| Otros Nombres | 1TP1Cuchillas quirúrgicas, 1TP1Cuchilla quirúrgica |

|---|---|

| Lugar de Origen | China |

| Aplicación | Metallurgy, Líneas de decapado, Plantas de laminación en frío, Plantas de acero inoxidable, Plantas de acero eléctrico, Plantas de galvanizado en caliente |

| Material | H13, H13K, LD |

| Número de Modelo | MT-MB |

| Servicio OEM | Disponible |

| Términos de Pago | L/C, T/T, Western Union |

| Embalaje | Caja de Cartón, Cajas de Madera |

| Tiempo de Entrega | 7-20 Días |

Compartir en:

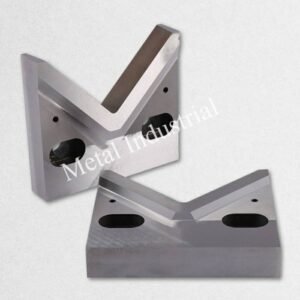

El término «cuchilla de corte para barras de refuerzo» se refiere a una herramienta de corte de alta resistencia diseñada específicamente para cortar barras de acero de refuerzo (varillas corrugadas). Estas cuchillas son componentes esenciales en las máquinas cortadoras de barras de refuerzo, utilizadas en obras de construcción, plantas de prefabricación e instalaciones de procesamiento de acero para cortar las barras a las longitudes requeridas para el refuerzo de hormigón. Las cuchillas de corte para barras de refuerzo están diseñadas para soportar la alta resistencia a la tracción y dureza de las barras de refuerzo, proporcionando cortes limpios y eficientes. Generalmente se presentan en pares, con una cuchilla inferior fija y una cuchilla superior móvil que aplica una fuerza considerable para cortar la barra. Su diseño prioriza la durabilidad, la resistencia y la precisión de los filos de corte para garantizar un procesamiento de barras de refuerzo preciso y seguro. Las cuchillas de corte para barras de refuerzo también se conocen como «cuchillas cortadoras de barras de refuerzo», «cuchillas cizallas para barras de acero», «cuchillas cortadoras de barras de refuerzo», «cuchillas guillotina para barras de refuerzo» o «cuchillas cizallas hidráulicas (para barras de refuerzo)», según el tipo de máquina cortadora en la que se utilicen.

Las cuchillas de corte para barras de refuerzo se utilizan principalmente en la construcción y la industria siderúrgica para cortar barras de acero de refuerzo a longitudes específicas. Su diseño robusto y su potente acción de corte las hacen indispensables para diversas aplicaciones, entre ellas:

El tamaño y el diseño del Cuchilla para Cizalla de VarillaLa potencia de la cizalla, así como su resistencia, determinan el diámetro máximo y la calidad de la barra de refuerzo que se puede cortar.

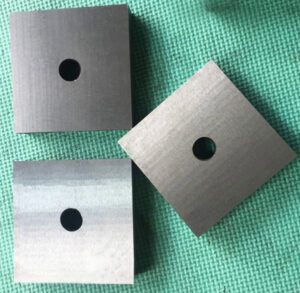

Los materiales empleados en la fabricación de cuchillas para cizallas de refuerzo son fundamentales por su capacidad para soportar las inmensas fuerzas y la abrasión propias del corte de barras de acero de refuerzo. Estos materiales deben ofrecer alta dureza, tenacidad y resistencia al desgaste. Algunos materiales comunes son:

El tratamiento térmico para lograr una dureza y tenacidad óptimas es un paso crucial en el proceso de fabricación de cuchillas para cizallas de refuerzo. El proceso específico de tratamiento térmico se adapta a la aleación de acero utilizada y a la aplicación prevista.

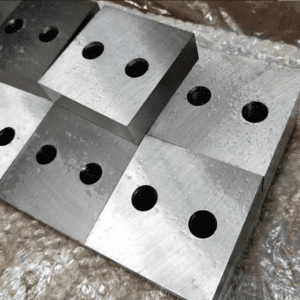

Las cuchillas para cizallas de refuerzo suelen venir en pares, con una cuchilla superior (móvil) y una inferior (fija). La geometría de los filos de corte es crucial para un corte limpio y eficiente. Las formas y características comunes incluyen:

La forma y el ángulo específicos de los bordes de corte, así como las dimensiones generales y la configuración de montaje de la cuchilla de corte de barras de refuerzo, están determinados por el tipo y la capacidad de la máquina cortadora de barras de refuerzo y el rango de tamaños de barras de refuerzo que está diseñada para manejar.

Si no encuentra la cuchilla que busca, también podemos personalizarla. ¡Consulte nuestras "Cuchillas Personalizadas" para saber cómo! ¡Bienvenido a consultar!

Disfrute de la comodidad de una importación sin interrupciones. Desde el transporte hasta el despacho de aduanas, manejamos todo el proceso. Solo tiene que pagar el IVA y esperar la llegada de sus productos.

Hemos visto nuestras cuchillas destacarse en innumerables aplicaciones y estamos listos para cualquier proyecto que nos presente. Espere precisión, durabilidad y precios competitivos inigualables.

Ya sea que nos proporcione dibujos, bocetos o muestras, podemos diseñar y fabricar para usted. También tenemos la experiencia para ayudar a modificar diseños y especificaciones existentes para mejorar casi cualquier aplicación de herramientas industriales. Por favor, contacte a nuestro equipo de ventas dedicado para discutir sus requisitos específicos.

Se realiza una serie de pruebas e inspecciones para controlar la calidad, incluyendo la inspección del primer artículo, la inspección de material entrante y materiales certificados, la inspección de calidad en proceso, y la inspección de calidad final.

Ya sea usted un importador, distribuidor, mayorista o usuario final, le damos la bienvenida. Benefíciese de MOQ mínimos, consultas sin complicaciones y mayor libertad de compra.

Considérenos su monitor exclusivo. Le proporcionaremos actualizaciones regulares sobre cada etapa crucial de su línea de producción. No importa la distancia, tendrá información en tiempo real sobre el progreso de su producto.

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China

Manténgase al día con nuestras últimas noticias.