Refurbishing blades with a perforating blade sharpening service saves more money than buying new blades often. Sharp blades last longer and help lower costs. They also help machines work faster and stop less often. Some examples are packaging, medical, and food processing. Each business needs different things for perforation. They may need special materials or tooth shapes. Companies should look at how they use blades. They should pick the best choice for their work.

- Packaging: Needs exact perforation so tearing is easy.

- Medical: Needs clean seals with correct perforation.

- Food Processing: Needs perforation for steam and packing.

चाबी छीनना

- Sharpening perforating blades saves money and makes less waste than buying new blades. Regular sharpening keeps blades sharp. It helps blades cut better. Machines work better and stop less often. Professional sharpening services make blades last longer. They use special coatings and treatments. This lowers how much you spend on maintenance. Cleaning and checking blades often helps them last longer. It also helps you make more products. You only need to replace blades if they are badly damaged. You also replace them if sharpening does not fix the cutting.

लागत तुलना

Refurbishing vs. Replacing

When companies look at refurbishing and replacing blades, they notice big cost differences. Refurbishing, which means sharpening, costs less at first than buying new blades. Sharpening makes the blade sharp again, so it can cut clean lines. This lets companies use the same blade many times, which saves money over time.

Refurbished blades are often shipped fast. This means companies get their blades quickly and keep machines working. New blades can take weeks to arrive, especially if they need special shapes or sizes. मैक्सटर Metal gives both choices. Their good prices and easy ordering help businesses pick what works best.

Here is a table that compares both options:

| कारक | Refurbishing (Sharpening) | Replacing (New Blades) |

|---|---|---|

| प्रारंभिक लागत | निचला | उच्च |

| समय सीमा | छोटा | लंबे समय तक |

| अनुकूलन | Limited | उच्च |

| Waste Produced | Less | More |

| Perforation Quality | Restored | New |

दीर्घकालिक बचत

Refurbishing blades helps companies save money for a long time. Blades that can be sharpened last longer and do not need to be replaced often. This means companies spend less and still get good perforation.

- Sharpening makes blades work almost like new.

- Cleaning and checking blades before sharpening makes sure only good blades get fixed.

- Using blades many times lowers costs.

- Less waste makes this a smart choice for businesses.

Maxtor Metal helps companies save with affordable new blades. Their quick shipping and small order sizes help businesses that need good perforation solutions.

ब्लेड प्रदर्शन

काटने की सटीकता

Cutting precision is important in every perforation job. Sharp blades make clean and straight lines. This helps products tear or break where they should. Dull blades can make rough edges and uneven cuts. They also cause more waste. Sharpening blades often keeps them working well. It also helps machines run better.

Sharpening and taking care of perforating blades is very important. It keeps cutting quality high and machines steady. Dull blades are harder to use. They make uneven cuts and rough edges. Machines may get louder and shake more. A sharpening plan based on material and blade coating helps stop these problems.

How often you sharpen depends on the material and blade coating. The table below shows how often to sharpen different blades for good cutting:

| सामग्री का प्रकार | ब्लेड कोटिंग | Recommended Sharpening Interval | Notes on Blade Life and Maintenance |

|---|---|---|---|

| पारंपरिक उच्च दबाव LDPE | बिना लेपित | 2 से 4 सप्ताह | Typical service life before sharpening needed |

| कम दबाव एलडीपीई | बिना लेपित | Approx. 26 hours | Blades dull quickly, requiring frequent sharpening |

| कम दबाव एलडीपीई | टेफ्लॉन-लेपित | 26 से 30 घंटे | Slightly extended blade life due to coating |

| कम दबाव एलडीपीई | Ny-कार्ब (कठोर धातु) | लगभग 20 घंटे | Coated blades last longer but still need sharpening |

| Low pressure LDPE (resharpened) | एन/ए | 8 से 24 घंटे | पुनः धारदार ब्लेडों का जीवनकाल कम हो जाता है |

| पारंपरिक उच्च दबाव LDPE | Uncoated (slitting) | सप्ताह में एक बार धारदार | Less frequent sharpening needed for slitting blades |

| Low pressure LDPE (slitting) | बिना लेपित | दिन में दो बार धारदार | High sharpening frequency without coating |

| Low pressure LDPE (slitting) | टंगस्टन कार्बाइड | सप्ताह में एक बार धारदार | Hard metal coating extends sharpening interval |

A sharp blade makes every cut right. This means less waste and faster work. Companies that sharpen on time get better products and fewer mistakes.

Durability Factors

Blade durability is about how long a blade works before it needs fixing or changing. Many things affect durability. These include blade material, coating, and how often it is sharpened. Refurbishing with special methods, like overlay welding or laser cladding, can make blades strong again and last longer.

- Refurbishing uses special repairs to make blades strong.

- Coatings protect blades from rust and heat damage.

- Newer repair methods can use better materials than before.

- Refurbished blades can last longer and need less fixing than old blades.

- This saves money and keeps machines working well.

Refurbished blades may not always be just like new ones. But new coatings and materials can help them work as well or even better. This means companies can trust refurbished blades for strong and steady cuts. They also last longer between repairs. Good blade durability means fewer stops and lower costs over time.

छिद्रण ब्लेड को तेज करने वाली सेवा

Professional Sharpening Benefits

Restoring Cutting Precision and Edge Quality

A professional perforating blade sharpening service makes blades sharp again. Skilled workers use special tools to fix the blades. This helps blades cut as well as when they were new. Sharp blades make clean cuts. This is important for packaging, textiles, and food processing. When blades are sharp, they make neat lines. This means less waste and better products.

ब्लेड का जीवनकाल बढ़ाना

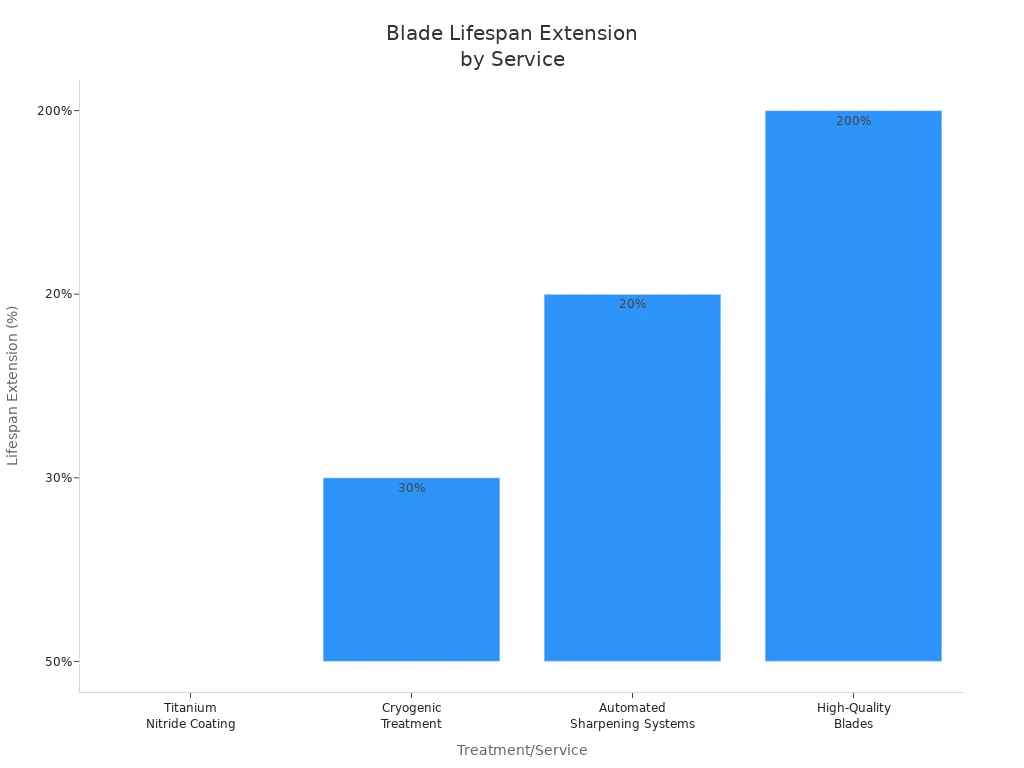

A good sharpening service helps blades last longer. Some treatments, like titanium nitride coating, make blades harder. Cryogenic processes also help blades stay strong. These methods stop blades from wearing out fast. Automated sharpening systems keep the blade edge even. The table below shows how these treatments help blades last longer:

| Treatment/Service | Measurable Benefit on Blade Lifespan |

|---|---|

| Titanium Nitride Coating | Sharpness retention increased by 50% |

| क्रायोजेनिक उपचार | Blade life extended by 30% |

| Automated Sharpening Systems | Blade longevity improved by up to 20% |

| High-Quality Blades (vs standard) | Lifespan extended from 3 months to 9 months |

Cost Savings Compared to Replacement

Sharpening blades saves money over time. Perforation blade sharpening costs less than buying new blades. Companies also pay less for fixing machines. Machines stop less often when blades are sharp. The table below shows how sharpening helps save money and time:

| Financial/Operational Impact | विवरण |

|---|---|

| डाउनटाइम में कमी | Monthly downtime cut from 20 to 10 hours |

| रखरखाव लागत बचत | Annual maintenance costs reduced by 50% |

| Increased Output | Additional $80,000 per year |

| Material Waste Reduction | Waste reduced from 5% to 2% |

Regular sharpening helps companies use blades longer. This means they spend less and make more money.

Consistent Performance Over Time

A good sharpening service keeps blades working well for a long time. Automated sharpening systems keep the blade edge just right. This means every cut is good. Taking care of blades helps them stay sharp and strong. Workers see fewer problems and machines stop less.

- Titanium nitride coating makes blades harder. Blades stay sharp 50% longer in fast jobs.

- Cryogenic treatment makes blades stronger. Blades last 30% longer in tough jobs.

- Precision grinding and automated sharpening keep the edge even. This helps blades last up to 20% longer.

- Cleaning and oiling blades can make them last 15%-25% longer.

- Training workers helps stop blade damage. This means up to 10% fewer blade changes.

Service Process Overview

Initial Blade Assessment and Inspection

The first step is checking the blade carefully. Technicians look for twists, bends, and chips. They also check the blade’s edge shape. Cleaning the blade helps them see all problems. They use their hands and eyes to check the blade. This step makes sure only the right parts get sharpened.

- Checking finds damage like chips or bends.

- Cleaning helps technicians see better.

- Technicians check blade thickness and edge shape.

- Good checking stops too much sharpening and keeps blades strong.

Precision Sharpening Techniques

Technicians use special ways to sharpen blades. They pick the best angle, usually 25 to 30 degrees. Automated tools help make the edge even. For small damage, hand grinding works. For big damage, machines fix the blade. These ways keep the blade edge sharp and strong.

Quality Control Procedures

Maxtor Metal checks quality at every step. They look at blades before, during, and after sharpening. Technicians check for chips and rough spots. They also test if the blade cuts well. Only the best blades go back to customers. This makes sure every blade cuts clean lines.

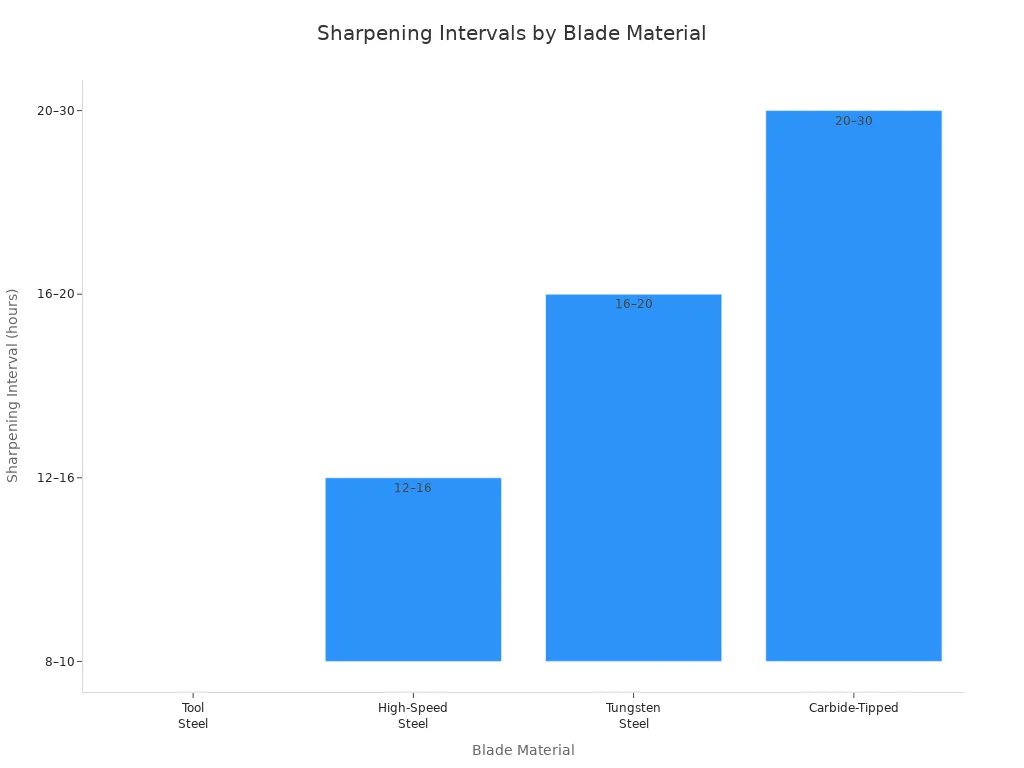

| ब्लेड सामग्री | Typical Sharpening Interval | Notes on Durability and Use |

|---|---|---|

| औजारों का स्टील | Every 8–10 hours | Suitable for general use; requires regular sharpening |

| उच्च गति स्टील | Every 12–16 hours | Retains sharpness longer; suitable for higher speeds |

| Tungsten Steel | Every 16–20 hours | Very hard, wear-resistant; less frequent sharpening needed |

| Carbide-Tipped | Every 20–30 hours | Longest lifespan; ideal for heavy-duty cutting tasks |

OEM Support and Customization Options

Maxtor Metal helps customers who need special blades. They make कस्टम ब्लेड from drawings or samples. Their team helps design blades for special jobs. Customers can pick blade shapes, tooth styles, and coatings.

Perforation Blade Maintenance

रखरखाव के सर्वोत्तम अभ्यास

Keeping perforating blades sharp helps machines work well. Companies that check blades often have fewer problems. They also get better results. Preventive maintenance means checking blades for damage. It also means cleaning and sharpening them at the right time. Operators should look at blades before every shift. They check for dull spots, chips, or dirt. Cleaning blades gets rid of dust and small pieces. This helps the blades cut better.

Blades must be lined up the right way. Technicians line up the cutter assembly very carefully. They keep it within 0.001-inch per foot. This stops uneven cuts. They use hand tools to put in knives. Power tools can hurt the threads. Before putting in new blades, they clean the knife beds. Even a tiny bit of dirt can move the blade. This can make the perforation bad. Rubber strips should touch the knives softly. This makes a seal and keeps out rough material. Water spray cools and oils the blades. This is important when cutting hard things.

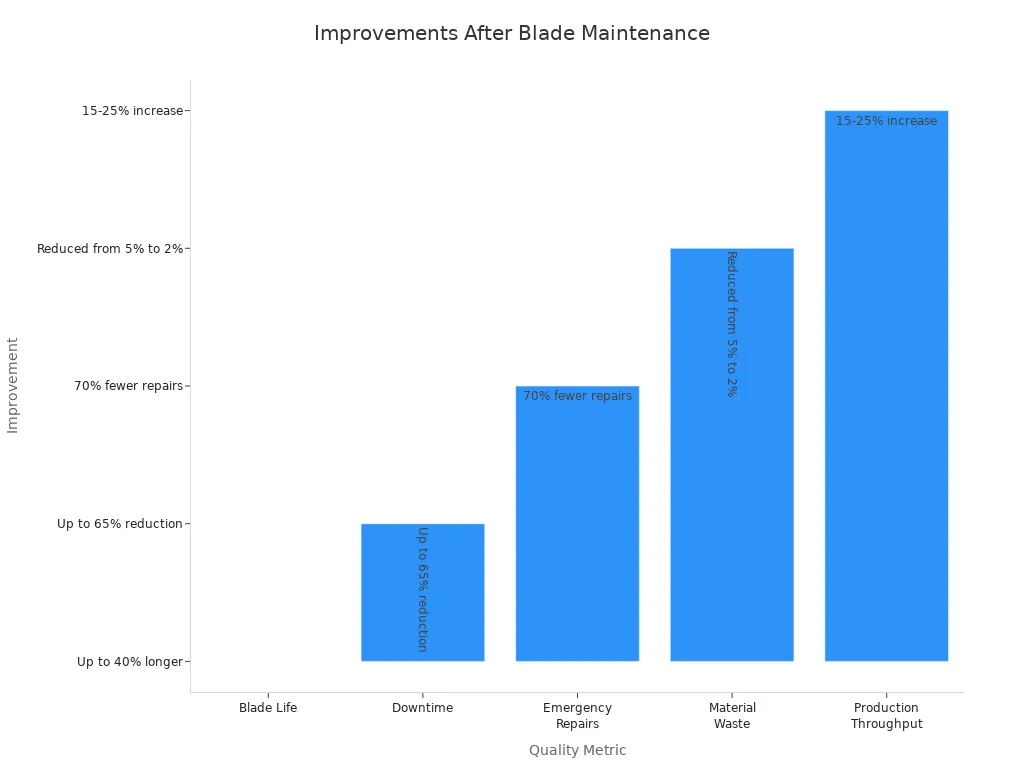

A good maintenance plan helps blades cut better. It also makes blades last longer. The table below shows how maintenance helps performance:

| मीट्रिक | Improvement After Regular Maintenance | Impact on Cutting Quality and Production |

|---|---|---|

| ब्लेड लाइफ | Up to 40% longer lifespan | Sharper edges, fewer defects |

| स्र्कना | Reduction up to 65% | Less interruption, higher throughput |

| आपातकालीन मरम्मत | 70% कम मरम्मत | More reliable cutting process |

| सामग्री अपशिष्ट | 5% से घटाकर 2% किया गया | Better cut quality, less waste |

| उत्पादन थ्रूपुट | Increased by 15-25% | Higher output, consistent quality |

डाउनटाइम कम करना

Preventive maintenance helps machines run without stopping. Dull or old blades can jam machines. They can slow down cutting or break machines. Sharpening blades on time stops these problems. Watching machine data, like RPM and tonnage, helps find blade wear early. Companies that track maintenance have fewer emergency repairs. They also waste less material.

One operator saw that dull blades made rough cuts. The perforation was not good. After sharpening, the machine worked better. The product was better too. This shows that regular maintenance stops big problems. Companies with a strict maintenance plan have up to 65% less downtime. They also have 70% fewer emergency repairs. They get more products and better quality.

Tip: Keep a maintenance log. Write down blade checks, sharpening, and changes. This helps teams remember and find problems early.

When to Replace or Refurbish

Replacement Criteria

Irreparable Damage or Chipping

Sometimes, sharpening will not fix a blade. If a perforating blade has deep chips, cracks, or broken teeth, it is not safe. These problems can happen after using the blade for a long time. They can also happen if the blade hits something hard. Operators should look for these issues during regular checks. If they find them, they must replace the blade right away. Tools need to be safe and work well to keep perforation quality high.

Excessive Wear Beyond Sharpening Limits

Blades get worn out as time passes. Each time you sharpen, a little bit of the blade is removed. After many sharpenings, the blade can get too thin or lose its shape. When this happens, it cannot make clean perforation lines. Tools like calipers help check if the blade is thick enough. If the blade is too thin, it should be replaced. This helps machines work well and stops bad cuts.

Consistent Decline in Cutting Quality After Sharpening

Sometimes, a blade does not cut well even after sharpening. If the blade keeps making rough or uneven lines, it may be worn out. This means it cannot stay sharp anymore. Replacing the blade at this point helps the machine work better and keeps products good.

Manufacturer’s Recommended Replacement Interval

Manufacturers do not give exact times to replace perforating blades. They say to follow good maintenance steps. This means cleaning, checking, and replacing blades when needed. Companies that do this have less downtime and save money. For example, one survey showed companies with good maintenance had 38% less downtime and saved over $5,000 each month. Operators should write down when they check and change blades. This helps them know the best time to replace blades for their work.

Note: How often you replace blades depends on how you use them, what you cut, and your maintenance plan. There are no strict rules, so each company should make its own schedule using experience and data.

Sharpening Indicators

Dull or Blunt Cutting Edge

A dull or blunt edge is a sign a blade needs sharpening. Operators may see the blade does not cut as easily as before. The lines may look rough or uneven. Checking blades often helps find this problem early.

Increased Cutting Resistance or Effort

When a blade gets worn, machines need more force to cut. Operators may notice they have to push harder or the machine slows down. This makes the blade wear out faster. Sharpening the blade makes cutting easy again.

Visible Burrs or Rough Edges on Cuts

If the blade leaves burrs or rough edges, it needs sharpening. Clean lines are important for good products. Burrs can cause problems in packaging, food, and other jobs. Checking blades often helps find these problems before they get worse.

Decreased Precision or Cleanliness of Perforation

Precision is important for every perforation job. When a blade is not sharp, cuts are not as accurate. The material may tear in the wrong place or not separate well. Operators should watch for changes in cut quality and sharpen blades when needed.

Noticeable Drop in Production Efficiency

A worn blade can slow down the whole line. Machines may stop more, and workers may need to fix jams or remove bad products. Watching how well the line works helps operators see when blades are getting dull. Sharpening blades at the right time keeps things moving and lowers waste.

Tip: Make a regular inspection plan. Check blades for dullness, burrs, and if they are hard to use. Write down each sharpening and replacement. This helps teams see patterns and plan maintenance before problems start.

| Sharpening Indicator | किसकी तलाश है | Action Needed |

|---|---|---|

| Dull or blunt edge | Blade does not cut easily | Sharpen blade |

| Increased cutting resistance | More force needed, machine slows down | Sharpen blade |

| Burrs or rough edges | Uneven or messy perforation lines | Sharpen blade |

| Decreased precision | Cuts are less accurate or clean | Sharpen blade |

| Drop in production efficiency | More stops, lower output | Sharpen blade |

Regular checks and maintenance keep blades sharp and machines working well. Operators who do these steps get better results and longer blade life.

Sustainability and Efficiency

अपशिष्ट में कमी

Refurbishing perforating blades helps cut down on waste. When companies fix and sharpen blades, they use each blade longer. This means fewer blades get thrown away. Many manufacturers now reuse most parts from old blades. They can reuse up to 70% of blade materials. This lowers the need for new metal and other resources. It also cuts carbon emissions by about 45% compared to making new blades. By fixing blades, companies help the environment and support recycling.

Perforation jobs often leave extra scraps. Using refurbished blades helps make less waste. Companies that check and repair blades often see fewer bad products. They also throw away fewer blades. This helps the planet and saves money.

Operational Impact

Sharp blades help machines work well. Regular care and sharpening keep machines running. When workers follow a set schedule, they stop surprise breakdowns. This means fewer stops and helps companies finish orders on time.

A good blade plan tracks blade numbers and sharpening times. It also trains workers to use blades the right way. These steps help keep production going and make work faster. Companies that use strong blades with good coatings get better cuts. Their blades last longer. They also avoid problems that waste materials and slow down shipping.

Keeping blades sharp helps companies work without stopping. This helps them be efficient and protect the environment.

| फ़ायदा | Impact on Operations |

|---|---|

| कम डाउनटाइम | Fewer machine stops, higher output |

| Improved cutting consistency | Better product quality, less waste |

| Timely order fulfillment | On-time shipments, satisfied customers |

| Lower maintenance costs | More savings, higher efficiency |

Refurbishing perforating blades with sharpening services saves a lot of money. Blades last longer when they are sharpened by experts. Companies get better cuts and have fewer machine stops. This also makes the workplace safer for everyone. Keeping blades sharp with regular care helps them work well. Maxtor Metal gives custom blade help and uses strong materials. They check quality carefully and help customers with maintenance tips. Their team works fast to return blades quickly. Businesses should check their blades often and pick the best option. This helps them get good results and keep customers happy.

सामान्य प्रश्न

How often should companies sharpen perforating blades?

Most companies sharpen blades every few weeks. The best time depends on what is being cut, the blade type, and how much work is done. Checking blades often helps workers know when to sharpen.

What are the signs that a blade needs replacement instead of sharpening?

Workers should look for deep chips or cracks. If a blade stays dull after sharpening, it should be replaced. Blades that cannot cut clean lines need to be changed.

Does sharpening affect the lifespan of a perforating blade?

Sharpening makes blades last longer by fixing the edge. Each time a blade is sharpened, a little bit is taken off. Good care and skilled sharpening help blades last as long as possible.

यह भी देखें

छिद्रण ब्लेड और उनके व्यावहारिक अनुप्रयोगों को समझना

पैकेजिंग में छिद्रण चाकू का व्यापक रूप से उपयोग क्यों किया जाता है

छेदने वाले ब्लेड चाकू में असमान छेद और असंगत रेखा की लंबाई का निवारण और अनुकूलन