सही वी-डाई ओपनिंग चुनने की शुरुआत आपकी सामग्री की मोटाई जानने से होती है। आप हमारी वेबसाइट देख सकते हैं शुरुआती लोगों के लिए प्रेस ब्रेक टूलिंग गाइड इस प्रक्रिया में आपकी मदद करने के लिए। यह मार्गदर्शिका आपके मोड़ों को सही रखने और आपकी दुकान को सुरक्षित रखने में मदद करती है। सही वी-डाई चुनने से दुर्घटनाओं की संभावना कम होती है और आपको बेहतर परिणाम मिलते हैं। व्यापक वी-डाई यह डाई को सुरक्षित रूप से जोड़ने में मदद करता है, जिससे झुकने पर जोखिम कम होता है। गाइड में शामिल आसान चार्ट आपको हर कदम पर आत्मविश्वास से भरने में मदद करता है।

- सही वी-डाई चुनने से दुर्घटना का जोखिम कम हो जाता है और मोड़ बेहतर हो जाते हैं।

- चौड़े वी-डाई भंगुर सामग्रियों के लिए ब्रिजिंग को अधिक सुरक्षित बनाते हैं।

चाबी छीनना

- जानें कि आपकी सामग्री कितनी मोटी है। इसे ध्यान से नापें ताकि आप सही वी-डाई ओपनिंग चुन सकें।

- आठ के नियम का प्रयोग करें। सर्वोत्तम V-डाई आकार प्राप्त करने के लिए अपनी सामग्री की मोटाई को आठ से गुणा करें।

- सही V-डाई प्रकार चुनें। सुरक्षित और अच्छे मोड़ के लिए अलग-अलग सामग्रियों को अलग-अलग डाई ओपनिंग की ज़रूरत होती है।

- अपने प्रेस ब्रेक की टन क्षमता की जाँच करें। सुनिश्चित करें कि यह आपके वी-डाई और सामग्री के बल को संभाल सकता है।

- पहले स्क्रैप सामग्री के साथ परीक्षण करें। अपना वास्तविक प्रोजेक्ट शुरू करने से पहले, यह सुनिश्चित करने के लिए कि आपका सेटअप काम कर रहा है, हमेशा एक परीक्षण मोड़ लें।

- सामान्य गलतियों से सावधान रहें। भौतिक गुणों को नज़रअंदाज़ न करें या गणित को न छोड़ें, वरना आपको बुरे परिणाम मिल सकते हैं।

- सुरक्षा को सर्वोपरि रखें। खुद को और दूसरों को सुरक्षित रखने के लिए हमेशा PPE पहनें और मशीन सुरक्षा नियमों का पालन करें।

- अपने औज़ारों का नियमित ध्यान रखें। अपने डाई और पंच की जाँच और सफ़ाई करते रहें ताकि वे अच्छी तरह काम करें और लंबे समय तक चलें।

वी-डाई मूल बातें

वी-डाई क्या है?

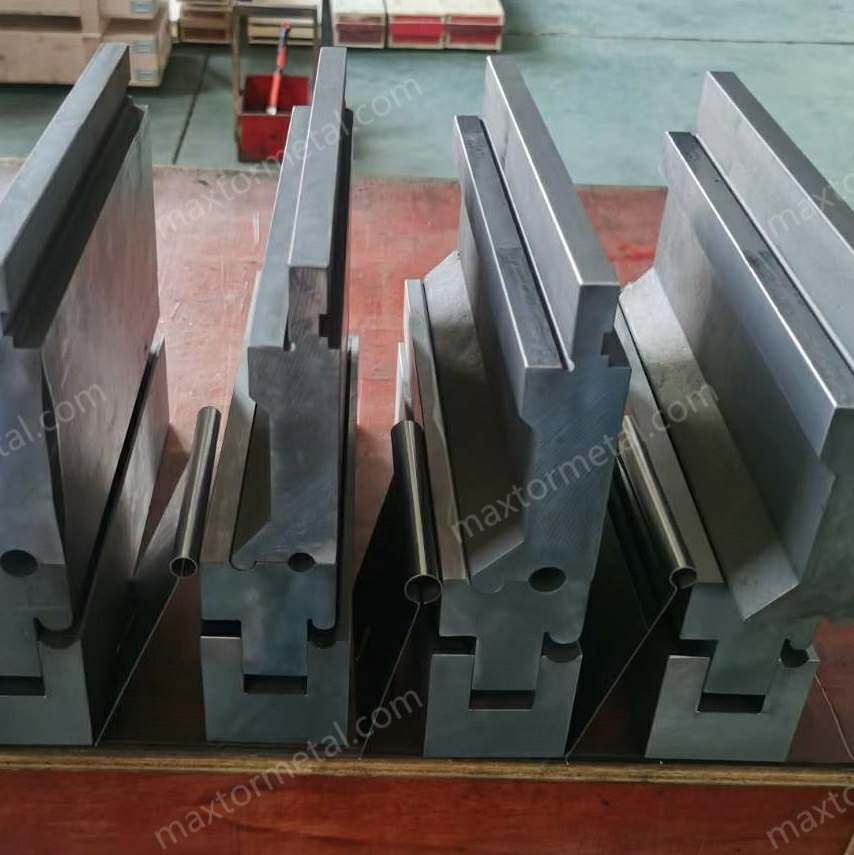

प्रेस ब्रेक टूल के प्रकारों के बारे में सुनकर आप सोच रहे होंगे कि वी-डाई क्या होती है। वी-डाई धातु के एक टुकड़े जैसा दिखता है जिसमें वी-आकार का एक खांचा बना होता है। इसी खांचे में जादू होता है। जब आप अपनी शीट मेटल को वी-डाई पर रखते हैं और पंच से दबाते हैं, तो धातु खांचे के साथ-साथ मुड़ जाती है। वी-डाई विभिन्न आकारों और साइज़ों में आती हैं, इसलिए आप सभी प्रकार की सामग्रियों को मोड़ सकते हैं। यहाँ कुछ सामान्य जानकारी दी गई है। वी-डाई प्रकार आप दुकानों में देखेंगे:

- सिंगल वी डाई - बुनियादी मोड़ के लिए एक खांचा।

- डबल वी डाई - दो खांचे, ताकि आप उपकरण बदले बिना आकार बदल सकें।

- मल्टी-वी डाई - अधिक विकल्पों और तेजी से काम करने के लिए कई खांचे।

| वी-डाई प्रकार | विवरण |

|---|---|

| सिंगल वी डाई | एक नाली, सरल मोड़ के लिए बढ़िया। |

| डबल वी डाई | दो खांचे, आपको आकार के बीच जल्दी से स्विच करने देता है। |

| मल्टी-वी डाई | कई खांचे, विभिन्न कार्यों के लिए उपयुक्त और समय की बचत। |

आपको लगभग हर धातु की दुकान में वी-डाई मिल जाएगी। ये स्टील, एल्युमीनियम और अन्य धातुओं को मोड़ने में आपकी मदद करती हैं। अगर आपको किसी खास ब्लेड या आकार की ज़रूरत है, तो आप कस्टम विकल्प देख सकते हैं, जैसे कस्टम ब्लेड.

वी-डाई का आकार क्यों मायने रखता है

सही वी-डाई आकार चुनना बेहद ज़रूरी है। छेद का आकार आपकी धातु के मुड़ने के तरीके को प्रभावित करता है। अगर आप चौड़े वी-डाई का इस्तेमाल करते हैं, तो आपको मोड़ की त्रिज्या ज़्यादा मिलेगी। इसका मतलब है कि आपका मोड़ ज़्यादा चिकना होगा और उसमें दरार पड़ने की संभावना कम होगी। अगर आप संकरे वी-डाई का इस्तेमाल करते हैं, तो आपको ज़्यादा कसा हुआ मोड़ मिलेगा, लेकिन अगर धातु बहुत मोटी या सख्त है, तो उसके टूटने का खतरा रहता है।

टिप: अधिकांश मोड़ों के लिए सबसे उपयुक्त स्थान वी-डाई ओपनिंग का उपयोग करना है जो लगभग मोटाई 8 गुना आपकी सामग्री का। इससे आपको अपनी धातु को नुकसान पहुँचाए बिना एक साफ़ मोड़ पाने में मदद मिलती है।

जब आप सही वी-डाई साइज़ का इस्तेमाल करते हैं, तो आपके बेंड बेहतर दिखते हैं और आपके पुर्जे आपकी इच्छानुसार फिट हो जाते हैं। अगर आप गलत साइज़ का इस्तेमाल करते हैं, तो आपको दरारें, खुरदुरे किनारे या ऐसे मोड़ दिखाई दे सकते हैं जो आपकी योजना से मेल नहीं खाते।

पंच और डाई अवलोकन

आइए बात करते हैं कि पंच और वी-डाई एक साथ कैसे काम करते हैं। पंच, प्रेस ब्रेक का ऊपरी हिस्सा होता है। यह आपकी धातु को नीचे की ओर धकेलता है, जिससे वह नीचे वी-डाई में धँस जाती है। वी-डाई धातु को सहारा देती है और मोड़ को आकार देती है। एक अच्छा मोड़ बनाने के लिए आपको दोनों हिस्सों की ज़रूरत होती है।

प्रेस ब्रेक टूल कई प्रकार के होते हैं, लेकिन पंच और वी-डाई सबसे आम हैं। आप अलग-अलग आकृतियों के लिए अलग-अलग पंच चुन सकते हैं, जैसे गहरे मोड़ के लिए गूज़नेक पंच या साधारण कोणों के लिए फ़्लैट पंच। Nanjing Metal अपने पंच और डाई के लिए 42CrMo मिश्र धातु इस्पात जैसी मज़बूत सामग्री का उपयोग करते हैं। इसका मतलब है कि आपको ऐसे उपकरण मिलते हैं जो लंबे समय तक चलते हैं और कठिन कामों में भी कारगर होते हैं। आप इन औज़ारों का इस्तेमाल कार कारखानों, हवाई जहाज़ के पुर्जों, फ़र्नीचर और यहाँ तक कि कृषि उपकरणों में भी देखेंगे।

जब आप सही पंच और वी-डाई चुनते हैं, तो आपके प्रेस ब्रेक टूलिंग का काम बेहतर होता है। आपको साफ़ मोड़, सुरक्षित संचालन और आपकी ज़रूरतों के मुताबिक़ पुर्जे मिलते हैं।

चयन के लिए प्रमुख कारक

जब आप प्रेस ब्रेक टूलिंग के साथ काम करना शुरू करते हैं, तो आपको वी-डाई चुनने से पहले कुछ ज़रूरी बातों पर विचार करना चाहिए। सही चुनाव आपको साफ़ मोड़ पाने में मदद करता है, आपके प्रेस ब्रेक को सुरक्षित रखता है, और आपकी मोड़ने की प्रक्रिया को ज़्यादा आसान बनाता है। आइए उन मुख्य कारकों पर गौर करें जिन पर आपको विचार करना चाहिए।

सामग्री का प्रकार

परिभाषा

सामग्री के प्रकार का मतलब है कि आप किस प्रकार की धातु को मोड़ना चाहते हैं। आम विकल्पों में माइल्ड स्टील, स्टेनलेस स्टील और एल्युमीनियम शामिल हैं। मोड़ने की प्रक्रिया के दौरान हर धातु अलग-अलग तरीके से काम करती है।

| संपत्ति | विवरण | वी-डाई चयन पर प्रभाव |

|---|---|---|

| सामग्री का प्रकार | स्टील, एल्युमीनियम और अन्य धातुओं में अद्वितीय गुण होते हैं। | सुरक्षित, स्वच्छ मोड़ के लिए आवश्यक V-डाई आकार को बदलता है। |

| तन्यता ताकत | टूटने से पहले धातु कितना बल सहन कर सकती है। | उच्च शक्ति के लिए दरार से बचने के लिए बड़े वी-डाई की आवश्यकता होती है। |

| लचीलापन | धातु बिना टूटे कितना खिंच सकती है। | अधिक तन्य धातुएं अधिक सख्त मोड़ों को संभाल सकती हैं। |

चयन संबंधी विचार

आपको अपनी वी-डाई को अपनी सामग्री के अनुसार चुनना होगा। एल्युमीनियम जैसी नरम धातुएँ आसानी से मुड़ जाती हैं, इसलिए आप छोटे वी-डाई ओपनिंग का इस्तेमाल कर सकते हैं। स्टेनलेस स्टील जैसी कठोर धातुओं के लिए बड़े ओपनिंग की ज़रूरत होती है। इससे दरारें पड़ने से बचती हैं और आपके प्रेस ब्रेक टूलिंग अच्छी स्थिति में रहते हैं। शुरू करने से पहले हमेशा धातु की लचीलापन और तन्य शक्ति की जाँच करें।

व्यावहारिक उदाहरण

अगर आप स्टेनलेस स्टील के टुकड़े को मोड़ना चाहते हैं, तो आपको उसी मोटाई के माइल्ड स्टील के लिए इस्तेमाल होने वाले वी-डाई से थोड़ा बड़ा वी-डाई चुनना चाहिए। इससे मोड़ने की प्रक्रिया के दौरान धातु टूटने से बच जाती है।

मोटाई

परिभाषा

मोटाई आपकी धातु की शीट की मोटाई है। आप इसे आमतौर पर मिलीमीटर या इंच में मापते हैं। मोटाई आपको बताती है कि आपको कितना बल चाहिए और किस आकार का वी-डाई इस्तेमाल करना है।

| सामग्री की मोटाई (मिमी) | अनुशंसित वी-डाई ओपनिंग (मिमी) |

|---|---|

| 2 | 16 |

| 3 | 24 |

| 5 | 40 |

चयन संबंधी विचार

आपकी धातु जितनी मोटी होगी, आपका वी-डाई उद्घाटन उतना ही चौड़ा होना चाहिए। यदि आप बहुत छोटा वी-डाई इस्तेमाल करते हैं, तो आपको अधिक बल लगाना होगा, जिससे आपके प्रेस ब्रेक या टूलिंग को नुकसान पहुँच सकता है। उदाहरण के लिए, एक 5 मिमी स्टील शीट 25 मिमी और 60 मिमी के बीच के वी-डाई ओपनिंग के साथ यह सबसे अच्छा काम करता है, 40 मिमी एक अच्छा मध्य बिंदु है। हमेशा सुनिश्चित करें कि आपके डाई ओपनिंग की मोटाई आपकी शीट की मोटाई से कम से कम दोगुनी हो।

टिप: खराब झुकने की गुणवत्ता, शीट में दरार, या उच्च बल की आवश्यकता का अर्थ अक्सर यह होता है कि आपका वी-डाई काम के लिए बहुत छोटा है।

व्यावहारिक उदाहरण

मान लीजिए आपके पास 3 मिमी मोटी माइल्ड स्टील शीट है। आपको लगभग 24 मिमी का वी-डाई ओपनिंग इस्तेमाल करना चाहिए। यह साइज़ आपको एक साफ़ मोड़ देता है और आपके प्रेस ब्रेक टूलिंग को सुरक्षित रखता है।

मोड़ कोण

परिभाषा

बेंड एंगल वह कोण है जो आप अपनी धातु में बनाना चाहते हैं। आपके प्रोजेक्ट के आधार पर, आपको एक तीक्ष्ण या चौड़े कोण की आवश्यकता हो सकती है।

चयन संबंधी विचार

वी-डाई ओपनिंग आपके बेंड एंगल को प्रभावित करती है। पतली सामग्री (4 मिमी तक) के लिए, लगभग छह गुना मोटाई वाली वी-डाई उपयुक्त होती है। मोटी सामग्री के लिए, आठ गुना मोटाई वाली वी-डाई का उपयोग करें। यदि आपकी वी-डाई बहुत बड़ी है, तो आपका बेंड एंगल गलत हो सकता है, और धातु आपकी इच्छानुसार नहीं मुड़ सकती। यदि यह बहुत छोटी है, तो शीट के ज़्यादा मुड़ने या टूटने का खतरा रहता है।

व्यावहारिक उदाहरण

अगर आप 2 मिमी शीट में 90° का मोड़ चाहते हैं, तो 16 मिमी का वी-डाई ओपनिंग इस्तेमाल करें। ज़्यादा तीखे कोण के लिए, आपको थोड़े छोटे डाई की ज़रूरत पड़ सकती है, लेकिन हमेशा ध्यान रखें कि आप अपने प्रेस ब्रेक पर ज़्यादा ज़ोर न डालें।

टन भार

परिभाषा

टन भार का अर्थ है वह बल जो आपके प्रेस ब्रेक को धातु मोड़ने के लिए चाहिए। आप इस बल को टन में मापते हैं। हर बार जब आप कोई मोड़ने का काम करते हैं, तो आपको यह जानना होगा कि आपकी मशीन कितना टन भार संभाल सकती है। अगर आप बहुत ज़्यादा बल लगाते हैं, तो आप अपने प्रेस ब्रेक या अपने टूलिंग को नुकसान पहुँचा सकते हैं। अगर आप बहुत कम बल लगाते हैं, तो हो सकता है कि आपकी धातु बिल्कुल भी न मुड़े।

| अवधि | इसका क्या मतलब है |

|---|---|

| टन भार | झुकने के लिए आवश्यक बल |

| क्षमता | आपकी मशीन द्वारा उपयोग किया जा सकने वाला अधिकतम बल |

चयन संबंधी विचार

आपको अपने झुकने वाले काम के लिए अपने टन भार का मिलान करना होगा। अपनी सामग्री की मोटाई और प्रकार की जाँच करके शुरुआत करें। मोटी या सख्त धातुओं को ज़्यादा बल की ज़रूरत होती है। नरम या पतली धातुओं को कम बल की ज़रूरत होती है। आपके वी-डाई का आकार भी टन भार को बदलता है। चौड़ी वी-डाई ज़रूरी बल को कम करती है, जबकि संकरी वी-डाई इसे बढ़ा देती है।

सुझाव: शुरू करने से पहले हमेशा अपने प्रेस ब्रेक की टन भार रेटिंग जाँच लें। अगर आप अपनी मशीन को उसकी सीमा से ज़्यादा चलाते हैं, तो उसके पुर्ज़े टूटने या खुद को चोट लगने का ख़तरा रहता है।

यहां कुछ बातें ध्यान में रखने योग्य हैं:

- अपनी सामग्री की मोटाई के अनुरूप वी-डाई ओपनिंग का इस्तेमाल करें। आठ का नियम आपको सही आकार चुनने में मदद करता है।

- अगर आप बहुत छोटा वी-डाई चुनते हैं, तो आपको ज़्यादा टन भार की ज़रूरत पड़ेगी। इससे आपका प्रेस ब्रेक जल्दी खराब हो सकता है।

- यदि आप बहुत बड़ा वी-डाई चुनते हैं, तो आपका बेंड पर्याप्त तीक्ष्ण नहीं होगा।

व्यावहारिक उदाहरण

मान लीजिए कि आप 4 मिमी मोटी स्टेनलेस स्टील की शीट को मोड़ना चाहते हैं। स्टेनलेस स्टील मज़बूत होता है, इसलिए आपको माइल्ड स्टील की तुलना में ज़्यादा बल की ज़रूरत होगी। अगर आप 32 मिमी के वी-डाई ओपनिंग (आठ के नियम का पालन करते हुए) का इस्तेमाल करते हैं, तो आपके प्रेस ब्रेक को मानक 1 मीटर मोड़ के लिए लगभग 40 टन बल की ज़रूरत होगी। अगर आपकी मशीन सिर्फ़ 30 टन ही संभाल सकती है, तो आपको ज़्यादा चौड़े वी-डाई का इस्तेमाल करना होगा या छोटे टुकड़े को मोड़ना होगा।

आपका सेटअप काम करता है या नहीं, यह जांचने का एक त्वरित तरीका यहां दिया गया है:

- अपनी सामग्री की मोटाई मापें.

- अपना वी-डाई उद्घाटन प्राप्त करने के लिए आठ से गुणा करें।

- यह देखने के लिए कि क्या आपका प्रेस ब्रेक काम संभाल सकता है, टन भार चार्ट या कैलकुलेटर का उपयोग करें।

अगर आपको यकीन न हो, तो स्क्रैप मेटल से एक टेस्ट बेंड करके देखें। इससे आपको गलतियों से बचने में मदद मिलेगी और आपका प्रेस ब्रेक भी सुरक्षित रहेगा।

आम शुरुआती गलतियाँ

कई शुरुआती लोग टन भार के मामले में छोटी-छोटी गलतियाँ कर बैठते हैं। यहाँ कुछ ऐसी गलतियाँ दी गई हैं जिन पर ध्यान देना चाहिए:

- प्रेस ब्रेक के अधिकतम टन भार की अनदेखी करना। इससे आपकी मशीन ख़राब हो सकती है।

- हर मोड़ने के काम के लिए एक ही वी-डाई का इस्तेमाल करें। अलग-अलग सामग्रियों के लिए अलग-अलग सेटअप की ज़रूरत होती है।

- यात्रा शुरू करने से पहले टन भार चार्ट की जांच करना भूल जाना।

- वी-डाई आकार को समायोजित किए बिना मोटी या कठोर धातुओं को मोड़ने का प्रयास करना।

नोट: हमेशा अपने नंबरों की दोबारा जाँच करें और संदर्भ चार्ट का उपयोग करें। प्रेस ब्रेक मशीनों के साथ काम करते समय सुरक्षा सबसे पहले आती है।

शुरुआती लोगों के लिए प्रेस ब्रेक टूलिंग गाइड

आठ का नियम

प्रेस ब्रेक टूलिंग के साथ काम शुरू करते समय आपने आठ के नियम के बारे में सुना होगा। यह नियम आपके वी-डाई ओपनिंग को चुनना बहुत आसान बनाता है। आठ का नियम कहता है कि आपको एक वी-डाई ओपनिंग चुननी चाहिए जो आपकी सामग्री की मोटाई से आठ गुना मोटी हो। उदाहरण के लिए, यदि आपकी शीट धातु 3 मिमी मोटी है, तो आपको 24 मिमी का वी-डाई ओपनिंग चाहिए। यह सरल सूत्र आपको साफ मोड़ पाने में मदद करता है और आपके प्रेस ब्रेक को सुरक्षित रखता है।

बख्शीश: आठ का नियम हर जगह दुकानों में लोकप्रिय है। यह आपको सर्वोत्तम प्रथाओं का पालन करने में मदद करता है और आपकी झुकने की प्रक्रिया को सुचारू बनाए रखता है। आप इस नियम का उपयोग अधिकांश सामग्रियों के लिए कर सकते हैं, लेकिन हमेशा जांच लें कि क्या आपके प्रोजेक्ट में किसी विशेष समायोजन की आवश्यकता है।

आठ का नियम किस प्रकार काम करता है, इस पर एक त्वरित नजर डालें:

वी-डाई उद्घाटन = 8 × सामग्री की मोटाई

अगर आप एक दृश्य चाहते हैं, तो कल्पना कीजिए कि एक तीर आपकी सामग्री की मोटाई से V-डाई के उद्घाटन की ओर इशारा कर रहा है। यह सूत्र आपको हर बार सही उपकरण चुनने में मदद करता है।

चरण-दर-चरण चयन

आइए, प्रेस ब्रेक टूलिंग के लिए वी-डाई चुनते समय आपको जिन चरणों का पालन करना होगा, उन पर नज़र डालें। ये चरण प्रक्रिया को सरल बनाते हैं और आपको सामान्य गलतियों से बचने में मदद करते हैं।

चरण 1: अपनी सामग्री का प्रकार पहचानें

सबसे पहले, यह तय करें कि आप किस तरह की धातु से काम कर रहे हैं। क्या आप माइल्ड स्टील, स्टेनलेस स्टील या एल्युमीनियम मोड़ रहे हैं? मोड़ते समय हर धातु की क्रिया अलग-अलग होती है। माइल्ड स्टील ज़्यादा मुलायम होता है, स्टेनलेस स्टील ज़्यादा मज़बूत होता है, और एल्युमीनियम आसानी से मुड़ जाता है।

टिप्पणी: अपनी सामग्री के प्रकार को जानने से आपको सही वी-डाई ओपनिंग चुनने में मदद मिलती है। कुछ धातुओं को दरारों या खुरदुरे मोड़ों से बचने के लिए बड़े या छोटे ओपनिंग की ज़रूरत होती है।

चरण 2: सामग्री की मोटाई मापें

इसके बाद, अपनी शीट मेटल की मोटाई नापें। सर्वोत्तम परिणामों के लिए कैलिपर या मोटाई नापने वाले उपकरण का उपयोग करें। नापने में एक छोटी सी गलती भी आपके मोड़ की गुणवत्ता को बदल सकती है।

बख्शीश: अपने माप की हमेशा दोबारा जाँच करें। सटीक मोटाई का मतलब है बेहतर मोड़ और सुरक्षित प्रेस ब्रेक टूलिंग।

चरण 3: आठ का नियम लागू करें

अब, आठ के नियम का प्रयोग करें। अपनी अनुशंसित वी-डाई ओपनिंग ज्ञात करने के लिए अपनी सामग्री की मोटाई को आठ से गुणा करें। उदाहरण के लिए, यदि आपकी धातु 2 मिमी मोटी है:

2 मिमी × 8 = 16 मिमी वी-डाई ओपनिंग

यह चरण आपको अपनी सामग्री के साथ अपने डाई का मिलान करने में मदद करता है। ज़्यादातर दुकानें इस नियम का इस्तेमाल करती हैं क्योंकि यह कई कामों के लिए कारगर है।

चरण 4: प्रेस ब्रेक क्षमता की जाँच करें

मोड़ना शुरू करने से पहले, सुनिश्चित करें कि आपका प्रेस ब्रेक आपके चुने हुए वी-डाई और सामग्री के लिए आवश्यक बल को संभाल सकता है। यदि आप बहुत अधिक बल लगाते हैं, तो आप अपनी मशीन या अपने टूलिंग को नुकसान पहुँचा सकते हैं।

टिप्पणी: अपने प्रेस ब्रेक की टन भार रेटिंग हमेशा जाँचें। मशीन पर ज़्यादा भार डालने से महंगी मरम्मत और असुरक्षित कामकाजी परिस्थितियाँ पैदा हो सकती हैं।

चरण 5: परीक्षण और समायोजन

अपनी सामग्री के एक टुकड़े से मोड़ का परीक्षण करें। मोड़ की गुणवत्ता देखें। अगर मोड़ सही नहीं है, तो अपने वी-डाई आकार को समायोजित करें या अपने माप की जाँच करें। कभी-कभी सही मोड़ पाने के लिए आपको थोड़े बड़े या छोटे डाई की आवश्यकता होती है।

बख्शीश: परीक्षण से आपको गलतियों को जल्दी पकड़ने में मदद मिलती है। इससे आपका समय बचता है और आपकी प्रेस ब्रेक टूलिंग अच्छी स्थिति में रहती है।

विशेष मामलों के लिए समायोजन

कभी-कभी, आपको विशेष सामग्रियों या तंग मोड़ों के लिए आठ के नियम को समायोजित करने की आवश्यकता होती है। सभी धातुएँ एक ही तरह से नहीं मुड़तीं। स्टेनलेस स्टील, माइल्ड स्टील से ज़्यादा कठोर होता है, इसलिए आपको बड़े वी-डाई ओपनिंग की आवश्यकता हो सकती है। एल्युमीनियम नरम होता है, इसलिए आप छोटे ओपनिंग का उपयोग कर सकते हैं।

विशेष मामलों के लिए यहां एक त्वरित मार्गदर्शिका दी गई है:

| सामग्री | वी-डाई ओपनिंग के लिए गुणक | 2 मिमी मोटाई के लिए उदाहरण |

|---|---|---|

| हल्का स्टील | 8 × मोटाई | 16 मिमी |

| स्टेनलेस स्टील | 10–12 × मोटाई | 20–24 मिमी |

| अल्युमीनियम | 6 × मोटाई | 12 मिमी |

- स्टेनलेस स्टील के लिए, 2 मिमी शीट के लिए 18 मिमी या 20 मिमी का वी-डाई ओपनिंग आज़माएँ। इससे दरार पड़ने से बचाव होता है।

- एल्युमीनियम के लिए आप छोटे छेद का उपयोग कर सकते हैं, जैसे 2 मिमी शीट के लिए 12 मिमी।

टिप्पणी: सर्वोत्तम परिणामों के लिए हमेशा सामग्री चार्ट या निर्माता के दिशानिर्देश देखें। अगर आपको किसी मुश्किल काम के लिए कस्टम समाधान चाहिए, तो आप यहाँ देख सकते हैं कस्टम ब्लेड विशेष मोड़ के लिए डिज़ाइन किया गया।

यदि आप विशिष्ट सामग्रियों के साथ काम करते हैं या आपको विशेष मोड़ त्रिज्या की आवश्यकता है, तो आप किसी टूलिंग विशेषज्ञ से बात करना चाहेंगे।

इन चरणों का पालन करके सही वी-डाई ओपनिंग चुनना आसान है। आप अपने बेंड्स को साफ़, अपनी शॉप को सुरक्षित और अपने प्रेस ब्रेक टूलिंग को सालों तक काम करते हुए रख सकते हैं।

वी-डाई आकार प्रभाव

सही प्रेस ब्रेक टूलिंग चुनना सिर्फ़ सही डाई चुनने से कहीं ज़्यादा है। आपके द्वारा चुना गया वी-डाई आकार आपके बेंड्स की बनावट, आपको कितने बल की ज़रूरत है, और यहाँ तक कि बेंडिंग के बाद आपकी धातु की कार्यप्रणाली को भी बदल देता है। आइए, शुरुआती लोगों के लिए प्रेस ब्रेक टूलिंग गाइड का पालन करते हुए, हर शुरुआती के लिए यह क्यों मायने रखता है, इसे समझते हैं।

मोड़ गुणवत्ता

जब आप सही प्रेस ब्रेक टूलिंग का इस्तेमाल करते हैं, तो आपके बेंड साफ़ और सटीक निकलते हैं। वी-डाई ओपनिंग बेंड रेडियस और सतह की फिनिश को नियंत्रित करती है। अगर आप बहुत छोटी डाई चुनते हैं, तो आपको दरारें या खुरदुरे किनारे दिखाई दे सकते हैं। अगर आप बहुत बड़ी डाई चुनते हैं, तो आपका बेंड टेढ़ा-मेढ़ा लग सकता है या आपकी योजना के अनुरूप नहीं हो सकता।

यहां एक त्वरित तालिका दी गई है जो दर्शाती है कि विभिन्न झुकने की विधियां मोड़ त्रिज्या को किस प्रकार प्रभावित करती हैं:

| झुकने की विधि | विवरण | मोड़ त्रिज्या संबंध |

|---|---|---|

| वायु झुकाव | पंच पूरी तरह से डाई में नहीं दबाता है। | वी-डाई आकार पर निर्भर करता है, लचीलापन प्रदान करता है लेकिन कम परिशुद्धता प्रदान करता है। |

| नीचे की ओर | पंच लगभग डाई के निचले भाग को छूता है। | बेंड त्रिज्या पंच टिप के करीब है, अधिक सुसंगत है। |

| गढ़ने | पंच धातु को पूरी तरह से डाई में दबा देता है। | त्रिज्या पंच टिप के बराबर है, सबसे सटीक और सबसे छोटी मोड़ त्रिज्या। |

आप इन सामान्य मोड़ गुणवत्ता समस्याओं से बचना चाहते हैं:

- अत्यधिक तंग मोड़ से दरारें

- विकृत किनारे या झुर्रियाँ

- मोड़ के पास गलत संरेखित छेद या आकृतियाँ

- बढ़ी हुई स्प्रिंगबैक जो अंतिम आकार को बदल देती है

शुरुआती लोगों के लिए एक अच्छी प्रेस ब्रेक टूलिंग गाइड आपको हमेशा याद दिलाती है कि अपनी बेंड त्रिज्या को अपनी सामग्री की मोटाई के कम से कम एक गुना पर सेट करें। छेद और कटआउट को बेंड लाइन से दूर रखें, और एकसमान बेंड दिशाओं का उपयोग करें। ये सुझाव आपको अपने सही प्रेस ब्रेक टूलिंग का अधिकतम लाभ उठाने में मदद करते हैं।

टन भार

आपके वी-डाई का आकार इस बात पर बहुत प्रभाव डालता है कि आपके प्रेस ब्रेक को कितना बल चाहिए। अगर आप छोटे वी-डाई ओपनिंग का इस्तेमाल करते हैं, तो बल एक छोटे से क्षेत्र पर केंद्रित होता है। इसका मतलब है कि मोड़ बनाने के लिए आपको ज़्यादा टन भार की ज़रूरत होगी। अगर आप चौड़े वी-डाई का इस्तेमाल करते हैं, तो बल फैल जाता है, और आपके प्रेस ब्रेक को ज़्यादा मेहनत नहीं करनी पड़ती।

उदाहरण के लिए, यदि आप पतली धातु को मोड़ रहे हैं, लगभग छह गुना मोटाई वाला एक डाई उद्घाटन यह अच्छी तरह काम करता है। मोटी धातु के लिए, आपको दस या बारह गुना मोटाई वाले डाई ओपनिंग की आवश्यकता हो सकती है। इससे आपको टन भार प्रबंधित करने में मदद मिलती है और आपकी मशीन सुरक्षित रहती है।

बख्शीश: अपने प्रेस ब्रेक को कभी भी उसकी टन भार सीमा से ज़्यादा न दबाएँ। ज़्यादा ज़ोर लगाने से आपके टूलिंग को नुकसान पहुँच सकता है, आपके पुर्ज़े खराब हो सकते हैं, या आपको चोट भी लग सकती है।

यदि आप गलत V-डाई आकार चुनते हैं तो क्या हो सकता है:

- उपकरण क्षति

- गलत झुकाव

- मोड़ पूरा करने के लिए पर्याप्त बल नहीं

शुरुआती लोगों के लिए प्रेस ब्रेक टूलिंग गाइड हमेशा आपको शुरू करने से पहले अपनी मशीन की टन भार रेटिंग की जाँच करने के लिए कहती है। अपने काम के लिए सही प्रेस ब्रेक टूलिंग का इस्तेमाल करें, और आप महंगी गलतियों से बचेंगे।

स्प्रिंग बेक

स्प्रिंगबैक तब होता है जब आपकी धातु झुकने के बाद अपने मूल आकार में वापस आने की कोशिश करती है। आपके द्वारा चुना गया V-डाई आकार आपको मिलने वाले स्प्रिंगबैक की मात्रा को प्रभावित करता है। मोटी सामग्री और बड़े मोड़ कोण आमतौर पर ज़्यादा स्प्रिंगबैक का मतलब होते हैं। अगर आप बहुत छोटी डाई का इस्तेमाल करते हैं, तो आपको और भी ज़्यादा स्प्रिंगबैक दिखाई दे सकता है, जिससे आपका अंतिम भाग खराब हो सकता है।

आप स्प्रिंगबैक को इस प्रकार नियंत्रित कर सकते हैं:

- अधिक मोड़ना: धातु को आवश्यकता से थोड़ा अधिक मोड़ें, ताकि वह सही कोण पर वापस आ जाए।

- सही पंच कोण का उपयोग करना: उदाहरण के लिए, यदि आप 2 डिग्री स्प्रिंगबैक की अपेक्षा करते हैं तो 88 डिग्री पंच का उपयोग करें।

- सही प्रेस ब्रेक टूलींग का चयन: बड़े नोज़ रेडियस वाला पंच तनाव और स्प्रिंगबैक को कम करने में मदद कर सकता है।

टिप्पणी: हमेशा एक टेस्ट बेंड करें और अपने नतीजों की जाँच करें। अगर आपको बहुत ज़्यादा स्प्रिंगबैक दिखाई दे, तो अपने वी-डाई साइज़ को एडजस्ट करें या कोई दूसरा पंच आज़माएँ।

अगर आप स्प्रिंगबैक को नज़रअंदाज़ करते हैं, तो हो सकता है कि आपको ऐसे पुर्ज़े मिलें जो आपकी ज़रूरतों के हिसाब से सही न हों। शुरुआती लोगों के लिए एक अच्छी प्रेस ब्रेक टूलिंग गाइड आपको हमेशा स्प्रिंगबैक की जाँच करने और ज़रूरत के अनुसार समायोजन करने की याद दिलाएगी।

सुरक्षा और दक्षता के लिए वी-डाई का आकार क्यों मायने रखता है

सही प्रेस ब्रेक टूलिंग का इस्तेमाल आपकी दुकान को सुरक्षित और आपके काम को कुशल बनाए रखता है। अगर आप बहुत छोटे वी-डाई का इस्तेमाल करते हैं, तो आपको ये जोखिम हो सकते हैं:

- अत्यधिक टन भार जो आपके प्रेस ब्रेक या टूलिंग को नुकसान पहुंचा सकता है

- सामग्री में दरार या अपूर्ण मोड़

- ऑपरेटर की चोट

यदि आपका वी-डाई बहुत बड़ा है, तो आप देख सकते हैं:

- खराब मोड़ सटीकता

- अत्यधिक मोड़ त्रिज्या

- वे भाग जो आपकी विशिष्टताओं के अनुरूप नहीं हैं

हमेशा संदर्भ चार्ट से अपने वी-डाई आकार की जाँच करें और कोई भी बड़ा काम शुरू करने से पहले एक परीक्षण मोड़ लें। शुरुआती लोगों के लिए हर प्रेस ब्रेक टूलिंग गाइड में पाया जाने वाला यह आसान कदम आपका समय बचाता है और आपके प्रोजेक्ट्स को ट्रैक पर रखता है।

सामान्य गलतियां

गलत डाई आकार

सामान्य संकेत

जब आप अपने प्रेस ब्रेक उपकरणों के साथ गलत आकार के डाई का उपयोग करते हैं, तो आपको कुछ चीजें नजर आ सकती हैं:

- यह मोड़ आपके चित्र या योजना से मेल नहीं खाता।

- कोने बहुत तीखे या बहुत गोल दिखते हैं।

- मोड़ रेखा के साथ दरारें दिखाई देती हैं।

- झुकने के बाद धातु समतल नहीं बैठती।

- झुकने की प्रक्रिया के दौरान आपको अजीब आवाजें सुनाई देती हैं या अतिरिक्त प्रतिरोध महसूस होता है।

कई शुरुआती लोग यह कम आंकते हैं कि डाई की चौड़ाई सामग्री की मोटाई के लिए है। कभी-कभी, आप ऐसा डाई चुन सकते हैं जो बहुत संकरा या बहुत चौड़ा हो, यह सोचकर कि यह हर काम के लिए उपयुक्त होगा।

नतीजे

गलत आकार के डाई का उपयोग करने से कई समस्याएं उत्पन्न हो सकती हैं:

- हो सकता है कि आपके हिस्से योजना के अनुसार एक साथ फिट न हों।

- धातु टूट या फट सकती है, विशेषकर यदि डाई बहुत छोटी हो।

- आप अपने प्रेस ब्रेक उपकरणों या यहां तक कि प्रेस ब्रेक को भी नुकसान पहुंचा सकते हैं।

- अनुचित संरेखण से उपकरण को क्षति हो सकती है।

- यदि सामग्री फिसल जाए या टूट जाए तो आपको उपकरण में घिसाव दिखाई दे सकता है या चोट लगने का भी खतरा हो सकता है।

बहुत अधिक चौड़ी डाई आपको बहुत अधिक बड़ा मोड़ त्रिज्या दे सकती है, जो देखने में अच्छा नहीं लगेगा या आपकी आवश्यकताओं को पूरा नहीं करेगा।

कैसे बचें

आप इन गलतियों से बच सकते हैं:

- हमेशा डाई की चौड़ाई को अपनी सामग्री की मोटाई के अनुरूप रखें।

- सही पासा चुनने के लिए संदर्भ चार्ट या आठ के नियम का उपयोग करना।

- प्रत्येक कार्य से पहले अपने प्रेस ब्रेक उपकरणों की जांच करें।

- यह देखने के लिए कि क्या मोड़ सही है, स्क्रैप सामग्री के साथ परीक्षण मोड़ बनाना।

- याद रखें कि चौड़ी डाइज़ से बड़े कोने की त्रिज्या प्राप्त करने में मदद मिल सकती है, जो कभी-कभी कुछ परियोजनाओं के लिए बेहतर लगती है।

अधिक भार

सामान्य संकेत

प्रेस ब्रेक पर ज़रूरत से ज़्यादा लोड डालना खतरनाक है। यहाँ कुछ संकेत दिए गए हैं जिन्हें आप देख सकते हैं:

- झुकते समय आपको तेज आवाज या अजीब आवाजें सुनाई देती हैं।

- आप अपने औजारों में दरारें या टुकड़े टूटते हुए देखते हैं।

- प्रेस ब्रेक रैम मुड़ा हुआ या अपनी जगह से हट गया दिखता है।

- टूटे हुए टुकड़े टूलींग से गिर सकते हैं, जो एक बड़ा सुरक्षा जोखिम है।

नतीजे

यदि आप अपने प्रेस ब्रेक को अधिक भार से भर देते हैं, तो आपको निम्न समस्याओं का सामना करना पड़ सकता है:

- आपके प्रेस ब्रेक को स्थायी क्षति, जैसे रैम अपसेट या डिफ्लेक्शन।

- ऐसे उपकरण जो जल्दी टूट जाते हैं, फट जाते हैं, या जल्दी खराब हो जाते हैं।

- ऐसी सामग्री जो टूटती है या बिल्कुल भी नहीं मुड़ती।

- आपको या दुकान में अन्य लोगों को गंभीर चोटें लगना।

सामग्री के लिए अपर्याप्त समर्थन भी डाई या प्रेस ब्रेक पर अत्यधिक बल उत्पन्न कर सकता है, जिससे और अधिक समस्याएं उत्पन्न हो सकती हैं।

कैसे बचें

आप इन चरणों का पालन करके ओवरलोडिंग को रोक सकते हैं:

| निवारक उपाय | विवरण |

|---|---|

| उचित उपकरण चयन | सुनिश्चित करें कि आपका टूलिंग सामग्री के प्रकार और मोटाई से मेल खाता है। |

| टूलिंग को विनिर्देशों से मिलाएं | ऐसे टूलिंग का उपयोग करें जो आपके प्रेस ब्रेक की टन क्षमता के अनुरूप हो। |

| उपयुक्त डाइज़ का चयन करें | सही टन भार के लिए सामग्री और मोटाई के आधार पर डाई का चयन करें। |

| वी-डाई चौड़ाई चयन | शीट की मोटाई से 6 से 12 गुना बड़ा वी-डाई ओपनिंग चुनें। |

| रखरखाव प्रथाएँ | अपने औजारों को नियमित जांच और रखरखाव के साथ अच्छी स्थिति में रखें। |

इसके अलावा, हमेशा जाँच लें कि आपके प्रेस ब्रेक उपकरण मशीन के विनिर्देशों, जैसे टन भार और बेड की लंबाई, से मेल खाते हों। कभी भी अनुमान न लगाएँ—चार्ट और गाइड का उपयोग करें।

भौतिक गुणों की अनदेखी

सामान्य संकेत

यदि आप भौतिक गुणों को अनदेखा करते हैं, तो आप देख सकते हैं:

- मोड़ पर दरारें, विशेष रूप से कठोर या भंगुर धातुओं में।

- मोड़ कोण वह नहीं है जो आपने उम्मीद की थी।

- झुकने के बाद धातु बहुत अधिक पीछे की ओर उछलती है।

- मोड़ बनाने के लिए आपको सामान्य से अधिक बल की आवश्यकता होगी।

नतीजे

अपनी सामग्री के गुणों की अनदेखी करने से निम्नलिखित परिणाम हो सकते हैं:

- उच्च-तन्य सामग्रियों के लिए अधिक बल की आवश्यकता होती है, जो आपके प्रेस ब्रेक उपकरणों को नुकसान पहुंचा सकता है।

- अप्रत्याशित स्प्रिंगबैक के कारण आपके विनिर्देशों के अनुरूप न होने वाले भाग।

- दरारें पड़ना, विशेषकर यदि आप एल्युमीनियम जैसी धातुओं को उनकी बनावट के विपरीत मोड़ते हैं।

- असफल मोड़ों से सामग्री और समय की बर्बादी।

तन्य शक्ति और तन्यता जैसे भौतिक गुण झुकने की प्रक्रिया में महत्वपूर्ण भूमिका निभाते हैं। मोटी या कठोर धातुओं के लिए बड़ी झुकने वाली त्रिज्या और अधिक टन भार की आवश्यकता होती है।

कैसे बचें

इन समस्याओं से बचने के लिए:

- मोड़ने से पहले हमेशा सामग्री की तन्य शक्ति और लचीलापन की जांच करें।

- कठोर धातुओं के लिए बड़े V-डाई उद्घाटन का उपयोग करें।

- दरार को कम करने के लिए अनाज की दिशा के लंबवत मोड़ने का प्रयास करें।

- धातु के प्रकार और मोटाई के आधार पर अपने डाई चयन को समायोजित करें।

- सर्वोत्तम परिणामों के लिए संदर्भ चार्ट और निर्माता दिशानिर्देशों का उपयोग करें।

टिप: अपनी सामग्री को जानने से आपको सही प्रेस ब्रेक उपकरण चुनने में मदद मिलती है और आपके झुकने के काम को सुरक्षित और सटीक बनाए रखने में मदद मिलती है।

गणना छोड़ना

सामान्य संकेत

हो सकता है कि आप जल्दबाजी में हों या आपको लगे कि आपको जवाब पता है, तो आप गणनाएँ छोड़ दें। यहाँ कुछ संकेत दिए गए हैं कि आप यह चरण भूल गए हैं:

- आप मापने के बजाय वी-डाई खोलने का अनुमान लगाते हैं।

- आप हर काम के लिए एक ही डाई का उपयोग करते हैं।

- आप ऐसे मोड़ देखते हैं जो गलत लगते हैं या आपकी योजनाओं से मेल नहीं खाते।

- आपको अपनी धातु में दरारें या असमान मोड़ दिखाई देते हैं।

नतीजे

गणनाएँ न करने से बड़ी समस्याएँ पैदा हो सकती हैं। हो सकता है कि आपके बेंड आपस में फिट न हों। इससे आपके प्रेस ब्रेक या टूलिंग को नुकसान पहुँच सकता है। कभी-कभी, बेंड सही न होने के कारण आप सामग्री बर्बाद कर देते हैं। अगर धातु फिसल जाए या टूट जाए, तो आपकी सुरक्षा भी खतरे में पड़ सकती है।

कैसे बचें

आप सरल गणना विधियों का उपयोग करके इन गलतियों से बच सकते हैं। हमेशा अपनी सामग्री की मोटाई नापें। आठ के नियम का उपयोग करें या संदर्भ चार्ट देखें। बेहतर परिणामों के लिए इन तरीकों को आज़माएँ:

| तरीका | विवरण | सूत्र/गणना उदाहरण |

|---|---|---|

| वायु निर्माण | अंदरूनी मोड़ त्रिज्या डाई खोलने का एक प्रतिशत है। | आंतरिक त्रिज्या = डाई उद्घाटन × 20% |

| परफेक्ट डाई ओपनिंग | निर्माण विधि की परवाह किए बिना त्रिज्या स्थापित करता है। | डाई ओपनिंग = (बाहरी त्रिज्या × 0.7071) × 4 |

| स्प्रिंगबैक समायोजन | स्प्रिंगबैक के लिए सामग्री की मोटाई के आधार पर डाई ओपनिंग को समायोजित करता है। | <0.125 इंच के लिए: (बाहरी त्रिज्या × 0.7071) × 4.85 |

सुझाव: शुरू करने से पहले हमेशा अपने नंबरों की दोबारा जाँच कर लें। जल्दी से गणना करने से आपका समय बचता है और आपका प्रेस ब्रेक सुरक्षित रहता है।

सुरक्षा अनुस्मारक

हमेशा पीपीई पहनें

धातु के साथ काम करते समय आपको हमेशा व्यक्तिगत सुरक्षा उपकरण (पीपीई) पहनना चाहिए। सुरक्षा चश्मा, दस्ताने और स्टील के पंजे वाले जूते आपको नुकीले किनारों और उड़ते हुए मलबे से बचाते हैं। छोटी सी चूक भी चोट का कारण बन सकती है, इसलिए हर समय तैयार रहें।

मशीन सुरक्षा प्रोटोकॉल का पालन करें

प्रेस ब्रेक मशीनों में सुरक्षा नियमों का पालन ज़रूर होता है। सुनिश्चित करें कि आपको आपातकालीन स्टॉप का इस्तेमाल करना आता है। अपने हाथों को चलते हुए हिस्सों से दूर रखें। मशीन के चलते समय उसमें हाथ न डालें। अगर आप इन नियमों का पालन करते हैं, तो आप खुद को और दूसरों को भी सुरक्षित रखते हैं।

कार्य क्षेत्र साफ़ रखें

एक साफ़-सुथरा कार्य क्षेत्र आपको दुर्घटनाओं से बचने में मदद करता है। फर्श से कबाड़ और औज़ार हटा दें। सुनिश्चित करें कि आपके पास घूमने-फिरने के लिए पर्याप्त जगह हो। अगर आप अपने कार्य क्षेत्र को साफ़-सुथरा रखेंगे, तो ठोकर लगने और गिरने का खतरा कम हो जाएगा।

ध्यान दें: सुरक्षा सभी का काम है। अपने सहकर्मियों को भी इन चरणों का पालन करने के लिए याद दिलाएँ।

उपकरण निरीक्षण और रखरखाव

नियमित रूप से डाई और पंच का निरीक्षण करें

आपको हर काम से पहले अपने डाई और पंच की जाँच करनी चाहिए। दरारें, चिप्स या घिसे हुए किनारों पर ध्यान दें। अगर आप नुकसान का पहले ही पता लगा लेते हैं, तो आप बाद में होने वाली बड़ी समस्याओं से बच सकते हैं।

घिसे या क्षतिग्रस्त टूलींग को बदलें

ऐसे टूल का इस्तेमाल न करें जो घिसे-पिटे या टूटे हुए लगें। उन्हें तुरंत बदल दें। नए टूल से आपको बेहतर मोड़ मिलेंगे और आपका प्रेस ब्रेक ज़्यादा देर तक काम करता रहेगा।

औज़ारों को साफ़ रखें और उचित रूप से संग्रहित करें

हर बार इस्तेमाल के बाद अपने औज़ारों को साफ़ करें। उन्हें सूखी जगह पर रखें जहाँ उन पर कोई खरोंच या टक्कर न लगे। अच्छी भंडारण आदतें आपके औज़ारों को लंबे समय तक चलने और बेहतर काम करने में मदद करती हैं।

टिप: नियमित रखरखाव से आपका पैसा बचता है और आपकी दुकान सुचारू रूप से चलती रहती है।

संदर्भ चार्ट और उदाहरण

वी-डाई ओपनिंग चार्ट

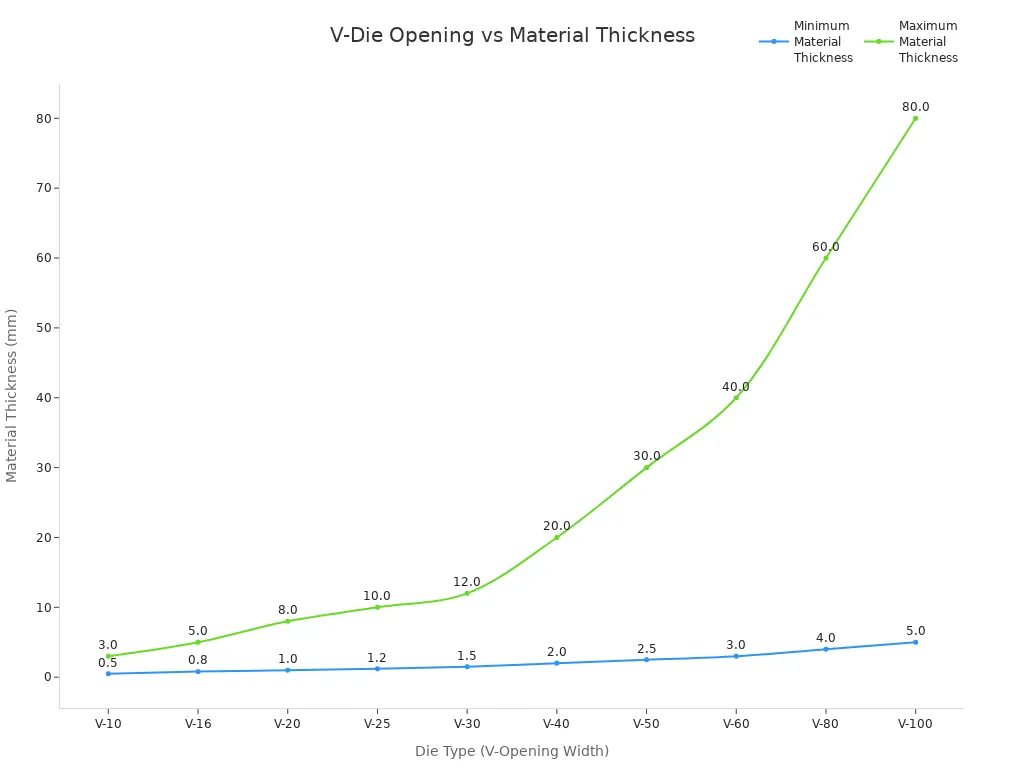

आप सोच रहे होंगे कि अपने प्रेस ब्रेक टूलिंग के लिए सही वी-डाई साइज़ कैसे चुनें। सबसे आसान तरीका है एक संदर्भ चार्ट का इस्तेमाल करना। यह चार्ट आपको अलग-अलग मटेरियल की मोटाई के लिए मानक वी-डाई ओपनिंग दिखाता है। आप अपनी मटेरियल की मोटाई जाँच सकते हैं और उससे मेल खाती वी-डाई चौड़ाई ढूँढ सकते हैं।

| डाई प्रकार | वी-ओपनिंग चौड़ाई (मिमी) | न्यूनतम सामग्री मोटाई (मिमी) | अधिकतम सामग्री मोटाई (मिमी) |

|---|---|---|---|

| वि 10 | 10 | 0.5 | 3.0 |

| वी -16 | 16 | 0.8 | 5.0 |

| वी-20 | 20 | 1.0 | 8.0 |

| वी-25 | 25 | 1.2 | 10.0 |

| वी-30 | 30 | 1.5 | 12.0 |

| वी-40 | 40 | 2.0 | 20.0 |

| वि 50 | 50 | 2.5 | 30.0 |

| वि 60 | 60 | 3.0 | 40.0 |

| वी-80 | 80 | 4.0 | 60.0 |

| वि 100 | 100 | 5.0 | 80.0 |

आप यह चार्ट भी देख सकते हैं कि प्रत्येक V-डाई उद्घाटन के साथ न्यूनतम और अधिकतम मोटाई कैसे बदलती है:

बख्शीश: मोड़ना शुरू करने से पहले हमेशा इस तरह के चार्ट का इस्तेमाल करें। इससे आपको गलतियों से बचने में मदद मिलेगी और आपके प्रेस ब्रेक टूलिंग को अच्छी स्थिति में रखने में मदद मिलेगी।

नमूना गणना

आइए आठ के नियम का उपयोग करते हुए एक त्वरित उदाहरण देखें। यह नियम अधिकांश कार्यों के लिए V-डाई का चयन आसान बनाता है।

- अपनी सामग्री की मोटाई नापें: मान लीजिए आपके पास 3 मिमी मोटी एक स्टील शीट है।

- मोटाई को 8 से गुणा करें।

3 मिमी × 8 = 24 मिमी - लगभग 24 मिमी के खुले भाग वाला V-डाई चुनें। आप 25 मिमी के खुले भाग वाला V-25 डाई भी इस्तेमाल कर सकते हैं।

अगर आपकी सामग्री 12 मिमी से ज़्यादा मोटी है, तो आप 10 के गुणक का इस्तेमाल कर सकते हैं। उदाहरण के लिए, 15 मिमी मोटी प्लेट के लिए 150 मिमी के वी-डाई ओपनिंग की ज़रूरत होगी।

टिप्पणी: आठ का नियम कोल्ड-रोल्ड स्टील और अधिकांश मानक कार्यों के लिए सबसे उपयुक्त है। मोटी या कठोर सामग्रियों के लिए, दरारों से बचने के लिए बड़े वी-डाई का उपयोग करें।

ऑनलाइन उपकरण

ऑनलाइन कैलकुलेटर की मदद से आप प्रेस ब्रेक टूलिंग का चुनाव और भी आसान बना सकते हैं। ये उपकरण आपकी सामग्री की मोटाई और प्रकार के आधार पर सही वी-डाई आकार चुनने में आपकी मदद करते हैं।

- प्रेस ब्रेक कैलकुलेशन | RMT – रेवोल्यूशन मशीन टूल्स™यह कैलकुलेटर 26 गेज से लेकर 1 इंच मोटी सामग्री के लिए काम करता है। आपको बस अपनी सामग्री की मोटाई दर्ज करनी है, और यह सबसे उपयुक्त वी-डाई ओपनिंग सुझाता है।

- एयर बेंडिंग टनेज चार्ट: ये चार्ट आपको विभिन्न वी-डाई आकारों और सामग्रियों के लिए आवश्यक बल दिखाते हैं। आप इनका उपयोग यह जांचने के लिए कर सकते हैं कि आपका प्रेस ब्रेक काम संभाल सकता है या नहीं।

बख्शीश: ऑनलाइन टूल आपका समय बचाते हैं और आपको महंगी गलतियों से बचने में मदद करते हैं। अपना अगला प्रोजेक्ट शुरू करने से पहले कैलकुलेटर आज़माएँ।

इन चार्ट, नमूना गणनाओं और ऑनलाइन टूल्स की मदद से, आप हर बार अपने प्रेस ब्रेक टूलिंग के लिए सही वी-डाई चुन सकते हैं। आपको बेहतर मोड़, सुरक्षित काम और अपनी दुकान में कम तनाव मिलेगा।

सफलता के लिए सुझाव

विशेषज्ञों से परामर्श करें

प्रेस ब्रेक टूलिंग शुरू करते समय आपको अनिश्चितता महसूस हो सकती है। यह सामान्य है। अगर आपको मदद की ज़रूरत हो, तो आप टूलिंग विशेषज्ञों से संपर्क कर सकते हैं। ये पेशेवर जानते हैं कि आपकी सामग्री और प्रोजेक्ट के लिए सही वी-डाई का चयन कैसे किया जाए। वे कस्टम बेंड या असामान्य सामग्रियों से जुड़े आपके सवालों के जवाब दे सकते हैं। अगर आपको कोई मुश्किल काम आता है, तो एक विशेषज्ञ आपका समय बचा सकता है और गलतियों से बचा सकता है।

नानजिंग Metal कस्टम प्रेस ब्रेक टूलिंग के लिए सहायता प्रदान करता है। आप विशेष आकार, साइज़ या सामग्री के बारे में पूछ सकते हैं। टूलिंग विशेषज्ञ आपको सामान्य गलतियों से बचने और आपकी झुकने की प्रक्रिया को सुचारू रखने में मदद करते हैं। आपको केवल सामान्य सुझाव ही नहीं, बल्कि आपकी ज़रूरतों के अनुरूप सलाह भी मिलती है।

बख्शीश: अगर आपको यकीन नहीं है तो अंदाज़ा मत लगाइए। किसी विशेषज्ञ से पूछिए। आपको बेहतर परिणाम मिलेंगे और हर प्रोजेक्ट के साथ आप ज़्यादा आत्मविश्वास महसूस करेंगे।

सबसे पहले सुरक्षा

प्रेस ब्रेक टूलिंग का इस्तेमाल करते समय सुरक्षा ज़रूरी है। आपको अपनी और दुकान में काम करने वाले अन्य लोगों की सुरक्षा सुनिश्चित करनी होगी। हमेशा व्यक्तिगत सुरक्षा उपकरण (पीपीई) जैसे सुरक्षा चश्मा, दस्ताने और मज़बूत जूते पहनें। ये उपकरण आपको तेज़ किनारों और उड़ते हुए मलबे से बचाते हैं।

अपनी प्रेस ब्रेक मशीन के सुरक्षा नियमों का पालन करें। आपातकालीन स्टॉप कहाँ है, यह जानें। अपने हाथों को चलते हुए पुर्जों से दूर रखें। मशीन के चलते समय कभी भी उसमें हाथ न डालें। साफ़-सुथरा कार्य क्षेत्र आपको गिरने और ठोकर खाने से बचाता है। बेकार सामान हटाएँ और औज़ारों को व्यवस्थित रखें।

| सुरक्षा कदम | यह क्यों मायने रखती है |

|---|---|

| पीपीई पहनें | नुकीली धातु से होने वाली चोटों से बचाता है |

| मशीन के नियमों का पालन करें | दुर्घटनाओं का जोखिम कम करता है |

| क्षेत्र को साफ रखें | फिसलने और गिरने से बचाता है |

टिप्पणी: सुरक्षा सबकी ज़िम्मेदारी है। अपने सहकर्मियों को भी इन चरणों का पालन करने के लिए याद दिलाएँ।

उपकरण रखरखाव

आप चाहते हैं कि आपके प्रेस ब्रेक टूल लंबे समय तक चलें और अच्छी तरह काम करें। नियमित रखरखाव आपके औज़ारों को बेहतरीन स्थिति में रखता है। आपको हर काम से पहले डाई और पंच की जाँच करनी चाहिए कि कहीं वे घिस तो नहीं गए हैं या उनमें कोई खराबी तो नहीं है। दरारें, चिप्स या घिसे हुए किनारों पर ध्यान दें। अगर कोई टूल घिसा हुआ या टूटा हुआ लगे तो उसे बदल दें।

नियमित रखरखाव आपको धातु को सटीकता से मोड़ने में मदद करता है। आप उन गलतियों से बचते हैं जो आपके पुर्जों को खराब कर सकती हैं। समस्याओं का जल्द पता लगाकर आप अपनी दुकान को भी सुरक्षित रखते हैं। आपके प्रेस ब्रेक का सही संरेखण और कैलिब्रेशन मोड़ने में होने वाली त्रुटियों को रोकता है। हर बार इस्तेमाल के बाद अपने टूलिंग को साफ करें और उसे सूखी जगह पर रखें।

- नियमित रखरखाव झुकने के कार्यों में सटीकता और स्थिरता सुनिश्चित करता है। आप उन अशुद्धियों से बचते हैं जो गुणवत्ता नियंत्रण संबंधी समस्याओं का कारण बन सकती हैं।

- नियमित निरीक्षण से सुरक्षा बेहतर होती है। घिसे हुए या खराब पुर्जों के कारण होने वाली दुर्घटनाओं का जोखिम कम होता है।

- लागत-कुशलता बढ़ती है। आप अपने प्रेस ब्रेक की उम्र बढ़ाते हैं और डाउनटाइम कम करते हैं।

बख्शीश: रखरखाव को अपनी आदत बना लें। इससे पैसे बचेंगे, देरी से बचेंगे और आपकी प्रेस ब्रेक टूलिंग सालों तक चलती रहेगी।

अब आपके पास शुरुआती लोगों के लिए प्रेस ब्रेक टूलिंग की एक स्पष्ट गाइड है। आपको ये बातें याद रखनी चाहिए:

- अपनी सामग्री की मोटाई मापें.

- वी-डाई खोलने के लिए आठ के नियम का उपयोग करें।

- झुकने से पहले संदर्भ चार्ट की जांच करें।

- सर्वोत्तम परिणामों के लिए परीक्षण करें और समायोजन करें।

सीखते रहें और अगर आपको कोई मुश्किल काम आता है, तो सवाल पूछें। अगर आपको विशेषज्ञ सलाह चाहिए, तो किसी सेल्स इंजीनियर से संपर्क करें। संपर्क पृष्ठआपको अपने अगले प्रोजेक्ट के लिए मदद मिलेगी!

सामान्य प्रश्न

प्रेस ब्रेक टूलिंग में आठ का नियम क्या है?

आठ का नियम आपको सही वी-डाई ओपनिंग चुनने में मदद करता है। आप अपनी सामग्री की मोटाई को आठ से गुणा करते हैं। यह आपको ज़्यादातर बेंडिंग कार्यों के लिए एक अच्छी शुरुआत देता है।

क्या मैं सभी सामग्रियों के लिए एक ही वी-डाई का उपयोग कर सकता हूँ?

नहीं, आपको ऐसा नहीं करना चाहिए। अलग-अलग सामग्रियों के लिए अलग-अलग वी-डाई ओपनिंग की ज़रूरत होती है। स्टेनलेस स्टील जैसी कठोर धातुओं के लिए बड़े ओपनिंग की ज़रूरत होती है। एल्युमीनियम जैसी नरम धातुओं के लिए छोटे ओपनिंग की ज़रूरत होती है।

मैं कैसे जानूं कि मेरा वी-डाई बहुत छोटा है?

आपको दरारें, खुरदुरे मोड़ दिखाई दे सकते हैं, या बहुत ज़्यादा बल की ज़रूरत पड़ सकती है। अगर आपका प्रेस ब्रेक तेज़ आवाज़ करता है या धातु ठीक से नहीं मुड़ती, तो हो सकता है कि आपका वी-डाई बहुत छोटा हो।

मेरी धातु झुकने के बाद वापस क्यों उछल जाती है?

स्प्रिंगबैक इसलिए होता है क्योंकि धातु अपने मूल आकार में वापस आना चाहती है। मोटी या सख्त सामग्री में स्प्रिंगबैक ज़्यादा होता है। आप इसे ज़्यादा मोड़कर या अपने वी-डाई साइज़ को एडजस्ट करके ठीक कर सकते हैं।

यदि मैं अपने प्रेस ब्रेक को ओवरलोड कर दूं तो क्या होगा?

ओवरलोडिंग से आपके प्रेस ब्रेक टूलिंग या मशीन को नुकसान पहुँच सकता है। आप खुद को भी चोट पहुँचा सकते हैं। झुकने से पहले हमेशा अपनी मशीन की टन भार सीमा की जाँच करें।

मुझे अपने प्रेस ब्रेक टूलिंग का कितनी बार निरीक्षण करना चाहिए?

हर काम से पहले अपने औज़ारों की जाँच करें। दरारें, चिप्स या घिसे हुए किनारों पर ध्यान दें। अपने औज़ारों को लंबे समय तक चलने के लिए उन्हें साफ़ करके ठीक से रखें।

क्या मुझे तंग मोड़ कोणों के लिए विशेष उपकरणों की आवश्यकता है?

हाँ, आपको चाहिए। टाइट बेंड के लिए अक्सर छोटे वी-डाई और एक खास पंच की ज़रूरत होती है। हमेशा पहले स्क्रैप मटेरियल से टेस्ट करें ताकि यह सुनिश्चित हो सके कि आपको मनचाहा बेंड मिल रहा है।

मैं वी-डाई संदर्भ चार्ट कहां पा सकता हूं?

आप प्रेस ब्रेक टूलिंग गाइड, ऑनलाइन कैलकुलेटर, या टूलिंग सप्लायरों से वी-डाई चार्ट प्राप्त कर सकते हैं। ये चार्ट आपको सामग्री की मोटाई को सही वी-डाई ओपनिंग से मिलाने में मदद करते हैं।

यह भी देखें

प्रेस ब्रेक पंच शीट मेटल बेंडिंग में कैसे काम करता है

लंबे समय तक चलने वाले उपकरणों के लिए प्रेस ब्रेक टूलिंग रखरखाव युक्तियाँ

कस्टम प्रेस ब्रेक टूलिंग आपकी विनिर्माण दक्षता को कैसे बढ़ाती है

प्रेस ब्रेक टूलिंग में महारत हासिल करना: पंच और डाई वियर की पहचान कैसे करें और उसे कैसे ठीक करें

प्रेस ब्रेक टूलिंग का जीवनकाल बढ़ाने और स्थायित्व को अधिकतम करने के लिए 5 आवश्यक सुझाव

एक प्रतिक्रिया

Your point of view caught my eye and was very interesting. Thanks.