अमूर्त

यह व्यापक मार्गदर्शिका बताती है कि कैसे ताप उपचार प्रक्रियाएं प्रदर्शन, स्थायित्व और काटने की परिशुद्धता में महत्वपूर्ण रूप से सुधार कर सकती हैं रोटरी कतरनी ब्लेडहीट ट्रीटमेंट के महत्व को समझकर और सही तकनीक का चयन करके, निर्माता ब्लेड की आयु बढ़ा सकते हैं और समग्र परिचालन दक्षता को बढ़ा सकते हैं। जानें कि रोटरी शियर ब्लेड के लिए हीट ट्रीटमेंट कैसे अधिक लागत प्रभावी समाधान और औद्योगिक अनुप्रयोगों में उत्पादकता में वृद्धि कर सकता है।

परिचय: ऊष्मा उपचार का महत्व रोटरी कतरनी ब्लेड

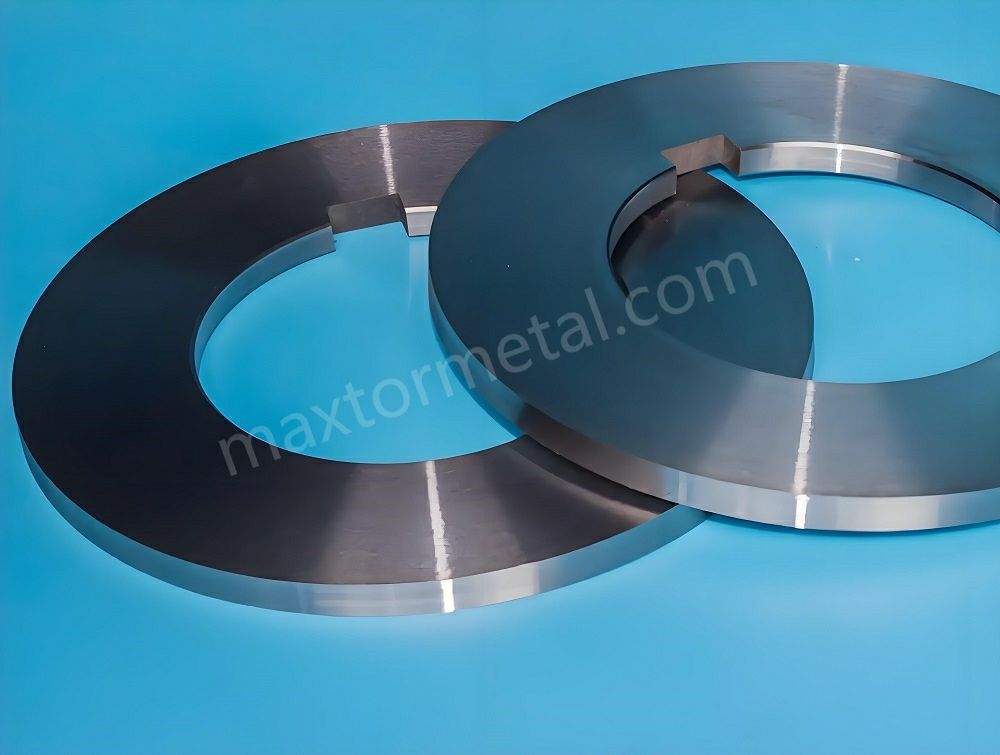

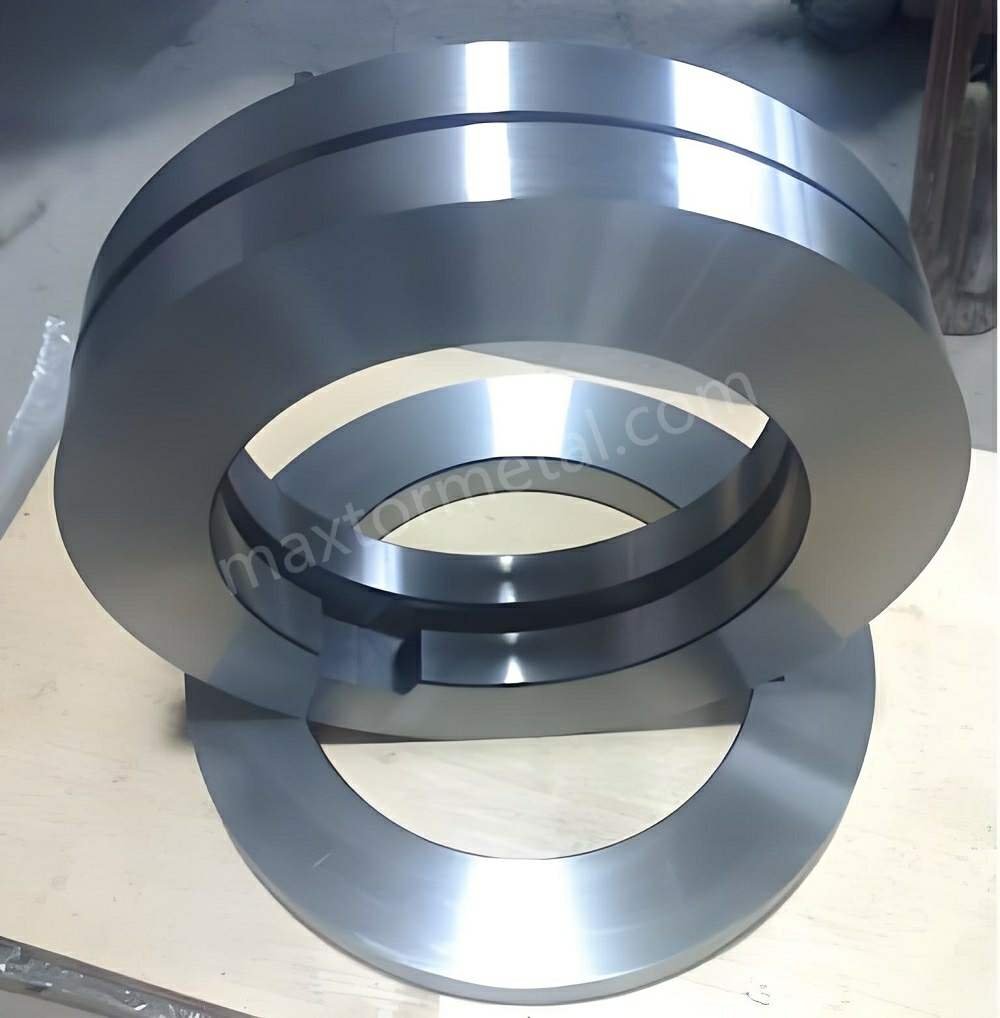

औद्योगिक परिवेश में जहां परिशुद्ध कटाई महत्वपूर्ण है, रोटरी कतरनी ब्लेड गुणवत्ता और दक्षता सुनिश्चित करने में महत्वपूर्ण भूमिका निभाते हैं। ये ब्लेड कई विनिर्माण प्रक्रियाओं का अभिन्न अंग हैं, जैसे कि स्लिटिंग, कटिंग और धातुओं का कतरना, प्लास्टिक और अन्य सामग्री। हालाँकि, समय के साथ, ये ब्लेड अत्यधिक गति, दबाव और घर्षण जैसी चरम स्थितियों के लगातार संपर्क में आने के कारण महत्वपूर्ण रूप से घिस जाते हैं। इस समस्या को हल करने के लिए, उष्मा उपचार ब्लेड के प्रदर्शन को बढ़ाने, उसके जीवनकाल में सुधार करने और काटने की परिशुद्धता बनाए रखने के लिए तकनीकों का उपयोग किया जाता है।

इस गाइड में, हम विभिन्न ताप उपचार प्रक्रियाओं का पता लगाएंगे जिनका उपयोग किया जाता है रोटरी कतरनी ब्लेड, उनके लाभ, और विभिन्न अनुप्रयोगों के लिए सर्वोत्तम विधि का चयन कैसे करें। इस लेख के अंत तक, आप समझ जाएँगे कि उच्च-प्रदर्शन प्राप्त करने के लिए ऊष्मा उपचार क्यों आवश्यक है रोटरी कटिंग ब्लेड जो समय की कसौटी पर खरे उतरते हैं।

रोटरी कटिंग ब्लेड हीट ट्रीटमेंट क्या है?

ताप उपचार एक नियंत्रित प्रक्रिया है जिसका उपयोग किसी सामग्री, विशेष रूप से धातु के भौतिक और यांत्रिक गुणों को बदलने के लिए किया जाता है। रोटरी कतरनी ब्लेडगर्मी उपचार का उद्देश्य कठोरता, स्थायित्व और पहनने के प्रतिरोध को बढ़ाना है। यह ब्लेड को उच्च तापमान के अधीन करके और फिर वांछित विशेषताओं को प्राप्त करने के लिए उन्हें एक विशिष्ट तरीके से ठंडा करके प्राप्त किया जाता है।

रोटरी कटिंग ब्लेड के लिए प्रमुख ताप उपचार विधियाँ

- एनीलिंग

एनीलिंग का उपयोग नरम करने के लिए किया जाता है रोटरी कतरनी ब्लेड और उनकी मशीनिंग क्षमता में सुधार होता है। इस प्रक्रिया में ब्लेड को एक निश्चित तापमान तक गर्म करना और फिर धीरे-धीरे ठंडा करना शामिल है, जिससे धातु की आंतरिक संरचना अधिक लचीली हो जाती है और उसमें दरार पड़ने की संभावना कम हो जाती है। औद्योगिक कतरनी ब्लेडउन्हें मशीन में आसानी से संसाधित करने और आगामी उपचारों के लिए तैयार करने के लिए आमतौर पर एनीलिंग किया जाता है। - शमन (सख्त करना)

कठोरीकरण किसी पदार्थ को गर्म करने की प्रक्रिया है। काटने वाला ब्लेड उच्च तापमान पर ले जाकर और फिर इसे तेजी से ठंडा करके, आमतौर पर इसे पानी या तेल में डुबोकर। इस प्रक्रिया से ब्लेड की कठोरता में उल्लेखनीय वृद्धि होती है, जिससे यह संचालन के दौरान टूट-फूट के प्रति अधिक प्रतिरोधी हो जाता है। रोटरी कटिंग ब्लेड शमन के अधीन ये उच्चतर तनाव को झेलने में सक्षम होते हैं तथा इनका स्थायित्व बेहतर होता है। - टेम्परिंग

सख्त होने के बाद, ब्लेड अक्सर बहुत भंगुर हो जाता है, यही कारण है कि टेम्परिंग आवश्यक है। टेम्परिंग में ब्लेड को गर्म करना शामिल है। रोटरी कतरनी ब्लेड कम तापमान पर रखें और फिर इसे धीरे-धीरे ठंडा होने दें। इससे आंतरिक तनाव और भंगुरता कम हो जाती है जबकि कठोरता का उच्च स्तर बना रहता है। उचित टेम्परिंग सुनिश्चित करती है कि रोटरी कटिंग ब्लेड वे फ्रैक्चर होने की संभावना के बिना अपनी काटने की क्षमता को बनाए रखते हैं। - carburizing

कार्बराइजिंग सतह को सख्त करने का एक प्रकार है जिसमें सतह की बाहरी परत में कार्बन मिलाया जाता है। रोटरी कतरनी ब्लेड इसकी कठोरता को बढ़ाने के लिए, जबकि कोर को अधिक लचीला बनाए रखना होता है। इस प्रक्रिया का उपयोग आम तौर पर उन अनुप्रयोगों के लिए किया जाता है, जिनमें ब्लेड के किनारे को घर्षण और प्रभाव के लिए विशेष रूप से प्रतिरोधी होना आवश्यक होता है। - nitriding

नाइट्राइडिंग एक अन्य सतह सख्तीकरण प्रक्रिया है जिसमें नाइट्रोजन को सतह में डाला जाता है। काटने वाला ब्लेडयह प्रक्रिया ब्लेड की कोर की मजबूती को बनाए रखते हुए एक कठोर, घिसाव प्रतिरोधी सतह बनाती है। Metal कतरनी ब्लेड नाइट्राइडिंग से उपचारित ये धातुएं संक्षारण और घिसाव के प्रति अत्यधिक प्रतिरोधी होती हैं, जिससे ये चुनौतीपूर्ण वातावरण के लिए आदर्श होती हैं।

The ताप उपचार के लाभ रोटरी कतरनी ब्लेड के लिए

ताप उपचार से प्रदर्शन में सुधार होता है रोटरी कतरनी ब्लेड कठोरता, स्थायित्व, पहनने के प्रतिरोध और काटने की सटीकता सहित कई प्रमुख क्षेत्रों में। आइए गर्मी उपचार से औद्योगिक क्षेत्र में मिलने वाले विशिष्ट लाभों पर करीब से नज़र डालें काटने वाले ब्लेड.

1. बेहतर कठोरता और घिसाव प्रतिरोध

कठोरता सबसे महत्वपूर्ण गुणों में से एक है Metal कतरनी ब्लेड क्योंकि इनका उपयोग अक्सर उच्च गति, उच्च प्रभाव वाले कटिंग अनुप्रयोगों में किया जाता है। शमन और कार्बराइजिंग जैसी ऊष्मा उपचार विधियाँ ब्लेड की कठोरता को बढ़ाती हैं, जिससे यह एक तेज धार बनाए रखने और बिना खराब हुए लंबे समय तक उपयोग को झेलने में सक्षम होती है। यह बढ़ी हुई कठोरता ब्लेड को घिसाव के प्रति अधिक प्रतिरोधी बनाती है और धार लगाने की आवृत्ति को कम करती है, जिससे रखरखाव की लागत कम होती है।

2. बेहतर स्थायित्व और लंबी सेवा अवधि

बढ़ी हुई कठोरता और पहनने के प्रतिरोध के साथ, गर्मी से उपचारित रोटरी कतरनी ब्लेड बिना उपचारित ब्लेड की तुलना में इनकी सेवा अवधि बहुत लंबी होती है। इसका मतलब है कि ब्लेड को कम बार बदलना पड़ता है और उपकरणों के लिए डाउनटाइम कम होता है। हीट-ट्रीटेड में निवेश करके रोटरी कटिंग ब्लेड, निर्माता परिचालन लागत को कम कर सकते हैं और अपनी उत्पादन लाइनों की समग्र दक्षता में सुधार कर सकते हैं।

3. कटिंग की सटीकता बनाए रखना

धातुकर्म, पैकेजिंग और कागज़ उत्पादन जैसे उद्योगों में सटीक कटिंग आवश्यक है। टेम्परिंग और नाइट्राइडिंग जैसी हीट ट्रीटमेंट विधियाँ भारी-भरकम कामों के दौरान विरूपण की संभावनाओं को कम करके ब्लेड की कटिंग सटीकता को बनाए रखने में मदद करती हैं। उचित रूप से हीट-ट्रीटेड रोटरी कतरनी ब्लेड इससे अधिक स्वच्छ, अधिक सटीक कटौती हो सकती है, जिससे तैयार उत्पाद की गुणवत्ता में सुधार हो सकता है।

4. संक्षारण और थकान के प्रति प्रतिरोध में वृद्धि

कुछ खास वातावरणों में इस्तेमाल किए जाने वाले ब्लेड, जैसे नमी या संक्षारक पदार्थों के संपर्क में आने वाले ब्लेड, जंग और क्षरण के प्रतिरोधी होने चाहिए। नाइट्राइडिंग और कार्बराइजिंग जैसी हीट ट्रीटमेंट विधियाँ बेहतर बनाती हैं रोटरी कतरनी ब्लेड जंग का प्रतिरोध करने की क्षमता। इसके अतिरिक्त, गर्मी उपचार प्रक्रिया थकान और दरार के जोखिम को कम करती है, जिससे यह सुनिश्चित होता है कि ब्लेड चरम स्थितियों में भी प्रभावी बना रहे।

रोटरी शियर ब्लेड के लिए सही ताप उपचार प्रक्रिया का चयन

अपने लिए उपयुक्त ताप उपचार विधि का चयन करना रोटरी कतरनी ब्लेड ब्लेड की सामग्री, इच्छित अनुप्रयोग और विशिष्ट प्रदर्शन आवश्यकताओं सहित कई कारकों पर निर्भर करता है। आपके ब्लेड के लिए सर्वोत्तम हीट ट्रीटमेंट प्रक्रिया का चयन करने के लिए नीचे कुछ दिशानिर्देश दिए गए हैं:

1. ब्लेड की सामग्री पर विचार करें

विभिन्न सामग्रियाँ ऊष्मा उपचार प्रक्रियाओं पर अलग-अलग तरह से प्रतिक्रिया करती हैं। उदाहरण के लिए, उच्च कार्बन स्टील्स और औजार स्टील्स आम तौर पर वांछित कठोरता प्राप्त करने के लिए शमन और तड़के से गुजरना पड़ता है, जबकि स्टेनलेस स्टील्स नाइट्राइडिंग से सतह की कठोरता को बढ़ाने में मदद मिल सकती है, बिना उनके संक्षारण प्रतिरोध से समझौता किए। हीट ट्रीटमेंट विधि का चयन करते समय, इष्टतम प्रक्रिया निर्धारित करने के लिए ब्लेड की सामग्री संरचना को समझना आवश्यक है।

2. आवेदन और प्रदर्शन आवश्यकताओं को समझें

आपके प्रदर्शन की आवश्यकताएं रोटरी कतरनी ब्लेड हीट ट्रीटमेंट प्रक्रिया के चयन में मार्गदर्शन करना चाहिए। उच्च घिसाव प्रतिरोध की आवश्यकता वाले अनुप्रयोगों के लिए, कार्बराइजिंग या नाइट्राइडिंग आदर्श हो सकते हैं। यदि आपको ऐसे ब्लेड चाहिए जो बिना दरार के उच्च प्रभाव को झेल सकें, तो टेम्परिंग आवश्यक हो सकती है। हीट ट्रीटमेंट विशेषज्ञ के साथ काम करना आवश्यक है जो आपकी विशिष्ट आवश्यकताओं का आकलन कर सके और सर्वोत्तम समाधान सुझा सके।

3. लागत बनाम लाभ का मूल्यांकन करें

जबकि गर्मी उपचार से प्रदर्शन में काफी सुधार होता है रोटरी कटिंग ब्लेड, प्रक्रिया की लागत-प्रभावशीलता का मूल्यांकन करना महत्वपूर्ण है। कार्बराइजिंग और नाइट्राइडिंग जैसे अधिक उन्नत ताप उपचार विधियों में उच्च लागत लग सकती है, लेकिन वे मांग वाले अनुप्रयोगों में महत्वपूर्ण प्रदर्शन लाभ प्रदान करते हैं। ताप उपचार की लागत और विस्तारित ब्लेड जीवन और बेहतर उत्पादकता से संभावित बचत के बीच व्यापार-बंद पर विचार करें।

केस स्टडी: रोटरी कटिंग ब्लेड के प्रदर्शन पर हीट ट्रीटमेंट का प्रभाव

आइये ऊष्मा उपचार के प्रभाव को स्पष्ट करने के लिए एक वास्तविक उदाहरण पर नजर डालें। रोटरी कतरनी ब्लेड प्रदर्शन। धातु कतरनी सुविधा में, कंपनी ने मानक, अनुपचारित का उपयोग करने से स्विच किया काटने वाले ब्लेड गर्मी से उपचारित रोटरी कतरनी ब्लेडपरिणाम महत्वपूर्ण थे:

- ताप-उपचारित ब्लेड, अनुपचारित ब्लेड की तुलना में 40% अधिक समय तक चले।

- टूट-फूट के कारण ब्लेड की विफलता में 30% की कमी आई।

- 20% से रखरखाव लागत कम हो गई, क्योंकि ब्लेड को कम बार तेज करने की आवश्यकता पड़ती थी।

यह मामला दर्शाता है कि उच्च गुणवत्ता वाले ताप उपचार प्रक्रियाओं में निवेश करना रोटरी कतरनी ब्लेड इसके परिणामस्वरूप दीर्घकालिक बचत और परिचालन दक्षता में सुधार हो सकता है।

का चयन सही आपूर्तिकर्ता गर्मी उपचार के लिए Metal कतरनी ब्लेड

आपूर्तिकर्ता का चयन करते समय रोटरी कतरनी ब्लेड और हीट ट्रीटमेंट सेवाओं के लिए, इस क्षेत्र में सिद्ध विशेषज्ञता वाली कंपनी को चुनना महत्वपूर्ण है। आपूर्तिकर्ता का चयन करते समय विचार करने के लिए कुछ प्रमुख कारक इस प्रकार हैं:

1. अनुभव और विशेषज्ञता

उच्च गुणवत्ता वाले उत्पादन का मजबूत ट्रैक रिकॉर्ड रखने वाले आपूर्तिकर्ता की तलाश करें Metal कतरनी ब्लेड और उन्नत ताप उपचार सेवाएँ प्रदान करना। अनुभवी आपूर्तिकर्ता विभिन्न ताप उपचार विधियों की बारीकियों को समझते हैं और आपकी विशिष्ट आवश्यकताओं के लिए सर्वोत्तम समाधान की सिफारिश कर सकते हैं।

2. गुणवत्ता आश्वासन

सुनिश्चित करें कि आपूर्तिकर्ता उद्योग मानकों का पालन करता है और अपने उत्पादों के लिए गुणवत्ता आश्वासन प्रदान करता है। रोटरी कतरनी ब्लेडएक विश्वसनीय आपूर्तिकर्ता को ताप उपचार प्रक्रिया और परिणामी ब्लेड गुणों के संबंध में दस्तावेज उपलब्ध कराने में सक्षम होना चाहिए।

3. ग्राहक सहायता और परामर्श

एक ऐसा आपूर्तिकर्ता चुनें जो उत्कृष्ट ग्राहक सहायता प्रदान करता हो और आपके अनुप्रयोगों के लिए सर्वोत्तम विकल्पों पर आपसे परामर्श करने के लिए तैयार हो। एक जानकार आपूर्तिकर्ता आपको इस बारे में सूचित निर्णय लेने में मदद कर सकता है कि कौन सी ऊष्मा उपचार विधियाँ आपके लिए सर्वोत्तम परिणाम देंगी रोटरी कटिंग ब्लेड.

निष्कर्ष: रोटरी शियर ब्लेड के प्रदर्शन को बढ़ाने के लिए हीट ट्रीटमेंट महत्वपूर्ण है

निष्कर्ष के तौर पर, रोटरी कतरनी ब्लेड कई औद्योगिक कटिंग अनुप्रयोगों में एक महत्वपूर्ण घटक हैं, और इन ब्लेडों की प्रभावशीलता को गर्मी उपचार के माध्यम से काफी हद तक सुधारा जा सकता है। शमन, टेम्परिंग और नाइट्राइडिंग जैसी सही गर्मी उपचार तकनीकों को लागू करके, निर्माता अपने ब्लेड की कठोरता, स्थायित्व और काटने की सटीकता को बढ़ा सकते हैं, जिसके परिणामस्वरूप लंबी सेवा जीवन और कम परिचालन लागत होती है।

सर्वोत्तम परिणाम सुनिश्चित करने के लिए, अपनी विशिष्ट आवश्यकताओं के लिए सही हीट ट्रीटमेंट विधि चुनना और एक प्रतिष्ठित आपूर्तिकर्ता के साथ काम करना आवश्यक है जो हीट ट्रीटमेंट प्रक्रियाओं की जटिलताओं को समझता हो। हीट ट्रीटमेंट आपके प्रदर्शन को कैसे बेहतर बना सकता है, इस बारे में अधिक जानकारी के लिए रोटरी कतरनी ब्लेड, हमसे संपर्क करें आज परामर्श के लिए आइये।