औद्योगिक श्रेडर ब्लेड विभिन्न अनुप्रयोगों में सामग्री को कुशलतापूर्वक काटने के लिए आवश्यक हैं। वे कारखानों, रीसाइक्लिंग और अपशिष्ट प्रबंधन कार्यों में महत्वपूर्ण भूमिका निभाते हैं। ये ब्लेड श्रेडर के प्रदर्शन और सटीकता को बढ़ाते हैं। सही औद्योगिक श्रेडर ब्लेड का चयन करने से काम की गति में काफी वृद्धि हो सकती है और देरी को रोका जा सकता है। विशिष्ट आवश्यकताओं के लिए, कस्टम ब्लेड विशिष्ट चुनौतियों का समाधान कर सकते हैं। यदि आपको सहायता की आवश्यकता है, तो संकोच न करें संपर्क करें नानजिंग Metal विशेषज्ञ सलाह के लिए हमसे संपर्क करें। वे आपकी ज़रूरतों के हिसाब से सबसे अच्छे उपकरण चुनने में आपकी मदद कर सकते हैं।

चाबी छीनना

- श्रेडर ब्लेड पुनर्चक्रण, चीजें बनाने और अपशिष्ट प्रबंधन के लिए महत्वपूर्ण हैं।

- सही ब्लेड, जैसे सिंगल-शाफ्ट या कार्बाइड, का चयन करने से कतरन कार्य बेहतर होता है और लंबे समय तक चलता है।

- कुछ विशेष कार्यों के लिए बनाए गए विशेष ब्लेड बेहतर काम करते हैं, लंबे समय तक चलते हैं, और समय के साथ पैसे भी बचाते हैं।

- ब्लेड की सामग्री और उनके काम करने के तरीके को जानने से आपको सर्वोत्तम ब्लेड चुनने में मदद मिलती है।

- ब्लेडों की देखभाल करना और उन्हें समय पर बदलना कतरन को सुरक्षित रखता है और अच्छी तरह से काम करता है।

औद्योगिक श्रेडर ब्लेड को समझना

परिभाषा और कार्य

औद्योगिक श्रेडर ब्लेड क्या हैं?

औद्योगिक श्रेडर ब्लेड श्रेडर में सामग्री को काटने के लिए उपयोग किए जाने वाले उपकरण हैं। वे वस्तुओं को आसानी से संभालने के लिए छोटे टुकड़ों में तोड़ देते हैं। ये ब्लेड कारखानों, रीसाइक्लिंग और अपशिष्ट प्रबंधन में महत्वपूर्ण हैं। वे विशिष्ट कार्यों के लिए विभिन्न आकारों और आकारों में आते हैं। उनका मजबूत डिज़ाइन उन्हें बड़ी मात्रा में सामग्री को आसानी से संभालने में मदद करता है।

औद्योगिक श्रेडर ब्लेड कैसे काम करते हैं?

श्रेडर ब्लेड वस्तुओं को काटने या कुचलने के लिए निर्धारित गति से घूमते हैं। सामग्री को श्रेडर में डाला जाता है, जहाँ ब्लेड उन्हें अलग करने के लिए बल लगाते हैं। उदाहरण के लिए, 150 आरपीएम की गति ऊर्जा की बचत करते हुए दक्षता में सुधार कर सकती है। ब्लेड का डिज़ाइन, क्लीयरेंस और फीडिंग एरिया इस बात को प्रभावित करता है कि श्रेडिंग कितनी अच्छी तरह काम करती है।

| मीट्रिक/पैरामीटर | मूल्य/प्रभाव |

|---|---|

| इष्टतम सिलेंडर गति | 150 आरपीएम (6.26 मीटर/सेकेंड) न्यूनतम ऊर्जा खपत के साथ उच्चतम थ्रूपुट के लिए |

| थ्रूपुट में वृद्धि | 233% में 9 से 30 किग्रा/घंटा की वृद्धि हुई है, साथ ही हथौड़े की गति 1250 से 1750 आरपीएम तक बढ़ी है। |

| छलनी व्यास प्रभाव | 185% की थ्रूपुट क्षमता में 1750 आरपीएम पर 2 से 6 मिमी तक की वृद्धि के साथ सुधार |

| औसत कतरनी बल | कुचले हुए खजूर के बीज के लिए मापा गया 0.2495 kN |

| विशिष्ट ऊर्जा गणना विधि | प्रयोगों के दौरान खपत विशिष्ट ऊर्जा की गणना करने के लिए समीकरण संख्या 4 का उपयोग किया गया |

| सहसंबंध देखा गया | सिलेंडरों के बीच थ्रूपुट और फीडिंग क्षेत्र/क्लीयरेंस के बीच सकारात्मक सहसंबंध |

प्रमुख शब्दावली

श्रेडिंग में सामान्य शब्द

मुख्य शब्दों को जानने से श्रेडर को समझना आसान हो जाता है। यहाँ कुछ शब्द दिए गए हैं:

- प्रवाह: एक निर्धारित समय में एक श्रेडर द्वारा संसाधित सामग्री की मात्रा।

- कतरनी बलबल ब्लेड द्वारा वस्तुओं को काटने या फाड़ने के लिए प्रयोग किया जाता है।

- निकासीब्लेडों के बीच का स्थान जो काटने की सटीकता को प्रभावित करता है।

- फीड दर: सामग्री कितनी तेजी से श्रेडर में प्रवेश करती है।

ब्लेड के प्रकारों को समझना

श्रेडर ब्लेड विभिन्न कार्यों के लिए अलग-अलग प्रकार के होते हैं। सिंगल-शाफ्ट ब्लेड सटीक कट के लिए बेहतरीन होते हैं। डबल-शाफ्ट ब्लेड बड़े आइटम को अच्छी तरह से संभालते हैं। ग्रैनुलेटर ब्लेड तेजी से काम करते हैं, और टंगस्टन कार्बाइड ब्लेड कठिन कामों के लिए लंबे समय तक चलते हैं। इन प्रकारों को जानने से आपको सही ब्लेड चुनने में मदद मिलती है।

उद्योग अनुप्रयोग

विनिर्माण में श्रेडिंग

श्रेडर कारखानों को कच्चे माल को संसाधित करने और अपशिष्ट प्रबंधन में मदद करते हैं। उच्च-टोक़ ब्लेड धातु और प्लास्टिक जैसी कठिन वस्तुओं को काट सकते हैं। इससे सामग्री तैयार करना तेज़ और आसान हो जाता है।

पुनर्चक्रण प्रक्रियाएं

श्रेडर रीसाइकिलिंग में बहुत उपयोगी होते हैं। वे कागज, प्लास्टिक और इलेक्ट्रॉनिक्स को टुकड़े-टुकड़े कर सकते हैं। उदाहरण के लिए:

- दस्तावेज़ श्रेडर, पुनर्चक्रण के लिए कागज तैयार करते समय जानकारी को सुरक्षित रखते हैं।

- ई-स्क्रैप श्रेडर इलेक्ट्रॉनिक्स से भागों को पुनर्प्राप्त करते हैं, जिससे अपशिष्ट कम हो जाता है।

अपशिष्ट प्रबंधन समाधान

श्रेडर निपटान या पुनर्चक्रण के लिए कचरे के आकार को कम करते हैं। जैविक कचरे के लिए विशेष श्रेडर संक्षारक पदार्थों से होने वाले नुकसान से भागों की रक्षा करते हैं। यह सुनिश्चित करता है कि वे लंबे समय तक चलें।

सामग्री की संरचना

ब्लेड के लिए सामान्य सामग्री

औद्योगिक श्रेडर ब्लेड कठिन कामों के लिए मजबूत सामग्रियों से बनाए जाते हैं। आम सामग्रियों में शामिल हैं:

- हाई-स्पीड स्टील (एचएसएस)यह सामग्री बहुत मजबूत है और हमेशा तेज रहती है। यह धातु जैसी कठोर वस्तुओं को काटने के लिए अच्छी तरह से काम करती है।

- टंगस्टन कार्बाइड: यह बहुत कठोर होने के लिए जाना जाता है, यह लंबे समय तक चलता है। यह मोटी प्लास्टिक या धातुओं को काटने के लिए बहुत बढ़िया है।

- अलॉय स्टीलयह सामग्री मजबूत और लचीली दोनों है। यह सामान्य कतरन कार्यों के लिए अच्छा है।

- औजारों का स्टील: यह गर्मी को झेल सकता है और बहुत टिकाऊ है। यह कांच या सिरेमिक जैसी खुरदरी सामग्री को काटने के लिए एकदम सही है।

प्रत्येक सामग्री में विशेष विशेषताएं होती हैं जो इसे कुछ कार्यों के लिए अच्छा बनाती हैं। सही सामग्री चुनने से ब्लेड बेहतर काम करते हैं और लंबे समय तक चलते हैं।

प्रदर्शन पर सामग्री का प्रभाव

श्रेडर ब्लेड की सामग्री इस बात को प्रभावित करती है कि वे कितनी अच्छी तरह काम करते हैं और कितने समय तक चलते हैं। टंगस्टन कार्बाइड जैसी कठोर सामग्री धीरे-धीरे खराब होती है, इसलिए उन्हें कम प्रतिस्थापन की आवश्यकता होती है। मिश्र धातु स्टील जैसी नरम सामग्री अधिक झुकती है, जो कुछ कार्यों में मदद करती है।

शोध से पता चलता है कि ब्लेड के कोण और सामग्री भी प्रदर्शन को प्रभावित करते हैं। यहाँ कुछ निष्कर्ष दिए गए हैं:

| पहलू | निष्कर्ष |

|---|---|

| ब्लेड कोण | बड़े कोण (30°, 55°, 80°) को लंबे कट और मजबूत बलों के कारण अधिक ऊर्जा की आवश्यकता होती है। |

| सामग्री गुण | सामग्री के प्रकार के आधार पर ब्लेड की कटिंग की गुणवत्ता तथा उनकी ऊर्जा खपत में परिवर्तन होता है। |

| ऊर्जा के उपयोग | घर्षण और झुकाव के कारण काटने में बहुत अधिक ऊर्जा खर्च होती है। |

बेहतर परिणामों के लिए ब्लेड का डिज़ाइन भी मायने रखता है। उदाहरण के लिए:

- पीवीसी जैसे कठोर प्लास्टिक को काटने के लिए अधिक तीखे कोण (35-50 डिग्री) बेहतर होते हैं।

- दांतेदार किनारे भारी कतरन के लिए सर्वोत्तम होते हैं, जबकि चिकने किनारे साफ कटाई के लिए अच्छे होते हैं।

- 6 मिमी और 10 मिमी के बीच ब्लेड की मोटाई ब्लेड को अधिक मजबूत और अधिक कुशल बनाती है। पीईटी बोतलों को काटने के लिए, मोटे ब्लेड 20% लंबे समय तक चल सकते हैं।

इन विवरणों को जानकर, आप बेहतर काम करने वाले और लंबे समय तक चलने वाले ब्लेड चुन सकते हैं।

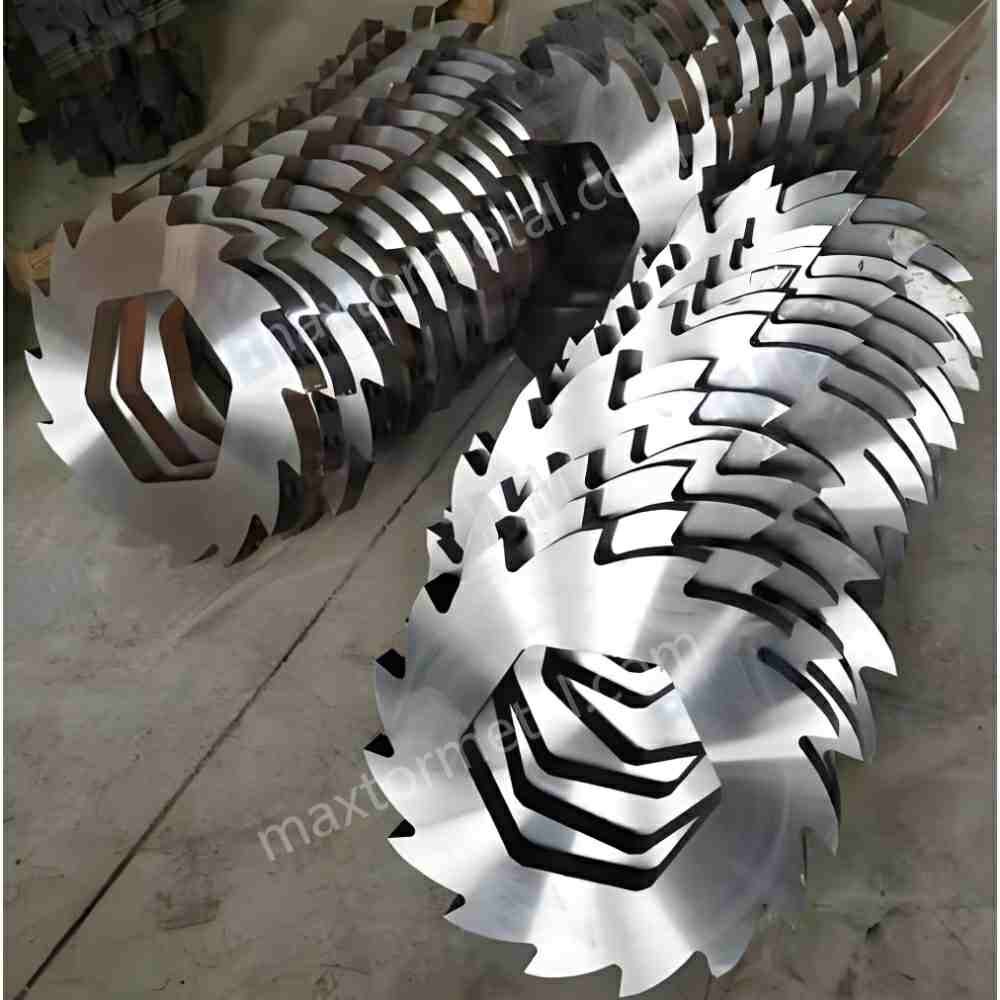

औद्योगिक श्रेडर ब्लेड के प्रकार और उनके उपयोग

1. सिंगल-शाफ्ट श्रेडर ब्लेड

प्रारुप सुविधाये

सिंगल-शाफ्ट ब्लेड सटीक और कुशल कटिंग के लिए बनाए जाते हैं। ये ब्लेड एक स्पिनिंग शाफ्ट पर रखे जाते हैं और हाइड्रोलिक पुशर के साथ काम करते हैं। पुशर कटिंग क्षेत्र में सामग्री को ले जाता है। ब्लेड में तेज, मजबूत किनारे होते हैं जो प्लास्टिक, कपड़े और बहुत कुछ काट सकते हैं।

बख्शीश: कई सिंगल-शाफ्ट ब्लेड में बदले जा सकने वाले हिस्से होते हैं। इससे उन्हें पूरी तरह बदले बिना ही तेज रखा जा सकता है। इससे समय और पैसे की बचत होती है।

उपयुक्त अनुप्रयोग

सिंगल-शाफ्ट ब्लेड सटीक कट की आवश्यकता वाले कामों के लिए बहुत अच्छे हैं। वे निम्न के लिए उपयोगी हैं:

- प्लास्टिक रीसाइक्लिंगप्लास्टिक कचरे को छोटे टुकड़ों में काटना।

- लकड़ी का टुकड़ा करनाऊर्जा या उत्पादों में पुनः उपयोग के लिए लकड़ी के टुकड़ों को तोड़ना।

- कपड़ा कतरना: पुनर्चक्रण के लिए कपड़ों को रेशों में काटना।

ये ब्लेड उन उद्योगों के लिए उपयुक्त हैं जो सामग्रियों के पुनः उपयोग पर केन्द्रित हैं।

2. डबल-शाफ्ट श्रेडर ब्लेड

डिजाइन विशेषताएँ

डबल-शाफ्ट ब्लेड, जिन्हें ट्विन-शाफ्ट ब्लेड भी कहा जाता है, में कटिंग एज के साथ दो शाफ्ट होते हैं। ये शाफ्ट कठोर सामग्रियों को फाड़ने के लिए विपरीत दिशाओं में घूमते हैं। उनका मजबूत डिज़ाइन उन्हें बिना अटके बड़ी मात्रा में सामग्री को संभालने देता है।

| विशेषता | फ़ायदा |

|---|---|

| इंटरलॉकिंग शाफ्ट | भारी या कठोर सामग्री को पूरी तरह से टुकड़े टुकड़े कर देता है। |

| उच्च टोक़ | भारी या सघन वस्तुओं को काटने की शक्ति देता है। |

| स्व-सफाई तंत्र | ब्लेडों के बीच सामग्री जमा होने से रोकता है, जिससे रखरखाव कम हो जाता है। |

प्रभावी उपयोग

डबल-शाफ्ट ब्लेड भारी-भरकम कतरन के लिए सबसे अच्छे होते हैं। वे निम्न के लिए अच्छे से काम करते हैं:

- Metal श्रेडिंग: पुनर्चक्रण के लिए स्क्रैप धातु को काटना।

- टायर का टुकड़ा करनापुराने टायरों को टुकड़ों में तोड़कर डामर या खेल के मैदानों में पुनः उपयोग करना।

- ई-कचरा पुनर्चक्रणपुराने इलेक्ट्रॉनिक्स से भागों को पुनः प्राप्त करना।

ये ब्लेड मजबूत और विश्वसनीय हैं, जिससे ये अपशिष्ट और रीसाइक्लिंग उद्योगों के लिए बेहतरीन हैं।

3. ग्रैन्यूलेटर श्रेडर ब्लेड

उच्च गति प्रसंस्करण

ग्रैनुलेटर ब्लेड तेजी से कतरने के लिए बनाए जाते हैं। वे सामग्री को जल्दी से कम करने के लिए आदर्श हैं। ये ब्लेड अन्य प्रकारों की तुलना में तेज़ी से घूमते हैं, जिससे वे हल्की सामग्रियों के लिए कुशल बन जाते हैं।

एक जर्मन रिसाइकिलिंग प्लांट ने टंगस्टन कार्बाइड ग्रैन्यूलेटर ब्लेड का उपयोग करके 22% की दक्षता में सुधार किया। उन्होंने प्रति टन प्लास्टिक पर 14% की ऊर्जा खपत में भी कटौती की।

सामान्य अनुप्रयोग

ग्रैनुलेटर ब्लेड का उपयोग उन उद्योगों में किया जाता है जहाँ बारीक कतरन की आवश्यकता होती है। वे अक्सर निम्नलिखित में पाए जाते हैं:

- प्लास्टिक रीसाइक्लिंग संयंत्रप्लास्टिक कचरे को पुनः उपयोग के लिए कणों में बदलना।

- खाद्य प्रसंस्करण: खाद्य अपशिष्ट को खाद या जैव ऊर्जा के लिए नष्ट करना।

- दवाइयोंसुरक्षित निपटान के लिए समाप्त हो चुके उत्पादों को नष्ट करना।

उनकी गति और दक्षता उन्हें लागत-बचत उद्योगों के लिए मूल्यवान बनाती है।

टिप्पणी: सामग्री के आधार पर ग्रैन्यूलेटर ब्लेड चुनें। टंगस्टन कार्बाइड ब्लेड लंबे समय तक चलते हैं और उच्च मात्रा वाले काम के लिए बहुत अच्छे होते हैं।

4. मल्टी-शाफ्ट श्रेडर ब्लेड

लचीला डिजाइन

मल्टी-शाफ्ट ब्लेड को मजबूत और अनुकूलनीय बनाया जाता है। इनमें कई घूमने वाले शाफ्ट होते हैं जिनमें दांत एक दूसरे से जुड़े होते हैं। यह डिज़ाइन उन्हें कई सामग्रियों को काटने में सक्षम बनाता है, जैसे कि नरम प्लास्टिक और कठोर धातुएँ। दांत वस्तुओं को काटने वाले क्षेत्र में खींचते हैं और उन्हें छोटे-छोटे टुकड़ों में तोड़ देते हैं।

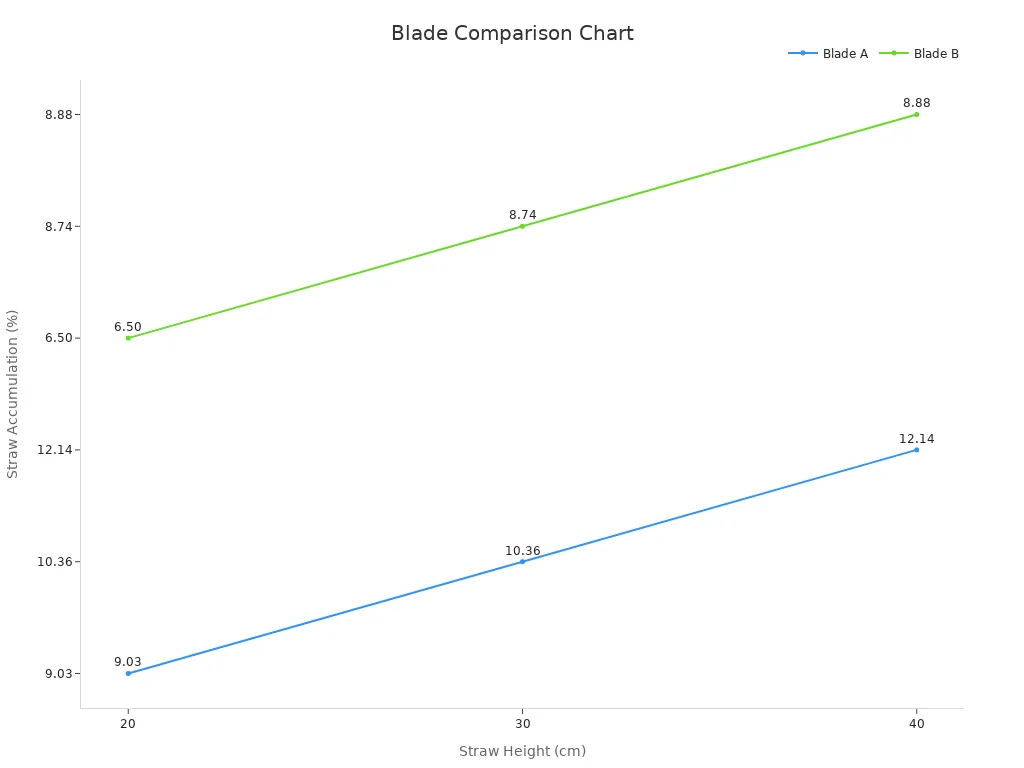

ये ब्लेड अन्य ब्लेडों की तुलना में सामग्री के जमाव को रोकने में बेहतर हैं। उदाहरण के लिए, परीक्षणों से पता चलता है ब्लेड बी, एक बहु-शाफ्ट प्रकार, ब्लेड ए से बेहतर काम करता है विभिन्न ऊंचाइयों पर पुआल के जमाव को कम करने में।

| ब्लेड का प्रकार | स्ट्रॉ की ऊंचाई (सेमी) | स्ट्रॉ बिल्ड-अप (%) | रिडक्शन बनाम ब्लेड ए (%) |

|---|---|---|---|

| ब्लेड ए | 20 | 9.03 | एन/ए |

| ब्लेड ए | 30 | 10.36 | एन/ए |

| ब्लेड ए | 40 | 12.14 | एन/ए |

| ब्लेड बी | 20 | 6.50 | 28.01 |

| ब्लेड बी | 30 | 8.74 | 16.63 |

| ब्लेड बी | 40 | 8.88 | 26.85 |

इस वजह से, कई उद्योगों में मल्टी-शाफ्ट ब्लेड का उपयोग किया जाता है।

विभिन्न सामग्रियों को संभालना

मल्टी-शाफ्ट ब्लेड बड़ी या विषम आकार की वस्तुओं को काटने के लिए बहुत बढ़िया हैं। उनका मज़बूत डिज़ाइन टायर, इलेक्ट्रॉनिक्स या बिल्डिंग कचरे से भी जाम होने से रोकता है। दांत अच्छी तरह से पकड़ते हैं और सामग्री को फाड़ते हैं, जिससे कतरना आसान रहता है।

ये ब्लेड तेजी से काम करते हैं, जिससे ये उन जगहों के लिए अच्छे होते हैं जहाँ बहुत सारा कचरा होता है। वे रीसाइक्लिंग प्लांट में मिश्रित सामग्रियों या कचरा केंद्रों में बड़ी मात्रा में कचरे को काट सकते हैं। कई तरह की वस्तुओं को काटने की उनकी क्षमता उन्हें बहुत उपयोगी बनाती है।

5. हाई-स्पीड स्टील ब्लेड

मजबूत और विश्वसनीय

हाई-स्पीड स्टील (एचएसएस) ब्लेड बहुत मजबूत और लंबे समय तक चलने वाले होते हैंइन्हें हीट ट्रीटमेंट का उपयोग करके बनाया जाता है जो उन्हें अधिक कठोर और पहनने के लिए प्रतिरोधी बनाता है। ये ब्लेड गर्म परिस्थितियों में उपयोग किए जाने पर भी तेज रहते हैं, जिससे वे कठिन कतरन कार्यों के लिए बेहतरीन बन जाते हैं।

एचएसएस ब्लेड की मुख्य विशेषताएं:

- मजबूत सामग्रियों को काटने के लिए बहुत कठिन।

- ये घिसते नहीं, इसलिए लंबे समय तक चलते हैं।

- गर्म कतरन कार्यों के लिए गर्मी को अच्छी तरह से संभालें।

ये गुण एचएसएस ब्लेडों को स्थिर प्रदर्शन की आवश्यकता वाले उद्योगों के लिए भरोसेमंद बनाते हैं।

सर्वोत्तम उपयोग

HSS ब्लेड दवा और रसायन जैसे उद्योगों में कतरन के लिए बहुत बढ़िया हैं। वे सटीकता और ताकत की आवश्यकता वाले कामों के लिए एकदम सही हैं। उदाहरण के लिए, वे पुरानी दवाइयों को सुरक्षित निपटान के लिए कुचल सकते हैं या रीसाइकिलिंग के लिए रासायनिक कंटेनरों को काट सकते हैं।

वे सामान्य श्रेडर में भी अच्छी तरह से काम करते हैं, प्लास्टिक, धातु और कपड़े काटते हैं। यदि आपको ऐसे ब्लेड की आवश्यकता है जो मजबूत और सटीक हों, तो HSS ब्लेड एक स्मार्ट विकल्प हैं।

6. टंगस्टन कार्बाइड ब्लेड

कठोर और लंबे समय तक चलने वाला

टंगस्टन कार्बाइड ब्लेड सबसे कठोर और मजबूत ब्लेड में से एक हैं। उनकी विशेष संरचना उन्हें हीरे जितना कठोर बनाती है। इसका मतलब है कि वे घिसाव का प्रतिरोध करते हैं और उच्च दबाव को आसानी से संभाल लेते हैं।

टंगस्टन कार्बाइड ब्लेड के लाभ:

- कठिन वस्तुओं को काटने के लिए अत्यंत कठोर।

- ये घिसाव प्रतिरोधी होते हैं, इसलिए इन्हें बार-बार बदलने की आवश्यकता नहीं होती।

- कठिन परिस्थितियों में भी लम्बे समय तक चलें।

इन ब्लेडों का उपयोग भारी-भरकम कामों के लिए श्रेडर में किया जाता है। उनकी मजबूती उन्हें कठिन कामों के लिए लागत बचाने वाला विकल्प बनाती है।

कठिन नौकरियाँ

टंगस्टन कार्बाइड ब्लेड कठोर या खुरदरी सामग्री को काटने के लिए बहुत बढ़िया हैं। इनका इस्तेमाल अक्सर खनन में चट्टानों और अन्य ठोस वस्तुओं को काटने के लिए किया जाता है। रीसाइक्लिंग केंद्र इनका इस्तेमाल मोटे प्लास्टिक, धातुओं और अन्य कठोर सामग्रियों को काटने के लिए करते हैं।

उदाहरण के लिए, ये ब्लेड पुराने टायरों को सड़कों या खेल के मैदानों के लिए दोबारा इस्तेमाल किए जा सकने वाले टुकड़ों में काट सकते हैं। कठिन कामों को संभालने की उनकी क्षमता उन्हें औद्योगिक श्रेडर के लिए महत्वपूर्ण बनाती है।

सही औद्योगिक श्रेडर ब्लेड का चयन

मुख्य विचार

सामग्री का प्रकार

आपको जिस सामग्री को काटना है, वह ब्लेड के प्रकार को निर्धारित करता है। धातु जैसी कठोर वस्तुओं को काटने के लिए ब्लेड की आवश्यकता होती है। टंगस्टन कार्बाइड या उच्च गति स्टील ब्लेड। प्लास्टिक या कपड़े जैसी नरम चीजें, इसके साथ बेहतर काम करती हैं अलॉय स्टील ब्लेड। प्रत्येक सामग्री इस बात को प्रभावित करती है कि श्रेडिंग कितनी अच्छी तरह काम करती है। उदाहरण के लिए, टंगस्टन कार्बाइड ब्लेड लंबे समय तक चलते हैं और क्षति का प्रतिरोध करते हैं, जिससे वे कठिन कामों के लिए बेहतरीन होते हैं।

| मुख्य विचार | इनसाइट्स |

|---|---|

| बाजार की गतिशीलता | नई प्रौद्योगिकियां श्रेडर ब्लेड के डिजाइन में सुधार करती हैं। |

| क्षेत्रीय विकास | एशिया-प्रशांत उद्योगों को कस्टम श्रेडिंग समाधान की आवश्यकता है। |

| वहनीयता | पर्यावरण-अनुकूल ब्लेड पुनर्चक्रण और हरित लक्ष्यों का समर्थन करते हैं। |

मोटाई की आवश्यकताएं

ब्लेड की मोटाई श्रेडिंग के प्रदर्शन को बदल देती है। मोटे ब्लेड सघन वस्तुओं को बेहतर तरीके से काटते हैं। पतले ब्लेड विस्तृत कट के लिए अच्छे होते हैं। उदाहरण के लिए, 6 मिमी से 10 मिमी मोटे ब्लेड पीईटी बोतलों को अच्छी तरह से काटते हैं और लंबे समय तक चलते हैं। सही मोटाई चुनने से ब्लेड मजबूत रहते हैं और डाउनटाइम कम होता है।

सामग्री का आयतन

सामग्री की मात्रा ब्लेड के चयन को प्रभावित करती है। बड़े कामों के लिए लंबे समय तक उपयोग के लिए मजबूत ब्लेड की आवश्यकता होती है। मल्टी-शाफ्ट ब्लेड बड़ी मात्रा में मिश्रित सामग्रियों को काटने के लिए बढ़िया हैं। छोटे कामों के लिए बेहतर है एकल शाफ्ट ब्लेड स्वच्छ एवं सटीक कट के लिए।

कार्य के लिए ब्लेड का मिलान

आवेदन की विशिष्टताएं

अलग-अलग कामों के लिए अलग-अलग ब्लेड डिज़ाइन की ज़रूरत होती है। रीसाइक्लिंग केंद्र इसका इस्तेमाल करते हैं दानेदार ब्लेड प्लास्टिक को छोटे-छोटे टुकड़ों में बदलने के लिए। अपशिष्ट केंद्र इसका उपयोग करते हैं डबल-शाफ्ट ब्लेड टायर और इलेक्ट्रॉनिक्स जैसी बड़ी वस्तुओं के लिए। सही ब्लेड चुनने से कतरन में सुधार होता है और ऊर्जा की बचत होती है।

बख्शीश: ब्लेड चुनने से पहले सामग्री और श्रेडिंग सेटअप के बारे में सोचें। इससे जाम से बचा जा सकता है और प्रदर्शन में सुधार होता है।

प्रदर्शन अपेक्षाएँ

ब्लेड का प्रदर्शन सामग्री, डिजाइन और उपयोग पर निर्भर करता है। उच्च गति स्टील ब्लेड कठोर प्लास्टिक और धातुओं को काटने के लिए बहुत अच्छे हैं। टंगस्टन कार्बाइड ब्लेड लंबे समय तक चलते हैं और कठिन काम को अच्छी तरह से संभालते हैं। सिंथेटिक हीरा ब्लेड विशेष कार्यों के लिए बहुत सटीक होते हैं। आपको क्या चाहिए यह जानने से आपको सबसे अच्छा ब्लेड चुनने में मदद मिलती है।

सामान्य ब्लेड सामग्री

उच्च गति स्टील

ये ब्लेड मजबूत होते हैं और गर्मी का प्रतिरोध करते हैं। वे कठोर कतरन कार्यों के दौरान तेज रहते हैं। वे धातुओं और प्लास्टिक को काटने के लिए एकदम सही हैं। उनकी कठोरता उन्हें कठिन कार्यों के लिए विश्वसनीय बनाती है।

टंगस्टन कार्बाइड

ये ब्लेड बहुत कठोर होते हैं और घिसाव का प्रतिरोध करते हैं। वे भारी कतरन को आसानी से संभाल लेते हैं। वे रीसाइक्लिंग और खनन कार्यों के लिए आदर्श हैं जहाँ ताकत मायने रखती है।

सिंथेटिक हीरा

ये ब्लेड बहुत सटीक होते हैं और नुकसान का प्रतिरोध करते हैं। वे कांच या सिरेमिक जैसी नाजुक वस्तुओं को काटने के लिए बहुत अच्छे हैं। हालांकि महंगे हैं, वे लंबे समय तक चलते हैं और बहुत अच्छी तरह से काम करते हैं।

| संपत्ति | उच्च गति स्टील | टंगस्टन कार्बाइड | सिंथेटिक हीरा |

|---|---|---|---|

| उच्च तापमान पर कठोरता | मज़बूत | मज़बूत | बहुत मजबूत |

| प्रतिरोध पहन | मध्यम | उच्च | बहुत ऊँचा |

| अस्थिभंग बेरहमी | मज़बूत | मध्यम | बहुत ऊँचा |

| ऊष्मीय चालकता | मध्यम | मध्यम | उच्च |

अनुकूलन विकल्प

कस्टम ब्लेड के लाभ

कस्टम श्रेडर ब्लेड में नियमित ब्लेड की तुलना में कई फायदे हैं। वे विशिष्ट आवश्यकताओं को पूरा करने, प्रदर्शन में सुधार करने और लंबे समय तक चलने के लिए बनाए जाते हैं। कस्टम डिज़ाइन दक्षता बढ़ाने और लागत कम करने में मदद करते हैं।

उदाहरण के लिए:

- एक जर्मन पीईटी बोतल रीसाइक्लिंग कंपनी को बचाया गया अपशिष्ट भंडारण लागत पर 40%उन्होंने सामग्री प्रबंधन में भी सुधार किया 60% और प्रति किलोग्राम कुचले हुए प्लास्टिक पर $0.30 की कमाई हुई।

- एक चीनी फर्नीचर कंपनी ने पुनर्नवीनीकृत 200 टन छर्रे मासिक.उन्होंने कच्चे माल की लागत में कटौती की 35% और वार्षिक लाभ में वृद्धि हुई $1.2 मिलियन.

कस्टम ब्लेड भी मानक ब्लेड से ज़्यादा समय तक चलते हैं। इनका जीवनकाल 15000 से 20000 तक हो सकता है। 50% लंबा, प्रतिस्थापन पर पैसे की बचत। सटीक मशीनिंग आकार को सटीक रखती है, जबकि विशेष फोर्जिंग और गर्मी उपचार उन्हें मजबूत बनाते हैं। ये विशेषताएं कस्टम ब्लेड को कठिन कामों के लिए एक स्मार्ट और टिकाऊ विकल्प बनाती हैं।

अनुकूलन कब चुनें

जब नियमित ब्लेड ठीक से काम नहीं करते हैं तो आपको कस्टम ब्लेड की आवश्यकता होती है। यदि आप अद्वितीय सामग्री या बड़े कार्यों को संभालते हैं, तो कस्टम ब्लेड बेहतर परिशुद्धता और ताकत देते हैं। उदाहरण के लिए, ऐसे उद्योग जो लकड़ी, कठोर प्लास्टिक, या नरम अपशिष्ट जैसी सामग्रियों से लाभ उठाएं D2, SKD-11, या 9CrSi.

कस्टम ब्लेड दक्षता में सुधार और डाउनटाइम को कम करने में भी सहायक होते हैं। वे विशिष्ट सामग्रियों को बेहतर तरीके से संभालते हैं, जाम और घिसाव को रोकते हैं। कस्टम टंगस्टन कार्बाइड ब्लेड का उपयोग करने वाले एक रीसाइक्लिंग प्लांट ने बेहतर कटिंग और कम रखरखाव की सूचना दी।

Nanjing Metal कस्टम श्रेडर ब्लेड बनाने में 18 साल का अनुभव है। उनकी कुशल टीम आपकी ज़रूरतों से मेल खाने वाले ब्लेड बनाने के लिए उन्नत तरीकों का इस्तेमाल करती है। चाहे आपको सटीक मशीनिंग की ज़रूरत हो या विशेष सामग्री की, नानजिंग Metal उच्च-गुणवत्ता वाले समाधान प्रदान करता है। उनके पास जाएँ मुखपृष्ठ अधिक जानने के लिए.

बख्शीश: कस्टम ब्लेड रीसाइकिलिंग, विनिर्माण और अपशिष्ट प्रबंधन के लिए बहुत बढ़िया हैं। वे समय के साथ प्रदर्शन में सुधार करते हैं और पैसे बचाते हैं, जिससे वे एक अच्छा निवेश बन जाते हैं।

यदि आप कस्टम ब्लेड में रुचि रखते हैं, तो नानजिंग Metal के बिक्री इंजीनियरों से संपर्क करें यहाँ विशेषज्ञ की सलाह के लिए.

कस्टम औद्योगिक श्रेडर ब्लेड का महत्व

कतरने में सटीकता

विशिष्ट आवश्यकताओं के लिए अनुकूलित डिज़ाइन

कस्टम श्रेडर ब्लेड आपकी श्रेडिंग आवश्यकताओं को पूरा करने के लिए बनाए गए हैं। वे विशेष सामग्रियों और प्रक्रियाओं को संभालने के लिए बनाए गए हैं। यह सटीक कट और बेहतर प्रदर्शन सुनिश्चित करता है। उदाहरण के लिए, धातु या प्लास्टिक जैसी कठोर वस्तुओं को काटने के लिए सही ताकत और आकार वाले ब्लेड की आवश्यकता होती है। कस्टम ब्लेड को श्रेडिंग को आसान और तेज़ बनाने के लिए डिज़ाइन किया गया है।

कस्टम डिज़ाइन किस प्रकार प्रदर्शन को बेहतर बनाते हैं, यह इस प्रकार है:

| विशेषता | फ़ायदा |

|---|---|

| मजबूत सामग्री | बेहतर मजबूती और सुरक्षा के लिए उच्च गुणवत्ता वाला स्टील और ताप उपचार। |

| विशेष डिजाइन | विशिष्ट कतरन कार्यों और अपशिष्ट प्रकारों से मेल खाने के लिए बनाया गया। |

| सावधानीपूर्वक परीक्षण | दोषों से बचने और ब्लेड टूटने को कम करने के लिए परीक्षण किया गया। |

| लंबा जीवनकाल | यह दोगुना समय तक चलता है, जिससे समय और धन की बचत होती है। |

| कम लागत | लंबे समय तक चलने और बेहतर काम करने से समग्र लागत में कटौती होती है। |

ये विशेषताएं श्रेडर को अधिक सटीकता और विश्वसनीयता से काम करने में मदद करती हैं।

उन्नत प्रदर्शन मीट्रिक्स

कस्टम ब्लेड जाम को रोककर और साफ कट बनाकर श्रेडर को बेहतर तरीके से काम करने में मदद करते हैं। इससे श्रेडिंग सुचारू रहती है और प्रोसेस की गई मात्रा बढ़ जाती है। कस्टम डिज़ाइन के साथ, श्रेडर कम घिसते हैं और बेहतर प्रदर्शन करते हैं।

दक्षता लाभ

कस्टम ब्लेड के साथ डाउनटाइम कम हो गया

कस्टम ब्लेड लंबे समय तक चलते हैं और उन्हें कम मरम्मत की आवश्यकता होती है। इससे डाउनटाइम कम होता है और श्रेडर चलते रहते हैं। उदाहरण के लिए, कस्टम ब्लेड पर स्विच करने से उनका जीवन 10 दिनों से बढ़कर 40 दिनों से अधिक हो सकता है। इसका मतलब है कम रुकावटें और कम रखरखाव लागत।

| तुलना | मानक ब्लेड | कस्टम ब्लेड |

|---|---|---|

| ब्लेड का जीवनकाल | 10 दिन | 40 दिन से अधिक |

| मासिक डाउनटाइम | 16 घंटे | 5 घंटे |

| वार्षिक प्रतिस्थापन लागत | $25,000 | $9,500 |

अनुकूलित सामग्री प्रसंस्करण

कस्टम ब्लेड्स से सामग्री तेजी से और कम जाम के साथ कटती है। रिपोर्ट्स से पता चलता है डाउनटाइम 65% तक कम हुआ, और आपातकालीन मरम्मत में 70% की कमी आती है। इन परिवर्तनों से समय की बचत होती है और उत्पादकता में सुधार होता है।

बख्शीश: कस्टम ब्लेड से श्रेडिंग भी सुरक्षित हो जाती है। ब्लेड की विफलता की दर प्रति वर्ष तीन से घटकर शून्य हो सकती है, जिससे कार्यस्थल अधिक सुरक्षित हो जाता है।

दीर्घायु और स्थायित्व

कस्टम ब्लेड के लिए उच्च गुणवत्ता वाली सामग्री

कस्टम ब्लेड में हाई-स्पीड स्टील या टंगस्टन कार्बाइड जैसी मज़बूत सामग्री का इस्तेमाल किया जाता है। ये सामग्री तेज़ रहती है और भारी इस्तेमाल के दौरान भी नुकसान नहीं पहुंचाती। हीट ट्रीटमेंट और सावधानी से की गई क्राफ्टिंग उन्हें और भी मज़बूत बनाती है।

मानक ब्लेड की तुलना में विस्तारित जीवनकाल

कस्टम ब्लेड नियमित ब्लेड की तुलना में बहुत लंबे समय तक चलते हैं। उनका जीवनकाल दोगुना हो सकता है, जिससे प्रतिस्थापन की आवश्यकता कम हो जाती है। इससे पैसे की बचत होती है और श्रेडर लंबे समय तक अच्छी तरह से काम करते रहते हैं।

कस्टम ब्लेड में निवेश करने से आपको बेहतर काम करने वाले उपकरण मिलेंगे और समय के साथ पैसे की भी बचत होगी।

लागत प्रभावशीलता

कस्टम ब्लेड से पैसे बचाएँ

कस्टम औद्योगिक श्रेडर ब्लेड समय के साथ पैसे बचाने में मदद करते हैं। इनकी कीमत पहले ज़्यादा होती है लेकिन ये लंबे समय तक चलते हैं, जिससे आपको नए ब्लेड की ज़रूरत कम पड़ती है। उदाहरण के लिए, पूरी तरह से कठोर ब्लेड सतह-कठोर ब्लेड की तुलना में दोगुने समय तक चलते हैं। इसका मतलब है कि कम प्रतिस्थापन और कम लागत।

| ब्लेड का प्रकार | प्रति ब्लेड प्रारंभिक लागत | औसत जीवनकाल | वार्षिक प्रतिस्थापन लागत (100 ब्लेड के लिए) |

|---|---|---|---|

| कठोर चाकू | $100 | 12 महीने | $10,000 |

| सतह-कठोर चाकू | $60 | 6 महीने | $12,000 |

टिकाऊ ब्लेड का उपयोग करने से डाउनटाइम और मरम्मत लागत भी कम हो जाती है। इससे श्रेडर सुचारू रूप से चलते रहते हैं और रखरखाव पर पैसे की बचत होती है।

कम अपशिष्ट, अधिक उत्पादन

कस्टम ब्लेड सामग्री को अधिक सटीकता से काटते हैं, जिससे अपशिष्ट कम होता है। टंगस्टन कार्बाइड या टाइटेनियम जैसी मजबूत सामग्री कई प्रकार की वस्तुओं को संभाल सकती है। इनमें पतली फिल्में और मोटा कार्डबोर्ड शामिल हैं। सटीक कटिंग का मतलब है कम बची हुई सामग्री और अधिक मूल्यवान टुकड़े बरामद होना।

उच्च गुणवत्ता वाले ब्लेड जाम होने से भी बचाते हैं, जिससे श्रेडर तेजी से काम करते हैं। इससे आप कम समय में ज़्यादा आइटम प्रोसेस कर सकते हैं। कस्टम ब्लेड चुनकर, आप पैसे बचाते हैं और कम कचरा पैदा करके पर्यावरण की मदद करते हैं।

उद्योग-विशिष्ट अनुप्रयोग

कारखानों के लिए कस्टम ब्लेड

कस्टम श्रेडर ब्लेड से फैक्ट्रियों को स्क्रैप काटने और कचरे को कम करने में लाभ होता है। मजबूत ब्लेड वाले कम गति वाले श्रेडर उपयोगी सामग्रियों को आसानी से निकाल लेते हैं। उदाहरण के लिए, मिश्र धातु स्टील ब्लेड धातुओं को काटने के लिए बहुत अच्छे होते हैं। पहनने के लिए प्रतिरोधी ब्लेड कठिन कामों में लंबे समय तक चलते हैं।

| आवेदन क्षेत्र | फ़ायदे | प्रौद्योगिकी प्रगति |

|---|---|---|

| उत्पादन | उत्पादन स्क्रैप को संभालता है, अपशिष्ट की मात्रा को कम करता है, मूल्यवान सामग्रियों को पुनः प्राप्त करता है | उच्च-टोक़, कम-गति श्रेडर, स्वचालन, वास्तविक समय निगरानी |

| ऑटोमोटिव | जीवन-काल समाप्त हो चुके वाहनों को नष्ट करना, धातुओं और घटकों का पुनर्चक्रण करना | मिश्र धातु इस्पात ब्लेड, पहनने के लिए प्रतिरोधी सामग्री |

कारखानों के लिए डिजाइन किए गए कस्टम ब्लेड सटीकता में सुधार करते हैं और देरी को कम करते हैं, जिससे श्रेडर अच्छी तरह से काम करते रहते हैं।

रीसाइकिलिंग के लिए विशेष ब्लेड

रीसाइक्लिंग केंद्रों को अलग-अलग सामग्रियों को संभालने के लिए कस्टम ब्लेड की आवश्यकता होती है। ये ब्लेड प्लास्टिक, धातु और ई-कचरे को कुशलतापूर्वक काट सकते हैं। टंगस्टन कार्बाइड ब्लेड मोटे प्लास्टिक के लिए एकदम सही हैं, जबकि मॉड्यूलर डिज़ाइन विशिष्ट कार्यों के लिए उपयुक्त हैं।

- कस्टम ब्लेड सामग्री को पुनः प्राप्त करने और लैंडफिल अपशिष्ट को कम करने में मदद करते हैं।

- ऊर्जा-बचत करने वाले श्रेडर पर्यावरण-अनुकूल लक्ष्यों का समर्थन करते हैं.

- IoT और AI उपकरण प्रदर्शन में सुधार करते हैं और समस्याओं का पहले ही अनुमान लगा लेते हैं।

कस्टम ब्लेड रीसाइकिलिंग को आसान और अधिक प्रभावी बनाते हैं। वे श्रेडर को सामग्रियों को बेहतर तरीके से संभालने, अपशिष्ट को कम करने और आउटपुट बढ़ाने में मदद करते हैं।

औद्योगिक श्रेडर ब्लेड रीसाइक्लिंग, अपशिष्ट और कारखानों के लिए महत्वपूर्ण हैं। अलग-अलग ब्लेड प्रकार, जैसे सिंगल-शाफ्ट या टंगस्टन कार्बाइड, विशिष्ट कार्यों को संभालते हैं। सही ब्लेड चुनने से श्रेडिंग तेज़ हो जाती है और देरी कम होती है।

कस्टम ब्लेड मजबूत और सटीक होते हैं। वे विशेष कार्यों में मदद करते हैं, पैसे बचाते हैं, और पर्यावरण के अनुकूल लक्ष्यों का समर्थन करते हैं।

| साक्ष्य का प्रकार | विवरण |

|---|---|

| प्रदर्शन जानकारी | सीमित डेटा उपलब्ध है; अधिकांश डेटा कम्पनियों द्वारा निजी रखा जाता है। |

| लागत विवरण | कीमतें प्रति टन दी गई हैं, लेकिन उनका स्पष्ट विवरण नहीं दिया गया है। |

| फ़ायदे | ब्लेड गति में सुधार करते हैं और उद्योगों को अधिक टिकाऊ बनाने में मदद करते हैं। |

विशेषज्ञ की सलाह के लिए, अपने श्रेडिंग परिणामों को बेहतर बनाने के लिए नानजिंग Metal से संपर्क करें।

सामान्य प्रश्न

औद्योगिक श्रेडर ब्लेड के लिए आमतौर पर कौन सी सामग्री का उपयोग किया जाता है?

औद्योगिक श्रेडर ब्लेड अक्सर किससे बनाए जाते हैं? हाई-स्पीड स्टील (एचएसएस), टंगस्टन कार्बाइड, अलॉय स्टील, और औजार स्टीलप्रत्येक सामग्री की अपनी विशेष ताकत होती है। उदाहरण के लिए, HSS गर्मी को अच्छी तरह से संभालता है, जबकि टंगस्टन कार्बाइड बहुत कठोर है और कठिन कामों के लिए बढ़िया है।

बख्शीश: आपको जो सामग्री काटनी है उसके आधार पर सामग्री चुनें।

मैं अपनी आवश्यकताओं के लिए सही श्रेडर ब्लेड का चयन कैसे कर सकता हूँ?

इन तीन बातों पर विचार करें:

- आप किस सामग्री को टुकड़े टुकड़े करेंगे (जैसे प्लास्टिक, धातु या कपड़ा)।

- आप प्रत्येक दिन कितनी सामग्री का प्रसंस्करण करेंगे।

- वह आकार जिसे आप कटे हुए टुकड़ों में चाहते हैं।

इनके आधार पर चयन करने से श्रेडर बेहतर काम करता है।

मुझे श्रेडर ब्लेड कब बदलना चाहिए?

आप कितनी बार ब्लेड बदलते हैं यह उपयोग और सामग्री के प्रकार पर निर्भर करता है। टंगस्टन कार्बाइड ब्लेड कठिन कामों के लिए लंबे समय तक चलते हैं। ब्लेड को अक्सर घिसाव के लिए जाँचें। अगर वे खराब तरीके से काटते हैं या क्षतिग्रस्त दिखते हैं तो उन्हें बदल दें।

टिप्पणी: ब्लेडों की देखभाल करने से वे लंबे समय तक चलते हैं।

क्या कस्टम श्रेडर ब्लेड विशेष सामग्रियों के लिए अच्छे हैं?

हां, कस्टम ब्लेड अद्वितीय सामग्रियों या कार्यों के लिए अच्छी तरह से काम करते हैं। वे विशिष्ट आवश्यकताओं के लिए डिज़ाइन किए गए हैं, जिससे वे अधिक सटीक और टिकाऊ बनते हैं। रीसाइक्लिंग और विनिर्माण उद्योगों को कस्टम ब्लेड से बहुत लाभ होता है।

श्रेडर ब्लेड को अच्छी तरह से काम करते रखने के लिए कुछ सुझाव क्या हैं?

- जमाव को रोकने के लिए ब्लेड को अक्सर साफ करें।

- घर्षण कम करने के लिए चलती भागों में तेल लगाएं।

- भारी उपयोग के बाद क्षति की जांच करें।

- आवश्यकता पड़ने पर ब्लेड को तेज करें या बदलें।

बख्शीश: सर्वोत्तम परिणामों के लिए निर्माता के निर्देशों का पालन करें।

यह भी देखें

पैकेजिंग ब्लेड रखरखाव के लिए अंतिम गाइड

शीटर चाकू रहस्य: एक पेशेवर की तरह बदलें और रखरखाव करें

सीधे काटने वाला चाकू: इसके औद्योगिक अनुप्रयोगों और सामग्रियों का एक सरल परिचय

3 प्रतिक्रियाएं

Thanks for ones marvelous posting! I genuinely enjoyed reading it, yyou are

a great author. I will ensure that I bookmark your

blog aand will come back at some point. I want to encourage you to continue your great posts,

have a nice evening!