| Otros Nombres | Cuchillas para fabricar bolsas, cuchillas para cortar bolsas, cuchillas para perforar bolsas, cuchillas en forma de T, cuchillas dentadas, cuchilla dentada para máquina envasadora vertical, cuchilla dentada para máquina envasadora vertical, cuchilla dentada para envasado vertical, cuchilla dentada para envasado vertical, cuchilla dentada para máquina envasadora vertical |

|---|---|

| Lugar de Origen | China |

| Aplicación | Plástico, Embalajes, Bolsas, Rollos |

| Material | Acero al carbono |

| Número de Modelo | CV-BM |

| Servicio OEM | Disponible |

| Términos de Pago | L/C, T/T, Western Union |

| Embalaje | Caja de Cartón, Cajas de Madera |

| Tiempo de Entrega | 7-20 Días |

Compartir en:

Las cuchillas de embalaje, también conocidas como cuchillas para máquinas de embalaje, son herramientas de corte especializadas diseñadas para integrarse en la maquinaria de embalaje. Estas cuchillas realizan diversas tareas de corte, corte longitudinal, perforación y sellado, esenciales para la preparación y el procesamiento de materiales de embalaje como películas, láminas, papel, cartón y otros materiales flexibles o rígidos utilizados para contener y proteger mercancías. El término "cuchillas de embalaje" es un término amplio que abarca una amplia gama de tipos de cuchillas adaptadas a las necesidades específicas de los diferentes equipos y procesos de embalaje.

Las cuchillas de embalaje son componentes fundamentales en numerosos procesos de envasado automatizado en diversas industrias. Sus aplicaciones son extensas e incluyen:

La selección de materiales para las cuchillas de envasado es crucial para garantizar la seguridad alimentaria (cuando corresponda), resistir la corrosión causada por diversas interacciones entre el producto y el material de envasado, y mantener un filo afilado y duradero para un funcionamiento constante a alta velocidad. Los materiales comunes incluyen:

A menudo se aplican tratamientos de superficie y recubrimientos como nitruro de titanio (TiN) o cromado para mejorar la dureza de la superficie, reducir la fricción y mejorar la resistencia al desgaste y la corrosión, extendiendo así la vida útil de las cuchillas de embalaje.

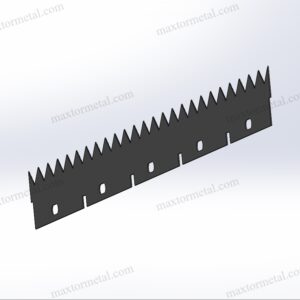

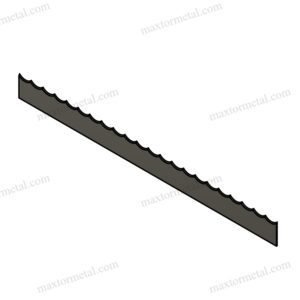

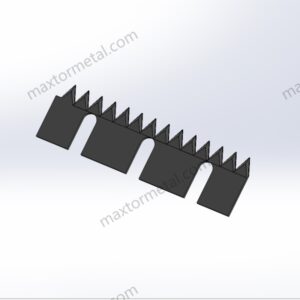

Las cuchillas de embalaje se fabrican en una amplia variedad de formas y configuraciones de borde para adaptarse a los mecanismos de corte o sellado específicos de diferentes máquinas de embalaje:

El principio de funcionamiento de las cuchillas de envasado varía según su función y la máquina en la que se integran. Las cuchillas de corte suelen emplear una acción de cizallamiento contra un yunque fijo u otra cuchilla móvil. Las cuchillas de sellado utilizan calor y presión para fusionar y cortar películas. Las cuchillas rotativas proporcionan un corte continuo al girar contra el material. La precisión de la geometría de la cuchilla, el filo, la fuerza aplicada y la sincronización con el funcionamiento de la máquina son factores cruciales para lograr cortes limpios y precisos y sellados fiables en los procesos de envasado.

Si no encuentra la cuchilla que busca, también podemos personalizarla. Consulte nuestra "Cuchillas Personalizadas” para saber cómo!

Disfrute de la comodidad de una importación sin interrupciones. Desde el transporte hasta el despacho de aduanas, manejamos todo el proceso. Solo tiene que pagar el IVA y esperar la llegada de sus productos.

Hemos visto nuestras cuchillas destacarse en innumerables aplicaciones y estamos listos para cualquier proyecto que nos presente. Espere precisión, durabilidad y precios competitivos inigualables.

Ya sea que nos proporcione dibujos, bocetos o muestras, podemos diseñar y fabricar para usted. También tenemos la experiencia para ayudar a modificar diseños y especificaciones existentes para mejorar casi cualquier aplicación de herramientas industriales. Por favor, contacte a nuestro equipo de ventas dedicado para discutir sus requisitos específicos.

Se realiza una serie de pruebas e inspecciones para controlar la calidad, incluyendo la inspección del primer artículo, la inspección de material entrante y materiales certificados, la inspección de calidad en proceso, y la inspección de calidad final.

Ya sea usted un importador, distribuidor, mayorista o usuario final, le damos la bienvenida. Benefíciese de MOQ mínimos, consultas sin complicaciones y mayor libertad de compra.

Considérenos su monitor exclusivo. Le proporcionaremos actualizaciones regulares sobre cada etapa crucial de su línea de producción. No importa la distancia, tendrá información en tiempo real sobre el progreso de su producto.

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China

Manténgase al día con nuestras últimas noticias.