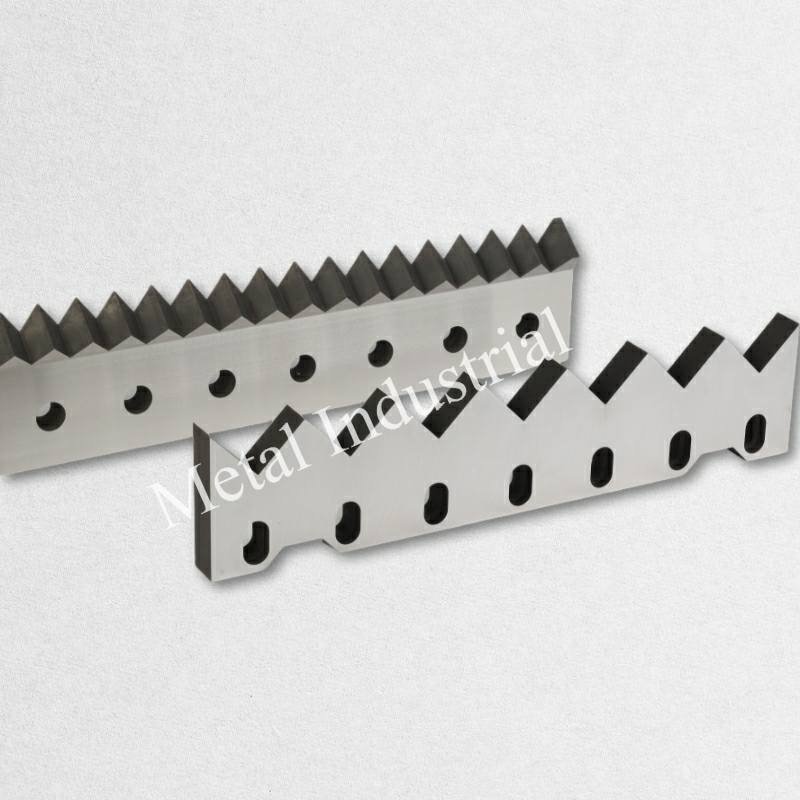

एकल शाफ्ट श्रेडर ब्लेड are important in shredding work. Blade design helps machines work better and last longer. These blades are used for tough jobs. When you shred big things like metal or plastic, hook-shaped blades grab and rip them apart. This makes shredding work well. The blade material helps blades stay sharp and strong. They do not break easily under pressure. Many companies want custom blades to fit their needs. They choose OEM or ODM options. Good quality control gives steady results. It helps with recycling and waste management goals.

चाबी छीनना

- Single shaft shredder blades are very important for waste processing. They help break down things like plastic, metal, and rubber into small pieces.

- Picking the right blade design is very important. Straight, serrated, and R-shaped edges work best for different materials.

- Custom blades can be made for special shredding needs. OEM options let you choose the size, shape, and material you want.

- Taking care of blades helps them last longer. Check blades every week for damage. Clean them after you use them. Sharpen them once a month.

- The material you pick changes how well blades work. Tool steels last a long time. Carbide-tipped blades are best for hard jobs.

- Putting blades in the right way keeps things safe and works better. Always follow the maker’s rules. Do safety checks after you put blades in.

- Training workers on safe shredding helps stop accidents. Teach them to check blades and spot signs of wear.

- Having a maintenance plan stops breakdowns. Plan to check, clean, and sharpen blades often. This keeps your shredder working well.

Single Shaft Shredder Blades Overview

Blade Function

Single shaft shredder blades help break down many kinds of waste. These blades cut, tear, and slice things into smaller pieces. You can find them in plastic recycling, wood processing, and metal recycling. They are also used for rubber and tire recycling, electronic waste recycling, and textile and fiber recycling.

- Plastic Recycling: Turns plastic waste into new products.

- Wood Processing: Changes wood waste into chips or mulch.

- Metal Recycling: Cuts metal scraps for easier handling and recycling.

- Rubber and Tire Recycling: Breaks tires into small pieces for reuse.

- Electronic Waste Recycling: Takes apart e-waste for material recovery.

- Textile and Fiber Recycling: Cuts fabric waste for making new textiles.

Single shaft shredder blades make waste easier to move and store. Picking the right blade for your job helps your recycling work go faster.

Design Principles

Blade design changes how well your shredder works. The shape, thickness, and edge style all matter. Straight blades give clean cuts for soft things. Serrated blades grip and cut tough or stringy items. R-shaped blades pull big or stretchy waste inside. You need to match the blade to your shredder and the material you use. This gives you better results and longer blade life.

Nanjing Metal Industrial makes blades with special forging and heat treatment. You get strong materials and careful machining. These things help blades stay sharp and last longer, even with hard jobs.

Tip: Always look at your shredder’s manual before picking new blades. The right blade keeps your machine safe and working well.

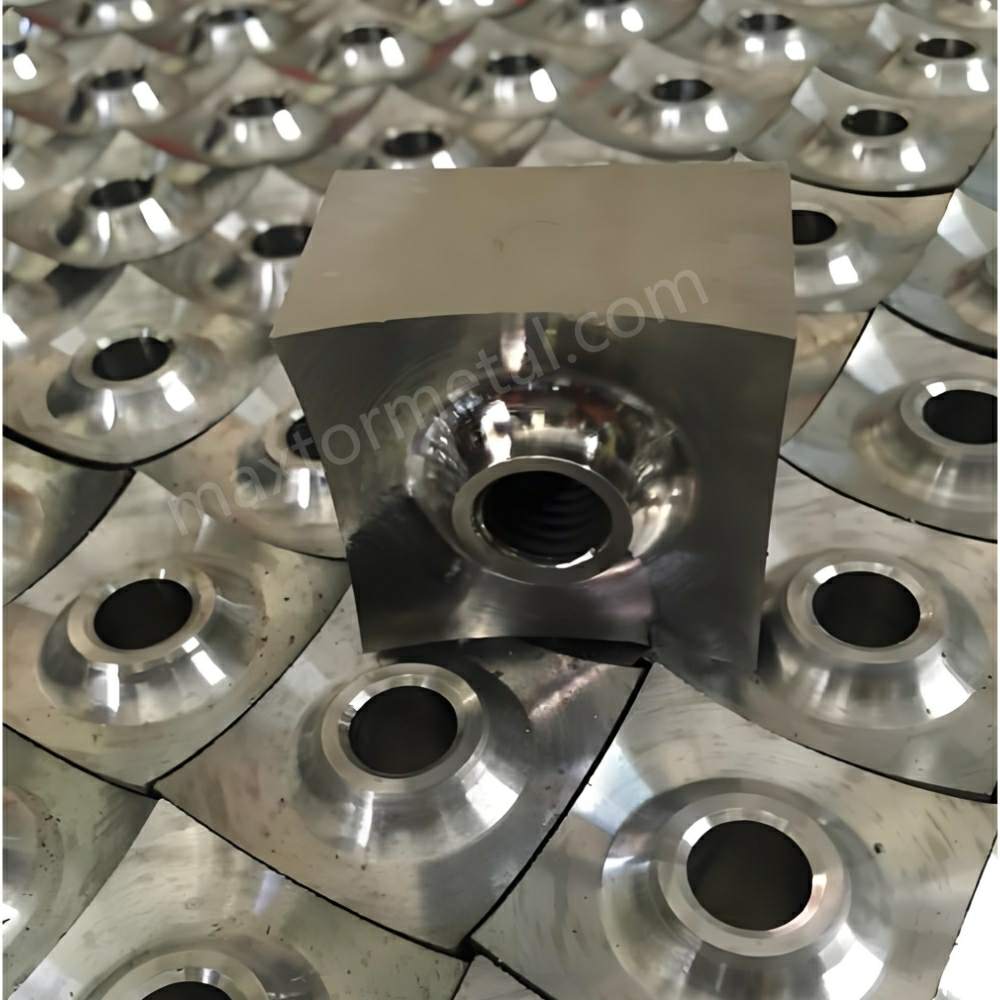

OEM Adaptation

Sometimes you need blades made just for your job. OEM adaptation lets you pick the size, shape, and material you want. Nanjing Metal Industrial has choices for single-shaft and multi-shaft shredder blades. You can talk to their team to make blades that fit your machine and job.

| विशेषता | फ़ायदा |

|---|---|

| Manufacturing to OEM specs | Makes sure blades fit and work their best |

| Advanced materials | Blades last longer and resist wearing out |

| Innovative designs | Shredding works better and faster |

| 50 years of expertise | Your shredder works longer with less downtime |

| Modern alloys | Blades are extra strong and work really well |

If you want blades made just for you, check out कस्टम ब्लेड for more ideas. Custom blades help you fix special shredding problems and keep your work going smoothly.

Shredder Blade Design Features

When you look at shredder blade design, you see that the edge style, structure, and how it is made are very important. These things help your machine work well with different materials. They help you get good results when you process waste.

एज शैलियाँ

The edge style of a blade changes how it cuts things. There are three main types: straight, serrated, and R-shaped. Each type works best for certain jobs.

सीधा

A straight edge is flat and smooth. This kind of blade gives even force across its surface. Straight edges are good for soft things like plastics, textiles, and paper. They are easy to sharpen and make clean cuts. They last a long time when used for easy jobs.

दाँतेदार

Serrated edges look like a saw with small teeth. This style helps the blade grip and cut better. Serrated blades are good for tough or stringy things like rubber, wood, and some metals. They stop things from slipping and help you shred hard waste. The jagged edge makes it easier to cut things that might slide past a straight blade.

R-Shaped

R-shaped blades have a curved or hook-like edge. This shape pulls material inside as it shreds. R-shaped blades are used for big or stretchy things like tires, cables, and mixed waste. They grab and tear, which helps stop jams and makes shredding faster. The hook shape helps with large or stretchy items.

Performance Comparison in Plastic vs. Metal Shredding

When you compare these edge styles, you see different results for plastics and metals. Straight edges make clean cuts in plastics but can wear out faster on metals. Serrated edges grip and cut both plastics and metals, especially if the material is tough or layered. R-shaped edges are best for big plastics and stretchy metals, helping you feed material smoothly and avoid clogs.

Small machines sometimes use double-edge or triple-edge blades. How you set up these blades, like in a V-shape or spiral, changes how fast they wear out and how much they can shred. Double-edge blades in a V-pattern can wear more on some blades. Triple-edge blades in a spiral can shred more material at once.

Blade Structure

The way your blade is built affects its strength and how long it lasts. You want a blade that stays strong under heavy loads and does not bend or break. Makers use good materials and smart designs to make this happen.

| सामग्री का प्रकार | गुण |

|---|---|

| High-strength cast iron | Excellent rigidity and stability |

| Steel | Withstands cutting forces and vibrations |

- Good materials help blades last longer.

- The shaft design keeps the blade steady.

- The shredder’s build supports the blade during hard jobs.

Some blades have concave or curved edges. These shapes help the blade grab and cut bulky or odd-shaped waste better.

Precision Machining

Precision machining makes sure blades have the right shape, size, and hardness. Makers use forging, CNC machines, and heat treatment to make blades that work well and last longer.

| तकनीक | विवरण |

|---|---|

| सीएनसी मशीनिंग | Makes sure blades are the right size and sharp. |

| लोहारी | Makes blades stronger and last longer. |

| उष्मा उपचार | Makes blades harder and tougher. |

Forging makes the blade’s structure better and stronger. Heat treatment, like triple tempering and vacuum steps, keeps the blade hard (HRC56-58) and tough for hard jobs. Makers use strong materials like SKD11, HSS, and 9CRSI to make blades last longer. Special machines help keep the blade the right size and sharpness.

Every blade is checked for quality. Tests for hardness, size, and surface finish make sure you get a good blade. Many makers follow rules like ISO 9001 for quality, CE Marking for safety, and ANSI B7.1 for safe use.

| प्रमाणीकरण | Issuing Authority | उद्देश्य | Relevance to Machine Blades |

|---|---|---|---|

| आईएसओ 9001 | International Organization for Standardization | Quality Management Systems | Makes sure blades are made well every time |

| CE Marking | European Union | Product Safety | Shows blades meet EU safety rules |

| ANSI B7.1 | American National Standards Institute | Safety Standards for Abrasive Wheels | Gives safety rules for using machine blades |

Tip: When you pick single shaft shredder blades, check that the maker uses good forging, heat treatment, and precision machining. This helps your shredder blade work its best and keeps your waste processing easy.

Materials for Single-Shaft Shredder Blades

When you pick single shaft shredder blades, you should think about what they are made of. The right material makes blades last longer and work better. Nanjing Metal Industrial uses strong materials for their blades. This helps the blades stay tough and reliable.

Tool Steels

Tool steels are a common choice for shredder blades. They are very hard and do not wear out fast. Many shredders use these steels in factories.

उपयुक्त अनुप्रयोग

Tool steels are good for shredding plastics, metals, cables, and rubber. These blades are sharp and last a long time, even with hard jobs.

- D2 and SKD-11: Good for metal, plastic, and cable shredding.

- High-Speed Steel (HSS): Best for cutting with high accuracy.

- Cold Work Die Steels (9CrSi): Good for cables and some metals.

Here is a table that shows tool steels and how hard they are:

| टूल स्टील प्रकार | विशेषताएँ | Typical Hardness Rating |

|---|---|---|

| उच्च कार्बन स्टील | Very hard and does not wear out fast, good for soft things like plastic and rubber. | Varies, generally high |

| Alloy Tool Steel (D2) | Tough, hard, and does not wear out fast, good for hard things. | High (around 58-62 HRC) |

| हाई-स्पीड स्टील (एचएसएस) | Cuts really well, can handle heat and heavy work. | Very high (up to 65 HRC) |

| Cold Work Die Steels | Good mix of price and wear for some jobs like cables. | मध्यम से उच्च |

फायदे और नुकसान

Tool steels are great because they do not wear out fast and are very exact. You can use them for many jobs. They are good for recycling because they stay sharp.

| सामग्री का प्रकार | लाभ | नुकसान |

|---|---|---|

| Tool Steels | Do not wear out fast, Very exact, Can be used for many jobs | Can break easily, Cost more, Need special heat treatment |

These blades last a long time, but they can break if hit too hard. Tool steels cost more and need special heat treatment.

Alloy Steels

Alloy steels are another good pick for shredder blades. You find these blades in big shredders that cut up large or mixed waste.

उपयुक्त अनुप्रयोग

Alloy steels are good for shredding mixed waste, big scraps, and things that need to handle hard hits. These blades are strong and do not break easily.

- CrMo variants: Good for heavy hits and mixed waste.

- H13: Good for jobs with lots of hits or heat.

Here is a table that shows alloy steels and what they are good at:

| Material Category | Common Examples | Key Strength(s) | Potential Weakness(es) | Typical Use Case |

|---|---|---|---|---|

| औजारों का स्टील | D2, SKD-11 | Does not wear out fast, Hard | Not as tough | Metal, Plastic, Cable |

| औजारों का स्टील | एच13 | Tough, Handles heat | जल्दी खराब हो जाता है | Jobs with hits, Hot jobs |

| अलॉय स्टील | CrMo variants | Very tough, Handles hard hits | जल्दी खराब हो जाता है | Mixed waste, Heavy hits |

| उच्च गति स्टील | M-series, T-series | Stays sharp, Hard | Costs more, Can break | Cutting with accuracy, Granulators |

| Cold Work Die Steel | 9CrSi | Wears out slowly, Good price | Needs good heat treatment | Cable jobs, Some metals |

फायदे और नुकसान

Alloy steels are very hard, strong, and tough. They do not rust easily and can handle heat.

| सामग्री का प्रकार | लाभ | नुकसान |

|---|---|---|

| Alloy Steels | Very hard, Strong and tough, Do not rust, Handle heat | Cost more, Need more care |

You may need to take care of these blades more often. They cost more, but they are strong for hard jobs.

Carbide-Tipped

Carbide-tipped blades are the best for really hard jobs. You use these blades when you need them to be super hard and not wear out.

उपयुक्त अनुप्रयोग

Carbide-tipped blades are good for shredding hard things like metal, rubber, and tough plastics. These blades work well in machines that run a lot.

- Cuts hard things with less damage.

- Works best in shredders that run for a long time.

फायदे और नुकसान

Carbide-tipped blades are very hard and can take hard hits. They stay sharp for a long time and do not need to be changed often.

| सामग्री का प्रकार | लाभ | नुकसान |

|---|---|---|

| कार्बाइड-टिप वाले ब्लेड | Super hard, Do not wear out, Can take hard hits, Handle heat | Cost more, Hard to fix, Can break |

You do not have to fix these blades often because they last longer. They work well in tough jobs, but they can break and cost more.

Tip: The material you pick for your shredder blades changes how often you need new blades and how well your shredder works. Good materials help you save time and money when you recycle.

सामग्री चयन

Picking the right material for your single shaft shredder blade is important. The right blade material helps your shredder work better and last longer. You want blades that cut well and save money over time. Each material has good and bad points. You should match the blade material to the waste you shred and your work needs.

You can see how different materials work and cost in this table:

| सामग्री | पेशेवरों | दोष | अनुप्रयोग |

|---|---|---|---|

| उच्च कार्बन इस्पात | Very hard, not expensive, good for most waste | Rusts easily, needs more care | Best for wood and plastic |

| अलॉय स्टील | Wears out slowly, does not rust much | Costs more, but lasts longer | Good for metals and hard plastics |

High-carbon steel blades are good for shredding wood, plastic, and soft things. They are hard and not costly. But they can rust and wear out fast, so you need to take care of them. If you shred mostly soft waste, high-carbon steel is a smart choice.

Alloy steel blades are stronger for harder jobs. They do not wear out or rust as fast because of special metals inside. These blades cost more, but you do not need to replace them often. If you shred metal or hard plastic, alloy steel blades help your shredder last longer.

Tip: Think about what kind of waste you shred the most. If you shred tough or mixed waste, alloy steel blades can save you money because they last longer.

You should also think about how much you use your shredder and how much waste you have. If you use your shredder a lot, strong blades like advanced alloys or carbide tips are best. These blades stay sharp and do not wear out quickly.

Some blades need to be sharpened and cleaned often. Others stay sharp longer and need less care. Picking the right blade material helps you save money in the long run.

Single shaft shredder blade designs need strong and tough materials to work well. If you pick the right material, your shredder works better and costs less to run. Always choose the blade material that fits your shredding job for the best results.

Types of Single Shaft Shredder Blades

Flat

संरचना विशेषताएँ

Flat blades are shaped like rectangles. They have a straight edge for cutting. The surface is smooth and flat. These blades fit tightly on the shredder shaft. The wide edge touches a lot of the material. Flat blades come in many sizes and thicknesses.

Suitable Materials

Flat blades work well with soft and medium-hard things. You can use them for plastics, paper, textiles, and some wood. They are best when you want straight, clean cuts.

फायदे और नुकसान

| लाभ | नुकसान |

|---|---|

| Easy to sharpen | Not good for tough waste |

| Simple to put on | Wears out faster on hard stuff |

| Makes clean cuts | May slip on stretchy things |

Flat blades work well for many jobs. You can sharpen them fast. They do not work as well with very tough or stretchy things.

विशिष्ट अनुप्रयोग

- Shredding plastic for recycling

- Cutting paper and cardboard

- Cutting fabric and fibers

- Chipping light wood

Tip: Pick flat blades if you want easy care and clean cuts with soft things.

Hook

संरचना विशेषताएँ

Hook blades have a curved or hook-shaped edge. The hook helps pull things into the shredder. The blade looks like a claw or bent finger. It has a thick base that holds the hook. This shape gives more power when shredding.

Suitable Materials

Hook blades are good for big, stretchy, or tough things. You can use them for tires, cables, rubber, and mixed waste. The hook shape stops jams and keeps things moving.

फायदे और नुकसान

| लाभ | नुकसान |

|---|---|

| Pulls in big items | Harder to make |

| Stops clogging | Not great for soft things |

| Works well with stretchy stuff | Can cost more |

Hook blades help shred large or stretchy things. They keep the shredder working well. These blades may cost more, but they work better for hard jobs.

विशिष्ट अनुप्रयोग

- Shredding tires and rubber

- Cutting cables and wires

- Handling mixed waste

- Breaking down big plastic items

Note: Hook blades are good for big or stretchy things and help stop jams.

Concave

संरचना विशेषताएँ

Concave blades have an edge that curves inward. The middle dips down like a shallow bowl. This shape touches more of the material. Concave blades often have strong edges for extra power.

Suitable Materials

Concave blades are used for hard, thick, or odd-shaped things. You can use them for metals, thick plastics, and heavy wood. The curved edge helps grip and cut tough things.

फायदे और नुकसान

| लाभ | नुकसान |

|---|---|

| Grips odd shapes well | Harder to sharpen |

| Cuts thick or hard things | May need special fitting |

| Stops slipping during shredding | Can be heavier |

Concave blades help control hard or weird-shaped things. They stop slipping and cut better. You might need special tools to sharpen or put them on.

विशिष्ट अनुप्रयोग

- Shredding metal scraps

- Cutting hard plastics

- Processing wood blocks

- Handling industrial waste

Tip: Use concave blades for extra grip and power with tough or uneven things.

Custom/OEM

संरचना विशेषताएँ

Custom and OEM blades help you fix special shredding problems. You can pick the blade’s size, shape, and edge style. Some blades have grooves or hooks. Some have a knife you can swap out. This lets you change old parts fast. Your shredder works longer without stopping. You can also choose how hard and thick the blade is. This helps match your machine and the stuff you shred.

Suitable Materials

Custom or OEM blades work with almost any material. These blades are good for:

- All kinds of plastics

- Rubber and tires

- Metals like aluminum and steel

- Textiles and leather

- Wood and paper

- Electronic waste

Custom blades fit your needs. They work for recycling, making things, or other jobs.

फायदे और नुकसान

Custom and OEM blades have many good points:

- They fit your machine perfectly.

- They handle special shapes or materials.

- They make shredding faster and better.

- They cut downtime with easy-to-change knives.

But there are some things to think about:

- Custom blades take more time to make.

- Special features can cost extra money.

Note: Custom blades fix problems that regular blades cannot. They are smart when you need something special.

विशिष्ट अनुप्रयोग

Custom and OEM blades are used in many jobs. Here is a table that shows how different industries use these blades:

| आवेदन क्षेत्र | विवरण |

|---|---|

| विशेष पैकेजिंग | Custom blades help packaging work go faster and cleaner. |

| खाद्य प्रसंस्करण | Special blades cut food safely and quickly. |

| चिकित्सा उपकरण विनिर्माण | Custom blades make safe and exact cuts for medical parts. |

| Textile and Leather Industry | Special blades cut tough fabrics and leather. |

| Automotive and Aerospace | Custom blades meet strict rules for car and plane parts. |

| Electronics Manufacturing | Special blades cut small electronic parts. |

| Recycling and Waste Processing | Custom blades help shred all kinds of waste. |

| Research and Development | Custom blades help with new and test projects. |

Custom blades help you match your tools to your job. You get better results and fewer problems.

Performance Comparison by Material

प्लास्टिक

When you shred plastic, you want clean cuts and speed. Flat blades work for most plastics. Serrated and R-shaped blades help with tough or layered plastics. Custom blades work for special shapes or mixed plastic. The right blade stops clogs and makes shredding smooth.

या रबर उद्योग

Rubber and tires need strong blades. Hook and concave blades grab and tear rubber. Serrated edges stop slipping. Custom blades work for thick or stretchy rubber. The right blade gives better speed and fewer jams.

धातु

Metal needs sharp, tough blades. Concave and custom blades grip and cut metal scraps. Serrated edges help with layered or bundled metals. Custom blades work for odd shapes or mixed metal. The right blade lasts longer and keeps shredding safe.

Tip: Always pick the blade that matches your material. This helps your shredder last longer and work better.

Multi-Shaft and Claw Designs for Bulky Waste

Design Overview

Multi-shaft shredders use two or more shafts. Each shaft holds many blades. Claw designs have blades shaped like hooks or claws. These grab and pull in big waste like furniture or tires. The blades work together to break down large items fast.

Here is a table that compares shredder types:

| Shredder Type | लाभ | सीमाएँ |

|---|---|---|

| Single-Shaft | Shreds lots of stuff, works for many jobs, handles big items | Not as good for metals and tires, needs more care |

| Dual-Shaft | Handles tough jobs, shreds mixed or dirty waste | May not make small, even pieces |

| Four-Shaft | Makes small, even pieces, shreds tough stuff | May be too much for easy jobs |

Application Examples

You see multi-shaft and claw designs in places with big or tough waste. Some examples are:

- Recycling centers that shred furniture or appliances

- Tire recycling plants

- Factories that shred big plastic or metal drums

- City waste stations that handle bulky trash

These designs help you shred big things faster and easier. You get better results and less downtime.

Blade Selection

Choosing the right blade for your shredder can make your work easier and more efficient. You need to think about what you are shredding, how much you shred, and what you want your machine to do. This section will help you match your needs to the best single shaft shredder blade designs.

एप्लिकेशन मिलान

Material Type Considerations

You should always match your blade to the material you want to shred. Each material has its own hardness and strength. If you pick the wrong blade, it can wear out quickly or not cut well.

- Material hardness and strength: Harder materials like metal need tougher blades. Softer materials like plastic or paper need blades that stay sharp but do not have to be as tough.

- Blade material selection: Some blades are made for high wear resistance. Others are made for sharpness or flexibility.

- Maintenance and care: If you shred tough materials, you need to check and care for your blades more often.

Tip: Always check what kind of waste you process most. This helps you pick the right blade for your job.

Shredding Volume and Frequency

How much and how often you shred affects your blade choice. If you run your shredder all day, you need blades that last longer and need less care.

- Material being shredded: The type of waste changes how fast blades wear out.

- Production volume: High-volume shredding needs durable blades to keep your machine running.

- Maintenance cycle: If you want fewer stops for maintenance, choose blades with high wear resistance.

- Budget: Think about how much you spend now versus how much you save later.

- Heat treatment: Blades with good heat treatment last longer and work better.

You can save time and money by picking blades that match your shredding schedule.

Compatibility with Shredder Model

Not every blade fits every shredder. You need to make sure your blade matches your machine’s size and power. Check your shredder’s manual or talk to your supplier. Using the right blade keeps your machine safe and helps it last longer.

Performance Needs

Desired Output Size and Uniformity

Think about how small you want your shredded pieces to be. Some jobs need tiny, even pieces. Others just need the waste to be smaller. The blade’s edge style and shape affect the size and look of the output.

- High cutting precision is important for jobs like electronics or textiles. It helps reduce waste and improve quality.

- The right blade geometry gives you cleaner cuts and better results.

Throughput and Efficiency Requirements

If you want to shred a lot of material quickly, you need blades that can keep up. The shape and angle of the blade matter.

- Blade geometry should match the material and how your machine works. This helps you shred faster and use less energy.

- The edge profile and angle of attack affect how cleanly and quickly you can cut. The right design means less force and smoother cuts.

Tip: If you notice jagged edges or stretched material, you may need a different blade design.

टिकाऊपन और घिसाव प्रतिरोध

You want blades that last as long as possible. Durable blades mean less downtime and lower costs. Look for blades made from strong materials with good heat treatment. Regular care and sharpening also help your blades last longer.

Cost vs. Longevity

Initial Investment vs. Long-Term Savings

You may pay more for high-quality blades at first, but they can save you money over time. Durable blades need fewer replacements and less maintenance. This means your shredder runs longer without stopping.

Maintenance and Replacement Costs

Maintenance costs can change based on the type of shredder you use. Here is a table that shows the difference:

| विशेषता | Single Shaft Shredder | Double Shaft Shredder |

|---|---|---|

| Maintenance Cost | Simpler structure, lower maintenance cost | More complex structure, higher maintenance cost |

Single shaft shredder blade designs often cost less to maintain. You spend less time and money on repairs.

Value of OEM/ODM Customization

Custom blades can give you the best fit for your needs. OEM and ODM services let you choose the blade’s size, shape, and material. You can also get technical support for special shredding problems. This helps you get better results and less downtime.

Note: Working with experienced suppliers gives you access to tailored solutions.

Final Tips for Blade Selection

- Match your blade to the material and volume you shred.

- Think about the output size and how fast you want to work.

- Choose durable blades for less downtime.

- Balance the upfront cost with long-term savings.

- Consider custom blades for special jobs or machines.

- Work with trusted suppliers to get the best advice and support.

Picking the right single shaft shredder blade designs helps you process waste more efficiently and supports your recycling goals.

रखरखाव

निरीक्षण

You need to inspect your shredder blades often to keep your machine running well. Regular checks help you spot problems before they get worse. Here are some steps you can follow to extend blade wear life:

- Check your blades for cracks, chips, or dull edges every week.

- Make sure all bolts and fasteners are tight.

- Look for signs of uneven wear or damage on the blade surface.

- Listen for strange noises during operation. These can mean a blade is loose or damaged.

- Schedule downtime for a full inspection and repair. This helps you avoid sudden breakdowns.

- Train your team to spot early signs of trouble. Good training helps everyone keep the shredder safe and efficient.

Tip: Use only high-quality replacement parts from trusted suppliers. This helps your shredder last longer and work better.

सफाई

Keeping your blades clean is important for safe and smooth shredding. Dirt and leftover waste can make blades dull faster. You should clean your blades after each use. Here are some cleaning tips:

- Wipe blades with a soft cloth and warm, soapy water.

- Avoid using harsh chemicals or rough pads that can scratch the blade.

- Dry blades right away to stop rust from forming.

- Remove any stuck pieces of waste before starting the shredder again.

A clean blade cuts better and helps your machine work with less effort. Clean blades also help you spot damage early.

तेज़ करने

Sharp blades make your shredder more efficient. Dull blades can slow down your work and cause more wear on the machine. You should sharpen your blades when you notice they are not cutting as well. Here are some sharpening tips:

- Hone the blade lightly before each use to keep the edge sharp.

- Use a whetstone, sharpening system, or electric sharpener when the blade gets dull.

- Always follow the manufacturer’s instructions for sharpening.

- Store blades in a safe place, like a blade guard or rack, to keep them sharp longer.

Note: Regular sharpening and proper storage help you get the most out of your single shaft shredder blade designs.

Issue Prevention

You can prevent many problems with single shaft shredder blade designs by following smart habits. Good issue prevention helps your shredder work longer and keeps your blades sharp. You save time and money when you stop problems before they start.

Start by using your shredder the right way. Always feed the right amount of material into the machine. Overloading the shredder can cause blades to wear out faster. If you shred tough items, check the blade type and make sure it matches the material. For example, hook blades work better for bulky waste, while flat blades suit soft plastics.

Monitor your shredder during operation. Listen for strange sounds like grinding or banging. These noises can mean a blade is loose or damaged. Watch for uneven cuts or slow shredding. If you see these signs, stop the machine and inspect the blades. Quick action can prevent bigger problems.

Keep your workspace clean. Remove leftover pieces of waste from the shredder after each use. Dirt and debris can cause blades to dull or jam. Clean blades also help you spot cracks or chips early.

Train your team to follow safety rules. Teach everyone how to check blades and use the shredder safely. Good training lowers the risk of accidents and keeps your recycling process smooth.

Use a maintenance schedule. Write down when you inspect, clean, and sharpen your blades. Regular care helps you catch small issues before they grow. You can use a simple table to track your maintenance:

| काम | आवृत्ति | नोट्स |

|---|---|---|

| निरीक्षण | साप्ताहिक | Look for damage |

| सफाई | After use | Remove debris |

| तेज़ करने | महीने के | Check blade edge |

| स्नेहन | महीने के | Oil moving parts |

Tip: If you notice blades wearing out too quickly, talk to your supplier. Nanjing Metal Industrial offers support and advice for single shaft shredder blade designs. Their team can help you choose the right blade and give tips for longer blade life.

Choose high-quality blades and replacement parts. Trusted suppliers test their blades for strength and sharpness. This helps you avoid unexpected breakdowns and keeps your shredder working well.

Stay alert for changes in shredding speed or output size. These changes can signal blade problems. Fixing issues early helps you keep your recycling goals on track and reduces downtime.

You can prevent most blade issues by following these steps. Good habits and regular care help your single shaft shredder blade designs last longer and handle all types of waste with ease.

ब्लेड प्रतिस्थापन

तैयारी

You need to prepare before you replace blades on your shredder. Good preparation keeps you safe and helps you finish the job faster. Start by turning off the shredder and unplugging it. Wait for all moving parts to stop. Wear safety gloves and goggles to protect your hands and eyes. Gather the right tools, such as wrenches, screwdrivers, and a cleaning cloth. Check your manual for any special instructions about your single shaft shredder blade designs.

Inspect the shredder area for leftover waste. Remove any pieces stuck near the blades. Clean the workspace so you can see what you are doing. Lay out the new blades and check them for cracks or chips. Make sure you have the right blade type for your machine. If you use custom blades, confirm the size and shape match your shredder.

Tip: Always keep a spare set of blades ready. This helps you avoid long delays during recycling work.

Removal

You must remove the old blades carefully. First, loosen the bolts or screws that hold the blades in place. Use the right tool to avoid stripping the bolts. Take out each blade one at a time. Place the old blades on a safe surface away from your workspace. Watch for sharp edges when you handle used blades.

Check the shaft and mounting area for damage. Clean away any dirt or leftover waste. If you see deep scratches or dents, you may need to fix these before installing new blades. Inspect the bolts and fasteners. Replace any that look worn or rusty.

Here is a simple checklist for blade removal:

- Loosen bolts and screws.

- Remove blades one by one.

- Place old blades in a safe spot.

- Clean shaft and mounting area.

- Inspect for damage.

Note: Never rush the removal process. Careful work helps you avoid accidents and keeps your shredder in good shape.

इंस्टालेशन

You need to install the new blades with care. Place each blade on the shaft, making sure it lines up with the mounting holes. Use new or cleaned bolts to secure the blades. Tighten each bolt evenly so the blades sit flat and do not wobble. Check the manual for the correct torque settings.

After you install all blades, spin the shaft by hand to check for smooth movement. Make sure the blades do not touch each other or the shredder walls. If you notice any problems, adjust the blades before you start the machine.

Here is a table to help you remember the installation steps:

| कदम | कार्रवाई |

|---|---|

| Position blade | Align with mounting holes |

| Insert bolts | Use new or cleaned bolts |

| Tighten bolts | Even pressure, correct torque |

| संरेखण की जाँच करें | Spin shaft by hand |

| Final inspection | Look for gaps or contact |

Tip: Always follow the instructions for your single shaft shredder blade designs. Proper installation helps you shred waste safely and keeps your recycling process running smoothly.

सुरक्षा जांच

When you finish installing new blades on your shredder, you need to perform safety checks before starting the machine. These steps help you avoid accidents and keep your single shaft shredder blade designs working at their best. Follow this checklist to make sure your shredder is safe and ready for use:

- सुरक्षात्मक गियर पहनें

Always put on safety glasses, gloves, a helmet, and a dust mask. This gear protects you from sharp edges and flying debris during blade replacement. - Power Down and Secure the Shredder

Make sure the shredder is unplugged and cannot start by accident. Lock out the power source if possible. This step keeps you safe while you work on the machine. - Inspect the Protective Guard

Check that the shredder’s protective guard is in place and not damaged. The guard stops pieces of waste from flying out during operation. - Clean the Main Shaft and Flange

Wipe down the main shaft and flange. Make sure both are flat, clean, and perpendicular to the shaft. Dirt or leftover material can cause the blade to sit unevenly. - Check Blade Alignment and Radial Runout

Place the new blades on the shaft. Make sure they line up straight and do not wobble. Check the radial runout and swing of the main shaft. Proper alignment helps your shredder cut waste evenly and prevents damage. - Use the Correct Flange Size

Use a large flange to hold the blade steady. For thin blades, the flange should be about half the diameter of the blade. For thicker blades, one-third is enough. This step keeps the blade from slipping during use. - Tighten Flange Nuts Properly

Secure the flange nuts with the right amount of force. Do not over-tighten or leave them loose. Proper tightening prevents the blade from moving or causing internal damage. - Protect Alloy Tips

Handle blades carefully to avoid chipping or damaging the alloy tips. Damaged tips can affect shredding performance and safety. - Test Blade Rotation

After installation, spin the shaft by hand. Let the blades rotate freely for about 30 seconds. Listen for unusual sounds and check for smooth movement. If you notice any problems, stop and fix them before running the shredder. - Final Visual Inspection

Look over the entire assembly. Make sure all bolts are tight, the workspace is clean, and nothing blocks the blades. Double-check that you removed all tools and loose items.

Tip: Never skip safety checks. Careful inspection protects you, your team, and your equipment. Good safety habits also help your recycling process run smoothly and reduce downtime from accidents.

By following these steps, you make sure your single shaft shredder blade designs stay safe and effective. You also help your shredder handle all types of waste with less risk.

सर्वोत्तम प्रथाएं

OEM Collaboration

Working with OEMs for single shaft shredder blade designs means you need strong teamwork. Trust helps you share ideas and fix problems fast. Being open makes it easy to know what each side wants. Good partnerships help you get better blades and improve your supply chain.

- Trust between you and your supplier brings better results.

- Being open helps you stop mistakes and delays.

- Good teamwork makes shredding work smoother.

You might have problems when working with OEMs. Blade details can change from place to place. This makes buying blades from other countries harder. Different rules can make blades hard to swap. These problems can slow things down and cause risks for your work.

Tip: Pick suppliers who know what you need and talk clearly. Trusted companies give help and help you find the right single shaft shredder blade designs for your job.

Scheduling

You need a good plan to keep your shredder working well. Regular checks and care help you stop sudden breakdowns. Plan when to change and sharpen blades based on how much you use your shredder and what you shred.

| काम | आवृत्ति | उद्देश्य |

|---|---|---|

| ब्लेड निरीक्षण | साप्ताहिक | Find damage early |

| सफाई | After use | Stop blades from getting dull |

| तेज़ करने | महीने के | Keep blades working well |

| प्रतिस्थापन | जरुरत के अनुसार | Avoid stopping work |

A clear plan helps you watch blade wear and know when to change them. You save time and money by stopping problems before they start. You also keep your single shaft shredder blade designs working their best.

Note: Write down your care tasks and follow your plan. This helps you get the most from your shredder blades.

ऑपरेटर प्रशिक्षण

Training operators is important for safe and good shredding. Teach your team how to check, clean, and change blades. Make sure everyone knows how to spot worn or broken blades. Good training stops accidents and keeps your shredder working well.

- Show workers how to use the shredder safely.

- Teach them how to check blade position and sharpness.

- Explain why safety rules matter.

You can use easy guides and lists to help your team remember each step. Well-trained workers help you get better results from your single shaft shredder blade designs.

Tip: Train your team often to keep them ready and lower mistakes. Safe and skilled workers help your recycling work go smoothly.

Summary of Key Tips:

- Match your blade to what and how much you shred.

- Plan regular checks, cleaning, and sharpening.

- Train workers to handle blades safely and spot problems early.

- Work with trusted suppliers for reliable single shaft shredder blade designs.

By following these best practices, you make shredding work better and help your blades last longer. You also make your workplace safer and more productive.

Understanding single shaft shredder blade designs helps you get the best results from your shredder. You should know how blade shape, material, and type affect performance. Custom options and strong quality checks give you blades that fit your needs.

- Check your blades often.

- Choose the right blade for your job.

- Ask experts for advice when you need help.

For expert help with single shaft shredder blade designs, हमारे बिक्री इंजीनियरों से संपर्क करें.

सामान्य प्रश्न

What are single shaft shredder blade designs?

Single shaft shredder blade designs describe the shape, edge style, and structure of blades used in single shaft shredders. You choose a design based on the type of material you want to shred and the results you need.

How do I know when to replace shredder blades?

You should check for dull edges, chips, or cracks. If your shredder works slower or makes uneven cuts, it is time to replace the blades. Regular inspection helps you avoid sudden breakdowns.

Which blade design works best for plastic shredding?

Flat and straight-edge blades work well for most plastics. If you shred tough or layered plastics, try serrated or R-shaped blades. The right single shaft shredder blade designs help you get clean cuts and prevent jams.

Can I use the same blade design for metal and plastic?

You should not use the same blade for both. Metal needs tougher, more wear-resistant blades. Plastic works best with sharp, straight blades. Always match your single shaft shredder blade designs to the material for better results.

How often should I sharpen shredder blades?

You should sharpen blades every month if you use your shredder often. For light use, check and sharpen as needed. Sharp blades help your single shaft shredder blade designs last longer and work better.

What is the benefit of OEM or custom blade designs?

OEM or custom single shaft shredder blade designs fit your machine and shredding needs exactly. You get better performance, less downtime, and blades that last longer. Custom blades solve special shredding problems.

How do I choose the right material for shredder blades?

You should think about what you shred most. For soft materials, high-carbon steel works well. For metals or tough waste, choose alloy or carbide-tipped blades. The right material helps your single shaft shredder blade designs last longer.

Are there safety tips for changing shredder blades?

Yes! Always turn off and unplug the shredder first. Wear gloves and safety glasses. Check that all bolts are tight and blades are aligned. Careful blade changes keep you safe and help your single shaft shredder blade designs work their best.

यह भी देखें

औद्योगिक श्रेडर ब्लेड और उनके अनुप्रयोगों के लिए एक गाइड

सिंगल-शाफ्ट श्रेडर ब्लेड के रहस्यों को उजागर करना: रखरखाव, चयन और समस्या निवारण गाइड

श्रेडर ब्लेड्स: वर्गीकरण, सामग्री चयन, सेवा जीवन और डिजाइन तकनीकों का विश्लेषण

औद्योगिक श्रेडर ब्लेड की शक्ति को अनलॉक करना: उद्योगों में प्रमुख अनुप्रयोग

2 प्रतिक्रियाएं