Elegir lo correcto Selección de material para cuchillas perforadoras depends on the specific application. The material you choose directly impacts the blade’s performance and durability. Engineers consider the type of material being cut, the required toughness of the blade, and the operating speed. Companies like Nanjing Metal offer a wide range of perforating blades and provide expert guidance to help customers select the best perforating blade material selection for their needs. Careful consideration of both technical requirements and work conditions ensures a more efficient and cost-effective perforating process.

Puntos clave

- Picking the right blade material helps blades cut better and last longer.

- Hardness, toughness, and corrosion resistance are important when picking materials.

- Tungsten carbide and ceramic blades last the longest but cost more at first.

- Stainless steel blades work best for food, medical, and wet places.

- High-speed steel is strong and not too expensive for fast cutting.

- Using the right blade material for what you cut stops damage and waste.

- Taking care of blades often keeps cuts neat and makes blades last longer.

- Asking experts and trying blades in real situations helps you pick the best one.

Why Blade Material Selection Matters

Performance and Longevity

Blade material selection is very important. It decides how long a perforating blade will last. It also affects how well the blade works. Each material has special features. These features change how strong and sharp the blade is. Carbon makes blades harder. Chromium helps blades resist damage and rust. Carbide blades use tungsten and cobalt. They last much longer than some steel blades. This means you do not need to change blades often. Production lines can keep working with less stopping.

Consejo: Picking the right mix of hardness and toughness helps blades last longer. It also keeps cutting results steady.

| Material | Dureza (HRC) | Resistencia al desgaste | Typical Lifespan (vs. 52100 Steel) |

|---|---|---|---|

| Herramienta de acero | 58-62 | Bien | 1x |

| Acero de alta velocidad | 60-65 | Very Good | 2-3x |

| Carburo de tungsteno | 75-80 | Excelente | 8-10x |

| Acero inoxidable | 55-60 | Bien | 1-2x |

Calidad del producto

The blade material you pick changes how good the finished products are. Each material gives special benefits. These benefits affect how sharp the blade is. They also change how clean each cut looks. High-speed steel stays sharp for neat cuts. Tungsten carbide works best for lots of cutting or tough jobs. Stainless steel does not rust. It is great for food packaging and medical uses where cleanliness matters.

| Material de la Cuchilla | Propiedades clave | Impacto en la calidad del producto |

|---|---|---|

| Acero de alta velocidad | Balanced hardness and toughness | Clean, consistent cuts |

| Carburo de tungsteno | Dureza excepcional, resistencia al desgaste. | Long-lasting, precise perforations |

| Acero inoxidable | Resistencia a la corrosión | Safe, hygienic cuts for sensitive uses |

| Herramienta de acero | Tough, hardenable | Durable for heavy-duty perforating |

Choosing the right material helps each perforating blade make smooth and accurate cuts. This is very important for packaging, printing, and textile industries.

Impacto en los costos

The material you choose also changes how much perforating costs. Better materials like solid carbide or advanced tool steels cost more at first. But they last longer and need fewer replacements. This saves money on repairs and keeps work moving. Cheaper materials may seem like a good deal. But they wear out faster and cause more stops. This can cost more in the long run.

| Blade Material Type | Benefits & Characteristics | Cost Implications |

|---|---|---|

| High-Quality Materials | Superior wear resistance, longevity | Higher initial cost, lower long-term cost |

| Low-Quality Materials | Lower strength, wears out faster | Lower initial cost, higher ongoing cost |

Selección de material para cuchillas perforadoras

Herramienta de acero

Propiedades

Tool steel is a common choice for Selección de material para cuchillas perforadoras. Many manufacturers like it because it is hard and tough. It also does not wear out quickly. There are different grades of tool steel. Each grade has its own special use for cutting and perforating. The table below shows the main types used for industrial blades:

| Tool Steel Grade | Propiedades clave | Typical Applications Relevant to Perforating Blades |

|---|---|---|

| W-Grade (Water-Hardening) | High carbon, very hard, lower cost, brittle, softens above 150°C | Basic blades, industrial cutting tools |

| O-Grade (Oil-Hardening) | High strength, abrasion resistance, good dimensional stability | Punches, thread cutting tools, wear-resistant blades |

| A-Grade (Air-Hardening) | Good toughness, low distortion, easy to machine | Blanking, die bending, blades needing shape retention |

| D-Grade (High Carbon Chromium) | Excellent wear resistance, toughness, high compressive strength | Long production runs, woodworking knives, forming rolls |

| S-Grade (Shock-Resisting) | Strong impact toughness, moderate wear resistance | Shearing blades, chipper knives, hot and cold working blades |

Tool steel blades keep their sharp edge after many uses. Grades like D2 and S7 are known for being strong and lasting long. These features make tool steel a good pick for many jobs.

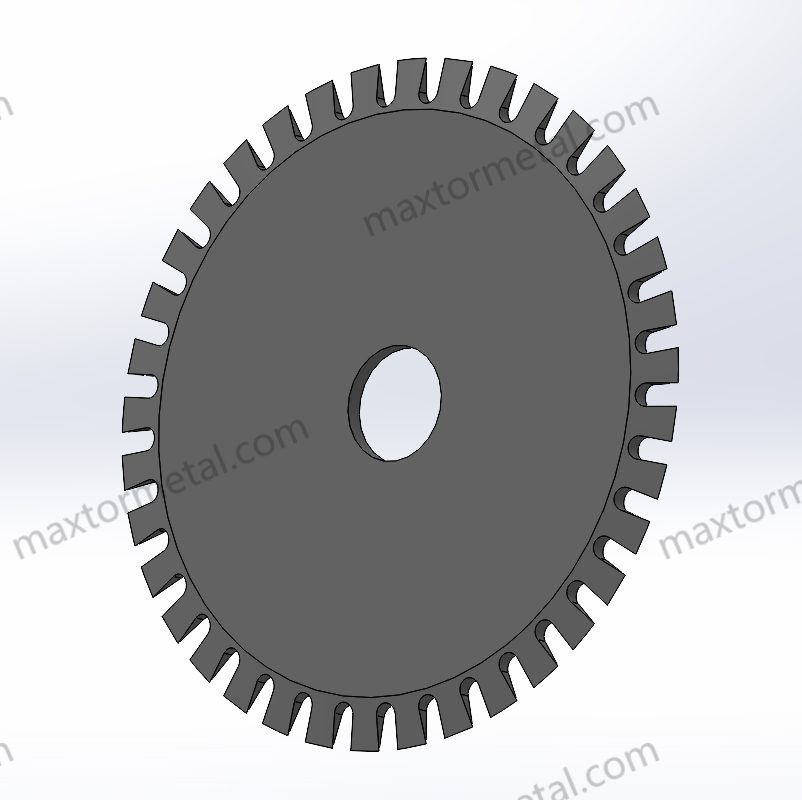

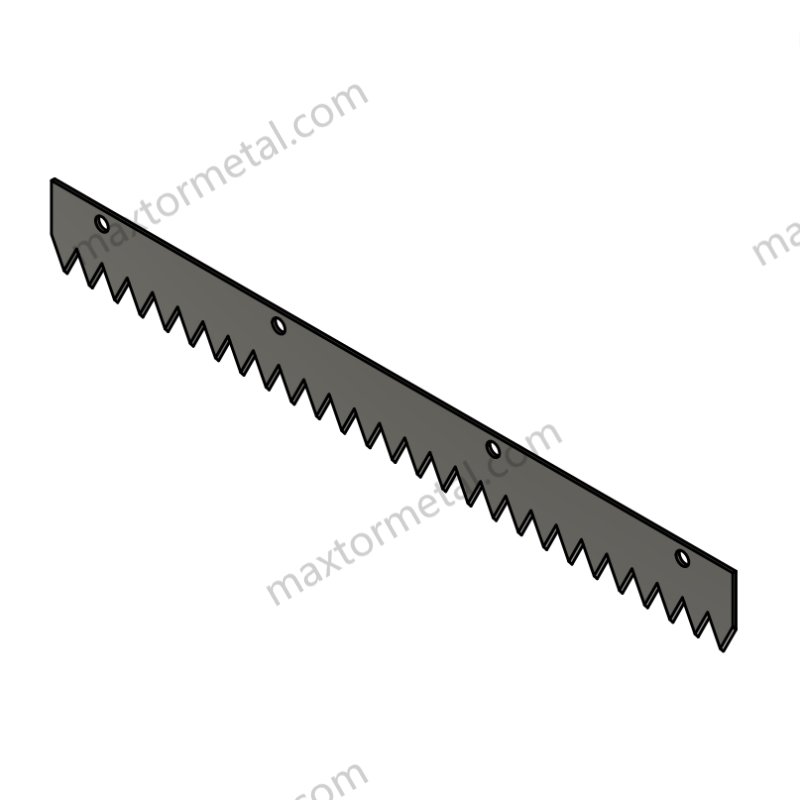

Usos

Many industries use tool steel for perforating. Packaging companies use these blades to make tear lines in bubble wrap and boxes. Paper companies use tool steel for checkbooks, labels, and notebooks. These blades help make clean cuts. Tool steel is also used for garbage bags and air fresheners. The blades cut well and last a long time. This means less time fixing or changing blades.

Acero de alta velocidad (HSS)

Ventajas

High-speed steel (HSS) has many good points for Selección de material para cuchillas perforadoras. HSS stays hard and sharp even when it gets hot. This makes it great for fast and nonstop cutting. HSS has special metals like tungsten and vanadium. These help it handle heat and last longer. HSS blades last longer than carbon or stainless steel blades. They are also tougher than carbide, so they do not chip or break easily.

| Advantage Aspect | High-Speed Steel (HSS) Benefit Relevant to Perforating Applications |

|---|---|

| Resistencia al calor | Maintains hardness at high temperatures, ensuring durability |

| Dureza | Cuts hard materials, keeps sharp edge |

| Resistencia al desgaste | Outlasts carbon and stainless steels under heavy use |

| Toughness and Shock Resistance | Handles shock and less rigid setups without chipping |

| Maquinabilidad | Easy to machine for precise blade manufacturing |

| Velocidad de corte | Enables faster cutting, improving efficiency |

| Costo | More cost-effective than carbide |

HSS blades work well on fast production lines. They give steady results even in tough places.

Aplicaciones

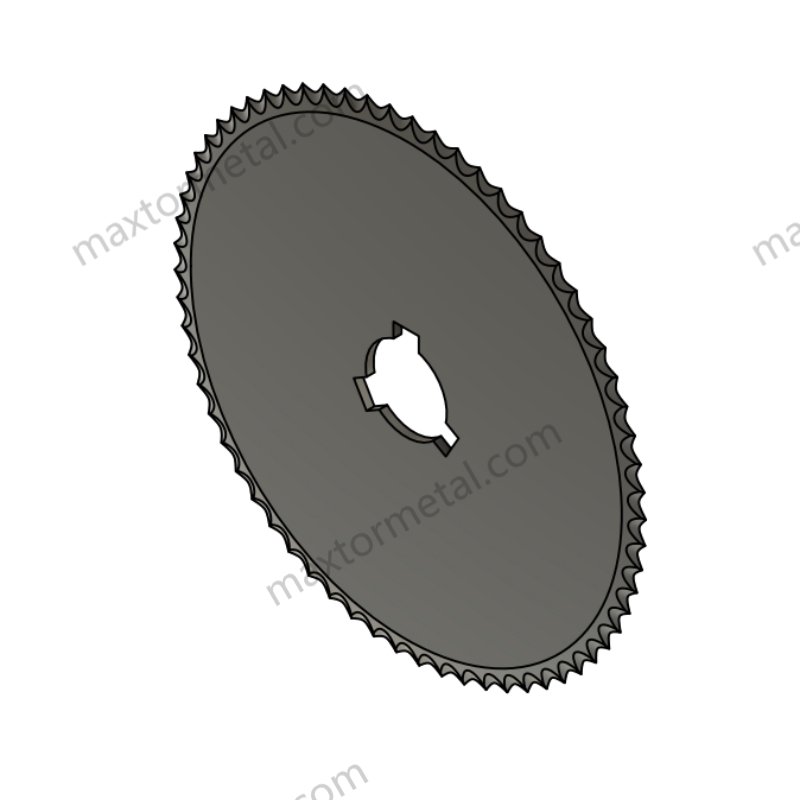

Manufacturers use HSS for perforating blades in metalworking and packaging. HSS blades are good for cutting soft metals and aluminum. They are used in round blades for making metal parts. HSS is also used for short jobs and repairs. It is tough and can do many things. Nanjing Metal makes HSS perforating blades for these hard jobs.

Acero inoxidable

Resistencia a la corrosión

Stainless steel does not rust, so it is a top pick for Selección de material para cuchillas perforadoras in tough places. Grades like 304, 316, and 316L do not get damaged by water or chemicals. The table below shows the main stainless steel grades for perforating blades:

| Stainless Steel Grade | Tipo | Common Use for Blades | Corrosion Resistance Properties |

|---|---|---|---|

| 304 | Austenítico | General purpose blades | Excellent corrosion resistance; good formability; widely used |

| 316 | Austenítico | Marine, chemical blades | Superior resistance in chloride environments due to molybdenum |

| 316L | Austenitic (low carbon) | Welded blades, chemical use | Improved resistance during welding; prevents carbide precipitation |

| 410 | Martensítico | Cutting tools, blades | Moderate corrosion resistance; high strength and hardness |

| 440 °C | Martensitic (high carbon) | Knives, surgical blades | High hardness and wear resistance; moderate corrosion resistance |

Austenitic stainless steels like 304 and 316 are strong and tough. They do not rust, so they are good for food, medical, and chemical uses.

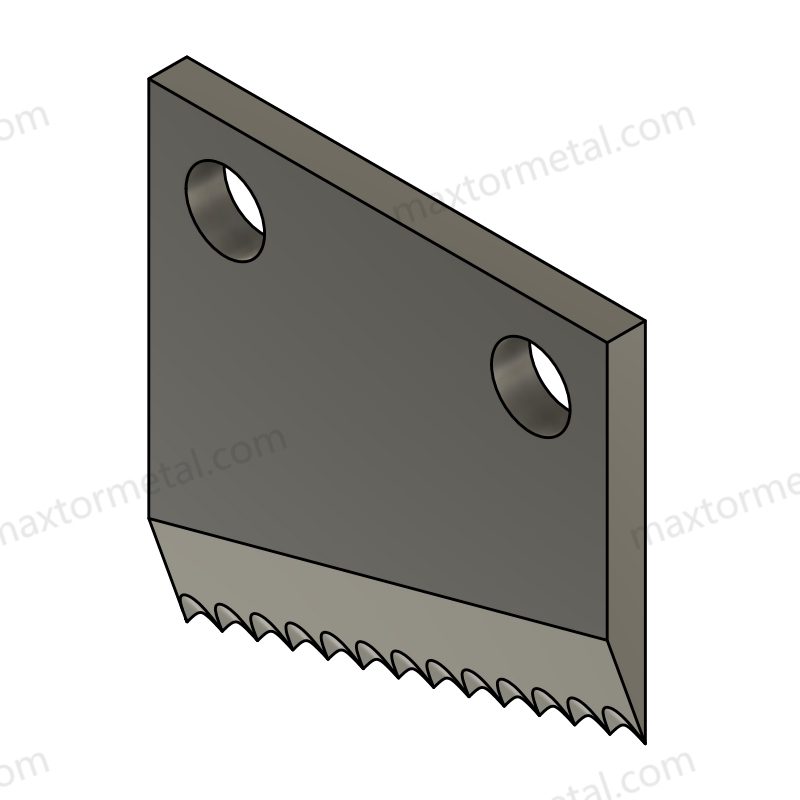

Food and Medical Uses

Stainless steel blades are important in food and medical work. Their smooth surface stops germs and mold from growing. This keeps things clean and safe. Stainless steel can be cleaned with steam or chemicals and still stay strong. In food factories, stainless steel plates help with washing and baking. In hospitals, these blades help keep things safe and clean.

Carburo de tungsteno

Dureza

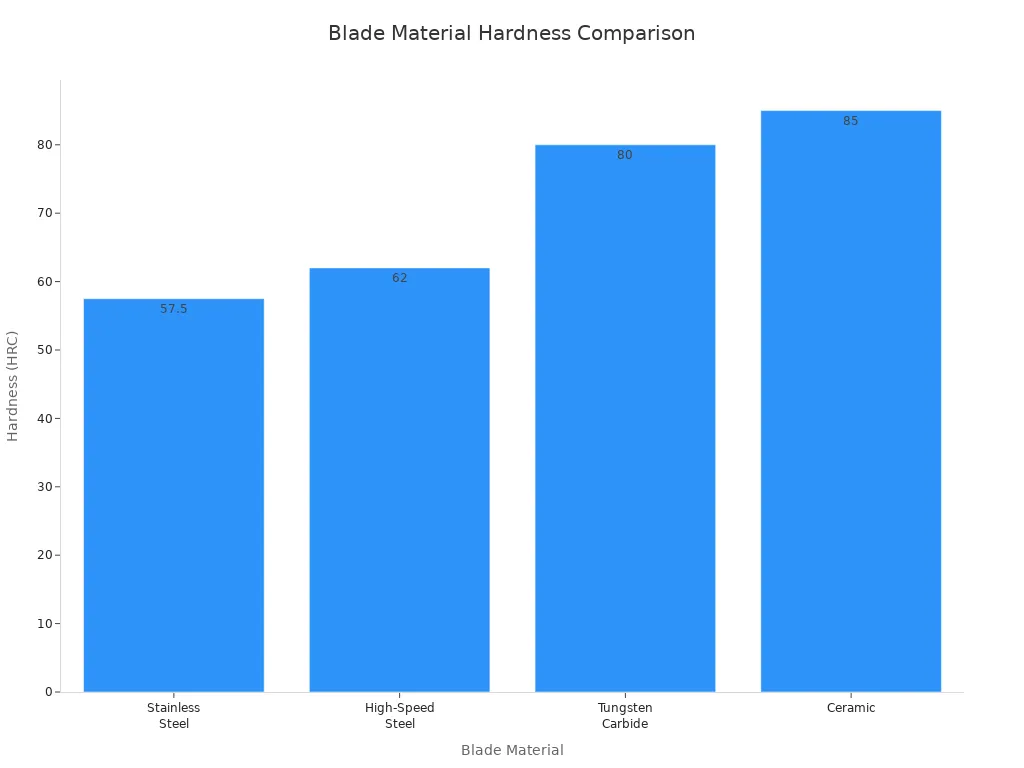

Tungsten carbide is very hard. This makes it special for perforating blade material selection. People use the Rockwell scale to check hardness. Tungsten carbide blades score 75–85 HRC. This is harder than most other blades. Because of this, blades stay sharp for a long time. Workers do not need to change blades often. This means less stopping during work.

| Material de la Cuchilla | Dureza (HRC) | Casos de uso ideales |

|---|---|---|

| Acero inoxidable | 55–60 | Alimentos, médicos, trabajos ligeros |

| Acero de alta velocidad | 60–64 | Papel, madera, plásticos |

| Carburo de tungsteno | 75–85 | Metal, caucho, compuestos |

| Cerámico | 80–90 | Láminas, microfilmes, óptica |

Solid carbide blades last longer than steel blades. This helps companies save time and money. The chart below shows how hard tungsten carbide is compared to other materials.

Tungsten carbide is great for cutting thick or tough things. These blades work well even when machines run fast.

Usos industriales

Many jobs use tungsten carbide blades for perforating. Printing presses use them for quick, neat cuts. Packaging plants use them for cutting strong films and foils. Factories making bags and films use these blades for nonstop cutting. Food factories use them for meat, bread, and snack packs.

- Printing (pressroom, bindery, mail room)

- Packaging (flexible packaging, corrugated, foil, thin metals)

- Converting (bag, film, paperboard, textiles, rubber)

- Food processing (meat, bakery, dairy, fruits, vegetables)

Tungsten carbide blades are tough and resist heat. They stay sharp in fast-moving factories and help cut down on waste. Using these blades helps companies use fewer blades and reach green goals.

Cerámico

Non-Metallic Benefits

Ceramic blades have special benefits for perforating blade material selection. These blades are very hard, with a rating of 80–90 HRC. Ceramic blades keep their sharp edge longer than most metal blades. They do not rust because they have no iron. This makes them good for cutting food, chemicals, and other sensitive things.

Ceramic blades are light and do not get hot easily. People use them where temperature is important. Because they are not metal, they do not rust or make things dirty. But ceramic blades can break if dropped or hit.

- Superior wear resistance

- Long-lasting sharpness

- Resistencia a la corrosión

- Lightweight and heat-resistant

Ceramic blades are best for gentle and careful cutting. They are great when you need clean cuts and blades that last.

Specialty Applications

Ceramic perforating blades work well in special places. Factories use them to cut rough things like fiberglass. These blades do not wear out fast on hard surfaces. Optical companies use ceramic blades for thin films and foils. Labs and electronics makers use them for clean, careful cuts.

Ceramic blades stay sharp and strong even in tough jobs. People pick them when they need blades that last and do not make things dirty. Even though ceramic blades can break, their good points are worth it for many special uses.

Material Comparison

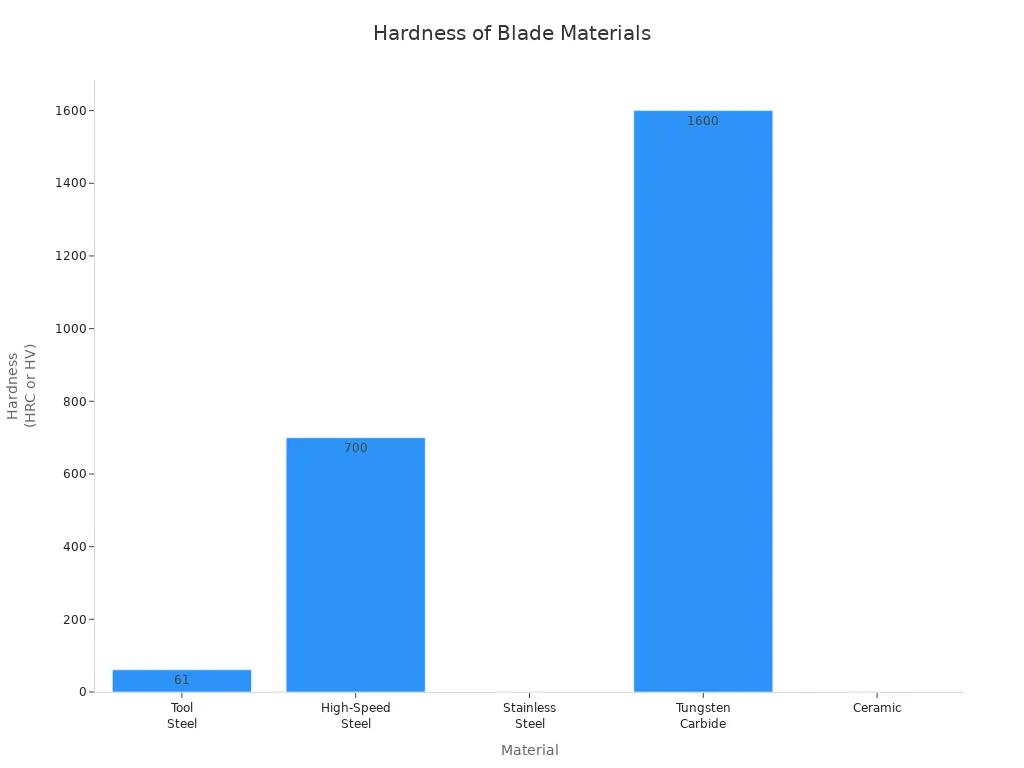

Picking the right blade material depends on hardness, toughness, and cost. The table below shows how common blade materials compare.

| Material | Dureza | Tenacidad | Cost and Cost-effectiveness |

|---|---|---|---|

| Herramienta de acero | Hard and tough; up to 60–62 HRC | Tough and moderately wear-resistant; easier to sharpen | Cost-effective; good for budget-conscious use but shorter lifespan |

| Acero de alta velocidad | Hardness around 700–900 HV; retains hardness at high temperatures | Tougher than tungsten carbide; resists chipping; good impact resistance | Moderate cost; easier and cheaper to sharpen; popular for industrial knives |

| Acero inoxidable | Less hard than tool steel and HSS; corrosion resistant | Less flexible and less effective in sharpening | Cost-effective; preferred in moist environments due to corrosion resistance |

| Carburo de tungsteno | Hardest material (1600–2200 HV); best edge retention | More brittle; prone to chipping if impacted | High upfront cost but longer tool life reduces replacement frequency |

| Cerámico | Very hard; maintains sharpness longest | Very brittle; susceptible to chipping and breakage | Expensive to sharpen; suitable for precise, gentle cutting tasks |

Tool steel and high-speed steel are tough and not too costly. Stainless steel does not rust and is good for wet places. Tungsten carbide and ceramic are the hardest and keep their edge the longest. These are best for hard jobs and special cutting.

Factors in Perforating Blade Material Selection

Material a cortar

Picking the right blade starts with knowing what you need to cut. Every material is different and can be hard for cutting tools. Things like thickness, density, and tear resistance matter a lot. These things help decide which blade material works best.

- Paper and plastic films are not very dense. They need blades that are sharp and do not rust. Tool steel or stainless steel blades are good for these.

- Cardboard, laminates, and composites are tougher. They are rough and wear blades out faster. Tungsten carbide or ceramic blades work better for these materials.

- Stainless steel blades are needed where rust is a big problem. This is important for food or medical packaging.

- Blade coatings like titanium nitride make blades last longer. They help blades work better, especially when machines run fast.

- Using the right blade for the material helps make clean cuts. It also helps blades last longer and keeps production running smoothly.

Choosing the correct blade for the material keeps quality high. It also helps reduce downtime in perforating work.

Durability Needs

Durability is very important when picking a blade. This matters most when you need to cut a lot or work all the time. The blade material should stay sharp and not break easily. The table below shows how common blade materials compare for durability:

| Material de la Cuchilla | Resistencia al desgaste | Hardness & Toughness | Sharpness Retention & Durability | Suitability for High-Volume Production |

|---|---|---|---|---|

| Carburo de tungsteno | Exceptional wear resistance | Very hard, good toughness | Maintains sharpness over extended use | Ideal for high-volume, abrasive materials |

| Powder Metallurgy Steels (e.g., CPM 10-V) | Superior wear resistance and toughness | High hardness with uniform microstructure | Long-lasting sharpness and durability | Suitable for demanding, continuous perforating tasks |

| Acero Aleado | Superior wear resistance in continuous cutting | Balanced hardness and toughness | Maintains cutting precision over long periods | Excellent for high-intensity, continuous production lines |

| Cuchillas Cerámicas | Unmatched wear resistance | Exceptional hardness but brittle | Excellent sharpness retention, but requires careful handling | Ideal for high-precision, high-capacity production with low maintenance frequency |

| Acero con alto contenido de carbono | Good initial wear resistance, diminishes quickly | Good hardness but less toughness | Requires frequent replacement in high-intensity use | Suitable for moderate volume or budget-sensitive operations |

| Acero inoxidable | Generally poor wear resistance | Lower hardness, good corrosion resistance | Dulls faster in high-wear environments | Less suitable for high-volume, high-wear unless corrosion is critical |

Blades need the right mix of hardness and toughness. This helps them last longer and work well. For busy factories, tungsten carbide or powder metallurgy steels are best. They do not need to be changed often.

Consejo: Always think about how much work and what kind of place you will use the blade. This helps you save time and money on repairs.

Velocidad de producción

How fast you work changes which blade you should use. Fast machines make blades wear out and get hot quickly. You need to pick blade materials that can handle this.

| Factor | Impact on Blade Material Choice | Explicación |

|---|---|---|

| Velocidad de producción | Higher speeds require harder, more wear-resistant materials like tungsten carbide or coated high-speed steel | These materials maintain sharpness and durability under increased wear and heat, ensuring clean cuts and reducing downtime in automated environments |

| Lower Speeds | Allows use of less wear-resistant materials but may reduce efficiency | Slower speeds reduce wear and heat, so softer materials can be used but at the cost of throughput |

| Film Thickness and Type | Thin films need very sharp, hard blades like ceramic at lower speeds to prevent tearing | Hard blades prevent damage to delicate films when cutting at slower speeds |

| Balancing Speed with Pressure and Tooth Profile | Critical to optimize cutting performance and blade longevity | Adjusting these parameters helps maintain cut quality and blade life when changing speed |

| Monitoring and Testing | Automated monitoring helps adjust speed and blade selection dynamically | Ensures consistent quality and efficiency by adapting to production conditions |

Operators need blades that can keep up with their machines. Hard blades like tungsten carbide or coated high-speed steel are best for fast work. Softer blades can be used for slower jobs, but they may not work as well. Watching and changing blade choices as things change helps get the best results.

Consideraciones de costos

Cost is very important when picking a Selección de material para cuchillas perforadoras. Companies need to think about the blade’s price and how long it will last. Some blades, like tungsten carbide, cost more at first. But these blades last much longer than regular steel blades. If blades last longer, workers do not have to change them as often. This means machines stop less and workers save time. Stainless steel and tool steel blades are cheaper to buy. But they may need to be replaced more often, especially if you cut a lot.

A simple chart can help people decide:

| Material de la Cuchilla | Costo inicial | Frecuencia de reemplazo | Ahorros a largo plazo |

|---|---|---|---|

| Herramienta de acero | Bajo | Alto | Moderado |

| Acero de alta velocidad | Moderado | Medio | Bien |

| Carburo de tungsteno | Alto | Bajo | Excelente |

| Acero inoxidable | Bajo | Alto | Moderado |

| Cerámico | Alto | Muy bajo | Excelente |

Consejo: Companies should look at all costs, not just the price. Think about how often you change blades and how much time is lost. This helps show which blade is really the best deal.

Mantenimiento

How much care a blade needs depends on what it is made of. Some blades need to be sharpened often to stay sharp. Tool steel and high-speed steel blades need more care. Tungsten carbide and ceramic blades stay sharp longer. This means you do not have to fix or change them as much.

Taking care of blades helps them last longer. Workers should do these things:

- Check blades often for damage or wear.

- Clean blades after using them so nothing builds up.

- Sharpen blades when they get dull to keep cuts clean.

- Change blades if they are chipped or not sharp anymore.

Blades that are cared for make cleaner cuts and waste less material.

Seguridad y cumplimiento

Safety and following rules are very important for Selección de material para cuchillas perforadoras. Some jobs, like food and medical work, need blades that are safe and clean. Stainless steel blades do not rust and are easy to clean. This makes them good for places where germs are a problem.

Some rules say what kind of blade you can use. For example, food packaging needs blades that do not make food unsafe. Workers must pick blades that follow safety rules in their country.

Important safety and rule points are:

- The blade material should not react with what you are cutting.

- Blades must be easy to clean and take care of.

- Companies need to give papers that show the blade is safe.

Picking the right blade keeps workers safe and products clean. It also helps companies follow the rules and avoid problems.

Aplicaciones

Embalaje

The packaging industry uses perforating blades for many jobs. These blades make easy-tear lines in bags and wrappers. Companies pick blade materials based on what they are cutting and where. Tool steel, high-speed steel, stainless steel, carbide, and ceramic all have special uses in packaging.

| Blade Material Category | Key Characteristics and Reasons for Selection |

|---|---|

| Plain Carbon Steel | Basic hardening ability, cost-effective for simple jobs |

| Acero Aleado | Improved hardness and performance, good for high-volume cutting |

| Aceros para herramientas | High hardness and wear resistance, ideal for demanding packaging lines |

| Carburo | Extremely high hardness, extends blade life, best for abrasive materials |

| Cerámico | Maintains hardness at high temperatures, used for specialty packaging |

| Metal en polvo | Uniform performance, good machinability for custom perforating knives |

Packaging needs blades that do not wear out or rust. Stainless steel 420 and 440 are good for food and liquid packaging because they do not rust. Tool steel and carbide blades are strong for cutting tough films. Nanjing Metal makes custom perforating knives for packaging. They match the blade material to each job. Their team helps customers pick the right blade for every use. This gives clean cuts and makes blades last longer.

Consejo: Using the right perforating knife helps save material and makes packaging faster.

Papel e impresión

Paper and printing companies use perforating blades for tear-off sheets and labels. These jobs need blades that stay sharp and cut well. The air is dry, so blades do not need to fight rust as much. Edge sharpness and cutting accuracy are more important.

| Material de la Cuchilla | Key Properties and Benefits | Typical Industry Applications and Notes |

|---|---|---|

| 52100 Steel | Strong, hard, contains chromium and carbon | Used in paper and printing for durability and precision |

| Acero de alto carbono | Retains sharpness, harder but not corrosion resistant | Common in dry environments like paper cutting |

| Cerámico | Highly wear resistant, stays sharp but brittle | Used in harsh, dry environments such as printing |

Paper perforating knives often use 52100 steel or high-carbon steel. These materials are strong and keep a sharp edge. Ceramic blades are good for long jobs where sharpness matters most.

Food and Medical

Food and medical packaging needs to be very clean and safe. Perforating blades here must not rust or get dirty. Stainless steel and D2 steel are the best choices. They do not corrode and are easy to clean. These materials follow safety rules and can be washed often.

Blades for food and medical jobs often need special features. Some packages need special holes for safety or air flow.

- Stainless steel blades stop rust and keep food safe.

- D2 steel is hard and resists rust.

- Custom blades can have special shapes and sizes for each job.

Textiles and Nonwovens

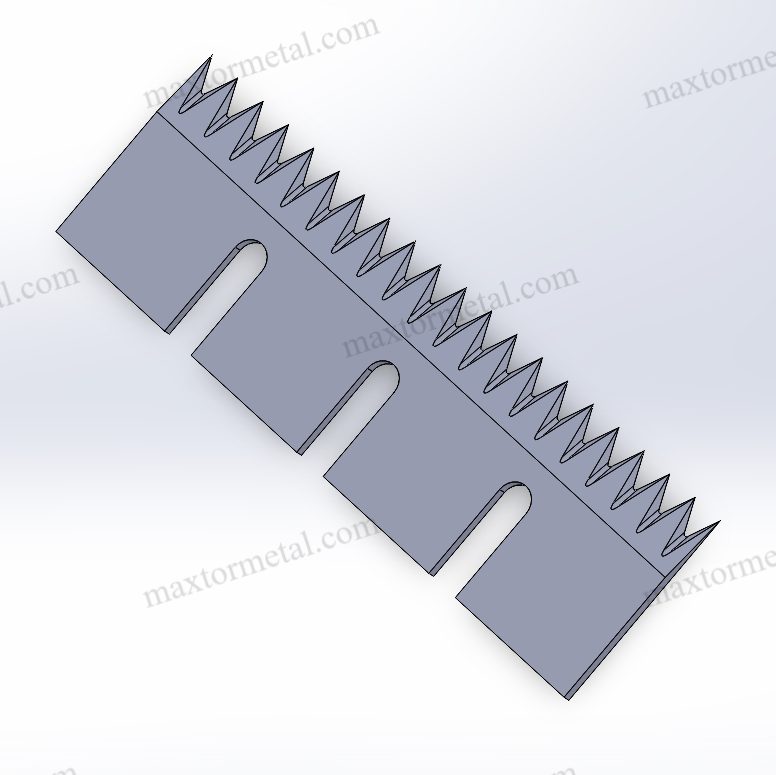

The textiles and nonwovens industry needs very accurate perforating blades for many jobs. Factories use these blades to make neat, easy-to-tear lines in fabrics and special textiles. Every material has its own problems. Fabrics might bunch up or come apart when cut. Nonwovens can stretch or break if the blade is not sharp. Picking the right perforating knife is very important for good work and saving time.

Key challenges in textile and nonwoven applications include:

- Fabrics can come apart if the blade is dull or the tooth shape is wrong.

- Soft, stretchy, or layered materials need special blade shapes for neat cuts.

- Fast machines need blades that stay sharp and do not wear out quickly.

- Each fabric type needs a different tooth shape, like crush cut or serrated blades.

- Circular knives are used for slitting, trimming, and perforating without hurting the material.

- Hot knives seal the edges to stop fraying, which is important for synthetic textiles.

| Challenge/Requirement | Explicación | Material/Design Solution |

|---|---|---|

| Clean, precise cuts without fraying | Blades must be sharp and have the right tooth shape to protect soft materials. | Premium-grade steel or carbide for sharpness and durability |

| Durability and sharpness maintenance | Blades should last through fast cutting and not need sharpening often. | Use of wear-resistant, high-quality materials like carbide |

| Compatibility with cutting machines | Blades must fit high-speed, accurate textile cutting machines. | Custom and OEM blade solutions tailored to fabric types |

| Matching blade geometry to fabric type | Blade thickness, edge, and tooth shape must match the softness and layers of the textile. | Customized blade design per fabric/nonwoven characteristics |

| Prevention of fraying and material damage | Sharp blades and the right tooth shape keep edges neat and stop unraveling. | Precision manufacturing and material selection |

| Operational demands | Blades must work well in busy factories and not need to be changed often. | Durable materials and optimized blade design |

Nanjing Metal makes custom perforating knives for textile and nonwoven jobs. Their team helps customers pick blades that fit each fabric’s needs. High-carbon steel and ceramic blades last a long time and help factories work without stopping. Carbide-tipped blades stay sharp longer and are good for fast cutting. Special blades, like crush cut knives, use pressure to cut soft or layered fabrics without harm. For synthetic fabrics, hot knives seal the edges so they do not fray.

Consejo: Picking the right perforating knife and blade material makes products better and cuts down on waste in textile factories.

Custom Perforating Knives

OEM and ODM Services

Manufacturers sometimes need blades made just for them. Standard blades do not always work for every job. OEM and ODM services help companies get special blades for their machines.

- ODM services make blades quickly and keep prices low.

- Customers get blades made for their own needs.

- Companies get help with marketing and training.

- Full support helps businesses grow and find new customers.

- Steel processing and heat-treatment happen in one place, so production is fast.

- Local teams help deliver blades on time.

- Production follows ISO 9001 rules and safety checks.

- OEM services make blades that fit special machines and jobs.

- These blades help factories work better and save money.

Design and Customization

Each job needs a different kind of blade. Custom perforating knives must fit the material and machine. Nanjing Metal works with customers to design the right blade. Their team can change blade shapes, tooth styles, and edges using drawings or samples.

Customers get these benefits:

- Blades shaped for paper, film, textiles, or rubber.

- Special coatings help blades last longer and cut smoother.

- Custom boxes and labels make blades easy to find and use.

- Orders can be small or big, depending on what is needed.

People can visit the página de cuchillas personalizadas to learn more or ask for a price.

Control de Calidad Riguroso

Quality control is very important when making blades. Nanjing Metal checks every step to make sure blades are good. They look at materials, watch production, and check finished blades before shipping.

- Quality control makes sure cuts are clean and strong.

- Tough materials like tungsten carbide and high-speed steel help blades last.

- Custom blades for packaging help factories make neat products.

- Checking blades often and replacing them on time stops problems.

- Clean cuts mean less waste and help save money.

Tests show custom micro-tooth blades help factories work longer without stopping. Cleaning and sharpening blades helps them last and cut well.

Errores comunes

Ignoring Application Needs

Many people pick a blade material without thinking about the job. Every job needs something special from the blade. Packaging, textiles, and food processing all need different blade features. Some people choose a blade just because it is cheap or easy to get. This can make the blade work badly and waste materials.

Common issues when ignoring application needs:

- Las cuchillas se desgastan rápidamente.

- Cuts are messy or not exact.

- Production slows down because blades need changing.

- Finished products do not meet quality rules.

Consejo: Always match the Selección de material para cuchillas perforadoras to what you are cutting and where you are working.

Mantenimiento de paso

Taking care of blades is important for how well they work and how long they last. Some workers forget to check or clean blades often. If you do not take care of blades, they get dull faster and break more easily. This mistake makes costs go up and machines stop more.

Signs of poor maintenance:

- Blades get dull and need sharpening a lot.

- Material gets stuck or ripped when cutting.

- More waste and bad products.

- Machines stop more for fixing.

| Tarea de mantenimiento | Beneficio | Frecuencia |

|---|---|---|

| Cuchillas de limpieza | Stops buildup and rust | Después de cada uso |

| Inspecting for wear | Finds damage early | Semanalmente |

| Sharpening edges | Keeps cuts good | Según sea necesario |

| Replacing blades | Keeps things safe and working | When worn |

Regular care helps blades last longer and makes Selección de material para cuchillas perforadoras work better. Companies should teach workers to follow a care plan.

Underestimating Cost Factors

Some buyers only look at the first price of a blade. They forget about costs for new blades, machine stops, and wasted material. Picking a cheaper blade might look smart at first. But it can cost more later.

Cost factors to consider:

- ¿Con qué frecuencia necesitas cuchillas nuevas?

- Time lost for fixing or cleaning

- Waste from bad cuts

- How cuts affect product quality

| Blade Material Type | Costo inicial | Replacement Rate | Valor a largo plazo |

|---|---|---|---|

| Herramienta de acero | Bajo | Alto | Moderado |

| Acero de alta velocidad (HSS) | Medio | Medio | Bien |

| Carburo de tungsteno | Alto | Bajo | Excelente |

| Acero inoxidable | Bajo | Alto | Moderado |

| Cerámico | Alto | Muy bajo | Excelente |

Smart Selección de material para cuchillas perforadoras looks at all costs, not just the price.

Misjudging Material Compatibility

Picking the wrong blade for a certain material causes problems. Many people forget that different materials react in their own way when cut. Paper, plastic, rubber, and textiles all act differently with blade edges and hardness. If the blade does not match the material, you get dull blades, rough cuts, or chipped edges.

Operators need to know what both the blade and the material are like. Stainless steel blades do not rust, but they can get dull fast on rough composites. Tungsten carbide blades stay sharp longer, but they might chip on soft, stretchy things. Ceramic blades are very sharp, but they can break if used on thick or hard materials.

The table below shows some common mistakes:

| Substrate Type | Material de cuchilla recomendado | Common Compatibility Mistake | Problema resultante |

|---|---|---|---|

| Papel | Tool Steel, HSS | Using soft stainless steel | Dull edges, uneven perforation |

| Plastic Film | Tungsten Carbide, Ceramic | Using tool steel | Rapid wear, frequent replacement |

| Industria del Caucho | Carburo de tungsteno | Using ceramic | Blade chipping, poor cut quality |

| Textiles | High-Speed Steel, Ceramic | Using carbide | Fraying, blade damage |

| Envasado de alimentos | Acero inoxidable | Using tool steel | Rust, contamination risk |

Some companies do not pay attention to these details. They pick blades just because they are cheap or easy to get. This leads to more machine stops and lower product quality. Teams should match blade hardness, toughness, and edge shape to the material.

Consejo: Try out blade materials on a small group before using them for everything. This helps make sure they work well and saves money.

When checking if things match, look at rust resistance, how long the edge stays sharp, and if the blade can handle fast work.

Operators should think about the environment too. Wet places, heat, and chemicals can change how blades work. Stainless steel is good for wet areas. Carbide is better for dry, fast jobs.

If you pick the wrong blade, you waste money and materials. Picking the right perforating blade material selection gives clean cuts, longer blade life, and smooth work. Teams that care about matching blades see fewer problems and better products.

Choosing the right blade for each material keeps machines safe and makes better cuts.

Tips for Perforating Blade Material Selection

Consult Experts

Getting help from experts is important when picking perforating blade material selection. Professionals know what each blade material can do. They understand how blades work in different places. Asking experts helps companies avoid expensive mistakes.

Consejo: Always get technical support before choosing perforating blade material selection. Experts look at what you are cutting, how fast you work, and safety needs. They help find the best blade for your job.

Talking to a supplier makes sure the blade fits the machine and the material. Their engineers check drawings and samples. They give ideas to make blade design and material better. This helps blades work well and last longer.

Test in Real Conditions

Testing blades in real work is very helpful. Companies should not only use technical data. Real tests show how blades work with the chosen material. Workers can check if the blade is sharp, strong, and cuts well. They see if the blade is safe and follows rules.

A simple way to test blades is:

- Put the blade in the production line.

- Run a small batch with the right material.

- Check if the cuts are clean and sharp.

- Write down how fast the blade wears out.

- Change blade material selection if needed.

Nota: Testing finds problems early. It lets companies fix things before big production starts.

Balance Cost and Performance

Companies need to think about both cost and performance for perforating blade material selection. Good blades may cost more at first. They last longer and help machines run without stopping. Cheap blades wear out fast. This means more repairs and slower work.

| Material de la Cuchilla | Costo inicial | Esperanza de vida | Necesidades de mantenimiento | Overall Value |

|---|---|---|---|---|

| Herramienta de acero | Bajo | Corto | Alto | Moderado |

| Acero de alta velocidad | Medio | Medio | Medio | Bien |

| Carburo de tungsteno | Alto | Largo | Bajo | Excelente |

| Acero inoxidable | Bajo | Corto | Alto | Moderado |

| Cerámico | Alto | Muy largo | Muy bajo | Excelente |

People who make decisions should look at all costs. They need to think about blade price, how often blades need changing, and how well production goes.

Companies that balance cost and performance get better results. They save money and make better products with smart perforating blade material selection.

Stay Updated on Materials

The world of Selección de material para cuchillas perforadoras changes fast. New materials and new technology come out every year. Companies that learn about these changes get ahead. They can make their cutting better, spend less money, and make nicer products.

Engineers and managers should check for new blade materials often. Many suppliers bring out new alloys, coatings, and ways to make blades. These new ideas help blades work better and last longer.

Consejo: Sign up for industry newsletters and go to trade shows. These places share news about new materials and smart ways to use Selección de material para cuchillas perforadoras.

Here are some ways to keep up:

- Read technical journals: These magazines have stories about new blade materials and how they are used.

- Join professional groups: These groups share research, news, and case studies about Selección de material para cuchillas perforadoras.

- Go to webinars and workshops: Experts talk about new trends and answer questions about how materials work.

- Ask suppliers for advice: Companies know about new products and can help pick the right materials.

A simple table helps track updates:

| Fuente | Type of Information Provided | Frecuencia |

|---|---|---|

| Technical Journals | Research articles, material reviews | Mensual |

| Industry Newsletters | Product launches, trends | Semanalmente |

| Trade Shows | Live demos, networking | Anualmente |

| Supplier Updates | New materials, technical support | As released |

Keeping up with Selección de material para cuchillas perforadoras helps companies avoid old choices. New materials can be tougher, stay sharper, or be safer. For example, new coated high-speed steel and powder metallurgy have changed how factories do lots of cutting.

Nota: Always check how blades work and compare them to new ones. Companies that try new materials in real work see better speed and product quality.

Staying updated is not just about following what is popular. It means making smart choices that help work and save money. Every new step in Selección de material para cuchillas perforadoras can give cleaner cuts, longer blade life, and better products for everyone.

Picking the right perforating blade material selection helps make products better. It also helps blades last longer and saves money. Companies get help from experts who know what works best. Custom blades are made for each job to fit specific needs.

- Nanjing Metal’s team gives advice to help pick the best blade.

- Custom blades and careful checks help packaging, printing, and textiles.

For special help and answers, talk to Nanjing Metal’s sales engineers aquí.

Preguntas frecuentes

What is perforating blade material selection?

Perforating blade material selection means picking the best material for a perforating blade. The choice depends on what you need to cut. It also depends on how long the blade should last. The place where you use the blade matters too.

Why does perforating blade material selection matter?

Choosing the right perforating blade material helps blades last longer. It makes cuts cleaner and keeps workers safe. It also saves money by needing fewer blade changes and less stopping.

Which materials work best for food packaging blades?

Stainless steel and D2 tool steel are best for food packaging. These materials do not rust and are safe for food.

How does production speed affect perforating blade material selection?

Faster machines need blades made from harder materials. Tungsten carbide and coated high-speed steel work well at high speeds. These materials keep blades sharp and help stop work delays.

How often should companies replace perforating blades?

How often you change blades depends on the blade material and what you cut. It also depends on how much you use the blade. Harder blades like tungsten carbide last longer. Checking blades often helps know when to change them.

What factors should companies consider during perforating blade material selection?

Companies should think about what they need to cut. They should also think about how tough the blade needs to be. Speed, cost, care, and safety rules are important too.