Si vous souhaitez choisir le broyeur adapté aux films et sacs en plastique, il est important de comprendre la différence entre Lames de broyeur de plastique vs. lames de granulateur est essentiel. Pour les déchets plastiques fins comme les films et les sacs, Lames de concasseur à un seul tranchant Réalisez des coupes nettes et optimisez le recyclage. Le choix de la lame influe directement sur la qualité du traitement des déchets plastiques et sur la quantité recyclable. Pour un recyclage optimal, il est essentiel d'associer le matériau, la conception et la compatibilité de la lame à la machine. Comparer les lames de broyeur et de granulateur de plastique vous permettra de traiter les déchets plastiques en réduisant l'usure de votre matériel et en garantissant un rendement plus constant. Comprendre l'impact du choix de la lame sur le recyclage du plastique vous aidera à sélectionner le broyeur le mieux adapté à vos besoins.

Principaux points à retenir

- Les lames d'un broyeur à plastique réduisent les gros morceaux de plastique résistant en plastique plus gros. Les lames d'un granulateur découpent le plastique en petits flocons pour le recyclage.

- Choisissez le type de lame en fonction du type de plastique. Les lames en V sont idéales pour les films souples et les sacs. Les lames plates conviennent aux plastiques fins. Les lames à griffes sont adaptées aux plastiques durs ou épais.

- Le matériau de la lame influe sur sa durée de vie et son prix. L'acier à outils est bon marché mais s'use rapidement. L'acier rapide a une meilleure durée de vie. Le carbure de tungstène offre la plus grande longévité pour un usage intensif.

- Adaptez l'épaisseur des lames et la puissance du broyeur à l'épaisseur du plastique. Vous obtiendrez ainsi de meilleurs résultats et une durée de vie accrue des lames. Les films fins nécessitent des lames fines et tranchantes, tandis que les plastiques épais requièrent des lames épaisses et robustes.

- Un entretien régulier est essentiel. Il faut vérifier, affûter et nettoyer les lames fréquemment. Cela garantit la sécurité et le bon fonctionnement des concasseurs, réduit les temps d'arrêt et améliore le recyclage.

Comparaison des lames

Lames de broyeur de plastique vs. lames de granulateur

Lorsque vous examinez les lames de broyeur et de granulateur de plastique, vous constatez qu'elles fonctionnent différemment. Les lames de broyeur réduisent les plastiques épais et résistants en petits morceaux. Les lames de granulateur, quant à elles, découpent le plastique en fines paillettes régulières. Ces paillettes sont prêtes pour l'étape suivante du recyclage. Connaître ces différences vous aidera à choisir le broyeur le plus adapté à vos besoins.

Voici un tableau récapitulatif pour vous aider à voir les principales différences :

| Fonctionnalité | Lames de broyeur en plastique | Lames de granulateur |

|---|---|---|

| Fonction principale | Réduction grossière de la taille des films et des sacs | Granulation fine et précise produisant des flocons uniformes |

| Types de lames | Griffe plate en forme de V (en forme de V pour les films souples) | Plat, à griffes, en V (optimisé pour des coupes nettes) |

| Épaisseur de la lame | Plus épais et plus résistant aux chocs | Découpe de précision plus fine (10 à 30 mm) |

| Résistance aux chocs | Élevé, pour les matériaux plus résistants | 40–50 Joules/cm² |

| Précision de coupe | Plus bas, manipule des plastiques durs et souples | Taille élevée et uniforme |

| Résistance à l'usure | Aciers à outils, revêtements en carbure de tungstène | Les lames en carbure de tungstène triplent leur durée de vie. |

| Efficacité énergétique | Modéré, supporte les gros volumes d'aliments | Amélioré, consommation d'énergie réduite avec le 14% |

| Pertinence | Plastiques souples et résistants comme les films et les sacs | Plastiques rigides, granulation propre de films/sacs |

Conseil : Les lames en V sont idéales pour broyer les films et sacs en plastique. Elles évitent les blocages lors du broyage de plastiques souples et résistants. Les lames plates conviennent aux plastiques fins. Les lames à griffes sont performantes avec les plastiques durs ou épais.

Application pour films et sacs en plastique

Vous devrez peut-être recycler différents types de déchets plastiques, comme les films LDPE, les sacs PP et les emballages alimentaires. La lame à choisir dépend de votre objectif de recyclage et du type de broyeur. Les broyeurs de plastique fonctionnent lentement mais sont très puissants. Ils réduisent les gros déchets plastiques en morceaux. pièces d'environ 15 à 40 mmLes granulateurs fonctionnent plus rapidement et utilisent des lames plus fines. Ils produisent des flocons plus petits et réguliers, généralement de 8 à 12 mm, ce qui facilite les étapes de recyclage ultérieures.

Les lames de broyeur de plastique Nanjing Metal sont disponibles en plusieurs modèles. Vous pouvez choisir entre l'acier à haute teneur en carbone et l'acier à outils D2. Traitées thermiquement et rectifiées par commande numérique (CNC), elles conservent leur tranchant et leur robustesse. Elles bénéficient d'un revêtement spécial antirouille et d'une conception réduisant les vibrations et l'usure. Vous pouvez également opter pour des dimensions et des profils de lames personnalisés, adaptés à votre broyeur et au type de plastique recyclé.

Pour gagner du temps et de l'argent, les lames de granulateur sont souvent plus adaptées au recyclage des films et des sacs. Plus faciles d'entretien et moins coûteuses à changer, elles permettent également une meilleure durabilité des revêtements. Les lames de broyeur, quant à elles, sont robustes mais nécessitent plus d'entretien et leur utilisation est plus onéreuse. Pour des lames sur mesure, consultez notre site web. page de lames personnalisées ou Contact Nanjing Metal pour obtenir de l'aide.

Types de lames pour films et sacs

broyeur de plastique

Caractéristiques structurelles

Il existe de nombreux types de lames pour broyeurs de plastique. Les plus courantes sont les lames à crochet, en forme de F et en V. Les lames à crochet saisissent et déchirent les déchets plastiques résistants. Elles sont particulièrement efficaces avec les films et sacs emmêlés. Les lames en forme de F présentent un faible espace entre les lames mobiles et fixes. Leur conception en V empêche les plastiques souples de s'enrouler autour des lames. Ceci optimise le broyage et permet d'obtenir des copeaux d'environ 40 mm. Le rotor supporte les lames mobiles, tandis que le stator maintient les lames fixes en place. Cette configuration permet de broyer efficacement les gros morceaux de plastique.

Matériaux courants

Les lames des broyeurs de plastique doivent être robustes. Elles sont souvent fabriquées en acier à outils, en acier rapide ou en carbure de tungstène. Ces matériaux leur confèrent dureté et résistance, et contribuent également à prolonger leur durée de vie. Un traitement thermique renforce encore leur solidité. Certaines lames sont revêtues d'une protection antirouille et anti-usure.

Types de films/sacs compatibles

Les broyeurs de plastique sont idéaux pour les déchets plastiques souples et résistants. Ils conviennent aux films LDPE, aux sacs PP, aux emballages alimentaires et aux films étirables. Ils sont particulièrement efficaces avec les déchets plastiques encombrants ou emmêlés. Leurs lames à crochets et en forme de F permettent de broyer ces plastiques sans se bloquer.

Avantages et inconvénients

Avantages :

- On peut broyer rapidement de grandes quantités de déchets plastiques.

- Les lames viennent à bout des films et sacs résistants et emmêlés.

- Les lames durent longtemps si vous en prenez soin.

Inconvénients :

- Les flocons sont plus gros et de tailles différentes.

- Des étapes supplémentaires peuvent être nécessaires pour obtenir des flocons plus petits.

- La réparation peut s'avérer plus difficile si les lames se bloquent ou s'usent.

Conseil : Utilisez des lames en forme de V ou de F pour éviter que le film ne s'enroule et pour faciliter le déchiquetage des films plastiques souples.

granulateur de plastique

Caractéristiques structurelles

Les lames des granulateurs de plastique existent en différentes formes : lames dentées, lames décalées et lames à palettes. Les lames dentées ont une forme complexe et permettent un broyage grossier et fin. Les lames décalées présentent de grands angles de coupe, ce qui réduit la résistance et facilite la coupe. Les lames à palettes utilisent un mouvement de coupe en V, comme des ciseaux, pour une découpe rapide des gros déchets plastiques. Le rotor supporte les lames mobiles, tandis que le stator assure la stabilité des lames fixes. L'écartement entre les lames est important et doit être réglé en fonction de la lame la plus large pour obtenir des flocons uniformes.

Matériaux courants

Les lames des granulateurs de plastique sont fabriquées en acier SKD11, V-4E, acier à outils et carbure de tungstène. L'acier SKD11 est dur et résistant à l'usure, idéal pour les plastiques courants. L'acier V-4E, plus robuste, convient aux plastiques renforcés de fibres de verre. Certaines lames sont dotées d'une pointe en carbure pour une résistance accrue.

Types de films/sacs compatibles

Les granulateurs de plastique sont particulièrement performants avec les déchets plastiques fins et propres. Ils conviennent aux films LDPE, aux sacs PP et autres plastiques souples. Les lames à biseau simple et à angle aigu permettent une coupe nette des petites quantités de déchets plastiques. Les lames à biseau composé ou inversé sont plus adaptées aux plastiques épais ou en grande quantité.

Avantages et inconvénients

Avantages :

- On obtient des flocons plus uniformes avec moins de poussière.

- Les lames produisent de petits flocons prêts à être recyclés.

- Il est plus facile de réparer et de changer les lames, et cela coûte moins cher.

Inconvénients :

- Le broyeur fonctionne mieux avec des déchets plastiques propres et fins.

- Il est indispensable de régler correctement l'écartement des lames pour obtenir de bons résultats.

- Les lames s'usent plus rapidement avec du plastique dur ou sale.

Remarque : Des lames bien affûtées et bien ajustées, ainsi qu'un écartement correct entre les lames, permettent d'obtenir de bons flocons et d'optimiser le fonctionnement du concasseur.

Tableau comparatif

Voici un tableau comparatif des lames de broyeurs et de granulateurs de plastique pour le recyclage des films et des sacs :

| Fonctionnalité | Lames de broyeur en plastique | Lames de Granulateur Plastique |

|---|---|---|

| Scénario d'application | Déchets plastiques volumineux, enchevêtrés et résistants | Déchets plastiques fins, propres et triés |

| Taille des flocons | 15–40 mm (moins uniforme) | 8–12 mm (uniforme) |

| Difficulté de maintenance | Modéré à élevé | Faible à modéré |

| Coût du changement de lame | Plus haut | Inférieur |

| Qualité de la sortie | Flocons grossiers, peuvent nécessiter un retraitement. | Fines paillettes, prêtes à être recyclées |

| Types de films/sacs compatibles | PEBD, PP, films étirables, emballages alimentaires | PEBD, PP, sacs fins, films propres |

| Options de matériaux de lame | Acier à outils, HSS, carbure | SKD11, V-4E, carbure |

| Personnalisation | Disponible | Disponible |

Pour broyer de grandes quantités de déchets plastiques résistants, optez pour un broyeur de plastique. Pour des déchets plastiques fins et propres, ou pour obtenir de belles paillettes, utilisez un granulateur de plastique.

Critères de sélection

Comment choisir un granulateur de plastique

Évaluation du type et de la forme du matériau

Vous devez savoir quel type de plastique vous souhaitez recycler. Les films et les sacs sont fabriqués en PEBD, PEHD ou PP. Chaque type possède une résistance et une flexibilité différentes. Les films fins nécessitent des lames affûtées et une vitesse réduite pour éviter qu'ils ne se déchirent. Les sacs épais requièrent des lames plus robustes et une puissance supérieure. Si vous avez des films mélangés ou superposés, utilisez des lames et des rouleaux modulaires et réglables. Cela vous permettra de broyer différents types de plastique sans endommager votre broyeur.

Évaluation de l'épaisseur du film et du sac

L'épaisseur du film ou du sac influe sur le fonctionnement de votre broyeur. Les films fins comme le PEBD nécessitent des lames affûtées et une alimentation précise. Les films d'épaisseur moyenne requièrent des lames plus robustes. Les films épais comme le PEHD ou le PP exigent des lames dures et des broyeurs puissants. Les lames épaisses durent plus longtemps, mais consomment davantage d'énergie. Pour des résultats optimaux et une durée de vie accrue des lames, il est essentiel d'adapter leur épaisseur à celle du plastique.

Compte tenu des niveaux de contamination

Les films et sacs sales peuvent endommager votre broyeur et produire des flocons de mauvaise qualité. Vous devriez Trier et laver le plastique avant de le broyerRetirez la saleté, le sable et autres débris pour protéger vos lames. Pour les films encrés ou multicouches, utilisez un tri et un délaminage spécifiques. Cela préserve votre broyeur et vous permet d'obtenir des paillettes propres. Si vous broyez des films sales ou multicouches, choisissez un broyeur doté de lames robustes et facile à nettoyer.

Choisir le bon type de granulateur en fonction des objectifs de recyclage

Vos objectifs de recyclage vous aideront à choisir le broyeur adapté. Si vous souhaitez obtenir des paillettes de qualité à vendre, utilisez un granulateur à coupe fine. Pour de grandes quantités de plastique résistant, optez pour un broyeur à haut rendement. Certains granulateurs peuvent broyer et produire des granulés, offrant ainsi plus de possibilités. Privilégiez les broyeurs dotés d'un variateur de vitesse, d'une alimentation robuste et d'une facilité d'entretien. Ces caractéristiques vous permettront d'atteindre vos objectifs et de réaliser des économies.

erreurs de sélection courantes

- Certaines personnes choisissent des broyeurs inadaptés à leurs plastiques ou à leurs besoins. Cela entraîne un faible rendement, une production de poussière accrue et une usure rapide des lames.

- Certains négligent l'entretien. Des lames ou des grilles difficiles d'accès ralentissent le nettoyage et entraînent davantage d'arrêts.

- D'autres négligent la conception des lames. Le nombre de lames, leur angle et leur tranchant influent sur la coupe et la consommation d'énergie.

- Un excès de matière alimentant le concasseur peut le bloquer, émousser les lames et surcharger les moteurs. Utilisez des alimentateurs automatiques pour éviter cela.

- La sécurité est primordiale. Choisissez toujours des concasseurs équipés d'arrêts d'urgence, de verrous de sécurité et de dispositifs de contrôle faciles d'accès.

Conseil : Vérifiez toujours si le fabricant propose un bon support et un service après-vente de qualité. Un bon support signifie moins d’interruptions de service et de meilleurs résultats.

Matériaux et contamination

Types de films et sacs en plastique (PEBD, PEHD, PP, etc.)

Vous trouverez de nombreux types de films et de sacs en plastique. Le PEBD est souple et se plie facilement. Il est utilisé pour les sacs et emballages alimentaires. Le PEHD est plus résistant et sert aux sacs et emballages épais. Le PP est robuste et ne fond pas facilement. Il est utilisé pour les emballages alimentaires et les sacs tissés. Chaque type de plastique nécessite un broyeur adapté. Le PEBD est plus efficace avec des lames affûtées et une vitesse réduite. Le PEHD et le PP requièrent des lames robustes et une puissance plus élevée.

| Type de film / Épaisseur | Type de lame et vitesse de coupe | Paramètres d'alimentation et de rouleau | Type et caractéristiques de la machine |

|---|---|---|---|

| couches minces (PEBD, 10–30 μm) | Lames petites et tranchantes ; vitesse de coupe plus lente | Rouleaux à faible tension ; écartement réduit entre les rouleaux | Extrudeuse monovis ; découpeurs modulaires pour films minces |

| Films moyens (30–60 μm) | Renforcement modéré de la lame | Vitesse d'alimentation et écartement des rouleaux modérés | Broyeur mono-arbre + ligne de lavage pour PEBD, PEHD, PP |

| Films épais (PEHD, PP, 50–150 μm) | Lames renforcées et trempées ; couple élevé | Rouleaux robustes avec des écartements plus larges ; haute tension | Lignes de granulation robustes avec moteurs puissants |

Influence de l'épaisseur du matériau sur le choix de la lame

L'épaisseur du plastique influe sur le fonctionnement de votre broyeur. Les lames épaisses se plient moins et durent plus longtemps avec les plastiques résistants. Les lames fines coupent bien les films souples, mais s'usent plus vite avec les plastiques durs. Les lames épaisses nécessitent plus de puissance. Pour des résultats optimaux et une durée de vie maximale des lames, il est essentiel de trouver le bon équilibre entre épaisseur, dureté et revêtement.

Manipulation de matériaux contaminés ou multicouches

Les films sales ou multicouches nécessitent un traitement particulier. Triez et lavez tous les plastiques avant le broyage. Retirez la saleté, le sable et les étiquettes pour protéger votre broyeur. Pour les films multicouches, utilisez des outils spéciaux pour séparer les couches. Un tri avancé, comme le tri par infrarouge proche, permet d'obtenir un plastique plus propre. Cela préserve votre broyeur et produit des paillettes de meilleure qualité.

- Trier les films par type, couleur et densité.

- Laver et sécher pour enlever la saleté et le sable.

- Utilisez des outils spéciaux pour les films multicouches.

- Utilisez un tri avancé pour obtenir un plastique plus propre.

Options de matériaux pour la lame (acier à outils, HSS, carbure)

Le matériau des lames influe sur leur coût et leur durée de vie. Les lames en acier à outils sont économiques mais s'usent rapidement. Les lames en acier rapide durent beaucoup plus longtemps et conviennent à la plupart des plastiques. Les lames en carbure de tungstène sont les plus chères, mais aussi les plus durables. Elles peuvent broyer plus de 1 100 tonnes avant d'être remplacées. Choisissez le matériau de lame adapté à votre concasseur et à votre budget.

- Acier à outils : Bon marché, durée de vie courte, convient pour un usage léger.

- HSS : Prix moyen, longue durée de vie, convient à la plupart des plastiques.

- Carbure de tungstène : Cher, durée de vie la plus longue, idéal pour le concassage intensif.

Considérations relatives à la durabilité et à l'entretien

Des lames robustes réduisent les temps d'arrêt et les coûts. Privilégiez les lames à revêtement résistant pour une durée de vie prolongée. Un accès facile aux lames et aux grilles facilite le nettoyage et la réparation. Contrôlez régulièrement l'affûtage et l'écartement des lames pour un fonctionnement optimal de votre concasseur. Ayez toujours des lames de rechange à portée de main pour éviter les arrêts prolongés.

Taille et capacité de production

Taille des particules de sortie requise

Il est important de connaître la taille des paillettes souhaitée avant de choisir vos lames. La plupart des films et sacs à recycler nécessitent des paillettes de 8 à 12 mm. Les lames à griffes sont idéales pour les films et sacs souples : elles coupent bien et ne s'encrassent pas. Les lames plates produisent des paillettes uniformes, optimales pour les plastiques recyclés de haute qualité.

| Type de lame | Caractéristiques de conception | Types de matériaux appropriés | Effet sur la taille des particules et l'efficacité du broyage |

|---|---|---|---|

| Lames à crochet | Dents incurvées en forme de crochet | Plastiques denses et épais | Convient aux plastiques résistants, moins adapté aux films ou aux sacs. |

| Lames à griffes | dents pointues et acérées | Films, matériaux flexibles | Découpe précise, réduction du colmatage, idéal pour les films/sacs |

| Lames plates | Bords lisses, droits/angulaires | Déchiquetage propre et uniforme nécessaire | Des tailles de particules constantes et uniformes pour une production de haute qualité |

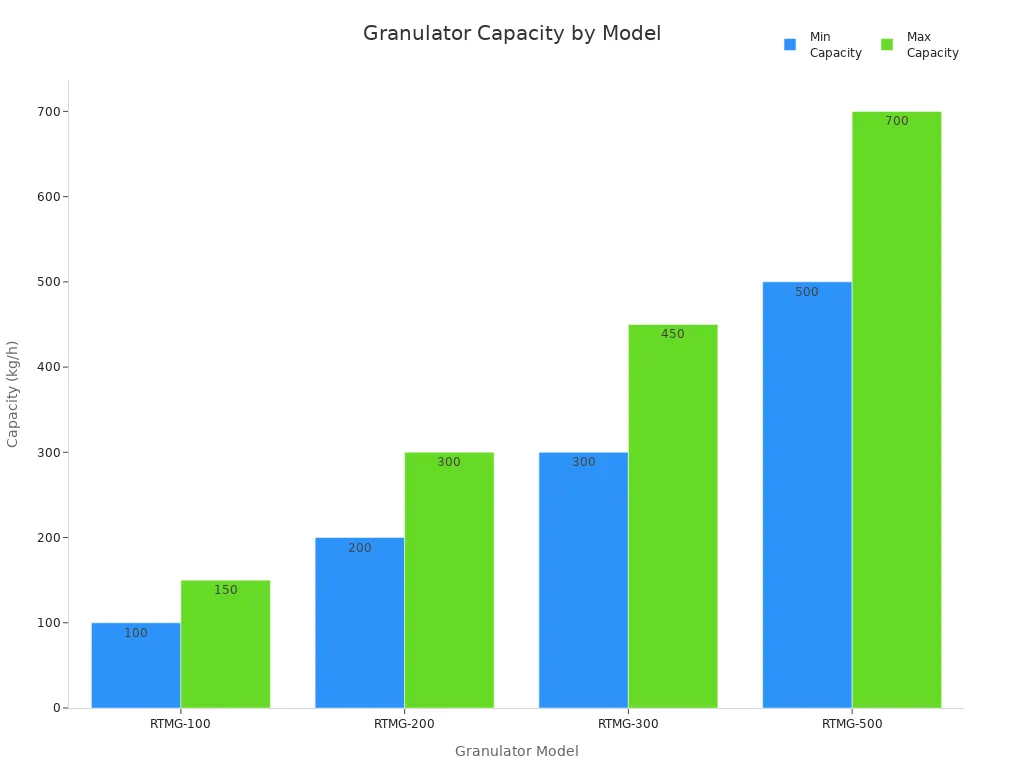

débit et capacité de production

La taille et la puissance d'un concasseur déterminent la quantité de plastique qu'il peut broyer. Les granulateurs peuvent traiter de 100 à 700 kg/h, avec des moteurs de 7,5 à 37 kW. Les broyeurs peuvent broyer de 500 à 1 000 kg/h et sont donc plus adaptés aux gros volumes. Choisissez toujours un concasseur adapté à vos besoins de recyclage.

| Modèle de granulateur | Puissance du moteur (kW) | Plage de capacité (kg/h) |

|---|---|---|

| RTMG-100 | 7.5 | 100 – 150 |

| RTMG-200 | 15 | 200 – 300 |

| RTMG-300 | 22 | 300 – 450 |

| RTMG-500 | 37 | 500 – 700 |

Les broyeurs comme le broyeur de film PET à arbre unique SHREDALL peuvent broyer jusqu'à 1000 kg/h avec un moteur de 50 ch.

Configuration de la machine pour différents besoins de production

Vous pouvez adapter votre broyeur pour obtenir les paillettes souhaitées. Modifiez le type de lames, la taille des tamis et la vitesse du rotor pour obtenir différents résultats. Pour les films souples, utilisez des broyeurs monocouches à lames froides. Pour les films multicouches résistants, utilisez des broyeurs ABA pour films soufflés afin d'obtenir une meilleure résistance. Le refroidissement à l'air ou à l'eau influe également sur la qualité des paillettes et sur la quantité que vous pouvez broyer.

| Type de machine | Fonctionnalités de configuration | Types de produits/sorties appropriés | Points clés de réglage |

|---|---|---|---|

| Film soufflé monocouche | Configuration simple à une seule couche | Films souples, films rétractables | Ajuster en fonction des besoins en films flexibles |

| Film soufflé ABA | Trois couches, haute résistance | Emballages résistants, couvertures de piscine | Multicouche pour plus de solidité |

| Repro-Air | Refroidi par air, compact | petite capacité, plastiques souples | Alimentation directe, sans eau |

| Repro-Flex | Refroidi à eau, grande capacité | Déchets diversifiés, rendement élevé | Compacteur intégré, filtration |

Concilier efficacité et consommation d'énergie

Un concassage efficace permet d'économiser de l'énergie et de l'argent. Recyclage mécanique Ce procédé consomme moins d'énergie que la fabrication de plastique neuf. Le tri et le nettoyage sont les étapes les plus énergivores ; optimisez-les donc. Utilisez des moteurs économes en énergie et des variateurs de vitesse. Modifiez votre processus pour réduire les déchets et améliorer le broyage.

| Méthode de recyclage | Aperçu de la consommation et de l'efficacité énergétiques | Stratégies d'optimisation |

|---|---|---|

| Recyclage mécanique | Utilise peu d'énergie, le tri et le nettoyage étant les principales tâches. La qualité diminue après plusieurs cycles. | Améliorer les routines, optimiser le tri/nettoyage, ajouter des matériaux résistants. |

| thermolyse | Consomme beaucoup d'énergie, nécessite une forte chaleur, coûte plus cher. | Utiliser des catalyseurs et le chauffage au micro-ondes pour un meilleur contrôle. |

| Recyclage chimique | Utilise moins d'énergie que la thermolyse, idéal pour les plastiques mixtes. | Trouver de meilleures façons de décomposer les plastiques. |

Réglage de l'écartement des lames et de la taille de l'écran

Écartement des lames et taille de l'écran Modifiez la qualité des flocons. Un petit espacement permet une meilleure coupe et un broyage plus silencieux. Les petits trous produisent des flocons uniformes, mais le broyage est plus lent. Les grands trous broient plus rapidement, mais les flocons sont moins uniformes. Ajustez la vitesse du rotor et le réglage des lames pour un résultat optimal.

| Facteur | Effet sur la qualité de la production |

|---|---|

| Écart de lame | Un écart réduit permet une meilleure coupe, produit de meilleurs copeaux et fait moins de bruit. |

| Taille de l'écran | Les petits trous produisent des flocons réguliers, les grands trous écrasent plus vite mais les flocons sont moins réguliers. |

| vitesse du rotor | À vitesse lente, il faut de petits trous ; à vitesse rapide, il faut de grands trous. |

| Configuration du couteau | Les couteaux inclinés coupent mieux et font moins de bruit, ce qui contribue à une meilleure qualité des copeaux. |

- Modifiez l'écartement des lames et la taille du tamis en fonction des différents plastiques.

- Veillez à maintenir un écart correct entre les couteaux mobiles et fixes pour obtenir la taille des copeaux.

- Utilisez une rotation rapide et le bon tamis pour un bon broyage.

Remarque : Vérifiez et modifiez régulièrement l'écartement des lames et la taille du tamis pour assurer le bon fonctionnement de votre concasseur.

Conseils pratiques

Adaptation du type de lame aux scénarios de recyclage

Pour un résultat optimal, choisissez la lame adaptée. Si vous travaillez avec des films ou des sacs en plastique souple, utilisez des lames en V ou à griffes. Ces lames coupent bien le plastique souple et évitent les bourrages. Pour les plastiques épais ou rigides, les lames plates ou robustes sont plus appropriées. Elles coupent les plastiques résistants et durent plus longtemps.

Réfléchissez à ce que vous attendez du recyclage. Si vous avez besoin de petits flocons uniformes, utilisez un granulateur à lames fines et tranchantes. Cela vous permettra de travailler plus rapidement et facilitera le tri. Pour les gros morceaux de plastique emmêlés, utilisez un broyeur à lames recourbées ou en forme de F. Ces lames broient le plastique rapidement. Vérifiez toujours le type de plastique que vous avez. Adaptez la forme et l'écartement des lames au type de plastique. Cela optimisera le fonctionnement de votre broyeur et vous fera gagner du temps.

Conseil : Créez un tableau indiquant les lames les plus adaptées à chaque type de plastique. Cela vous permettra de changer rapidement de lame et d’assurer le bon fonctionnement de votre ligne de recyclage.

Maintenance et sécurité

L'entretien régulier de votre concasseur garantit sa sécurité et son bon fonctionnement. Formez le personnel à l'utilisation et à la réparation de la machine. Portez toujours des gants et des lunettes de protection à proximité du concasseur. Avant toute intervention, coupez l'alimentation électrique et l'air comprimé. Attendez l'arrêt complet de la machine avant d'ouvrir la chambre de coupe.

Suivez ces étapes pour assurer la sécurité de votre concasseur :

- Vérifiez chaque semaine l'état des lames et des grilles afin de déceler les pièces émoussées ou cassées.

- Affûtez les lames toutes les 100 à 300 heures. Changez-les après 500 à 1000 heures, selon l'utilisation.

- Nettoyez régulièrement l'orifice d'alimentation et la chambre de broyage. Utilisez de l'air comprimé, et non de l'eau ou des nettoyants puissants.

- Vérifiez que les boulons sont bien serrés et assurez-vous que les protections sont en place avant de commencer.

- Utilisez les outils appropriés pour soulever les pièces lourdes. Soulevez avec vos jambes, pas avec votre dos.

- Soyez attentif aux bruits étranges ou aux secousses. Signalez tout problème à quelqu'un.

| Défi de maintenance | Causes | Solutions |

|---|---|---|

| Obturation | Des morceaux de plastique, des choses qui n'ont rien à faire là. | Nettoyer fréquemment, ralentir l'alimentation, vérifier les obstructions |

| Surchauffe | Les lames sont émoussées, manque d'huile. | Affûtez les lames, ajoutez de l'huile, contrôlez la force avec laquelle vous écrasez les lames. |

| Lames émoussées ou mal alignées | Lames usées, espacement incorrect | Affûter ou changer les lames, ajuster l'espacement |

| bruit élevé | Pièces détachées, lames émoussées | Resserrer les pièces, affûter ou changer les lames |

Remarque : Vérifier régulièrement votre concasseur et former tout le personnel permet d'éviter les accidents et d'assurer le fonctionnement optimal de votre ligne de recyclage.

Lorsque vous choisissez entre des lames de broyeur et des lames de granulateur pour plastique, tenez compte du type de lame dont vous avez besoin, de sa composition et de l'utilisation que vous souhaitez faire de vos déchets recyclables. Les lames en V sont idéales pour les films plastiques. Les lames plates conviennent aux plastiques fins. Utilisez des lames SKH-9 pour les plastiques souples et des lames SKD-11 pour les plastiques résistants. Consultez le tableau ci-dessous avant de faire votre choix :

| Élément de la liste de contrôle | Que rechercher |

|---|---|

| Type de matériau | Plastique souple, fin ou dur |

| Forme de la lame | En forme de V, plate ou en griffe |

| Niveau de contamination | plastique propre ou mélangé |

| Matériau de la lame | SKH-9, SKD-11, acier chromé |

| Besoins de production | Flocons fins ou grande capacité |

Des lames de qualité et un entretien régulier de votre concasseur contribuent à prolonger sa durée de vie. Si vous avez besoin de lames spéciales, veuillez contacter notre ingénieur commercial. ici.

FAQ

Quelle est la principale différence entre les lames de broyeur à plastique et les lames de granulateur ?

Les lames des broyeurs de plastique réduisent les gros morceaux de plastique en plus petits fragments. Les lames des granulateurs découpent les films et sacs plastiques en minuscules flocons. Les broyeurs sont efficaces pour les travaux difficiles. Les granulateurs produisent des flocons petits et réguliers.

Comment choisir le broyeur de plastique adapté aux films et aux sacs ?

Examinez le type de plastique dont vous disposez. Vérifiez son épaisseur et son état (saleté, etc.). Déterminez la quantité de plastique à broyer. Choisissez des lames adaptées à votre tâche de recyclage. Assurez-vous que le broyeur fonctionne correctement avec votre plastique et qu'il vous offre le rendement souhaité.

Pourquoi le matériau des lames est-il important pour l'efficacité du recyclage ?

Le matériau des lames influe sur leur durée de vie. Les lames robustes, comme celles en acier à outils ou en carbure, offrent une meilleure coupe et permettent de broyer davantage de films et de sacs plastiques. Le recyclage est ainsi plus rapide et votre broyeur dure plus longtemps.

Puis-je utiliser le même broyeur pour différents types de broyeurs de plastique ?

Certains broyeurs fonctionnent avec différentes machines. Il est impératif de vérifier la compatibilité des lames et le bon réglage. Veillez à toujours choisir le type de lame et le réglage du broyeur adaptés à votre plastique. Cela garantit la sécurité et vous assure un résultat optimal.

À quelle fréquence dois-je entretenir ou remplacer les lames d'un granulateur de plastique ?

Vérifiez les lames chaque semaine. Affûtez-les après 100 à 300 heures d'utilisation. Remplacez-les après 500 à 1 000 heures, selon la quantité de plastique broyé et le type de plastique utilisé. Un entretien régulier garantit le bon fonctionnement de votre granulateur et prévient les pannes.

Voir aussi

Choisir entre les Lames de Rechange OEM et Aftermarket pour les Broyeurs de Plastique Industriels

Guide de remplacement de la lame du broyeur à plastique : quand et comment le faire correctement

Quand remplacer les lames du broyeur à plastique : signes d'usure et conseils d'entretien