का चयन circular slitter blades can seem confusing at first. You need to think about compatibility, price, and how you’ll use them. Using the wrong blade can cause bad cuts and waste materials, leading to delays in work. Picking high-quality circular slitter blades is very important. Whether cutting paper, metal, or fabric, custom blades from Nanjing Metal work best for specific needs. Companies like Nanjing Metal manufacture blades for different industries. If you’re unsure, don’t hesitate to संपर्क a reliable supplier for help.

चाबी छीनना

- Pick the right blade material for your job. Stainless steel works well for food, while carbon blades cut tough stuff better.

- Choose the correct blade edge type. Straight edges are good for thin materials, and serrated edges cut thick or hard materials easily.

- Think about blade size and thickness. Matching the blade to your material helps it work better and saves resources.

- Take care of your blades often. Check, clean, and sharpen them to keep them working well and lasting longer.

- Custom blades can make cutting easier. They are made for specific tasks, giving better results and wasting less material.

Understanding Circular Slitter Blades

सर्कुलर स्लिटर ब्लेड क्या हैं?

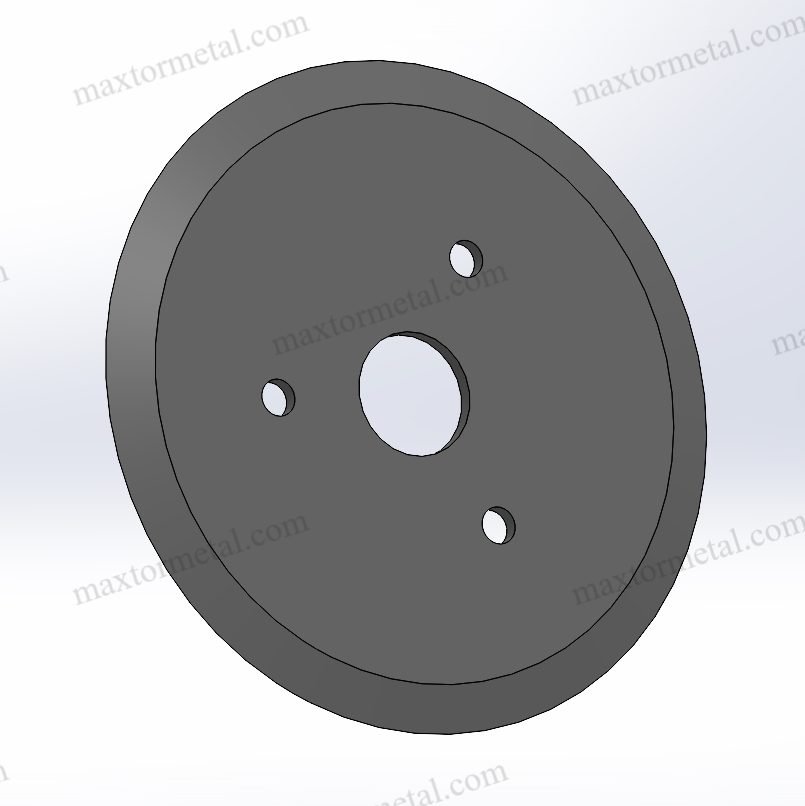

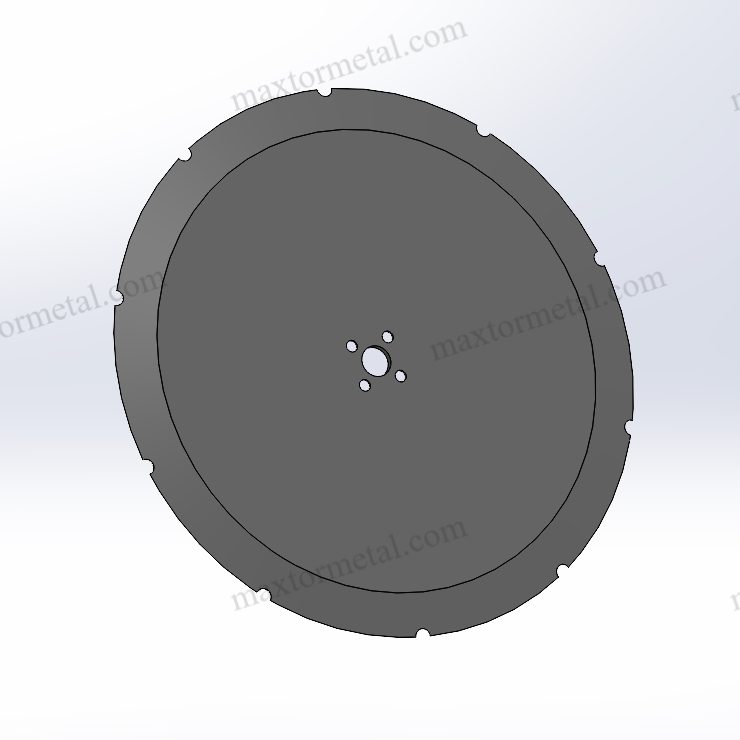

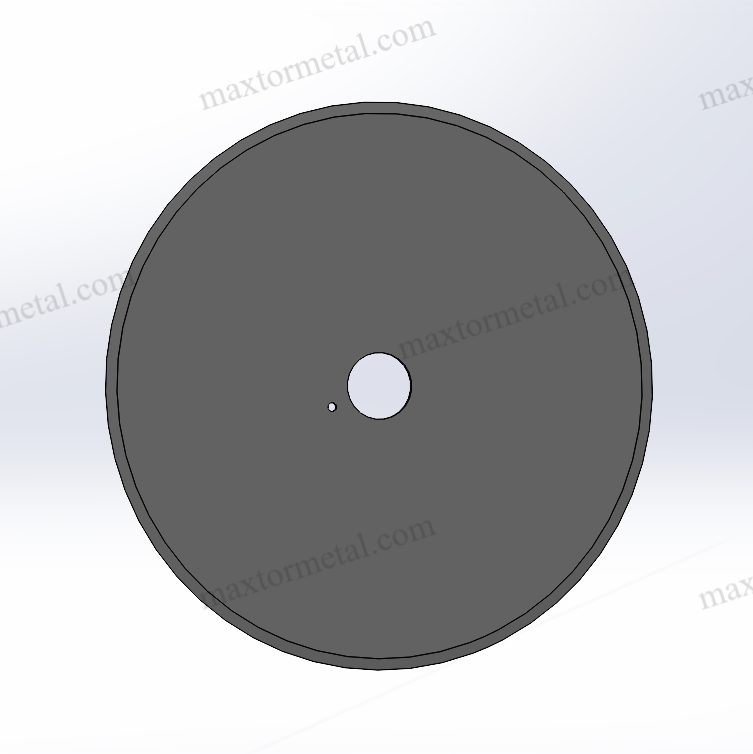

Circular slitter blades are tools made for cutting materials precisely. These round blades spin while cutting to make clean, exact slices. They are used in industries like paper, fabric, plastic, and metal. These blades are important for fast and accurate cutting jobs.

Think of them as quiet helpers in factories. Whether slicing thin paper or thick metal, they make sure the work is done well. Their ability to handle many tasks makes them popular in different industries.

Common Names and Terminology

Circular blades have different names depending on the industry. People might call them rotary blades, disc cutters, or slitting knives. Even with different names, they are the same tool.

Knowing these names helps when talking to suppliers or workers. For example, in textiles, they might be called rotary cutters. In metalwork, they could be slitting knives. Using the right term helps you get the blade you need.

How Circular Slitter Blades Work

Circular blades cut by spinning against a surface, either still or moving. Imagine a pizza cutter slicing dough—that’s how these blades work, but bigger and more precise.

The blade’s sharpness and material decide how well it cuts. Harder materials may need serrated edges or tougher blades. Choosing the right blade for the material ensures smooth cuts, less waste, and longer blade life.

Circular Blade Uses in Different Industries

Circular blades are useful tools for many jobs. They are found in industries needing accurate cutting. Their ability to cut various materials makes them important. Let’s see where these blades are most helpful.

- कागज और पैकेजिंग: These blades cut paper into rolls or sheets. They also trim cardboard and packaging materials neatly. If you’ve seen a cleanly cut box, a circular blade likely did it.

- वस्त्र: In textiles, these blades cut fabrics smoothly. They work on cotton, silk, and polyester without damaging them. This helps make quality clothes and furniture covers.

- Metal प्रसंस्करण: Cutting metal sheets or coils needs power and accuracy. Circular blades for metalwork handle steel and aluminum well. They are key tools in car-making and construction.

- प्लास्टिक: These blades cut thin films or thick plastic sheets easily. They are used to make plastic items with smooth edges and exact sizes.

- खाद्य प्रसंस्करण: Clean cuts are important in food work. Circular blades slice bread, meat, and frozen foods neatly. This keeps food looking good and fresh.

These examples show how circular blades are used in many areas. From packaging to textiles, they help improve work quality and speed.

बख्शीश: Pick a blade that fits your material and cutting job. This gives better results and makes the blade last longer.

Key Factors to Consider When Choosing Circular Slitter Blades

Picking the right circular blades can feel tricky. Breaking it into steps makes it easier. Let’s look at the main points to help you choose wisely.

Selecting the Right Blade Material

Stainless Steel vs. Carbon

The blade’s material affects how well it works and lasts. Stainless steel and carbon are common choices, each with its own perks. Stainless steel doesn’t rust and handles wet places well, making it great for food work. Carbon blades are sharper and tougher, perfect for cutting hard stuff like metal or thick plastic.

Think about where you’ll use the blade and what you’ll cut. For food jobs, stainless steel is safer. For heavy-duty cutting, carbon is better.

क्या आप जानते हैं? Picking the right blade material boosts work speed and accuracy. Studies show that material choice improves cutting and makes blades last longer.

Durability for Production Runs

Long production runs need strong blades. Weak blades slow work and cost more. Stainless steel lasts longer in wet places, while carbon blades handle tough cutting jobs. Match the blade to your work needs to save time and money.

Evaluating Blade Edge Types

Straight Edges for Precision

Straight edges make clean cuts. They’re great for cutting paper, fabric, and packaging. Thin materials like silk or plastic need straight edges for smooth cuts without damage.

Serrated Edges for Tough Materials

Serrated edges are better for hard jobs. They grip while cutting, making them good for thick metal or tough fabrics. Serrated blades work well when straight edges slip or struggle.

| ब्लेड का प्रकार | सामग्री की संरचना | Performance Characteristics | उपयुक्त अनुप्रयोग |

|---|---|---|---|

| करबैड | Tungsten-cobalt alloys | Hard and durable, great for precise, fast cuts | Cutting tough materials, long jobs |

| चीनी मिट्टी | Ceramic materials | Very hard, smooth cuts, low friction | Cutting paper, plastic films |

| Steel | Ordinary/tool steel | Less hard, good for simple tasks | Basic cutting jobs |

Choose straight edges for clean cuts. Use serrated edges for thicker or harder materials.

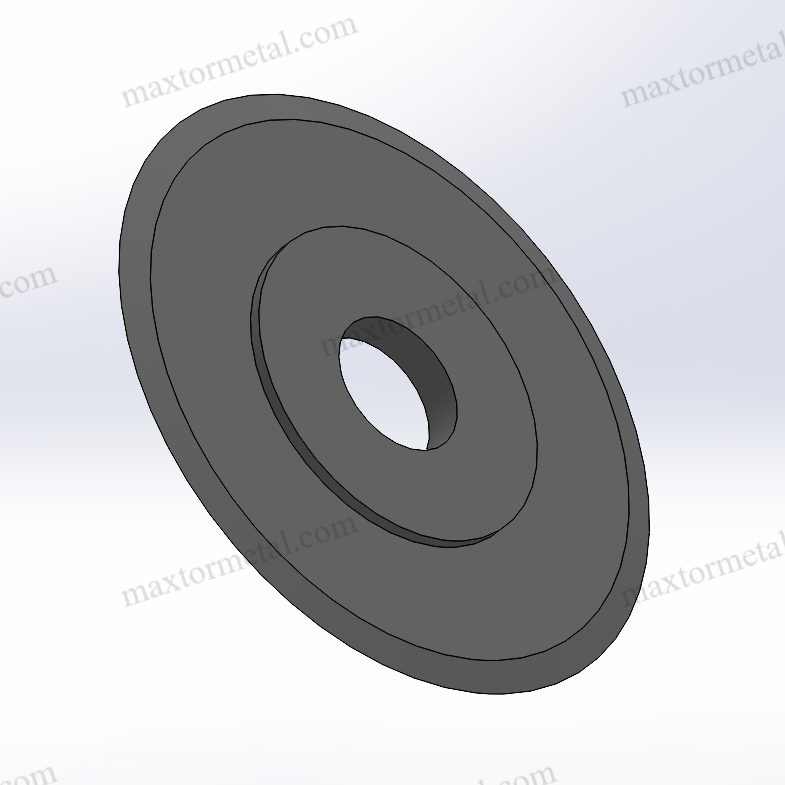

Determining Blade Dimensions

Size Requirements for Applications

Blade size matters a lot. Small blades may not cut well. Big blades might harm your material or tools. Always check the size needed for your job. Thin films need small blades. Thick metal needs bigger ones.

Thickness Impact on Performance

Blade thickness also affects cutting. Thick blades are strong for heavy tasks but less precise. Thin blades are accurate but wear out faster under pressure.

| प्रमाण | प्रभाव |

|---|---|

| Tight tolerances need careful machining, raising costs. | Higher costs due to precision needs. |

| Loose tolerances speed up production, cutting lead times. | Faster work and better efficiency. |

| Overly tight tolerances waste materials. | More expenses overall. |

| A ±0.01mm tolerance may scrap 5-10% of blades. | More waste and higher costs. |

| Adjustments saved $500,000 yearly by reducing waste. | Big savings and better efficiency. |

Pick the right blade size and thickness for your job. This helps balance precision and strength, saving money and improving results.

Understanding Coatings and Treatments

Benefits of Surface Coatings

Surface coatings help circular blades work better and last longer. They lower friction, so blades cut smoothly without overheating. This is useful for materials like metal or plastic, where heat can cause damage.

Coatings also protect blades from wearing out too quickly. Titanium nitride (TiN) coatings are popular because they make blades harder and prevent rust. If you cut rough materials, coated blades last longer and save money on replacements.

बख्शीश: For sticky materials like adhesives or plastics, use non-stick coatings. These stop residue from building up and keep blades cutting smoothly.

Longevity Through Treatments

Special treatments can make blades stronger and last longer. Heat treatments change the blade’s structure, making it tougher and less likely to wear out. Cryogenic treatments freeze blades at very low temperatures to improve their durability.

These treatments help blades stay sharp, even with heavy use. If you have long production runs, treated blades can save time and reduce downtime.

Matching Hardness Levels

Rockwell Hardness Considerations

Blade hardness is important when choosing circular blades. The Rockwell Hardness Scale shows how strong a material is against bending or breaking. A blade that’s too hard might crack, while a soft one could wear out fast. Finding the right balance is key.

- Hardness affects how well and how long a blade cuts.

- Toughness is also important for cutting hard or rough materials.

- Harder materials like steel need harder blades, while softer materials need less rigid ones.

Matching the blade’s hardness to the material ensures cleaner cuts and longer blade life.

Anvil Hardness Compatibility

The blade’s hardness should match the cutting surface, called the anvil. If the anvil is too hard, it can damage the blade. If it’s too soft, it may wear out quickly.

- Hard materials need matching tools to avoid breaking.

- Case-hardened materials need special blades for smooth cutting.

Matching hardness levels helps blades and anvils last longer and work better together.

Assessing Cutting Speed and Volume

Impact on Blade Selection

Cutting speed affects how well a blade works. Faster speeds create more heat, which can dull or warp the blade. For high-speed cutting, choose blades with heat-resistant coatings or materials like stainless steel.

Feed rate and cutting depth also matter. Faster feed rates wear blades faster, and deeper cuts need stronger blades. Balancing these factors keeps blades working well and lasting longer.

Production Volume Requirements

Cutting large amounts of material needs strong, durable blades. Long shifts or high production runs require blades that won’t wear out quickly.

- A textile company used stainless steel blades and replaced them 30% less often. This also boosted production by 12%.

- Watching blade wear during production helps plan replacements and avoid delays.

Choosing the right blade for your workload ensures steady performance and saves money over time.

कस्टम ब्लेड समाधान

अनोखे कामों के लिए विशेष ब्लेड

Sometimes, regular circular blades don’t work well for certain tasks. Different industries have specific needs that standard blades can’t handle. That’s when custom blades become important. These blades are made to match your exact needs, so they work perfectly with your materials and processes.

For example, in the food industry, you might need to cut soft pastries or frozen meat. A regular blade might not give clean cuts. A custom blade lets you pick the right size, edge, and material for the job. The same applies to textiles or metalwork. Whether cutting soft cloth or hard steel, a custom blade ensures accuracy and speed.

Custom blades also fix problems that standard ones can’t. If you’re cutting sticky materials like glue, you can get a blade with a non-stick coating. For fast production lines, you can choose heat-resistant blades. These custom options help solve issues and keep your work running smoothly.

बख्शीश: When ordering a custom blade, explain your materials and cutting process clearly. This helps the maker design a blade that fits your needs.

Why Choose Custom Blades?

Why should you go for custom blades? They offer more than just a perfect fit. First, custom blades make work faster and more accurate. They reduce waste and save time by cutting better. You’ll see improvements in both quality and speed.

Second, custom blades last longer. When a blade is made for your specific job, it wears out slower. This means fewer replacements and lower costs. For instance, a company cutting large amounts of paper switched to custom blades and saw them last 20% longer.

Lastly, custom blades give you more options. You’re not stuck with what’s in stores. Need a blade with a special shape? You can get it. Want a certain coating or treatment? That’s possible too. Custom blades let you adjust to changes and stay ahead in your work.

क्या आप जानते हैं? Many companies, like Nanjing Metal, offer advice to help you design the right blade. Don’t hesitate to ask for help and explore your choices.

Custom blades are worth the investment. They help solve tough problems, improve work quality, and save money. If you want the best results, custom blades are the way to go.

उद्योग-विशिष्ट अनुप्रयोग

Food Processing Needs

Importance of Clean Cuts

Clean cuts in food processing are very important. They keep food safe and fresh. Cutting bread, meat, or frozen foods neatly helps avoid waste. Uneven cuts can cause contamination or spoilage. Picking the right blade is key for good results.

Rules like the FDA’s Food Traceability Final Rule stress clean tools. Blades that meet these rules help you stay compliant. They also make work faster and safer. Companies design blades that are strong, easy to clean, and safe for food contact. This ensures smooth operations without risking safety.

सामग्री संगतता

Different foods need different blades. Soft pastries need gentle blades, while frozen meat needs tough ones. Using the wrong blade can ruin food or slow work. Match the blade type to the food you’re cutting. Stainless steel blades are popular because they resist rust and are easy to clean. They work well in wet or sticky places.

बख्शीश: For sticky foods like dough or cheese, use non-stick blades. They cut better and are easier to clean.

Blade Types for Food

Blades are made for specific food tasks. Straight-edged blades slice neatly, while serrated edges cut tough items like crusty bread. Some blades have coatings to stop food from sticking. Picking the right blade improves speed and reduces waste.

Textile Industry Requirements

Precision Cutting for Fabrics

Cutting fabrics needs clean, accurate slices. This stops edges from fraying and keeps quality high. Whether cutting silk or denim, the right blade matters. Machines that cut automatically save time and give better results than manual cutting.

| ब्लेड का प्रकार | मुख्य निष्कर्ष |

|---|---|

| Automatic Cutting Machine | Faster work, better quality, and less time wasted. |

| Straight Knife Cutting Machine | Precise cuts but slower than automated machines. |

| Overall Comparison | Automation boosts speed and quality in textile production. |

This table shows how blade choice affects production. Automated systems with good blades are best for speed and accuracy.

Blade Durability for Long Runs

Textile work often lasts a long time, wearing out blades quickly. Strong blades save money and time by lasting longer. High-carbon steel blades are great for heavy tasks. Ceramic blades work well for lighter jobs. Durable blades keep production running smoothly.

Custom Blades for Unique Textiles

Special fabrics need custom blades for clean cuts. Stretchy or woven materials may not work with regular blades. Custom blades let you pick the size, edge, and material for your needs. This avoids damage and gives better results.

Paper Industry Considerations

Types of Paper Cuts

Different paper jobs need different blades. Thin sheets for notebooks need straight-edged blades for clean cuts. Thick cardboard needs serrated edges for tough trimming. Matching the blade to the paper type reduces waste and improves results.

Blade Edge Selection

Picking the right blade edge is important for paper cutting. Straight edges make smooth cuts, perfect for printing paper. Serrated edges work better for rough materials like cardboard. Choosing the right edge saves time and keeps blades sharp.

टिप्पणी: For sticky paper, use non-stick blades. They stop residue buildup and keep cuts clean.

Performance in High Volumes

Paper cutting often involves large amounts of work. Strong blades like tungsten carbide or coated steel handle this well. Sharpening and cleaning blades regularly helps them last longer. High-quality blades keep production fast and avoid delays.

Metal कटिंग अनुप्रयोग

Special Blade Features

Cutting metal needs strong, reliable blades. Circular slitter blades for metal are made to handle tough materials like steel, aluminum, and copper. These blades often have special coatings, like titanium nitride, to reduce heat and friction. Some also have serrated edges to grip the metal better while cutting.

If you work with metal, picking the right blade is important. For example, a blade with high Rockwell hardness can easily cut thick metal sheets. Softer blades may wear out fast or make messy cuts. Always match the blade’s features to the type of metal for the best results.

Hardness Needs

Blade hardness is key when cutting metal. A soft blade dulls quickly, while a very hard one might crack under pressure. The Rockwell Hardness Scale helps you understand blade strength.

For heavy jobs, choose blades with a hardness of 60 or more. These blades handle tough materials without losing sharpness. For softer metals like aluminum, a lower hardness blade works well and costs less.

बख्शीश: Check the hardness of both the blade and the metal. This helps the blade last longer and cuts better.

उत्पादन क्षमता

Efficiency matters in metal cutting. The right blade speeds up work and reduces waste. High-quality blades with heat-resistant coatings allow faster cutting without losing quality.

For big jobs, use blades made for high-volume cutting. These blades stay sharp longer, reducing downtime for sharpening or replacing. Choosing the right blade improves efficiency and keeps production smooth.

Plastic Industry Needs

Blades for Different Plastics

Plastics vary from thin films to thick sheets. The blade you need depends on the plastic. Straight-edged blades are great for cutting thin materials like plastic wrap. Serrated blades work better for tougher plastics like PVC or acrylic.

Each plastic has its own challenges. Some melt from heat, while others crack if the blade isn’t sharp. Picking the right blade ensures clean cuts and less waste.

Cutting Speed Tips

Cutting speed affects how well a blade works. Faster speeds create heat, which can melt some plastics. Use blades with non-stick coatings or heat-resistant materials to avoid this.

For high-speed production, choose blades that handle fast cutting without dulling. For delicate plastics, slower speeds give precise cuts without damage.

Custom Blades for Plastics

Sometimes, regular blades don’t work well. Custom blades are great for special plastic-cutting needs. If you’re cutting sticky plastics, non-stick blades stop residue buildup. For thick plastics, reinforced blades work better.

Custom blades improve cutting and reduce waste. They also save time by lasting longer and needing fewer replacements.

Automotive Industry Uses

Accurate Component Cutting

In the automotive industry, precision is crucial. Whether cutting metal for car bodies or plastic for interiors, the right blade ensures clean, accurate cuts. This is especially important for parts that must fit perfectly, like engine pieces or dashboards.

High-quality blades made for automotive work help achieve this precision. Look for sharp, durable blades to meet industry demands.

Blade Durability and Care

Automotive production lines run long hours, putting stress on blades. Durable blades keep things running smoothly. Regular cleaning and sharpening help blades last longer and work better.

Blades with wear-resistant coatings need fewer replacements. This saves money and reduces downtime, keeping production efficient.

Custom Blades for Auto Parts

Standard blades may not meet all automotive needs. Custom blades solve this by offering exact sizes and edges. For example, a custom blade can cut rubber seals or trim metal panels perfectly.

Custom blades also adapt to new materials or designs. They ensure quality and efficiency, even with changing production needs.

Cutting Types and Configurations

Slitting Techniques

What is Slitting?

Slitting cuts materials into smaller strips using special tools. It’s like slicing bread into even pieces but for factories. This method is common in industries like paper, metal, and plastic. Slitting is precise, creating clean edges and reducing waste. It’s perfect for making large amounts of products quickly.

Why Use Slitting?

Slitting is popular because it’s fast and works on many materials. It can handle thin films or thick sheets while saving material and money. For example, using a beveled punch in slitting can cut the piercing force by half. This makes the process smoother and uses less energy.

Here’s a table showing how different materials react to slitting:

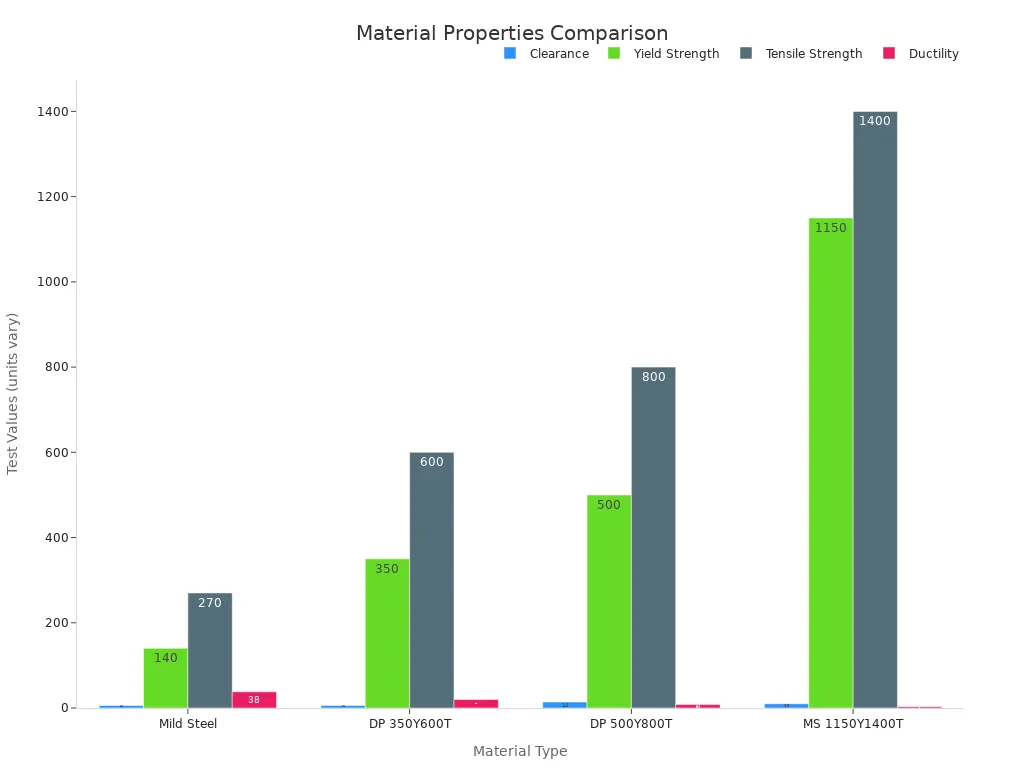

| सामग्री का प्रकार | Clearance (%) | Yield Strength (MPa) | तन्य शक्ति (एमपीए) | Ductility (%) |

|---|---|---|---|---|

| हल्का स्टील | 6% | 140 | 270 | 38 |

| DP 350Y600T | 6% | 350 | 600 | 20 |

| DP 500Y800T | 14% | 500 | 800 | 8 |

| MS 1150Y1400T | 10% | 1150 | 1400 | 3 |

This table shows how easy or hard it is to slit different materials. For example, mild steel is easier to cut because it’s more flexible than harder materials like MS 1150Y1400T.

Trimming Methods

What is Trimming?

Trimming removes extra material to make something the right size or shape. It’s like giving a haircut to your material. Industries like automotive and packaging use trimming to make edges smooth and neat.

Why is Trimming Important?

Trimming helps create clean, accurate edges. In cars, it shapes metal panels and plastic parts. In packaging, it makes boxes fit perfectly. Using the right tools for trimming saves material and improves production speed.

Shearing Processes

What is Shearing?

Shearing cuts materials by applying force to break them in a straight line. It’s like cutting paper with scissors but for bigger, tougher materials. This method is great for cutting metal or plastic sheets into specific shapes.

Benefits of Shearing

Shearing is quick, accurate, and good for making lots of products. For example, a rooftop punch can lower the force needed by 80%, saving energy. It also keeps materials from bending too much, giving a clean cut every time.

Here’s a chart showing how materials perform with different cutting setups:

This chart explains how things like material strength and clearance affect shearing. Knowing these details helps you pick the best setup for your job.

Scoring Techniques

What is Scoring?

Scoring makes shallow cuts or grooves in materials. It doesn’t cut all the way through. Think of it as creating a fold line for bending or shaping. This method is often used in packaging to make neat folds for boxes. Scoring uses controlled pressure to ensure clean bends without breaking the material.

To score well, you need the right blade and settings. Softer materials like cardboard need less pressure. Harder materials like plastic need more force. Adjusting the blade’s sharpness and depth helps you get good results every time.

Where Scoring is Used

Scoring is useful in many areas. In packaging, it helps fold boxes neatly for easy assembly. In metalwork, it prepares sheets for bending. In crafts, it creates grooves for designs.

Scoring isn’t just about looks—it also stops materials from cracking or tearing. Whether you’re working with paper, plastic, or metal, scoring gives a clean, professional finish.

Blade Configurations

सीधे ब्लेड

Straight blades are great for clean, precise cuts. They have flat edges, making them perfect for cutting thin materials like paper or plastic. They’re also good for scoring because they make even grooves.

Straight blades are versatile and easy to use. Keep them sharp for the best results.

घुमावदार ब्लेड

Curved blades are made for special tasks. Their rounded edges cut thicker or tougher materials smoothly. They work well for trimming rubber, leather, or some metals.

Curved blades also reduce stress on materials, preventing damage. If you’re cutting heavy-duty materials or complex shapes, curved blades are a good choice.

सामग्री से ब्लेड का मिलान

Choosing the Right circular slitter blades

Not all blades work for every material. Straight blades are best for soft, thin materials like paper. Curved blades handle tougher materials like rubber or metal better. Picking the right blade makes cutting easier and protects your tools.

For example, use a straight blade for thin plastic sheets. For thicker plastic, a curved blade works better. Always match the blade to the material.

ब्लेड प्रदर्शन

Blade performance depends on the job. Using the wrong blade can cause bad cuts, wasted material, or tool damage. Straight blades are precise, great for detailed work. Curved blades are strong, ideal for tough tasks.

By knowing your material and cutting needs, you can pick the best blade. This improves your work and helps your tools last longer.

Maintenance Tips for Long-Lasting Performance

आपकी देखभाल करना circular slitter blades is simple. With proper care, they last longer and work better. Follow these tips to keep them in great shape.

नियमित निरीक्षण अनुसूची

क्षति की तलाश करें

Check your blades often for problems like dull edges or chips. These can ruin cuts and harm materials. A quick look before using them can prevent bigger issues later.

Spot Problems Early

Finding damage early saves money on repairs or replacements. Tools like sound tests or heat scans can find hidden issues. These methods are great for spotting problems you can’t see.

| Inspection Tool | यह क्या करता है? | Why It’s Useful |

|---|---|---|

| Sound Tests | Finds hidden cracks inside blades. | Detects damage you can’t see easily. |

| Heat Scans | Shows heat changes to find flaws. | Quick and doesn’t harm the blade. |

| दृश्य जांच | Looks for surface problems. | Easy and cheap for everyday use. |

बख्शीश: Regular checks stop problems before they start. Using real-time tools helps blades last longer.

सफाई प्रक्रिया

Use the Right Cleaner

Clean blades with safe solutions made for tools. These remove dirt without harming the blade. For sticky stuff, non-stick coatings make cleaning easier. Always follow cleaning instructions from the maker.

Skip Strong Chemicals

Strong cleaners can damage blades over time. Use mild ones to keep blades strong. If unsure, test the cleaner on a small spot first. This avoids unnecessary wear.

Proper Storage Techniques

ब्लेड को सुरक्षित रूप से स्टोर करें

Keep blades in dry, safe places to avoid rust or damage. Use racks or cases made for blades to keep them organized and protected.

Cover Sharp Edges

Blades are sharp and need care. Cover edges with guards when not in use. This stops chips and keeps them ready for work. Good storage keeps blades safe and lasts longer.

टिप्पणी: Cleaning and storing blades properly saves money and improves performance. A little care goes a long way!

Blade Sharpening Practices

जानें कब तेज करना है

Sharpen blades regularly to keep them cutting well. Watch for rough edges or uneven cuts—they mean the blade needs sharpening. Busy jobs may need sharpening more often, while lighter tasks can wait longer.

Check your blades weekly if you use them every day. This helps catch dull blades early and avoids delays. Sharpening often makes blades last longer and keeps work smooth.

Pick the Right Tools

Use proper tools to sharpen blades correctly. Hand sharpeners are good for quick fixes, but grinding machines work better for precise sharpening. Match the tool to the blade type. For example, diamond tools are great for hard blades like tungsten carbide.

Don’t sharpen too much—it wears blades out faster. Follow the maker’s instructions for the best results. Using the right tools and methods improves blade performance and saves money on replacements.

प्रतिस्थापन दिशानिर्देश

Know When to Replace

Blades don’t last forever, even with good care. Look for cracks, chips, or heavy wear. If sharpening doesn’t fix the blade, it’s time to replace it. Old blades can ruin materials and slow work.

If you’re sharpening more often, the blade might be wearing out. Replace it early to avoid problems and keep cuts clean.

Plan Ahead for Replacements

Replacing blades doesn’t have to stop work. Keep extra blades ready and change them during slow times. If you use custom blades, order replacements early to avoid delays.

Planning ahead saves time and keeps production running smoothly. It’s a simple way to stay efficient.

Documentation and Tracking

Keep Maintenance Records

Write down when you sharpen or replace blades. This helps you remember important care tasks. Include details like dates, tools used, and any problems noticed.

Logs also show patterns. If a blade wears out quickly, you can find out why. Good records make maintenance easier and better.

Track Blade Performance

Watch how long blades last and how often they need sharpening. This helps you pick the best blades and plan future buys.

Tracking also shows if your care routine is working. If blades last longer after changes, you’re doing it right. Keeping track helps you get the most from your blades.

कस्टम ब्लेड के लाभ

Why Customization Matters for Specific Applications

Not all blades work for every job. Using standard blades can cause problems like bad cuts, wasted materials, or needing replacements often. Custom blades fix these issues because they are made to fit your exact needs. Whether cutting soft fabrics or tough metals, a custom blade gives better accuracy and works more efficiently.

Think about food processing. A regular blade might have trouble with sticky dough or frozen meat. But a custom blade, with non-stick coatings or stronger edges, handles these tasks easily. The same goes for industries like packaging or automotive, where special materials need unique solutions. Custom blades help you work faster and improve quality.

बख्शीश: Tell the manufacturer about your materials and cutting process when ordering custom blades. This helps them make the best blade for your needs.

Advantages of Custom Blades Over Standard Options

कस्टम ब्लेड have benefits that regular ones can’t offer. First, they last longer. A blade made for your job wears out slower, saving money on replacements. For example, some companies saved 28% in yearly costs by switching to custom blades.

Second, custom blades make work faster. A box factory cut downtime from 14 hours to less than 5 by using special micro-tooth blades. A plastic plant extended blade life from 10 to 42 days, reducing downtime by 65% and saving $18,000 a year. These examples show how custom blades improve productivity and lower costs.

Finally, custom blades give cleaner cuts. Whether cutting paper, plastic, or metal, they improve quality. A meat plant reduced blade changes by 50% and stopped cross-contamination complaints. Custom blades make work easier and deliver better results.

How Nanjing Metal Provides Tailored Solutions

Nanjing Metal is a trusted maker of custom circular slitter blades. With 18 years of experience, they design and produce blades for many industries. Their team focuses on precision and durability, ensuring each blade meets your specific needs.

They offer many customization options. Whether you need certain sizes, edge styles, or coatings, they can create the perfect blade for your job. Their expertise is trusted in industries like food processing, packaging, and automotive.

If you want better cutting tools, Nanjing Metal can help. Visit their मुखपृष्ठ to learn more about their custom solutions. For personal help, contact their sales engineers आज।

Steps to Order Custom Blades from Nanjing Metal

Getting custom blades from Nanjing Metal is easy. Follow these steps:

- Identify Your Requirements

Think about what you need. Write down the material, blade size, edge type, and coatings. This helps explain your needs clearly.बख्शीश: Not sure what you need? Nanjing Metal’s sales engineers can assist you. - संपर्क करें नानजिंग Metal

Visit their contact page. Send an email or call their team. Share your details and ask questions. - Discuss Customization Options

Talk with their experts about your blade design. They’ll suggest materials, edges, and coatings that fit your needs. Ask about durability and performance. - कोटेशन का अनुरोध करें

Once the design is ready, ask for a price estimate. Nanjing Metal offers clear pricing, so you’ll know the cost upfront.टिप्पणी: Ordering more blades may save money with discounts. - Place Your Order

Agree on the design and price, then order your blades. Nanjing Metal will start making them right away. - Track Your Order

After ordering, you’ll get updates on production and shipping. Their team ensures fast delivery to keep your work on track.

Follow these steps to get custom blades made just for you. Nanjing Metal makes the process simple and stress-free!

Supplier Selection and Buying Tips

Picking a Trustworthy Supplier: What to Look For

Choosing the right supplier is important for good products and smooth work. You need someone who delivers on time, offers strong blades, and understands your needs. How can you find the best one? Start by checking their quality control. Good suppliers test their products carefully, use advanced tools, and follow global rules like ISO9001.

Here’s what reliable suppliers usually do:

| गुणवत्ता नियंत्रण चरण | इसका क्या मतलब है |

|---|---|

| अंतिम उत्पाद जांच | Includes surface checks and using accurate measuring tools. |

| परीक्षण उपकरण | Devices like micrometers and hardness testers ensure precise results. |

| मानकों का अनुपालन | Following ISO9001 ensures steady quality and dependable products. |

Picking a supplier with these steps means you can trust their blades to work well.

Why Quality Checks and Certifications Matter

Quality checks aren’t just fancy words—they promise the blades will work as expected. Certifications like ISO9001 prove that a supplier follows strict rules for quality. These certifications mean every blade is tested for strength, accuracy, and safety.

Working with certified suppliers lowers risks like getting bad products or delays. This is extra important for jobs where precision is key. Always ask for proof of certifications before buying. It’s a simple way to avoid big problems later.

Buying in Bulk to Save Money

Buying many blades at once is a smart way to save money. It also ensures you always have enough blades for your work. Planning purchases, grouping similar items, or working closely with suppliers can help you save more.

Here are some tips to save money:

| Strategy | यह क्या करता है? |

|---|---|

| Grouping Items | Combine similar items to get better deals and bulk discounts. |

| Working with Suppliers | Build strong relationships to improve service and lower costs. |

| Managing Risks | Spot and fix problems in supplier choices to save money and avoid issues. |

Tracking things like savings and supplier options can also help. For example:

- Savings show how much you save by buying in bulk or negotiating better deals.

- Supplier options help you find new suppliers or renegotiate for better prices.

Using these tips helps you save money while keeping blade quality high.

Evaluating Customer Support and After-Sales Services

Picking a supplier for circular slitter blades isn’t just about buying. It’s also about getting help when things go wrong. Good customer support and after-sales services are very important. Here’s how to check if a supplier is reliable:

1. Quick Replies Are Key

A good supplier answers your questions fast. If you ask about blade details or report a problem, you shouldn’t wait long. Test this by sending a question before buying. Did they reply quickly? Were they helpful? These signs show how good their service is.

2. Knowledgeable Staff

The supplier’s team should know their products well. If you have a problem, they should give clear advice. For example, if a blade isn’t cutting well, they should help you find out why. A skilled team saves you time and stress.

3. Helpful After-Sales Services

After-sales help is as important as the purchase itself. Look for suppliers offering warranties, repairs, or blade sharpening. These services show they care about keeping you happy.

बख्शीश: Ask if they provide guides or training for blade care. This helps your tools last longer.

4. Check Reviews

See what other customers say. Reviews often mention how suppliers handle problems. Look for comments about their support team and how fast they respond. A supplier with good reviews is usually a safe choice.

Good customer support means you won’t feel stuck when issues arise. Take time to check this before choosing a supplier.

Picking the right circular slitter blades is very important. Good blades last longer and work better for your industry. High-quality blades cut faster, waste less, and stay sharp longer. For instance, ceramic blades chip less, while tungsten carbide blades last much longer than steel ones. Cleaning and oiling blades often can make them last 40% longer. This keeps your tools strong and dependable.

Custom blades are even better because they fit your exact needs. They help you cut more accurately and improve your work. Nanjing Metal is a trusted company that makes great custom blades. Their blades help you work faster and avoid delays. Choosing the right blades and taking care of them saves money and gives better results.

सामान्य प्रश्न

What is the best material for circular slitter blades?

The best material depends on your task. Stainless steel resists rust and works in wet areas. Carbon steel is strong for cutting tough materials. Tungsten carbide lasts a long time. Pick the material that matches your cutting job for the best results.

मुझे कितनी बार अपने ब्लेड को तेज करना चाहिए?

Sharpen blades when cuts look rough or uneven. If you use them daily, check them weekly. Busy work may need sharpening more often. Regular sharpening keeps blades working well and lasting longer.

Can I use one blade for different materials?

You can, but it’s not the best idea. Using the wrong blade can damage your material or wear out the blade faster. It’s better to use blades made for specific materials. This gives cleaner cuts and makes the blade last longer.

Are custom blades worth the investment?

Yes, they are! Custom blades are made to fit your needs. They cut better, waste less, and last longer. Many companies save money and work faster by using custom blades designed for their jobs.

मुझे कैसे पता चलेगा कि ब्लेड कब बदलना है?

Replace a blade if sharpening doesn’t help or if it’s cracked, chipped, or very worn. Old blades can ruin materials and slow down work. Plan ahead so you’re ready to replace blades without delays.

यह भी देखें

सर्कुलर स्लिटर चाकू में विकास और नवाचार: औद्योगिक काटने की दक्षता बढ़ाने की कुंजी

रबर स्लिटर ब्लेड चुनने की अंतिम गाइड

बेहतरीन कटिंग प्रदर्शन के लिए स्लिटर ब्लेड की तीक्ष्णता को अधिकतम कैसे करें

2 प्रतिक्रियाएं