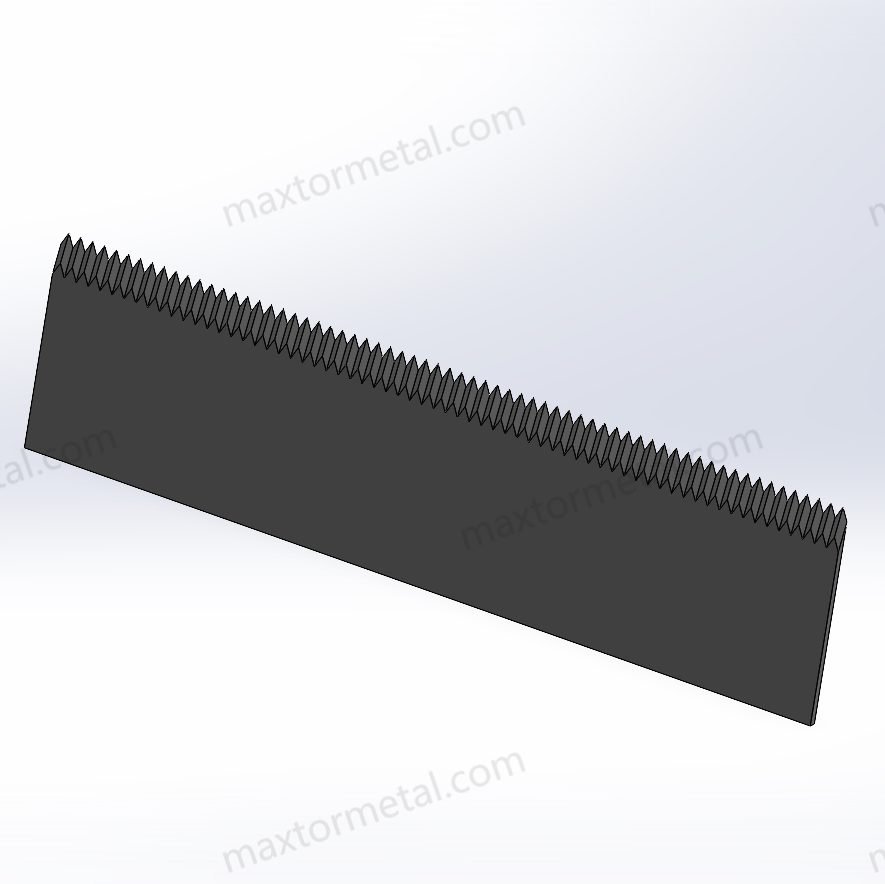

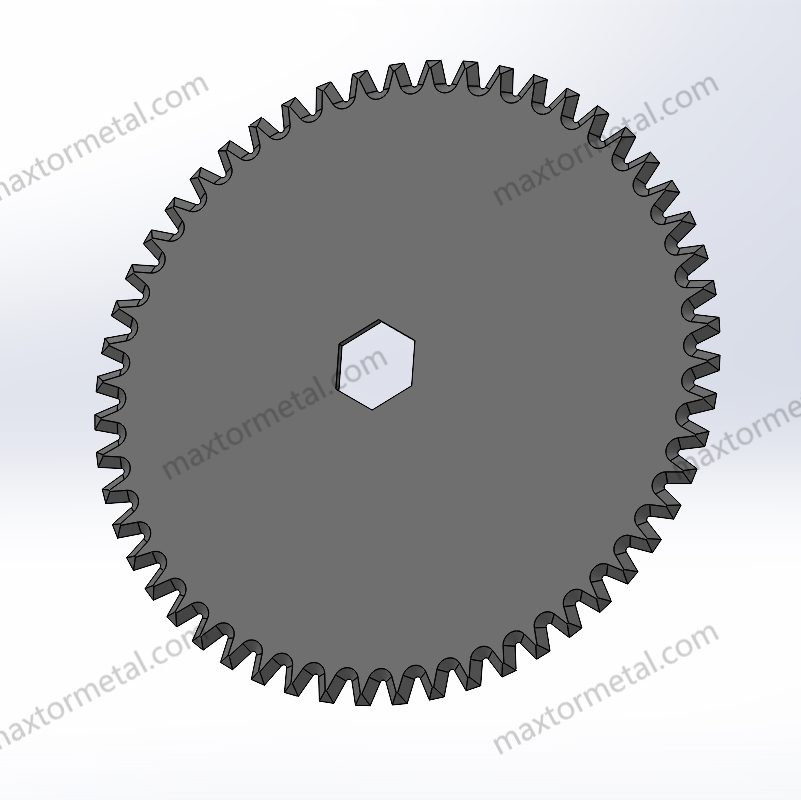

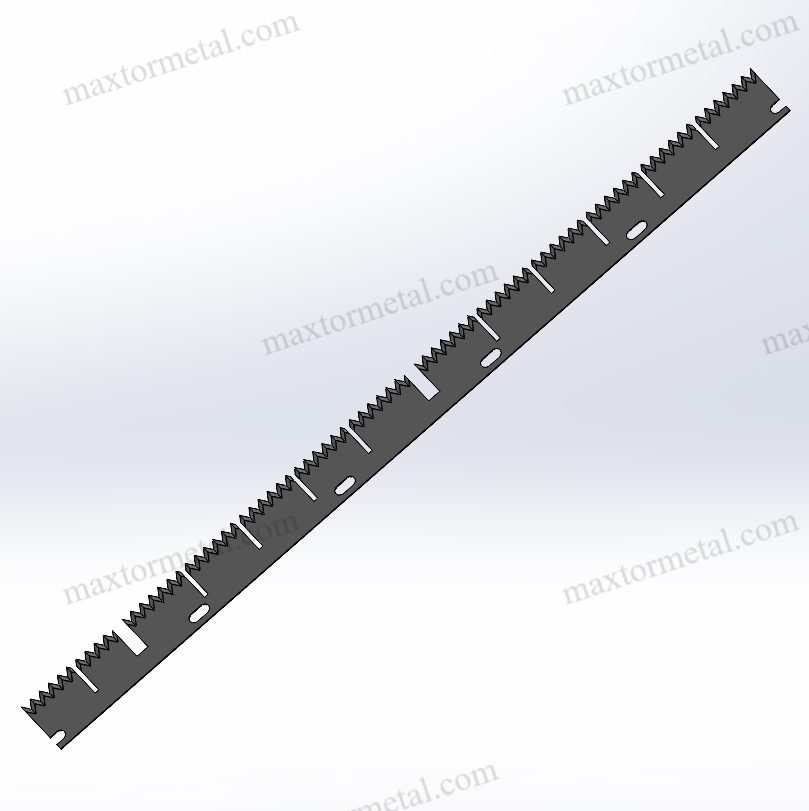

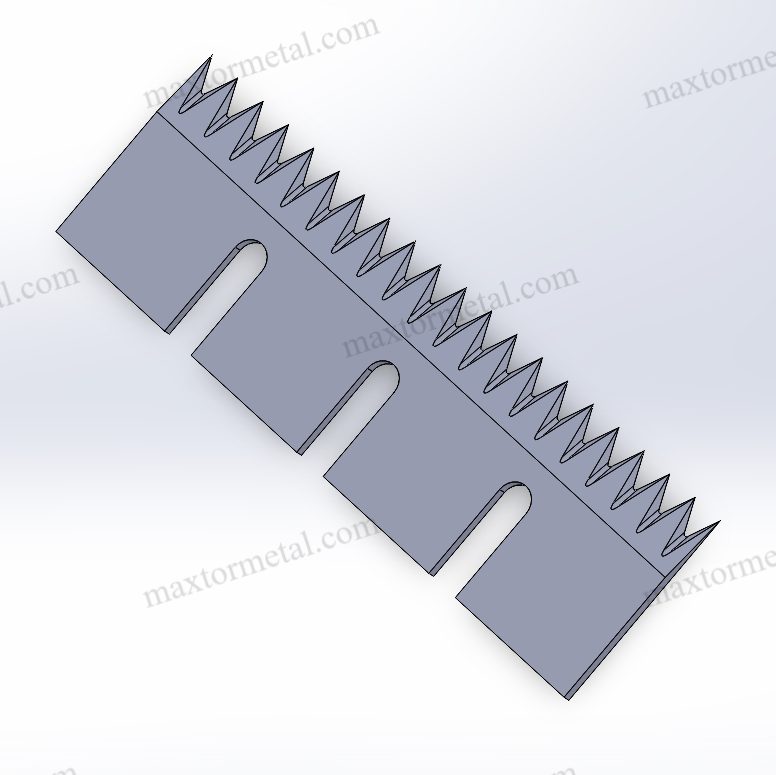

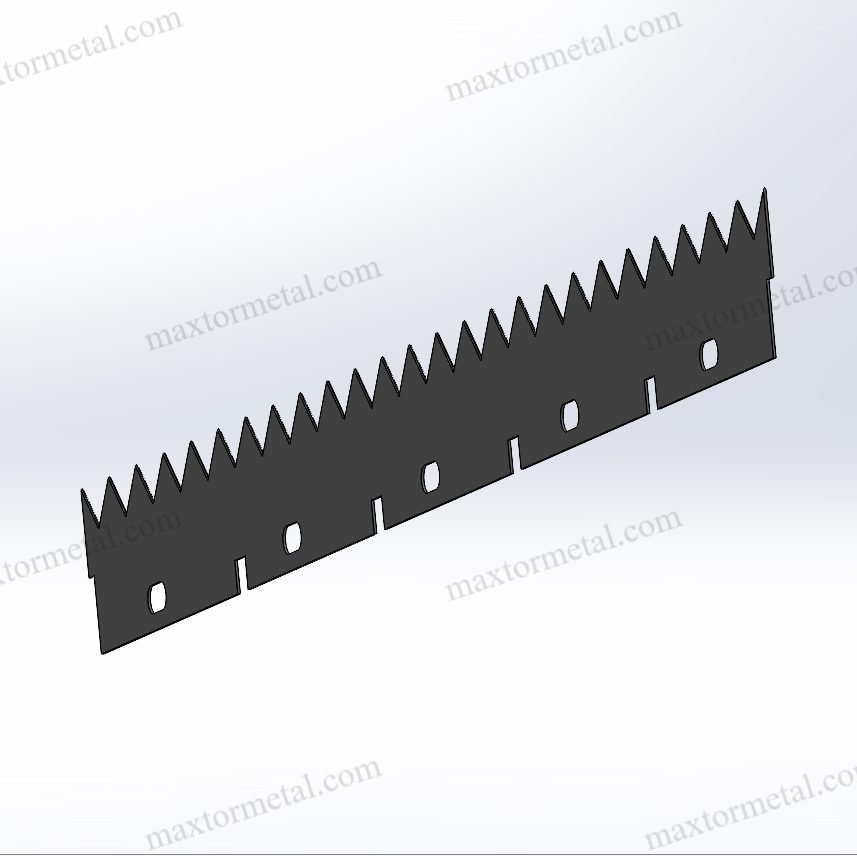

Perforating blades are very important in the food industry. They help keep food safe and clean. These strong blades make packaging that shows if it has been opened. They also help control who can get medicine and stop food from getting dirty. Perforated machine knives let air move in packages. This helps stop mold and keeps food fresh longer. In food processing, stainless steel blades do not rust. They can be cleaned often. This keeps things clean and meets safety rules. Good blades with a clean design stop germs and help keep food safe.

- खाद्य उद्योग में छिद्रण ब्लेड applications:

- Join bottle caps and seal rings to show if opened and keep people safe.

- Split pills in medicine packs to control use and help food safety.

- Make holes in packages to let air in and stop moisture and germs.

- Let steam out safely in microwave bags to keep food safe.

It is important to take care of blades and pick the right materials. This helps stop germs and keeps food safe at every step.

चाबी छीनना

- Use food-grade materials that do not rust, like stainless steel, to keep blades safe and clean.

- Clean blades often and check them to stop germs and keep blades sharp and working well.

- Follow safety rules and write down what you do to make sure you follow the rules and keep food safe.

- Pick suppliers with care and teach workers how to keep blades safe and clean.

- Use new technology and special coatings to make blades last longer, stay clean, and work better.

विनियामक अनुपालन

Food Safety Standards

Perforating blades in food industry places must follow strict safety rules. These rules help keep people safe and make sure food is good quality. The food processing industry uses these blades to make packaging that keeps food fresh and safe. Manufacturers need to pick food-grade materials like stainless steel 304 or 316. These materials stop contamination. They do not rust and can be cleaned often. This helps keep things clean and safe.

Key safety rules for perforating blades in food processing are:

- Use food-grade, corrosion-resistant materials to stop contamination.

- Make blades easy to clean and disinfect so germs do not build up.

- Blades must be strong and stay sharp to keep food safe.

- Blades should cut well to keep food quality and safety the same.

- Follow international rules like ISO 22000, ISO 8442, and NSF/ANSI 51.

The food processing industry also follows rules from the European Food Safety Authority. These groups set high standards for safety and hygiene in food making. Companies must write down their steps and keep records to show they follow the rules. This helps track products and materials. It also makes it easier to handle recalls or check problems.

Note: Good records and tracking are needed to meet rules and keep food safe all the way through the supply chain.

International Regulations

The world food processing industry has many rules to follow. Groups like the FDA and USDA in the United States, and the European Food Safety Authority in Europe, make strict rules for equipment in food making. These rules say perforating blades in food industry jobs must meet certain safety and hygiene standards.

International rules like ISO 22000 and EN 1672-2 give steps for food safety and clean machine design. These rules help companies match what the world expects. Following these rules keeps people safe and helps companies avoid legal trouble.

Manufacturers must keep good records about blade materials, how they are made, and how they are cared for. This tracking helps fix safety problems fast and shows they follow the rules. Companies that follow world rules and keep good records earn trust from customers and rule makers.

Tip: Regular checks and staff training help companies keep following safety rules and world regulations in the food processing industry.

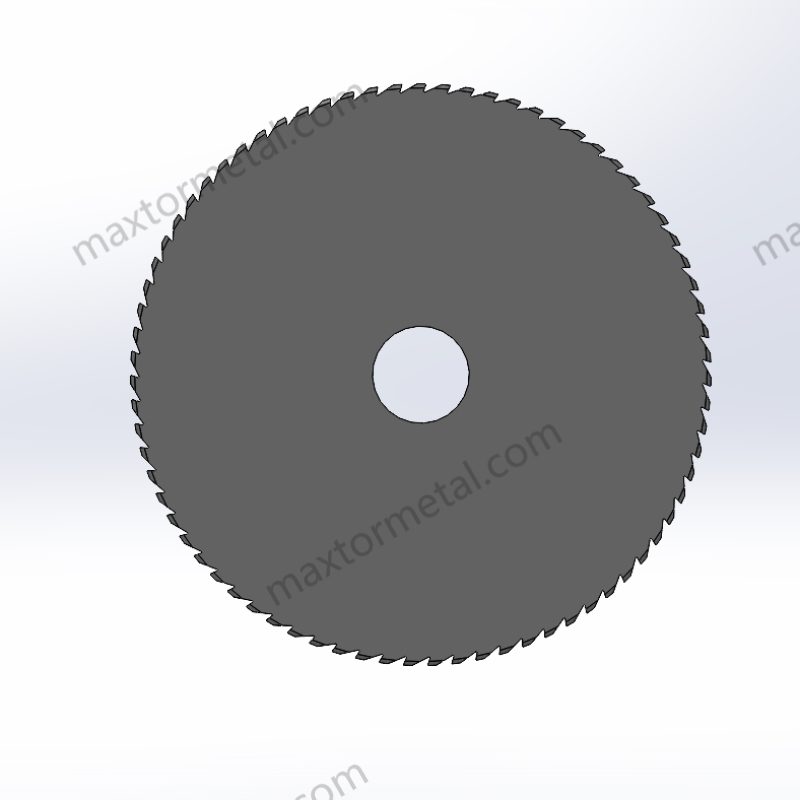

सामग्री चयन

Food-Grade Materials

Picking the right blade material is very important for food safety. Companies use food-grade stainless steel because it does not rust and is easy to clean. Krumar Knives says stainless steel is the top choice for food processing. This material keeps things clean, lasts a long time, and makes blades strong. High-speed steel (HSS) is also used for some jobs. It stays strong when hot and is tough for hard cutting work.

| सामग्री का प्रकार | Key Properties for Food Industry Use |

|---|---|

| स्टेनलेस स्टील | Does not rust, keeps things clean, good for food packaging and processing. Common grades: 440C, 440, 420J2. |

| हाई-स्पीड स्टील (एचएसएस) | Very hard, tough, stays strong when hot, used for long cutting jobs. |

| औजारों का स्टील | Wears down slowly, tough, used for many jobs. |

| टंगस्टन कार्बाइड | Very hard, does not wear out fast, best for rough materials. |

| पाउडर Metallurgy स्टील्स | Wears down slowly, tough, used for hard jobs. |

Nanjing Metal has many blade materials that are safe for food. They check quality at every step when making blades. Customers can pick stainless steel, HSS, or other types for their needs. They make sure each blade follows strict rules.

Note: The right blade material helps keep things clean and follows food safety rules.

जंग प्रतिरोध

Blades that do not rust are important for food safety and last longer. Food-grade stainless steel, like grades 304 and 316, has lots of chromium and nickel. These make a surface that does not react with food or smells. 316 stainless steel has molybdenum, which helps stop rust from salt. This is good for wet or sour places.

- Blades that do not rust stop stains and holes.

- Smooth blades are easy to clean and stop germs from growing.

- Blades that do not rust stay strong and clean for a long time.

- These blades need less fixing and last longer.

Rules from the FDA and NSF say only safe materials can touch food. Stainless steel blades meet these rules and are strong. Companies that use blades that do not rust save money and keep food safe.

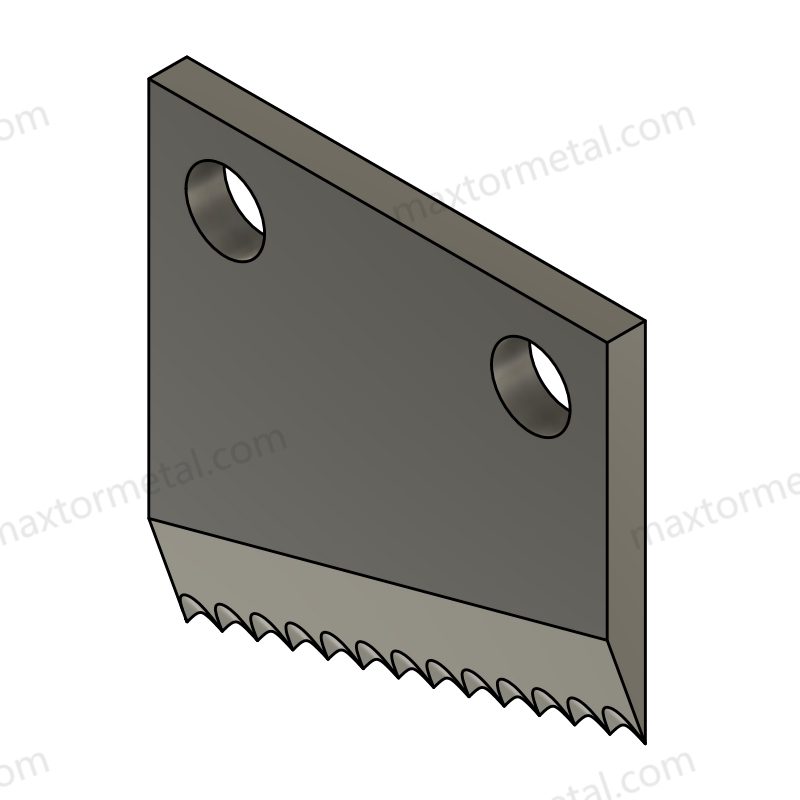

Hygienic Design

Easy Cleaning

Hygienic design is very important in the food industry. Companies pick blade shapes that are easy to clean. Smooth surfaces on perforating blades stop food and dirt from sticking. This helps lower the chance of contamination during food processing. Many companies use stainless steel because it does not rust and is easy to keep clean. Some also use nylon or plastic blades. These do not react with food and help keep things hygienic.

Tip: Clean and check blades often to keep away germs and dirt. Doing this helps keep things clean and makes equipment last longer.

A good hygienic design means there are not many small spaces or corners. Germs cannot hide as easily. Workers can clean these blades faster and better. Companies that do this help keep food safe and meet hygiene rules.

Minimizing Contamination

Stopping contamination is very important in food processing. Perforating blades can cause problems if not made carefully. Manufacturers use nylon, plastics, and titanium to help stop contamination. Plastic and nylon blades do not leave metal pieces in food. This lowers the risk of contamination. Titanium blades fight germs and last longer. This makes them a good choice for keeping things clean.

- कस्टम ब्लेड shapes and materials fit special packaging needs.

- Cleaning and checking blades often removes dirt and germs.

- Smooth, non-reactive surfaces help stop contamination early.

Focusing on hygienic design helps companies control contamination at every step. By picking the right materials and cleaning methods, they keep products safe and protect people’s health.

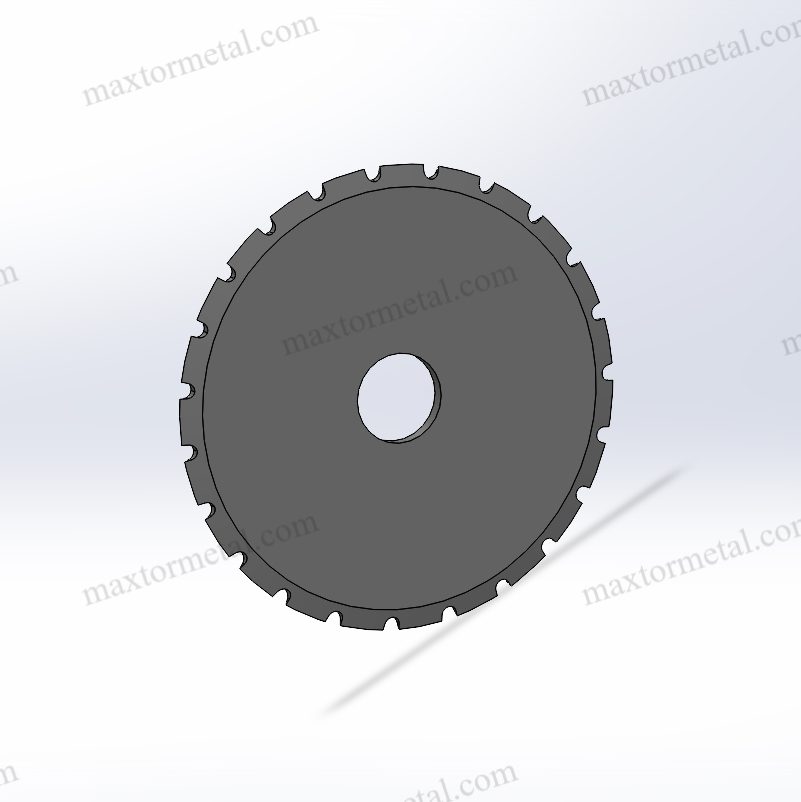

ब्लेड प्रदर्शन

Sharpness and Durability

Sharpness is very important for how well blades work. When blades are sharp, they cut food cleanly and neatly. This helps food look nice and makes less waste. Sharp blades also keep food in good shape, which helps it taste and look better. If blades get dull, they can crush or rip food. This makes it easier for bacteria to get in and grow. That can make food unsafe and lower blade quality.

Blades made from materials that do not rust, like stainless steel, last longer. These materials stop biofilm from building up, which keeps food safe. Companies using high-quality blades have fewer accidents at work. Sharp blades help stop slips and cuts, so the workplace is safer.

Tip: New technology, like smart sensors and machines that sharpen blades, helps keep blades sharp. These tools help workers do more and stop machines from breaking down as much.

निरीक्षण और सफाई

Checking and cleaning blades often helps them work well. Workers should look for damage, dull spots, or wear on blades. Cleaning gets rid of food bits and stops germs from growing. Companies should sharpen blades every week or after a certain number of cuts, depending on the food.

A simple checklist can help workers:

- Look for chips, cracks, or rust on blades.

- Make sure blades still cut cleanly.

- Clean blades with safe cleaners after each use.

- Write down when blades are cleaned and fixed.

| निरीक्षण चरण | उद्देश्य | आवृत्ति |

|---|---|---|

| Visual check | Find damage or wear | दैनिक |

| Sharpness test | Make sure blades cut well | साप्ताहिक |

| सफाई | Remove food and germs | प्रत्येक उपयोग के बाद |

| Maintenance log update | Track safety and blade quality | Every session |

If blades are not cared for, about 30% of food safety problems can happen in factories. By checking and cleaning blades, companies keep food safe and protect people’s health.

Maintenance and Hygiene

नियमित रखरखाव

Taking care of blades is very important in food factories. Workers must follow clear steps to keep perforating blades clean and safe. These steps help stop germs and keep food clean. Companies make a plan for cleaning, checking, and caring for blades. This plan helps keep things clean and makes sure blades work well every day.

The table below shows common blade care jobs in food factories:

| रखरखाव कार्य | आवृत्ति | Purpose/Notes |

|---|---|---|

| सफाई | प्रत्येक उपयोग के बाद | Gets rid of dirt, glue, ink, and stops clogs |

| दृश्य निरीक्षण | दैनिक | Finds damage, dirt, and worn blades |

| माउंटिंग जांच | दैनिक | Makes sure blade is put in right |

| स्नेहन | साप्ताहिक | Lowers rubbing and heat |

| तेज़ करने | जरुरत के अनुसार | Keeps blades cutting well |

| Calibration | महीने के | Makes sure holes are even |

| भंडारण | After use | Keeps blades safe and helps them last longer |

Workers clean blades with gentle cleaners and dry them well to stop rust. They do not use strong chemicals or rough tools so blades stay sharp. Daily checks help find chips, cracks, or other problems early. Lubricating every week helps blades move easily and last longer. Sharpening happens when blades get dull, not just on a set day. Checking and cleaning blade holders helps stop uneven wear and damage.

Tip: Taking care of blades often makes food safer, helps blades last longer, and keeps things clean in food factories.

Replacement Practices

Changing blades at the right time is important for safety and keeping things clean. Workers check blade edges every month to find dull spots, chips, or uneven cuts. Sharpening or changing blades helps cuts stay neat and clean. Cleaning blades and dies every week stops dust from making blades dull. Lubricating moving parts every week helps blades work better and last longer. Checking blade alignment every month stops bad cuts and blade damage.

| रखरखाव कार्य | Reason for Task | अनुशंसित आवृत्ति |

|---|---|---|

| ब्लेड के किनारों का निरीक्षण करें | To find dull spots, chips, or uneven cuts | महीने के |

| Sharpen or replace blades | To keep cuts neat and clean | As needed (after checking) |

| ब्लेड और डाई साफ़ करें | To stop dust from making blades dull | साप्ताहिक |

| गतिशील भागों को लुब्रिकेट करें | To lower rubbing and wear | साप्ताहिक |

| Check blade alignment | To stop bad cuts and blade damage | महीने के |

Workers look for signs that show blades need to be changed:

- Nicks, chips, cracks, or worn edges mean blades should be replaced right away.

- Dull blades make machines get hot and slow down cutting.

- Longer cutting times mean blades are dull and work slower.

- If blades need sharpening or fixing a lot, they are almost worn out.

- Blades that are worn or broken can snap and cause safety problems.

Watching for these signs helps companies keep food clean and safe. Changing blades on time helps keep things clean and lowers the chance of germs. Companies that do these things protect workers and make sure food is good quality.

Note: Good blade care and changing blades when needed helps companies reach safety goals and keep food clean at every step.

Impact on Food Safety

Preventing Contamination

Perforating blades help keep food safe by stopping contamination. Companies pick stainless steel because it does not rust or get dirty easily. Blades with smooth surfaces and round edges are easier to clean. This means less food or dirt sticks to them. If blades can be taken apart, workers can clean every part. This helps stop germs from building up. Workers check, clean, and sharpen blades often to keep them working well.

- Stainless steel blades do not rust or grow biofilm.

- Smooth blades make it easy to wash away food and germs.

- Workers use warm water and gentle soap to clean blades after use.

- Drying blades and storing them in cool places keeps them strong.

- Sharpening and polishing blades stops damage that can hide germs.

Doing these things lowers the chance of germs spreading in food factories. Following world safety rules makes sure blades are clean and safe. These steps help workers do their jobs better and keep food safe.

Ensuring Product Quality

Good perforating blades help make better food packages. These blades make even holes so people can open packages easily. Holes in packages let air move and stop mold from growing. This keeps food fresh for longer.

Blades made from strong materials like tungsten carbide and stainless steel last longer. They work fast and do not break easily. Stainless steel blades do not rust, so they are good for places that need lots of cleaning. This helps keep food clean and safe.

Sharp blades make neat cuts and protect food from damage. If blades are dull or broken, cuts can be messy and unsafe. Good blades keep packages strong and help people trust the food they buy.

Innovations and Trends

Advanced Coatings

New technology has changed how companies use perforating blades. Now, blades can have special coatings like titanium or ceramic. Some blades have non-stick layers too. These coatings help blades last longer and stay sharp. They also make cleaning easier and stop bacteria from sticking. Companies use these coatings to follow food safety rules. Blades with coatings do not rust and keep cutting well for a long time. Workers do not need to sharpen or change them as much. This saves time and money.

- Titanium and ceramic coatings make blades stronger.

- Non-stick layers stop food and germs from sticking.

- Coated blades help keep things clean and need less care.

स्वचालन

Automation makes food processing safer and faster. Some smart blades have sensors that check if they are worn out. These sensors tell workers when to fix or clean blades. Laser cutting makes blades sharper and more exact. Machines can sharpen blades by themselves. This means workers do not have to do as much. These tools help companies keep up with hygiene rules and make fewer mistakes.

- IoT sensors check blade health all the time.

- Laser-made blades cut better and cleaner.

- Machines that sharpen blades save time and keep workers safe.

वहनीयता

Sustainability is now very important for making blades. Companies use metals that can be recycled and last a long time. Tungsten carbide is one of these strong metals. Making blades close to where they are used cuts down on shipping pollution. Some factories use green energy and materials that break down in nature. New ways of making blades, like CNC machines and lasers, make less waste. These steps help companies protect the earth and meet world goals.

- Recyclable and biodegradable materials help cut waste.

- Strong blades last longer and mean less trash.

- Green factories use less energy and make less pollution.

व्यावहारिक सुझाव

आपूर्तिकर्ता चयन

Picking the right supplier helps keep food safe and good. Companies should choose suppliers who give material certificates like ISO 9001. These papers show blades are safe for packaging. Good suppliers follow ANSI B165.1 for safety and ASTM E18 for hardness. They use special heat-treatment and CNC machines to make blades exact. Labs test blades to check hardness and how long edges last. Factory checks help look at quality and tracking systems.

- Pick makers with over five years of work.

- See if the supplier has a big factory and many workers.

- Check if deliveries come on time more than 95% of the time.

- Make sure they do forging, grinding, and coating themselves.

- For custom blades, check if they can make samples and review drawings.

Companies can look at कस्टम ब्लेड for special packaging. Suppliers who test samples and show good results help keep food safe.

Staff Training

Training workers helps them use blades safely and keep things clean. Training teaches workers how to clean, check, and store blades. Workers learn to find dull edges, chips, or cracks. They follow safety steps when changing or sharpening blades. Training updates help staff learn new safety rules and packaging needs. Bosses watch how workers do their jobs and give advice. Trained teams have fewer accidents and make better products.

Tip: Hold safety workshops every month to teach best ways and tell staff about new packaging rules.

Compliance Documentation

Keeping good records helps meet safety and rule needs. Companies write down blade materials, how they are made, and when they are cleaned. Records include checklists, cleaning notes, and blade change history. These papers help track where packaging comes from and show safety rules are met. Auditors look at records during factory visits. Good records help companies fix safety problems or recalls fast.

| Document Type | उद्देश्य | Review Frequency |

|---|---|---|

| Material Certificates | Show blades are safe | Each shipment |

| Inspection Logs | Check blade condition | साप्ताहिक |

| Cleaning Reports | Prove blades are clean | प्रत्येक उपयोग के बाद |

| Replacement Records | Track blade changes | महीने के |

Good records help customers and rule makers trust the company. Companies that care about safety and rules keep their good name and make sure packaging is high quality.

Meeting safety and hygiene rules for perforating blades keeps people safe. It also helps companies do well. Picking the right materials and cleaning blade shapes stops germs. Taking care of blades often helps follow the rules. Using new coatings, machines, and teaching workers makes products better. It also helps work go faster. Learning about new ideas and picking good suppliers keeps blades working well. To get better, companies should check what they do and work with experts.

For special help or advice, talk to a sales engineer यहाँ.

यह भी देखें

प्लास्टिक फिल्म छेदने वाले ब्लेड का अनुकूलन: गति, दबाव और दांत प्रोफ़ाइल मिलान

पैकेजिंग में छिद्रण चाकू का व्यापक रूप से उपयोग क्यों किया जाता है

छेदने वाले ब्लेड चाकू में असमान छेद और असंगत रेखा की लंबाई का निवारण और अनुकूलन