You want to keep machines working for a long time when cutting scrap metal and thick plates. Pick heavy duty shear blades that last long and have the right steel for your job. Match the blade material to the metal you cut. Find shear blades with new manufacturing and custom choices. Metal Industrial gives you these features. Think about the total cost, like maintenance, to help your work stay efficient.

Key Takeaways

- Pick heavy duty shear blades made from strong stuff for better strength and work. Use blade material that matches the metal you cut. This helps you get cleaner cuts and makes blades last longer. Think about the total cost, like fixing and replacing blades, when you choose them. Check and take care of blades often to stop problems like dull edges, cracks, or blades not lining up. Use the right blade shape, like rake angle and space, to help blades cut better and last longer. Pick blades made for special jobs, like alligator shear blades for scrap metal and plate shear blades for sheet metal. Buy good blades from trusted companies to make sure they work well for hard cutting jobs. Keep your work area clean and clear of trash to help blades last longer and keep cuts good.

Heavy Duty Shear Blades: Role in Uptime

What Are Heavy Duty Shear Blades?

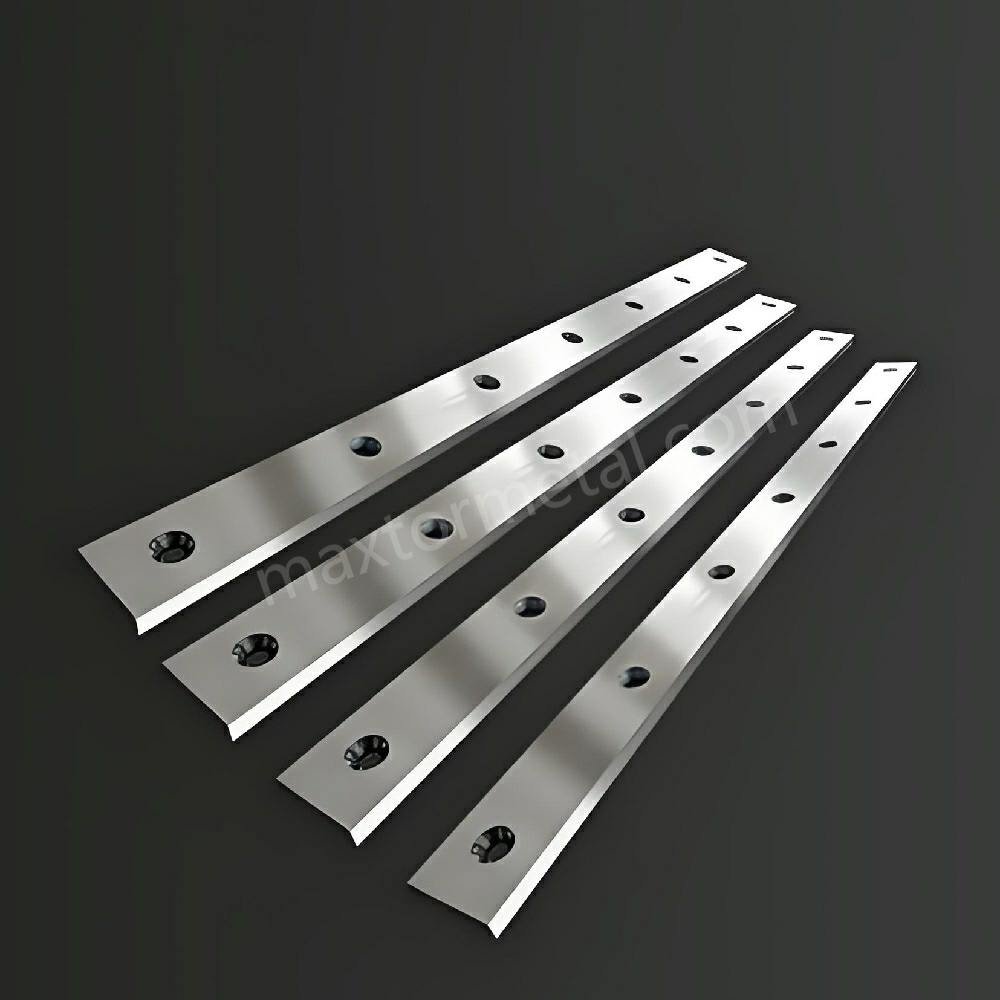

Heavy duty shear blades help you cut hard things like steel and scrap. These blades use strong materials and get special heat treatment. This makes them tough and hard for big jobs. Many industries use these blades, like recycling and manufacturing. They work with hydraulic shearing machines and other cutters. The blade design lets you make clean and exact cuts.

Here is a table that shows the main features and uses of heavy duty shear blades:

| Key Features | Applications |

|---|---|

| High-Grade Materials | Metal Processing: Cutting steel sheets, aluminum plates |

| Precision Engineering | Paper Production: Trimming and cutting paper rolls |

| Vacuum Heat Treatment | Rubber Processing: Slicing rubber sheets |

| Custom Configurations | Plastic Manufacturing: Cutting plastic films and sheets |

| Recycling: Shearing scrap into manageable sizes |

Impact on Cutting Efficiency and Downtime

Picking the right shear blades helps you cut better and faster. These blades cut quickly and do the same job every time. This makes recycling go faster. You spend less time on each cut, so machines run longer. The blades make pieces that are all the same size. This helps you handle metal and scrap more easily.

A table below shows how heavy duty shear blades help with cutting and downtime:

| Description | Impact on Cutting Efficiency and Downtime |

|---|---|

| Quick and consistent cutting | Speeds up the recycling process, reducing time per cut |

| Produces uniform material sizes | Enhances downstream processing and workflow |

| Seamless integration with other systems | Minimizes material handling and downtime |

| 70-85% faster cutting than traditional methods | Increases overall efficiency and output |

| Consistent force for clean cuts | Ensures precision and effective processing |

Tip: Good shear blades help your machines last longer. You do not need to change blades often.

Applications in Scrap Metal and Thick Plate Processing

Heavy duty shear blades are used where tough cutting jobs happen. In scrapyards, they help you cut scrap metal fast. This boosts how much work you get done. Recycling centers use these blades to make scrap smaller for more work later. Metal shops use them to cut thick steel plates, beams, and pipes.

Here are some main ways shear blades are used in these places:

- Big recycling plants and steel mills use them for lots of cutting.

- They cut thick metals, scrap steel, and old machines.

- These blades can make 3-4 cuts each minute, which helps you work faster.

You can count on heavy duty shear blades to keep your work going well. They help you cut metal, scrap, and plates with good speed and dependability.

Key Factors in Shear Blade Selection

Material Compatibility for Cutting

Blade Steels: A8 Modified, S7, Cr12MoV, H13, D2, HSS

When you pick heavy duty shear blades, look at the steel type. Each steel grade has its own special features. A8 Modified and S7 steels can handle strong hits. Cr12MoV and D2 steels last longer because they resist wear. H13 steel works well when cutting gets very hot. High-speed steel (HSS) helps you make very accurate cuts and works for tough jobs.

The table below shows how these material features help you choose:

| Material Property | Definition | Impact on Selection |

|---|---|---|

| Strength | Handles heavy loads | Strong metals need tough blades for good cuts |

| Durability | Stays strong against damage | Durable blades last longer when used a lot |

| Thickness | How thick the metal is | Thick plates need more force and special blade shapes |

| Surface Finish | How smooth the metal is | Good finish keeps the cut looking nice |

| Ductility | Stretches without breaking | Ductile metals bend better when cut |

| Hardness | Hard to scratch or change shape | Hard metals need special blades |

| Malleability | Can be shaped without cracking | Helps shape metal without breaking |

| Toughness | Takes hits without breaking | Needed for metals under heavy force |

| Thermal Conductivity | Moves heat away | Helps blades work better when cutting hot metals |

Choosing for Scrap Metal vs. Sheet Metal

Pick the right blade steel for your job. For scrap metal, use blades with high toughness and impact resistance. S7 and A8 Modified steels are good for scrap because they handle rough cuts. For sheet metal, use blades with sharp edges and high wear resistance. D2 and Cr12MoV steels help you make smooth cuts and keep the surface nice. When cutting thick plates, you need blades that are strong and last long. This helps your machines work without stopping.

Tip: Always check the metal type and thickness before picking shear blades. This helps you get better results and longer blade life.

Blade Hardness and Toughness

Heat Treatment and Wear Resistance

Heat treatment makes shear blades stronger and tougher. Makers use special heat treatment to make blades harder and tougher. Blades with high hardness last 40-50% longer than regular blades. You change blades less often and save money. Wear resistance is important when cutting steel plates or thick metal. Blades that resist wear keep their edge and cut well for a long time.

Balancing Impact Resistance

You need to balance hardness and toughness in blades. Hard blades last longer but can break easier. Tough blades take hits and do not crack. Makers test blades for hardness and toughness with special tests. This helps you find blades that work well for big cutting jobs. When you cut scrap or thick plates, you want blades that do not chip or break. This balance helps blades work better and last longer.

Blade Geometry and Optimization

Rake Angle and Clearance for Thick Plate

Blade geometry helps you cut thick plates better. The rake angle and clearance help you make straight and clean cuts. A good rake angle means you need less force to cut. Proper clearance keeps the blade from getting stuck and makes the cut smooth. You should change these features based on how thick the metal is.

Edge Design for Efficient Cutting

The blade edge shape matters for cutting well. The upper blade shape controls side force and helps you get even edges. The bottom of the upper blade helps stop burrs and cracks. Non-circular blade shapes give you more control and less tool wear. You get better edge quality and blades last longer.

| Geometric Feature | Effect on Cutting Performance |

|---|---|

| Shape of the upper blade | Controls side force for straight and even edges |

| Bottom surface of the upper blade | Helps stop burrs and cracks |

| Non-circular shape | Gives more control, less wear, and better edge quality |

Note: If you need blades for special jobs, you can order custom blades from Nanjing Metal Industrial. Custom blade shapes help you match blades to your machine and metal.

Manufacturer Reputation and Quality

When you pick heavy duty shear blades, trust matters. A good company gives you more than just blades. You get better cuts and blades that last longer. You also have less downtime. If a company has a good reputation, their blades work well in real jobs. Using blades from a trusted company gives you better results in metal work.

Metal Industrial’s Quality Control

You want blades that work every time. Metal Industrial checks each blade with strict steps. They look at size, hardness, and edge sharpness. Advanced machines test the steel and finished blades. This means you get blades that cut clean and last long.

Metal Industrial uses special heat treatment and forging. These steps make blades tough and strong. You can cut thick steel or scrap without worrying about fast wear. The company also lets you order custom blades. If you need blades for sheet metal or special shapes, you can ask for a design that fits your job.

Note: Quality control helps blades work well in many places, like recycling and construction.

Certifications and Support

Certifications show a company follows safety and quality rules. Metal Industrial has important certifications for its blades. These include ISO standards for making and testing materials. When you see these certifications, you know the blades are safe and work well.

Support is important in busy factories and workshops. Metal Industrial helps with installation, maintenance, and fixing problems. If you have questions or need advice, you can talk to their team. This support keeps your machines working and blades in good shape.

The table below shows how reputation affects blade quality and reliability. Modular designs from trusted companies last more than twice as long as regular tools. You spend less time changing blades and more time cutting metal.

| Tool Type | Mean Time to Failure (MTTF) | Operational Lifespan Increase |

|---|---|---|

| Modular Design | > 500 h | More than double |

| Conventionally Manufactured | ~ 266 h | N/A |

Picking a company with a strong reputation gives you peace of mind. You know your shear blades will cut well and work strong in every job. This is true for all metals, from thick steel plates to lighter ones. You get good results in all uses of shear blades.

Types of Shear Blades for Cutting Applications

Alligator Shear Blades for Scrap Metal

Alligator shear blades help with hard cutting jobs. You use them in scrap yards and recycling centers. These blades cut thick steel, pipes, and beams. Their design lets you cut big metal pieces fast. The blades work well because they handle strong impacts.

High Impact Performance

Alligator shear blades are good for cutting tough metals. You see them used when processing scrap. The blades are made from strong materials like high-carbon steel or alloy tool steel. They make clean cuts on aluminum, copper, and steel. The blades stay sharp and do not bend, even with thick plates.

Here is a table that shows which blade material works best for each metal type:

| Metal Type | Recommended Blade Material | Performance Characteristics |

|---|---|---|

| Aluminum | High-carbon steel | Stays sharp, cuts cleanly |

| Copper | Alloy tool steel | Cuts soft metals without bending |

| Stainless Steel | High-speed steel (HSS) | Handles heat during cutting |

| Hardened Steel | Tungsten carbide | Tough enough for hard metals |

Tip: Pick the right blade material for the metal you cut. This helps you get better results and makes blades last longer.

Common Failure Modes

You need to watch for problems with alligator shear blades. These problems can slow your work or hurt your machine. Uneven cuts happen when blades get dull or are not lined up. Pressure loss can come from leaking hydraulic fluid or worn seals. Slow cutting may mean low fluid or clogged filters. Loud noise can mean loose parts or not enough oil. Electrical problems can stop your machine if wires or switches break.

Here is a table that lists common problems and what causes them:

| Failure Mode | Likely Causes |

|---|---|

| Uneven Cuts | Blade misalignment, Worn, chipped, or dull blades, Improper blade gap, Uneven hydraulic pressure |

| Pressure Loss | Hydraulic fluid leaks, Worn or damaged seals, Faulty hydraulic pumps, Air trapped in the hydraulic system |

| Slow Operation | Low hydraulic fluid levels, Clogged filters, Worn hydraulic components, Electrical control issues |

| Excessive Noise | Loose or damaged components, Insufficient lubrication, Worn bearings, Misaligned blades |

| Electrical Problems | Faulty wiring, Damaged switches, Blown fuses, Malfunctioning sensors |

Note: Doing regular maintenance helps you avoid these problems. It keeps your cutting smooth.

Plate Shear Blades for Sheet Metal

Plate shear blades help you cut sheet metal and thin plates. You use them in metal shops and factories. These blades give you precise cuts. Their special shape lets you cut steel and other metals with smooth edges.

Geometry and Material Selection

You get better cuts by picking the right blade shape and material. The rake angle and clearance change how much force you need. They also affect how smooth the cut looks. You use high-speed steel or Cr12MoV for cutting sheet metal. These materials stay sharp and resist wear. The blade shape helps stop burrs and cracks.

Tip: Change the blade angle and clearance for plate thickness. This gives cleaner cuts and helps blades last longer.

Comparison with Alligator Shears

Plate shear blades and alligator shear blades are different. Plate shear blades make precise cuts on thin metals. Alligator shear blades are better for scrap and thick steel. Plate shear blades move straight when cutting. Alligator blades chop down. Use plate shear blades for smooth edges. Use alligator blades for tough jobs.

| Feature | Plate Shear Blades | Alligator Shear Blades |

|---|---|---|

| Cutting Motion | Straight shearing | Chopping action |

| Best For | Cutting sheet metal, plates | Scrap metal, thick steel |

| Edge Quality | High-precision, smooth | Rougher, less precise |

| Material Selection | HSS, Cr12MoV, D2 | High-carbon, alloy tool steel |

Specialty Shear Blades

Specialty shear blades help with special cutting jobs. You use them for unique shapes, sizes, and materials. These blades are used in metalworking, recycling, and custom jobs.

Rotary Shear Blades

Rotary shear blades spin to cut metal sheets and plates. You use them for fast, nonstop cutting in production lines. The blade angle and clearance help you cut well. You get smooth edges and quick work.

- Metalworking and fabrication: Rotary blades cut sheets for car and airplane parts.

- Recycling industry: Rotary blades cut scrap metal into smaller pieces.

- Custom shapes: You can order rotary blades in special sizes for your machine.

Guillotine Shear Blades

Guillotine shear blades move straight down to cut metal. You use them for cutting big plates and sheet metal. These blades give you precise cuts and smooth edges. You see guillotine blades in factories that process steel and aluminum.

- Hot crop shear blades: Guillotine blades can be made for special cutting needs.

- Custom manufacturing: You can get guillotine blades for different materials and thicknesses.

Note: Specialty shear blades let you match the blade to your job. You get better results and faster cutting.

You see many ways to use shear blades in metalworking, recycling, and making things. Pick the right blade type for your job. This helps you work faster and keeps machines running longer.

Evaluating Shear Blade Quality and Matching Needs

Assessing Blade Material and Manufacturing

Visual Inspection and Certifications

Look at the blade surface for cracks or chips. Check if the edges are even and smooth. A good blade looks uniform and sharp. High-quality blades have a nice finish and sharp edge. Ask for certifications like ISO standards. These show the blade is safe and high quality. Reliable suppliers give certificates and test reports for each batch.

The table below helps you compare poor and good blades:

| Aspect | Poor-Quality Blades | High-Quality Blades |

|---|---|---|

| Safety | Can chip or break easily | Tough and strong all over |

| Production Costs | Need to replace often, waste materials | Work better and cost less per use |

| Service Life | Do not last long, cause more downtime | Last longer with fewer problems |

| Economic Benefit | One blade does the job of many replacements | More work done and less fixing needed |

| Material Properties | Weak and uneven metal | Good alloy mix and heat treatment |

| Cutting Quality | Cuts are rough and not smooth | Cuts are smooth and burrs are controlled |

| Recommendations | Use for regular steel only | Use for strong steel and tough jobs |

Supplier References

Ask for references from other customers. Good suppliers have a record of strong blades for metal work. You can get feedback from people in recycling or building. This helps you know if the blades work well with hydraulic shearing machines and tough steel. Trusted suppliers like Nanjing Metal Industrial share references and case studies to show how their blades perform.

Matching Geometry to Machine and Material

Manufacturer Specifications

Match the blade shape to your machine and metal type. Makers give details about rake angle, clearance, and blade size. These help you cut with high precision and fewer burrs. Always check your machine manual and blade guide before buying. The right blade shape makes cutting faster and keeps your machine safe.

The table below lists what to look for when matching blades:

| Criteria | Description |

|---|---|

| Material shear strength | How strong the metal is for cutting. |

| Rake angle | The angle between blades affects force and how metal acts. |

| Ductility and work hardening | How much the metal bends and changes when cut. |

| Knife condition and clearance | Blade shape and space between blades help make clean cuts. |

| Back piece depth and support systems | Machine design supports cutting and affects how well it works. |

Customization for Unique Applications

Sometimes you need blades for special jobs. Custom blades match your machine and metal type. You can order blades with special shapes, sizes, or alloy mixes. Custom blades help you cut better and last longer. You spend less time fixing blades and get more work done. To learn more, visit the custom blades page.

- Custom blades fit your machine and metal.

- You get smoother cuts and blades last longer.

- Maintenance is easier and needed less often.

Total Cost of Ownership

Blade Life vs. Upfront Cost

Think about the total cost, not just the blade price. Good blades last longer and need fewer changes. This saves money over time. Strong blades for steel and metal cost more at first, but give more value. You get safer work and higher output with blades that last.

Buying strong blades means less money spent on repairs and replacements. In factories, tough blades help you work faster and safer. The higher price pays off with longer life and fewer problems.

Downtime and ROI

You want blades that keep machines working. Downtime costs money and slows work. Good blades wear less and need less fixing. Hydraulic shearing machines with sharp blades use less energy and work better. Right blade clearance lowers burrs and saves on finishing.

Think about these things for total cost:

- Price to buy

- Setup and starting costs

- Costs for energy, fixing, and workers

- Saving energy with hydraulic systems that use pressure only when needed

- Longer time between fixes because blades wear less

- Easier repairs and less downtime

Shear blades are important for your work. They affect how much you make, energy use, and product quality. The real cost includes hidden costs from energy and machine wear. Sharp blades can save 15% energy compared to dull ones. Dull blades waste power and wear out machines faster. Bad blade clearance makes more burrs and adds finishing costs.

Tip: Pick blades that last long and have good shape. You will save money and get better results when cutting metal.

Failure Modes and Maintenance for Heavy Duty Shear Blades

Cracking and Fracture Prevention

Heavy duty shear blades work under a lot of stress. Cracks and breaks can stop your work and cost money. You can stop these problems by using the right steps when making and using blades.

Pre-Loading and Installation

Setting up blades the right way helps them last longer. You need to use the right tension and line up the blades. Too much force or a bad angle can cause cracks. Always read the machine manual for torque and placement. Make sure surfaces are clean and dry so blades do not slip.

Manufacturers use different ways to stop cracks and breaks. The table below shows some common methods:

| Strategy Type | Specific Strategies |

|---|---|

| Process Control Measures | – Keep the right temperature and speed during rolling and forging. – Cool blades evenly and use careful heat treatment. – Use good welding with steps to lower stress. – Watch stress levels during making with special tools. |

| Material Design Approaches | – Change the mix of metals to make blades tougher. – Add special metals to keep the blade strong inside. – Make the inside of the blade better so cracks do not start. – Use heat treatment to make blades tough. |

| Remediation Techniques | – Heat blades to lower leftover stress. – Treat the surface to make it stronger. – Fix small cracks with welding and heat. – Throw away or fix blades with big cracks. |

| Quality Assurance Systems | – Check blades often with good inspection steps. – Test blades without breaking them during making. – Write down all steps and test results. – Teach workers how to spot problems. – Make plans to fix cracks if they show up. |

Tip: Always look at the blade and where you put it before installing. Clean parts and the right torque help stop cracks early.

Early Failure Signs

You can find early blade problems if you know what to check. Catching problems early lets you fix them before work stops.

- Check blades often for wear and damage.

- Look for tiny cracks, chips, or rough edges.

- Listen for strange sounds when the machine runs.

- Watch for bad cuts, like rough edges or more burrs.

- Use special tools to find tiny cracks before they get bigger.

- Oil moving parts to stop friction and heat.

- Clean machines often to stop jams and problems.

If you spot trouble early, you can fix it before it gets worse. This keeps machines working and saves you money.

Note: Checking blades often helps you avoid big repairs and keeps work going smoothly.

Abrasive Wear vs. Impact Damage

Shear blades can get two kinds of damage: abrasive wear and impact damage. Each type needs a different way to fix it.

Abrasive wear happens when hard bits like dust or metal rub the blade. This slowly takes away blade material. Impact damage comes from hard hits, like cutting thick metal or hitting something hard.

- Abrasive wear is caused by hard bits scraping the blade surface.

- Dust, especially silica, can hurt metal blades a lot.

- Three things affect abrasive wear:

- If dust is harder than the blade, it can scratch it.

- Big bits can cause wear if they are bigger than the space between parts.

- More dust means faster wear.

- Impact damage happens when cutting very hard or thick stuff, or if blades are not lined up right.

Tip: Keep your workspace clean and watch for dust or bits. This helps stop wear and keeps blades sharp.

Maintenance Strategies

You can make blades last longer by taking care of them.

- Clean blades and machines after each job to remove dust and metal bits.

- Oil blades and moving parts to stop friction and heat.

- Store blades in a dry place so they do not rust.

- Fix or change broken blades right away to keep machines safe.

- Check blades often for small cracks or chips.

- Plan regular checkups to catch problems early and stop breakdowns.

- Write down all repairs and maintenance.

These steps help you do more work and spend less on fixing blades.

Real-World Case Studies

Many factories and recycling centers use these steps to keep blades working well. For example, one recycling plant cleans and checks blades every day. They have fewer breakdowns and blades last longer. Another metal shop uses special tools to find tiny cracks early. They fix blades before they break, so machines keep running and downtime is less.

Note: Good care helps you avoid expensive repairs and keeps cutting jobs running well.

Case Studies: Shear Blades in Scrap and Plate Processing

Alligator Shear Blades in Scrap Metal

Material Selection and Uptime Results

Alligator shear blades are used in many scrap yards. These blades help cut big, tough metal fast. Picking the right blade material helps machines work longer. You do not have to stop as much for repairs. Many companies use machines that are easy to move and have hydraulic drive. This means you can bring the machine to the scrap pile. You can cut large pieces right where they are.

Here is a table that shows how alligator shear blades help you work better and faster:

| Feature/Benefit | Description |

|---|---|

| Portable Design | The machine is light and easy to tow. You can cut scrap where it is found. |

| Hydraulic Drive | A 26.5 HP hydraulic drive lifts and cuts metal. You do not need as much hard work. |

| Single Operator Use | One person can run the machine. Other workers can do other jobs. |

| Safety Mechanism | Two-handed controls keep you safe. This stops accidents from happening. |

| Versatility | Cuts many kinds of scrap. You can recycle more and make more money. |

| Complements Recycling Line | Works with other machines. You can turn scrap into pieces to sell much faster. |

You save time because you do not have to move scrap far. The right blade material means you do not need to change blades often.

Plate Shear Blades for Sheet Metal

Geometry Optimization and Maintenance

Plate shear blades help you cut sheet metal with smooth edges. You can make them work better by changing blade shape and doing regular care. Remote monitoring lets you watch how the machine works from far away. You can see how much you cut and if there are problems.

- Change cutting speed and feed rate for each metal type. This helps you get better cuts and makes blades last longer.

- Predictive analytics uses old data to guess when you need to fix things. You can fix problems before they stop your work.

- Tungsten Carbide blades last longer than normal steel. You can cut more before needing a new blade.

- Heat treatment makes blades hard and tough. This helps them work well and last longer.

- Sharpen or change blades often to keep cuts good. This helps you spend less money on repairs.

Doing these things keeps your machines working and gives you better results.

Industry Lessons and Best Practices

You can learn a lot from using shear blades at work. There are some best ways to keep machines running and get more done.

- Take care of blades before problems start. Check if blades fit and if the edge is sharp before each shift.

- Keep blade gaps and bolts tight at the right level.

- Look at blades often for damage or wear. Sharpen or change them when needed.

- Clean blades after every shift. This stops dirt and rust from building up.

- Set blade clearance to 5-10% of the metal thickness for best cuts.

- Follow the maker’s rules for changing and putting in blades.

- Only use blades that the maker says are right for your machine.

Tip: Cleaning and checking blades often helps you stop breakdowns and keeps your work going.

You save money and keep machines working by following these steps. You also help keep workers safe and jobs running smoothly.

To keep machines working longer, pick heavy duty shear blades that fit your job. Make sure the blade material and shape match your machine and the metal you cut. Doing this helps you:

- Cut better and get good quality pieces

- Save energy and have less machine stoppage

- Use blades made for your type of work

Metal Industrial gives you strong blades, custom choices, and good help. Check how your blades work often. If you need help or special blades, contact Metal Industrial.

FAQ

What makes heavy duty shear blades different from regular blades?

Heavy duty shear blades are made with stronger steel. They get special heat treatment to make them tough. These blades last longer and work better on thick metal or scrap.

How often should you replace shear blades?

Check your blades after each big job. If you see chips, cracks, or dull spots, change them. Looking at blades often helps you stop problems before they start.

Can you use one blade type for all metals?

You need to match the blade material to the metal you cut. Using the wrong blade can make bad cuts. It also wears out the blade faster.

What is the best way to maintain shear blades?

Clean blades after every use. Oil the moving parts so they work well. Keep blades in a dry place so they do not rust. Check for damage often to help blades last longer.

How do you choose the right blade geometry?

Look at your machine and how thick the metal is. Use the maker’s guide to pick the right rake angle and clearance. This helps you get smooth and clean cuts.

Why do blades sometimes crack or break?

Blades can crack if you use too much force. Bad alignment or wrong setup can also cause breaks. Always follow the instructions and check for damage early.

What are application-specific shear blades?

Application-specific shear blades are made for special jobs. You get blades that fit your machine and the metal you need to cut.

Do certifications matter when buying shear blades?

Certifications show blades are safe and high quality. Ask the supplier for ISO or other certificates before you buy.

See Also

The Ultimate Buyer’s Guide to Industrial Shear Blades: 7 Quality Checks Before You Purchase

Sharpen Shear Blades Like a Pro: Avoiding Common Grinding Mistakes and Extending TCO

The Definitive Guide to Setting Shear Blade Clearance: Formulas, Mistakes, and Zero-Burr Results

H13 Hot Work Shear Blades: Mastering High-Temperature Metal Cutting and Billet Shearing

Achieving Zero-Burr Cuts with Precision Guillotine Shear Blades