You use lames de refendage rotatives to make accurate and clean cuts. These blades are important in tough manufacturing jobs. The shape of each blade helps you get precise results. It also helps you stop mistakes from happening. Blade material, quality control, and burr reduction all change how accurate your cuts are. They also affect how smooth the finish looks. Look at how these things compare:

| Point de preuve | Description |

|---|---|

| Matériau de la lame | The blade material you pick changes how long it lasts. It also changes how well it cuts and how good the cut looks. |

| Contrôle Qualité Rigoureux | Strong quality control makes sure every blade is made right. This is very important for keeping your cuts accurate. |

| Burr Reduction | Ways to lower burrs and debris make the cuts better. They also help the production process work faster. |

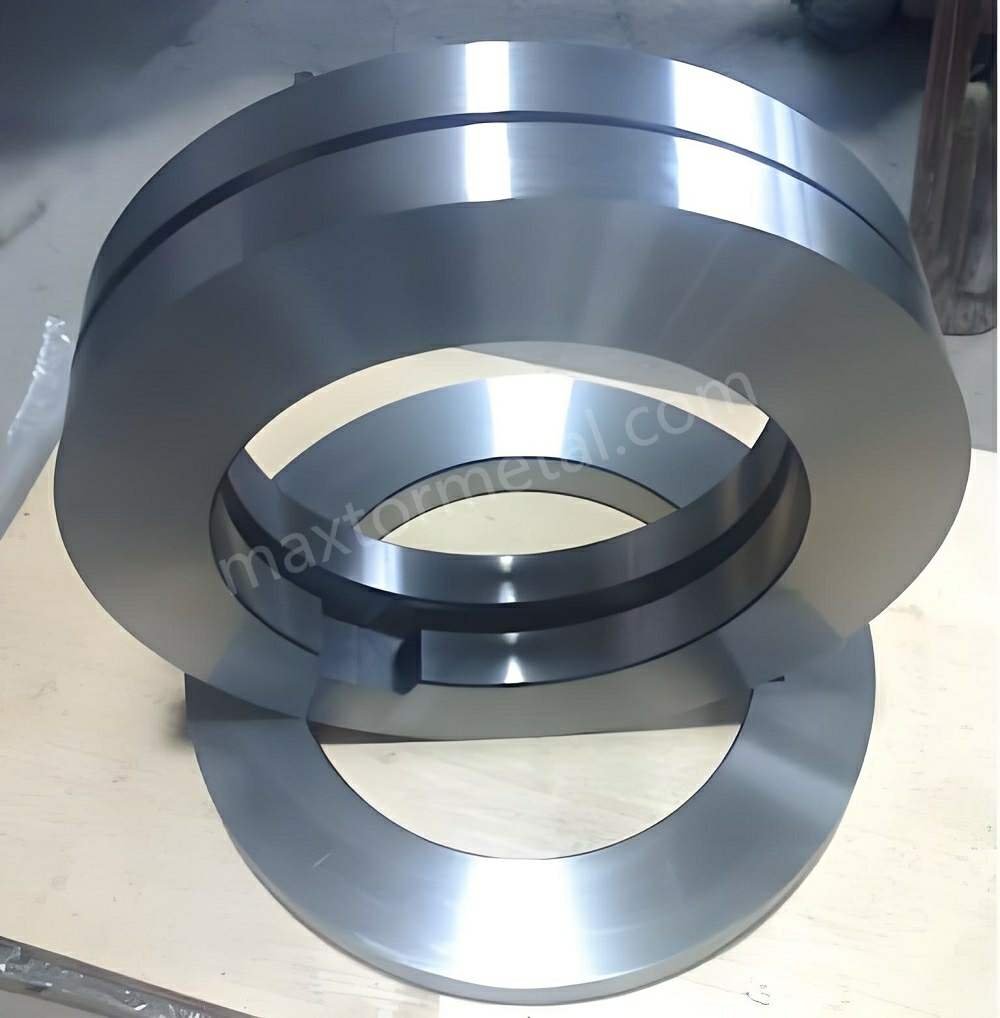

Nanjing Metal Industrial’s Roller Shearing Blades are very precise. They help you get accurate and dependable results every time.

Principaux points à retenir

- Pick the best blade material for strong and good cuts. Tungsten carbide stays sharp longer than regular steel.

- Learn about edge profiles. Square edges make sharp cuts but wear out fast. Rounded edges last longer and chip less.

- Pick the right bevel angle. Single-bevel blades are strong for straight cuts. Double-bevel blades cut cleaner and need less force.

- Think about blade thickness. Thicker blades bend less and stay steady. Thinner blades are better for small, careful cuts.

- Keep blades sharp to make better cuts. Check and sharpen blades often to make less waste and protect machines.

- Look at the surface finish. Polished blades slide easier and keep cuts neat. Ground blades may need cleaning more often.

- Change blade geometry for different materials. Matching the blade to the material helps make good cuts and fewer mistakes.

- Ask experts for custom blade designs. Special blades can cut better and help with your production needs.

Rotary Slitter Blade Geometry Essentials

Edge Profile

Square vs. Rounded

When you pick rotary slitter blades, you should check the edge profile. The edge can be square or rounded. Each one changes how your circular slitter blades work. Square edges make sharp and clean cuts. But they can wear out faster. Rounded edges last longer and help stop tiny chips. You can see how different edge radii change cut quality in this table:

| Rayon du bord | Effect on Cut Quality |

|---|---|

| 30µm | Reduced micro-chipping by 40%, lowering blade replacement frequency. |

| 15µm | Required 10% less cutting force than a sharp 5µm blade. |

| 10µm to 20µm | Reduced defective cuts by 15%, leading to lower material waste and higher yield. |

If you want your blades to last longer, you might choose a rounded edge. If you need the sharpest cut, a square edge is better. The best choice depends on your material and what you want to do.

Initial Contact Impact

How your rotary slitter blades first touch the material is important. A sharp and well-made edge profile helps you get clean and accurate cuts. If the edge is too dull, you might see more burrs or rough spots. If the edge is too sharp, it can chip or wear out fast. You need to find a good balance between sharpness and strength. This helps you get the accuracy you want and keeps your work running well.

Bevel Angle

Single vs. Double

The bevel angle is another important part of rotary slitter blade geometry. You can pick single-bevel or double-bevel circular slitter blades. Single-bevel blades have one slanted side. They give you a strong edge and are good for straight cuts. Double-bevel blades have two slanted sides. They help you make cleaner cuts and use less force. You should pick the bevel type based on your material and the cut you need.

Tapered Sides

Some rotary slitter blades have tapered sides. Tapered sides help lower friction and heat when cutting. They also stop material from sticking to the blade. This makes the blade work better and gives you more accurate results. Tapered sides are helpful when you cut sticky or thick materials.

Thickness and Diameter

Rigidity and Stability

The thickness and diameter of your rotary slitter blades change how stable and strong they are. Thicker blades are more rigid. They help stop flexing and wobbling, so you get better accuracy and cleaner cuts. Thinner blades can bend or break more easily, especially with hard materials. The tables below show how thickness and core size affect stability:

| Core Thickness | Impact on Stability |

|---|---|

| Thicker Cores | Greater rigidity, less wobbling, improved accuracy on hard materials. |

| Blade Thickness Range | Effect on Rigidity and Stability |

|---|---|

| 0.004 in. to 0.125 in. | Thicker blades provide greater rigidity, reducing flexing during cutting. Thinner blades are more prone to flexing and breaking. |

If you work with thick or tough materials, you need strong machines and more power to support your blades:

| Épaisseur du matériau | Required Mechanical Systems |

|---|---|

| Matériaux épais | Robust systems and higher power drives needed for effective slitting. |

Choix des matériaux

The material you pick for your circular slitter blades changes how long they last and how well they cut. Tungsten carbide blades last up to three times longer than regular steel blades. They have a hardness rating of about 1,500 Vickers. Standard steel blades rate between 700 and 900 Vickers. For most rotary slitter blades, D2 and M2 steel work well. If you cut metal foils or films, carbide blades are the best. Picking the right material helps you get the accuracy and strength you need.

If you want to learn more about custom blade geometry and material choices, you can visit the custom blades page. You can also see how Nanjing Metal Industrial uses advanced blade technology and top materials in their Roller Shearing Blades to help you get high accuracy and clean cuts in your work.

Finition de surface

Polished vs. Ground

You can pick a polished or ground finish for your rotary slitter blades. A polished blade is very smooth. This smooth surface stops dust and small bits from sticking. When you use polished rotary slitter blades, your cuts are more exact. You also spend less time cleaning the blades. In one test, engineers tried two top-dished upper knives with ceramic coating. They polished the blades to see how the surface changed cutting. The mirror-polished rotary slitter blades worked great on thin metal foil. You get fewer burrs and a cleaner edge with a polished finish.

A ground blade is rougher. This roughness can make more material stick to the blade. When this happens, cut quality can drop. You may need to clean the blade more often. If you want your rotary slitter blades to work well, think about how the surface finish will help your work.

Tip: Pick a polished finish for rotary slitter blades if you want high accuracy and less cleaning time.

Microstructure Effects

The microstructure of rotary slitter blades is very important. It changes how well the blades cut and how long they last. You should look at things like hardness, toughness, wear resistance, and grain size. Each one changes how the blade works in a different way. Here is a table that explains these things:

| Propriété | Description |

|---|---|

| Dureté | Measured on the Rockwell C scale. Harder blades stay sharp longer but can chip if too brittle. |

| Dureté | Helps the blade take hits. Tough blades do not break easily. You need a balance to stop chipping or dulling. |

| Résistance à l'usure | Makes the blade last longer. You can make this better with heat treatment and by changing the microstructure. |

| Grain Size | Smaller grains make the blade stronger and help it cut better. |

When you pick rotary slitter blades, think about both the surface finish and the microstructure. A good mix gives you clean cuts, longer blade life, and less work fixing them. You can ask for blades with special finishes or microstructures to fit your needs.

Micro-Cutting Mechanics

Pressure Distribution

Shear vs. Fracture

When you use circular slitter blades, the way pressure spreads across the blade edge changes how the material breaks. You want to control if the material shears or fractures. Shearing gives you clean cuts and high precision. Fracture can cause rough edges and more waste. The pressure you apply, the properties of the material, and the cutting force all play a role. If you work with slitting films and foils, you need to pay close attention to these factors.

Here is a table that shows what affects the transition between shear and fracture:

| Facteur | Description |

|---|---|

| Pressure Distribution | Changes the cutting force and the switch from shearing to fracturing during slitting. |

| Propriétés des matériaux | Young’s modulus, yield stress, and fracture toughness affect how the material reacts. |

| Force de coupe | Drives the process and decides if you get shear or fracture. |

| Chip Thickness | Thinner chips can change how the material breaks. |

| Friction | Can make the material bend or break instead of shear. |

| Non-dimensional Thickness | Decides if you get fracture or plastic bending during cutting. |

If you want high accuracy and precision, you need to balance these factors. You can adjust your rotary slitter blades and machine settings to get the best results.

Edge Sharpness Role

The sharpness of your circular slitter blades makes a big difference in cutting efficiency and cut quality. A sharp edge helps you get clean cuts and reduces the chance of tearing. If you use a rounded edge, you spread the cutting force more evenly. This helps your blades last longer and keeps the cut smooth.

- Enhanced durability: A good edge radius spreads the force, so your blades chip and wear less.

- Improved cutting quality: Rounded edges give you cleaner cuts and fewer jagged edges.

- Increased efficiency: A well-designed edge lowers resistance, so you can cut faster and use less energy.

When you work with slitting films and foils, edge sharpness becomes even more important. You want to keep your blades sharp and check them often to keep your precision high.

Burrs and Deformation

Burr Formation Causes

Burrs are small pieces of material that stick out from the edge after cutting. They can lower your accuracy and make your products look rough. Many things can cause burrs when you use rotary slitter blades. You need to watch for these common causes:

| Cause | Explication |

|---|---|

| Propriétés des matériaux | Stress during cutting can tear the material and make burrs. |

| Processing Settings | Wrong machine settings can lead to more burrs. |

| Clearance Issues | If the gap between blades is wrong, you get more burrs. |

| Usure de la lame | Dull blades do not cut well and leave jagged edges. |

| Process Parameters | Wrong speed or pressure can make burrs worse. |

| Knife Sharpness | Dull knives crush instead of slice, making more burrs. |

| Ajustement du jeu | Not enough clearance makes the blade push, not slice, causing burrs. |

You can see that both the blade and the way you use it matter for burr control.

Geometry Solutions

You can solve burr and deformation problems by choosing the right blade geometry and settings. Here are some tips:

- Set the correct blade clearance. If the gap is too big, you get rough, torn edges. If it is too tight, you get high wear and more burrs.

- Use sharper blades for cleaner cuts and less burrs.

- Try wave edge blades. These spread the cutting force and help you get smoother edges.

Here is a table that shows how blade geometry affects burrs:

| Géométrie de la lame | Effect on Cutting Efficiency and Burr Formation |

|---|---|

| Sharper Blades | Cleaner cuts, fewer burrs. |

| Wave Edge Blades | Even force, less edge burrs. |

You can also check your blade clearance:

| Jeu de lame | Effect on Burr Formation |

|---|---|

| Too Large | Rough, torn edges. |

| Too Tight | High side pressure, more burrs. |

If you want high precision and cutting efficiency, you need to match your circular slitter blades and machine settings to your material. This helps you get the accuracy you need and keeps your production smooth.

Defect Analysis

Edge Radius Issues

You may see defects like dust, chips, or rough edges if your circular slitter blades are not set up right. A dull or poorly sharpened blade can make dust and chips. If you use the wrong edge radius, you can get rough edges or even slitter skip, where the blade does not cut all the way through. You want to keep your blades sharp and check the edge radius often.

Here is a table of common defects and what causes them:

| Defect Type | Causes |

|---|---|

| Dust | Blunt knives, damaged bearings, overspeed, too much overlap, or unstable guidance. |

| Chips and Nicks | Wrong knife position or blade placement. |

| Bords rugueux | Dull blades, poor grinding, or wrong cutting parameters. |

| Slitter Skip | Dull edges, not enough side-loading, or wrong shear angle. |

| Excessive Overlap | Too much contact, often from new materials not fit for the machine. |

You can avoid these problems by checking your blade geometry and keeping your blades in good shape.

Taper Effects

The taper of your circular slitter blades also affects defect rates. If you use the wrong taper, you can get too much side pressure or not enough. This can lead to excessive wear, burrs, or even slitter skip. You want to set the right taper for your material and machine. This helps you keep your cutting efficiency high and your precision sharp.

Tip: Always check your blade geometry and machine settings before starting a new job. This helps you avoid defects and get the best results from your rotary slitter blades.

Usure de la lame

Sharpness vs. Durability

When you pick rotary slitter blade geometry, you need to think about sharpness and durability. Sharp blades make clean and exact cuts. Dull blades can cause trouble. They make cuts that are not even and waste more material. Machines can wear out faster and need more repairs. You may also have to stop work more often for maintenance. The table below shows what happens when blades wear out:

| Impact | Description | Preuve |

|---|---|---|

| Coupes inégales | Dull blades create inconsistent edges, leading to product rejection. | Manufacturers using dull blades see up to 15% more defective products than those with sharp blades. |

| Déchets de matériaux | Inaccurate cuts from dull blades increase material waste. | A study found that precision-sharpened slitting knives reduced scrap rates by 25%, saving $100,000 annually. |

| Increased Wear on Equipment | Dull blades require more force, leading to faster wear on machinery. | Preventive maintenance can lower machine repair expenses by 20%. |

| Temps d'arrêt pour maintenance | Frequent sharpening interrupts production, causing costly downtime. | An hour of unscheduled maintenance can result in thousands of dollars in lost revenue. |

You want your rotary slitter blades to stay sharp as long as they can. The right blade geometry helps slow down wear and keeps your cuts neat. Thicker blades last longer but might not cut as smoothly. Thinner and sharper blades cut better but wear out faster. You have to choose if you want blades that last longer or blades that cut the best.

Honed Edges

Honed edges help your rotary slitter blades work their best. A honed edge is smooth and even. This makes less friction and gives you cleaner cuts. Honed edges also spread out the cutting force. This means your blades chip less and last longer.

You can keep your blades in good shape if you do these things:

- Check blades after each shift for wear or damage.

- Clean blades after every use to remove dirt and debris.

- Sharpen blades on a regular schedule and watch for signs of dullness.

- Use high-quality blades that match the materials you cut.

- Store blades in a controlled environment to prevent rust or damage.

Tip: If you keep your rotary slitter blades sharp and take care of them, you will see fewer mistakes and less waste. You will also save money on repairs and lost time.

Rotary slitter blade geometry is important for how long your blades last and how well they cut. If you pay attention to sharpness, durability, and edge honing, your work will go smoothly and your cuts will be accurate.

Precision Rotary Slitter Blades in Industry

Electronics & Transformers

Ultra-Thin Foil Cutting

In electronics and transformer factories, you cut very thin foils. These foils are easy to tear or damage. You need rotary slitter blades that are very sharp and precise. The shape of the blade is very important for thin foils. Even a small change in the edge radius can change how well you cut.

Custom circular slitter blades help you work with delicate foils. You can pick from flat, dish, single bevel, compound bevel, or hollow ground top knives. Each blade shape works best for a different foil or film. Double hollow ground blades stop soft foils from rolling or tearing. If you cut foils with brittle coatings, you may need to use vacuum extraction to clean up debris right after cutting.

- First, pick the best top knife shape for your job.

- Work with a blade maker to match the blade to your needs.

- Double hollow ground blades are best for soft foils.

- Wide-rim knives are good for thick films or shaped products.

- For brittle coatings, plan to remove debris quickly.

You can find more custom blade choices on the page de lames personnalisées.

Clean Shear Needs

Electronics need very clean cuts. You want every cut to be smooth and have no burrs. The right rotary slitter blades help you do this. You must pick the right knife style for your job. Double hollow ground blades give the cleanest cuts for soft foils. Flat-profile blades are good for cutting paper. Wide-rim knives help with thick films and stop burrs.

- Picking the right knife style is very important for clean cuts.

- The shape of your top knife changes how good your cut is.

- You can choose from many blade shapes to get the best results.

When you need high-precision rotary slitter blades for electronics, always think about the material and the finish you want. Custom circular slitter blades help you meet strict rules for accuracy and cleanliness.

Steel & Construction

Heavy Plate Slitting

Steel and construction jobs use rotary slitter blades to cut thick plates and coils. You need blades that can handle strong force and keep their shape. The shape of the upper blade controls side force and helps you get straight edges. The bottom of the upper blade helps stop burrs and cracks. Some jobs use non-circular shapes for more control and less wear.

| Geometric Feature | Effet sur les performances de coupe |

|---|---|

| Shape of the upper blade | Controls side force for straight and even edges |

| Bottom surface of upper blade | Helps stop burrs and cracks |

| Non-circular shape | Gives more control, less wear, and better edge quality |

You can use custom circular slitter blades to match the steel’s thickness and hardness. Nanjing Metal Industrial has many choices for tough jobs.

Longevity Factors

You want your rotary slitter blades to last a long time. In steel and construction, you work with hard materials and long runs. You can make blades last longer if you do these things:

- Check blades after each shift for wear or damage.

- Clean blades after every use to get rid of dirt.

- Sharpen blades often and look for dull spots.

- Use good blades that fit your materials.

- Store blades in a safe place to stop rust or damage.

Cutting steel with figure lines must be very exact. How well you cut affects how you use steel in building and cars. High-precision rotary slitter blades help your work go smoothly and make less waste.

Automotive & Appliances

Speed vs. Precision

Car and appliance factories need both speed and accuracy. You must use rotary slitter blades that stay sharp when you cut fast. These blades also need to resist heat and keep their edge. Precision rotary slitter blades help you make tight cuts and clean edges. You need to line up the blades right and pick the best blade shape.

- Fast jobs need blades that do not get dull or hot.

- Accurate cuts need tight setup and good alignment.

- The material, coating, and blade shape all matter for good results.

You can pick custom circular slitter blades with special coatings or materials for your needs. High-precision rotary slitter blades help you balance speed and accuracy in every job.

Normes de qualité

You must follow strict rules in car and appliance factories. Rotary slitter blades must pass tests and meet safety rules. The table shows some important standards:

| Certification | Issuing Authority | But | Relevance to Machine Blades |

|---|---|---|---|

| ISO 9001 | International Organization for Standardization | Quality Management Systems | Ensures high-quality manufacturing |

| CE Marking | European Union | Product Safety | Confirms compliance with EU safety regulations |

| ISO 14001 | International Organization for Standardization | Environmental Management Systems | Promotes environmentally friendly practices |

| ANSI B7.1 | American National Standards Institute | Safety Standards for Abrasive Wheels | Provides safety guidelines for machine blades |

| UL Certification | Underwriters Laboratories | Product Safety Testing | Verifies adherence to safety standards for electrical tools |

You also need good quality control to keep blades sharp and even.

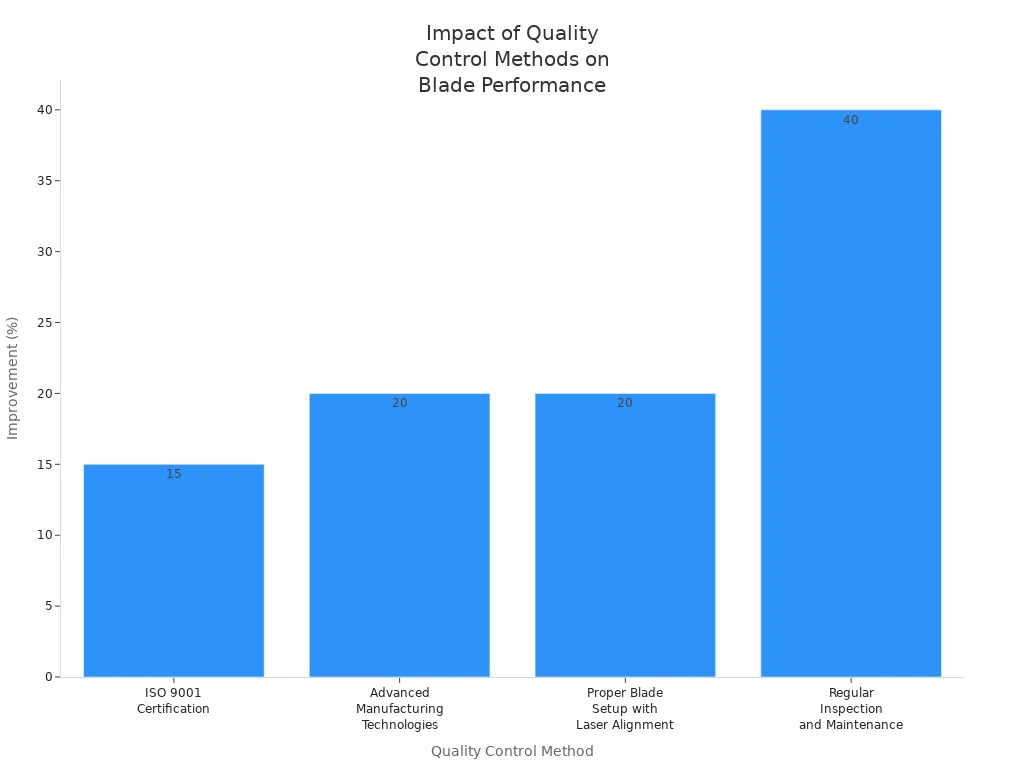

| Quality Control Method | Impact on Precision and Consistency |

|---|---|

| ISO 9001 Certification | 15% more accurate production and fewer defects |

| Advanced Manufacturing Technologies | 20% better durability and precision for blades |

| Proper Blade Setup with Laser Alignment | 20% fewer errors and 15% fewer edge defects |

| Inspection et entretien réguliers | Blades last up to 40% longer |

You must also follow safety and environmental rules.

| Regulation Type | Description |

|---|---|

| Occupational Safety | Follows OSHA rules to ensure worker safety. |

| Impact environnemental | Complies with EPA regulations for emissions and waste. |

| Product Safety Standards | Adheres to ASTM and ISO standards for product quality. |

When you use high-precision rotary slitter blades and custom circular slitter blades that meet these rules, you make better products and keep your workplace safe.

New Energy & Packaging

Battery Foil Slitting

In new energy jobs, you cut battery foils. These foils are very thin and easy to damage. The shape of the rotary slitter blade is important for cutting them well. You need blades with sharp edges and the right bevel angles. These things help stop the foil from tearing or wrinkling. When you use the right blade shape, your cuts are clean and the edges are smooth.

Battery foils are usually made from aluminum or copper. These metals need blades that are very hard and have a shiny, polished surface. A polished blade slides easily and does not let foil stick. You should keep the space between blades small. This helps stop burrs and keeps the foil from bending.

| Fonction de la lame | Benefit for Battery Foil Slitting |

|---|---|

| Sharp Edge Profile | Prevents tearing and ensures clean cuts |

| Tight Clearance | Reduces burrs and edge deformation |

| Polished Finish | Lowers friction and keeps foil smooth |

| High Hardness | Maintains sharpness during long runs |

You can ask for special rotary slitter blade shapes for your foil’s thickness and material. This helps you follow strict battery rules. It also makes your product safer and better.

Waste Minimization

You want to make as little waste as possible when you cut packaging and new energy materials. The shape of the rotary slitter blade helps you do this in a few ways:

- Picking the right blade gives you neat and exact cuts. This means you throw away less material.

- Good tension control keeps the material flat. You do not get wrinkles or crooked cuts.

- Knowing what material you have helps you pick the best blade. This makes the cutting process better and lowers waste.

When you use the right rotary slitter blade shape, you waste less and get more good product. You also save money and use fewer resources. In packaging, neat cuts mean you trim less and throw away fewer rolls. In battery foil cutting, you avoid mistakes that cost a lot and keep your work running well.

Tip: Always match your rotary slitter blade shape to your material and job. This helps you cut neatly and keep waste low.

| Waste Minimization Factor | How Rotary Slitter Blade Geometry Helps |

|---|---|

| Coupes nettes | Reduces scrap and improves product quality |

| Contrôle de la tension | Prevents wrinkling and misalignment |

| Compatibilité des matériaux | Optimizes blade choice and slitting process |

You can talk to blade makers to get rotary slitter blades made just for your needs. This helps you get the best results in new energy and packaging work.

Selecting Rotary Slitter Blades for Precision

Material Assessment

Hardness Matching

You need to pick rotary slitter blades that match the hardness of what you are cutting. This helps you get better cuts and makes your blades last longer. If your blade is too soft, it will wear out fast. If it is too hard, it might break or chip. You should also think about how hard the anvil is. The anvil costs more to replace than the blade. So, you want a blade that works well with the anvil.

When you check if the blade fits your material, remember these things: Pick a blade that lasts as long as you need. Make sure the blade matches what you are cutting. Ask a blade expert for help if you are not sure. Think about what kind of material you need to cut. Check where you will use the blade. Think about how fast you need to work. Look at how much the blade costs. Make sure the blade is good quality. Study the material to see if it fits your job. Think about any specific needs for your work. Decide if the blade is a good deal for the price.

Thickness Adjustment

The thickness of your rotary slitter blades changes how well they cut. Picking the right thickness helps you make better cuts and waste less. Here are some tips for picking blade thickness: Use thin blades for soft things like foam or rubber. Thin blades make smooth cuts and do not drag as much. Pick thick blades for hard things like steel or glass. Thick blades last longer and cut more exactly. The right thickness can make your cuts up to 25% more accurate.

Rotary slitter blades can cut many types and thicknesses of material. When you use the right blade, you keep your cuts tight and work faster.

Application Demands

Tolerance Needs

You need to know how exact your cuts must be. Some jobs need very tight tolerances. For these jobs, you need blades that are ground very carefully. The outside and inside of the blade must be just right. You also need the top and bottom knives to line up well. Good bottom knives and spacers help you stay accurate. If you want the best cuts, use high-precision materials like HSS, PM steel, or carbide blades.

Speed Considerations

How fast your machines run changes what blades you need. You should pick the right blade for your speed. The table below shows which blades fit each speed:

| Speed Category | Options de matériaux de lame | Considérations clés |

|---|---|---|

| Low to medium speed lines | D2 / Cr12MoV | Good life and not too expensive |

| Medium to high speed lines | HSS (M2) or PM steel | Handles more heat and lasts longer |

| Very high speed or 24/7 production | Carbide slitter blades | Costs more but lasts longer and needs fewer changes |

If you run your machines fast, you need blades that can take more heat and wear. Carbide blades are best for very fast or nonstop work.

Standards & Quality Control

ISO/ASTM Guidelines

You should always check if your rotary slitter blades meet important rules. ISO 9001 means the maker checks quality very well. Every blade gets tested for strength, accuracy, and safety. ASTM rules, like ASTM A681 for tool steels and ASTM E18 for Rockwell hardness, help you know if the blade is right for your job. These rules make sure you get good blades that last longer.

Inspection Practices

Checking your rotary slitter blades often keeps them working well. You should look for wear, cracks, or chips before you use them. Use the right tools to check blade thickness and size. Write down how your blades work and when you fix them. This helps you find problems early and keep your cuts sharp.

Tip: Work with a trusted company like Nanjing Metal Industrial. Their team can help you pick the right blade shape and material for your job.

Customization & Support

Blade Design Consultation

You can get better cuts if you work with experts. These experts know a lot about rotary slitter blade geometry. When you talk to a blade engineer, you get advice that fits your job. You can ask questions about edge profiles, bevel angles, and blade thickness. The engineer helps you pick the best shape and size for your work.

Many companies have special services to help you choose the right rotary slitter blade geometry. These services make sure your blades work well and last longer. Here is a table that shows some common support options:

| Service Type | Description |

|---|---|

| Custom Rotary Knife Solutions | Designed for precision and durability across various industrial applications, enhancing productivity. |

| Custom Rotary Die Design Services | Tailored to materials and production goals, ensuring high-performance dies for specific needs. |

| Slitting Services | Offers custom slitting and blade design, along with knife sharpening and regrinding services. |

| Custom Machine Knives for OEMs | Capable of producing knives specific to OEM configurations and diverse applications. |

You can use these services to fix problems like burrs or uneven cuts. If your blades wear out fast, you can ask for help. If you need a blade for a new material or machine, you can get a custom design. The right rotary slitter blade geometry helps you cut faster, waste less, and get better results.

Tip: Always tell the blade engineer about your material, machine, and speed. This helps them design the best blade for your needs.

Conseils d'entretien

Taking care of your rotary slitter blades keeps them sharp and safe. Good maintenance helps your blades last longer and keeps your cuts clean. Here are some easy tips you can follow:

- Clean your blades after every use. Wipe off dust, oil, and small pieces.

- Check the edge for chips, cracks, or dull spots before each shift.

- Sharpen your blades on a regular schedule. Do not wait until the blade is very dull.

- Store blades in a dry place to stop rust and damage.

- Use the right tools to put in and take out blades. This stops bending or breaking.

- Write down when you clean, sharpen, or replace each blade. This helps you find problems early.

If you follow these steps, you will make fewer mistakes and waste less. Your rotary slitter blade geometry will stay correct, and your machines will run well.

Note: If you have questions about blade care or need help, you can ask your blade supplier. Many companies give training and advice to help you get the best results from your rotary slitter blades.

You have learned that rotary slitter blade geometry affects your work. Picking the right blade shape helps you make clean and exact cuts every time. In many jobs, you get these benefits:

- Sharp blades and smooth surfaces help you waste less.

- Good edge shapes and tight fits make your cuts more accurate.

- High-quality blades give you steady results.

- You get better products and lose less material when working fast.

Check your blades often and change them if your materials or needs are different. If you want help or special blades, you can talk to a sales engineer ici.

FAQ

What is rotary slitter blade geometry?

Rotary slitter blade geometry describes the shape, angle, and size of the blade edge. You use this geometry to control how the blade cuts materials. The right geometry helps you get clean and accurate cuts.

Why does blade geometry matter for cut quality?

Blade geometry changes how the blade touches and slices the material. If you pick the right geometry, you get smooth edges and less waste. The wrong geometry can cause burrs or rough cuts.

How do I choose the best edge profile?

You should match the edge profile to your material. Square edges give sharp cuts for hard materials. Rounded edges last longer and work well for softer materials. Ask an expert if you are not sure.

What is the difference between single and double bevel blades?

Single bevel blades have one slanted side. They give strong, straight cuts. Double bevel blades have two slanted sides. They make cleaner cuts and need less force. You pick the type based on your job.

How does blade thickness affect performance?

Thicker blades stay stable and resist bending. You use them for tough or thick materials. Thinner blades make finer cuts but can flex more. Always match blade thickness to your cutting needs.

How often should I check my rotary slitter blades?

You should check your blades before each shift. Look for dullness, chips, or cracks. Regular checks help you keep your cuts precise and your machines safe.

Can I get custom rotary slitter blade geometry?

Yes, you can ask for custom blade shapes, sizes, and finishes. Custom geometry helps you solve special cutting problems and improve your results.

What materials work best for rotary slitter blades?

You can use high-speed steel, tungsten carbide, or alloy tool steel. The best material depends on what you cut and how long you want the blade to last.

Voir aussi

Lames de Cisaille Rotative pour Métal

Que Sont les Lames de Cisaille Rotative et Comment Fonctionnent-elles?

Exploration des applications des lames de refendage Metal dans la fabrication

Comment choisir la lame de cisaille à rouleaux adaptée à vos besoins

Lames de Coupe Rotatives Après-Vente vs. OEM : Une Analyse Coûts-Avantages