If abrasive-filled compounds keep chewing through your blades, you’re not alone. Between 0–50% glass fiber, talc/CaCO3 fillers, high line-speed shear, and frequent start/stop cycles, edge life collapses—and pellet quality goes with it. Upgrading to tungsten carbide pelletizer knives addresses the core failure modes while stabilizing pellets and trimming unplanned downtime across strand, die-face/underwater, and ring/centrifugal systems.

Key takeaways

- Tungsten carbide pelletizer knives maintain edge sharpness longer in abrasive-filled polymers, supporting blade-life gains, steadier pellet dimensions, and fewer changeovers.

- Dominant wear modes include three-body abrasion from fillers and impact micro-chipping during start/stop; material selection plus correct setup counter both.

- Numeric clearances and bevels are machine-specific—always confirm in your OEM manual; treat tables here as qualitative guidance.

- Benchmark in your plant before full rollout: log cuts-to-dullness, pellet fines/burrs, and changeover intervals to build a defensible ROI.

Why Tungsten carbide pelletizer knives matter: the wear you’re really fighting

Abrasive mineral fillers (talc, CaCO3) and glass fiber ends act like sandpaper at the cutting interface. At high line speeds, the edge sees three-body abrasion that rounds the cutting radius and elevates fines. Frequent start/stop increases impact loading and thermal cycling, which can drive micro-chipping on harder but less-tough edges.

Standards help frame what you’re measuring. Abrasion resistance is often compared with tests such as ASTM G65 (dry sand/rubber wheel), which quantifies volume loss under a standardized abrasive flow. While not a 1:1 replica of pelletizing, it explains why harder, wear-resistant materials typically last longer under abrasive regimes, all else equal. For hardness itself, industry uses Rockwell scales per ASTM E18—cemented carbide grades are commonly reported on HRA, while tool steels are on HRC—so direct conversions are inappropriate; focus on application performance instead. See the standards context in the ASTM corrosion and wear standards listing and the ASTM E18 summary (2022).

Tungsten carbide vs. tool steel: how they differ in the cut

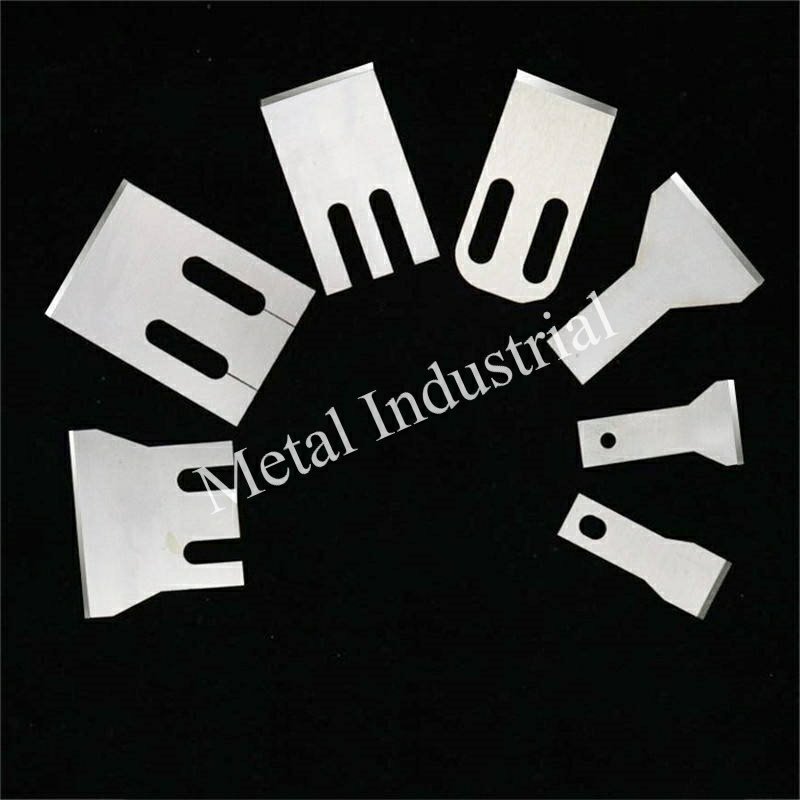

Material choice is only part of the equation, but it’s foundational. Carbides bring high hardness and abrasive wear resistance; tool steels (e.g., D2, M2) bring greater toughness and ease of regrinding. Because OEM geometries and loads vary, use this table as a qualitative decision aid and confirm details with your supplier and OEM manual.

| Attribute | Tungsten carbide (WC-Co) knives | Tool steels (e.g., D2, M2, A8) |

|---|---|---|

| Hardness reporting | Typically HRA/HV (per ASTM E18 context) | Typically HRC/HV (per ASTM E18 context) |

| Abrasive wear resistance | Very high under mineral-filled/glass-filled compounds | Moderate to good; faster edge rounding in abrasive feed |

| Toughness/impact tolerance | Lower than most tool steels; manage engagement pressure | Higher; more forgiving during start/stop impacts |

| Regrind behavior | Fewer, careful regrinds; specialized wheels/skills | Easier, more frequent regrinds acceptable |

| Cost vs. TCO | Higher unit price; potential total cost savings via longer service intervals and fewer changeovers | Lower upfront cost; may require more frequent changeovers |

| Typical best-use scenarios | High filler load (0–50% GF, talc/CaCO3), high line speed, powder metallurgy feed hardness | Lower filler loads, impact-prone startup profiles, budget-constrained short runs |

For a practical overview within our site, see Choosing the best pelletizer knife.

Edge geometry and pelletizer type: principles that keep pellets clean

Geometry, clearance, and alignment decide whether your material choice pays off. Numeric values are model-specific—always follow your OEM’s manual—but these principles are widely applicable.

Strand pelletizers. Consistent strand draw and clean pinch are essential. A sharp, well-supported edge and parallelism to the bed/roll reduce smearing that shows up as burrs and fines. Keep the die face clean and polished to limit drag.

Die-face/underwater pelletizers. The knife must track flat to the die plate with stable contact pressure; too little pressure increases tails; too much accelerates wear. Many OEMs employ hard wear surfaces; MAAG notes die plates with tungsten-carbide nibs to sustain sharpness in underwater service, underscoring why hard interfaces help with filled formulations, as highlighted on the MAAG AMN tools page.

Ring/centrifugal pelletizers. Balance and edge integrity matter at speed. Minor eccentricity amplifies vibration, degrading cut quality. Verify blade mass/balance if switching materials or suppliers and re-check fastener torque after heat cycles.

A conservative, non‑model-specific example: aim for a knife‑to‑die (or moving‑to‑fixed knife) gap of roughly 0.2–0.3 mm as an initial setting, then use low‑speed test cuts to fine‑tune—this range is a general guideline, not an OEM spec. Contact/engagement force varies by system (spring, hydraulic or servo) and isn’t universally published; set pressure conservatively and increase while observing tails, fines and vibration. Follow the safe adjustment sequence: inspect → set parallelism/gap → clean → test cuts at low speed → iterate → lock. (See MAAG AMN tools, Econ EUP brochure, and maintenance guidance from Cowin Extrusion.)

Retrofit checklist: switching to carbide with confidence

Before you swap, walk through a structured retrofit. Record baseline metrics (fines, burrs, pellet length dispersion, hours-to-changeover) so you can prove the result.

- Mechanical fit and fasteners: confirm dimensions, hole pattern, countersinks, and screw length; torque to OEM spec.

- Parallelism and clearance: blue-check or dial-indicate against die/bed; set clearance per the OEM manual.

- Balance and vibration: verify blade mass and run a slow-roll check; correct any imbalance before full speed.

- Engagement pressure: set initial contact pressure conservatively; increase gradually while monitoring tails and fines.

- Thermal considerations: bring system to temperature before final adjustments; re-check clearance after thermal expansion.

- Trial log: record resin, filler %, line speed, pellet length target, fines %, burr rate, noise/vibration notes.

- Post-run inspection: under magnification, check for micro-chipping or edge recession; schedule the next inspection accordingly.

For a maintenance perspective from equipment and knife vendors, see Cowin Extrusion’s tips.

Maintenance best practices that protect your investment

Treat carbide like the precision tool it is. Schedule visual checks by throughput hours, not just calendar time. After any start/stop sequence, listen for new vibration or scraping; small setup deviations can snowball into fines. Keep die faces clean and flat; residue drags strands and can force operators to overfeed contact pressure, accelerating wear. Regrind sparingly and to the original geometry using appropriate wheels; over-sharpening alters clearance interaction and shortens service life. If trend logs show a step-change in edge life, investigate alignment, fastener torque, and die surface flatness before blaming material.

TCO and ROI: a simple worked example

Use your own logs to estimate the payback. Here’s a sample structure you can adapt.

| Input/Result | Tool steel baseline | Tungsten carbide scenario |

|---|---|---|

| Blade unit cost | $300 | $900 |

| Average hours per blade before changeover | 40 | 110 |

| Changeover labor + downtime cost per event | $450 | $450 |

| Hours produced per month | 400 | 400 |

| Blade changes per month | 10 | 3.6 |

| Monthly blade spend | $3,000 | $3,240 |

| Monthly changeover cost | $4,500 | $1,620 |

| Total monthly cost | $7,500 | $4,860 |

| Estimated monthly savings | — | $2,640 |

Assumptions are illustrative only; validate with plant data.

Micro-example: a neutral replacement workflow using a custom vendor

Disclosure: Nanjing METAL is our product.

Consider a strand pelletizer cutting a 30% glass-filled PP. The plant logs frequent burrs and changeovers (~every 40 hours) using D2 knives. They decide to trial tungsten carbide pelletizer knives while keeping all other process conditions constant.

- Define the target. The team documents baseline metrics (fines %, pellet length dispersion, hours-to-dull) and photographs the die face.

- Verify geometry. They share drawings and photos to validate cutting length, hole pattern, and chamfer geometry; the vendor returns a drawing for signoff, including edge support details and permissible regrind stock.

- Fit and align. After arrival, the maintenance lead dry-fits the knife, checks parallelism to the bed, and torques fasteners to spec. A blue-check confirms uniform contact.

- Controlled startup. With the line at temperature, they start with conservative engagement pressure, gradually increasing while monitoring tails and vibration. Operators log burr observations at fixed intervals.

- Inspect and schedule. Post-shift, they examine the edge under magnification to look for micro-chipping and record hours toward the next inspection.

Anonymized plant trial (strand pelletizer, 30% GF PP): an anonymous compounder logged n=10 runs per condition over a 3‑month window. Baseline (D2): average cuts‑to‑dull = 40 operating hours, fines = 3.8% (percent passing 1.0 mm sieve), and ~10 changeovers/month. After switching to tungsten‑carbide knives: cuts‑to‑dull = 110 hours, fines = 2.1%, and ~3–4 changeovers/month. Measurement protocol: fines sampled every shift, sieved (1.0 mm) and weighed; “dull” defined as a sustained >5% rise in fines or visible edge rounding under 10× magnification. Results reported as an anonymized trial; verify on your line.

This workflow is replicable with most qualified suppliers. For a factual overview of drawing-based fabrication, see Plastic pelletizer blade.

When not to choose tungsten carbide

- Impact-dominant profiles. If your process sees hard impacts (frequent slugs, misfeeds, or severe start/stop shocks), a tougher tool steel may be safer while you stabilize the process profile.

- Very low-volume or R&D lines. If runtime is short and changeover cost is minimal, the upfront price of carbide may not pay back.

- Support limitations. If regrinding services for carbide aren’t available locally, logistics time may negate the benefits. Mitigate by stocking a small buffer of finished knives and scheduling consolidated regrinds.

Sources and further reading

- Standards context: ASTM corrosion and wear standards (G65 listed); ASTM E18 Rockwell hardness summary (2022).

- OEM context: MAAG AMN underwater pelletizing tools.

- Internal primer: Choosing the best pelletizer knife.

Additional authoritative references

- OEM manuals and setup guidance: Always default to your specific model’s manual for clearances, bevels, and contact-pressure settings. See the OEM documentation portals for current guides and service instructions: Nordson BKG service and support documentation et MAAG’s official downloads for Gala/Automatik pelletizing systems.

- Rockwell scales and conversions: For why HRA (common for carbides) and HRC (common for tool steels) are not directly convertible, consult ASTM E140 Standard Hardness Conversion Tables (latest edition) et NIST Special Publication 960-5 “Rockwell Hardness Measurement of Metallic Materials” (2nd ed.). These primary sources explain scale ranges, limitations, and the empirical nature of conversions—use application performance and direct testing for decisions.

—

Author: A process engineer and blade specialist with hands-on experience in strand and underwater pelletizer retrofits, carbide/tool steel edge selection, and maintenance programs for abrasive-filled compounding lines.

Ready to validate the ROI on your line? For a drawing-to-part quote or feasibility review, contact Nanjing METAL—attach photos and baseline logs for faster feedback.