| Otros Nombres | Cuchillo térmico para manualidades, cuchillos térmicos eléctricos, cortador de espuma, hojas de cuchillo térmico, cortador con cuchillo térmico, cuchillos térmicos, cuchillo térmico industrial, cuchillo térmico para plástico, cuchillo térmico para cortar cuerdas, cortadores térmicos, tipos de cuchillos térmicos, cuchillo térmico para cintas |

|---|---|

| Aplicación | Industria automotriz, instalación de alfombras, construcción, manualidades y pasatiempos, trabajos eléctricos, corte de espuma, fabricación de juntas, industria náutica, embalaje, fabricación de plásticos, procesamiento de caucho, industria textil, corte de correas y cuerdas |

| Número de Modelo | CB-HKB |

| Servicio OEM | Disponible |

| Términos de Pago | L/C, T/T, Western Union, XTransfer |

| Embalaje | Caja de Cartón, Cajas de Madera |

| Tiempo de Entrega | Basado en la cantidad |

Compartir en:

Un cuchillo caliente, también conocido como cortador térmico o cuchillo eléctrico, es una herramienta con una cuchilla calentada eléctricamente que se utiliza para cortar y, en ocasiones, sellar materiales sintéticos fundiéndolos. A diferencia de los métodos tradicionales de corte en frío, que pueden dejar bordes deshilachados en telas y otros materiales, un cuchillo caliente funde el material al cortar, lo que resulta en un borde limpio y sellado que evita que se deshilache o se deshilache. El término "cuchillo caliente" se refiere directamente a la cuchilla calentada que realiza el corte.

Los cuchillos calientes son herramientas versátiles con una amplia gama de aplicaciones en diversas industrias y oficios gracias a su capacidad para cortar y sellar limpiamente materiales sintéticos. Algunos usos comunes incluyen:

Las hojas de cuchillos calientes Generalmente se fabrican con materiales que conducen y retienen el calor eficazmente. Entre los materiales más comunes se incluyen:

La hoja también puede estar recubierta con materiales como teflón para reducir la fricción y evitar que el material derretido se adhiera a la hoja, lo que garantiza un corte más suave.

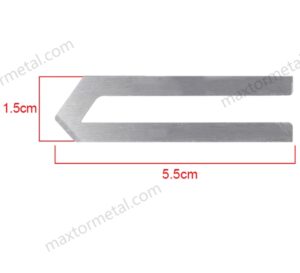

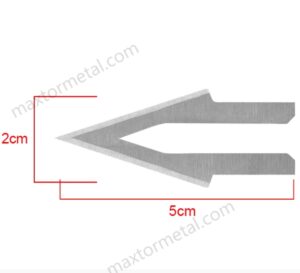

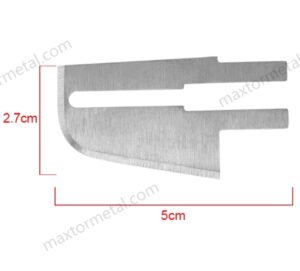

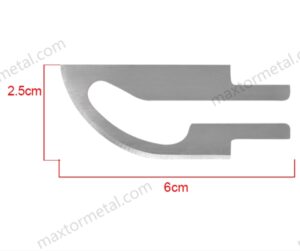

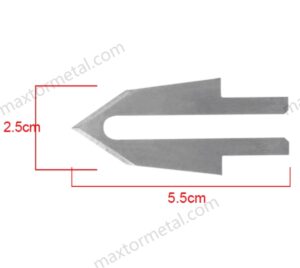

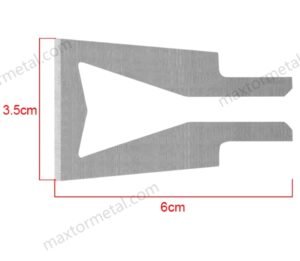

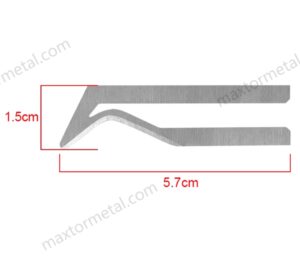

cuchillos calientes Vienen con una variedad de formas de cuchillas intercambiables para adaptarse a diferentes tareas de corte y materiales. Algunas formas comunes incluyen:

El principio de funcionamiento de un cuchillo caliente El proceso consiste en que la cuchilla calentada eléctricamente funde el material sintético al contacto. El calor ablanda el material, permitiendo que la cuchilla lo atraviese con mínima resistencia. Para el sellado, los bordes fundidos se resolidifican rápidamente tras el paso de la cuchilla, creando un acabado fusionado y limpio. La temperatura de la cuchilla suele ajustarse para adaptarse a diferentes materiales y velocidades de corte.

No sólo ofrecemos tamaños estándar de cuchillas de ranurado superior, sino también cuchillas especiales diseñadas para mejorar su productividad. Todo lo que tiene que hacer es proporcionarnos planos o muestras.

Contacte hoy mismo con nuestro amable equipo de ventas. Le ayudarán a evaluar sus necesidades específicas y le ofrecerán opciones de actualización de eficacia comprobada. También puede solicitar un presupuesto.

1. Servicio de importación sin complicaciones y en un solo lugar

Disfrute de la comodidad de una importación sin interrupciones. Desde el transporte hasta el despacho de aduanas, manejamos todo el proceso. Solo tiene que pagar el IVA y esperar la llegada de sus productos.

2. Precios competitivos

Hemos visto nuestras cuchillas destacarse en innumerables aplicaciones y estamos listos para cualquier proyecto que nos presente. Espere precisión, durabilidad y precios competitivos inigualables.

3. ODM y OEM disponibles

Ya sea que nos proporcione dibujos, bocetos o muestras, podemos diseñar y fabricar para usted. También tenemos la experiencia para ayudar a modificar diseños y especificaciones existentes para mejorar casi cualquier aplicación de herramientas industriales. Por favor, contacte a nuestro equipo de ventas dedicado para discutir sus requisitos específicos.

4. Control de calidad

Se realiza una serie de pruebas e inspecciones para controlar la calidad, incluyendo la inspección del primer artículo, la inspección de material entrante y materiales certificados, la inspección de calidad en proceso, y la inspección de calidad final.

5. Adquisiciones flexibles, cooperación ilimitada

Ya sea usted un importador, distribuidor, mayorista o usuario final, le damos la bienvenida. Benefíciese de MOQ mínimos, consultas sin complicaciones y mayor libertad de compra.

6. Monitoreo en el extranjero, informe del progreso de la producción en tiempo real

Considérenos su monitor exclusivo. Le proporcionaremos actualizaciones regulares sobre cada etapa crucial de su línea de producción. No importa la distancia, tendrá información en tiempo real sobre el progreso de su producto.

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China

Manténgase al día con nuestras últimas noticias.