Straight, Slanted, V-shaped, Circular, Custom shapes, Rotor/Stator types |

| Materiales | High-Speed Steel (HSS), SKD11, Carbide, Tool Steel, D2, Alloy Steel, Powder Metallurgy Steels (e.g., CPM 10V) |

| Tratamientos de superficies | Heat Treatment, Coatings such as Titanium Nitride, Chromium, Diamond-Like Carbon (DLC) |

| Precision & Tolerances | High precision manufacturing with specific cutting angles and clearances |

| Customization Services | OEM/ODM services; customization based on drawings, samples, or specific pelletizer brands |

After-Sales Support

Warranty and Replacement Policies

Good after-sales support means clear warranty and replacement rules. Many suppliers give a one-year warranty and lifetime service for industrial blades. This protects buyers from bad blades and keeps them working.

Technical Assistance and Troubleshooting

Suppliers help before and after delivery. They give tips before shipping, help with setup, and fix problems. Fast expert help means less downtime and better cutting.

Spare Parts Availability

Good suppliers keep track of what customers buy. They send spare parts when needed. This keeps pelletizing work running well.

Response Time and Customer Service Quality

Quick replies show good customer service. Many suppliers answer in one working day. High ratings, like 5.0 or 4.7 out of 5, show they care about quality and support.

🛠️ Consejo: Pick suppliers with good after-sales service, technical help, and spare parts. These things help you succeed with custom industrial blades for a long time.

For more info or to talk about custom industrial blades, contact a sales engineer at Nanjing Metal Industrial CO., Limited.

Pelletizer Cutter Blade Selection Tips

Material and Coating Choices

Picking the right material for pelletizer cutter blades is important. Makers use strong metals like D2 steel and tungsten carbide. These metals help blades last longer and not wear out fast. Non-stick coatings stop stuff from sticking to the blade. This keeps cutting smooth and helps machines work without stopping. Some coatings, like titanium nitride, make blades harder and stop rust. Some jobs need heat-resistant or serrated knives for special materials. Using the best mix of metal and coating helps blades last longer and make better pellets.

Tip: Non-stick coatings help you clean blades faster and keep them sharp for a long time.

Compatibility with Machines

Pelletizer cutter blades need to fit the pelletizing machine. The right blade shape and size help make even cuts and same-size pellets. Special knives are made for things like rubber or hot plastics. Custom industrial blades can fit special machines or jobs. Blades that are easy to put in or take out save time on repairs. Always check your machine’s rules before picking a blade.

| Machine Type | Recommended Blade Type | Característica clave |

|---|---|---|

| Strand Pelletizer | Straight or serrated blades | Consistent pellet size |

| Underwater Pelletizer | Heat-resistant blades | Withstand high temperatures |

| Die-Face Pelletizer | Non-stick coated blades | Reduce material buildup |

Mantenimiento y longevidad

Taking care of blades helps them work well. Clean blades after using them to stop stuff from building up. Check for damage or dullness to keep pellets even. Oil moving parts to stop wear and help blades last. If blades get dull or sticky, clean them or change machine settings. Buying good blades means you do not have to replace them often and saves money over time.

🛠️ Checking and cleaning blades often keeps them cutting well and makes them last longer.

Picking a trusted blade supplier helps your machines work better. It also makes blades last longer and saves money on repairs. The world market for industrial blade coatings was worth $1.5 billion in 2023. This market keeps growing because new coatings make blades stronger and work better. More companies use pelletizing systems because of new technology and caring for the environment. This means people need better and certified products. Looking at features, certificates, and customer help lets buyers choose wisely.

Preguntas frecuentes

What factors affect the lifespan of pelletizer cutter blades?

The type of blade material matters a lot. Heat treatment and coating quality also help blades last longer. Taking care of blades and putting them in right is important. If workers follow the maker’s rules, blades will work better.

How often should companies replace pelletizer cutter blades?

How often you change blades depends on how much you use them. The kind of material and machine settings also matter. Most places check blades often. They change blades if cuts look uneven or if work slows down.

Can suppliers provide custom blade designs for unique machines?

Yes, many companies can make special blades. Customers can send in drawings or samples. Suppliers then make blades that fit certain machines or jobs.

What certifications should buyers look for in a blade supplier?

Buyers should look for ISO 9001, CE, or SGS certificates. These show the company follows world safety and quality rules.

How can buyers ensure they select the right blade for their process?

Check your machine’s rules, what you are cutting, and the pellet size you want. Ask experts for help if you are not sure. Try out sample blades before buying a lot to make sure they work.

Ver también

Encuentre las Cuchillas de Granulación Perfectas para Sus Necesidades de Procesamiento de Plástico

Cuchillas Granuladoras Comparadas: Encuentre Fácilmente el Ajuste Correcto

¿Qué Son las Cuchillas de Granulador y Cómo Funcionan en la Industria?

Cómo seleccionar la cuchilla peletizadora adecuada para su industria

Guía Completa para Elegir la Mejor Cuchilla Peletizadora para Su Máquina