Memilih yang tepat pisau perforasi dari Nanjing Metal untuk pekerjaan Anda dapat membuat atau menghancurkan lini produksi Anda. Setiap material berperilaku berbeda saat dipotong, jadi memilih bilah khusus yang sesuai dengan sifatnya sangatlah penting. Misalnya, penelitian menunjukkan bahwa mengubah bentuk bilah, seperti panjang pitch dan radius sudut, memengaruhi cara lembaran polipropilena ditekuk dan dilipat. Penggunaan pisau yang salah dapat mengakibatkan lipatan yang lemah atau bahkan merusak bahan Anda. Lihat tabel di bawah ini untuk melihat bagaimana pemilihan bahan pisau yang tepat memengaruhi kinerja dan efisiensi:

| Jenis Bahan | Manfaat dalam Penggunaan |

|---|---|

| Karbida Wolfram | Bertahan lama, menangani material keras, meningkatkan kecepatan |

| Besi tahan karat | Tahan karat, cocok untuk kemasan dan makanan |

| Keramik | Tetap tajam, aman untuk penggunaan khusus |

| Perkakas Baja | Kuat, ideal untuk kebutuhan bilah khusus |

| Pisau yang dilapisi | Berjalan lebih lama, mengurangi waktu henti |

Bila Anda memilih pisau perforasi dari Nanjing Metal yang disesuaikan dengan material Anda, Anda menghemat waktu, mengurangi limbah, dan menjaga mesin Anda tetap beroperasi pada kinerja puncak. Untuk informasi lebih lanjut atau untuk mendiskusikan kebutuhan spesifik Anda, silakan Kontak Nanjing Metal langsung.

Poin-poin Utama

- Pilih pisau perforasi yang sesuai dengan jenis, ketebalan, dan ketangguhan material Anda untuk mendapatkan potongan yang bersih dan menghindari kerusakan.

- Pilih bahan bilah seperti karbida untuk pekerjaan berat, baja tahan karat untuk penggunaan basah atau terkait makanan, dan baja perkakas untuk kebutuhan pemotongan umum.

- Pertimbangkan kecepatan produksi dan gunakan bilah berlapis atau perawatan khusus untuk menjaga bilah tetap tajam dan mengurangi waktu henti.

- Uji potongan sampel dan sesuaikan pengaturan pisau sebelum produksi penuh untuk meningkatkan kualitas pemotongan dan mengurangi perawatan.

- Pisau khusus yang disesuaikan dengan mesin dan material Anda dapat menghemat waktu, menurunkan biaya, dan meningkatkan kinerja pemotongan.

Bahan

Bahan Industri Umum

Saat Anda melihat pemotongan industri, Anda akan melihat berbagai macam material. Masing-masing material memiliki efek yang berbeda saat Anda menggunakan pisau perforasi. Beberapa material paling umum yang akan Anda gunakan meliputi:

- Kertas: Tipis, fleksibel, dan mudah robek. Anda dapat menemukannya di kemasan, label, dan tiket.

- Film plastik: Bahan-bahan ini kuat dan fleksibel. Bahan-bahan ini digunakan dalam kemasan makanan, kemasan medis, dan kantong fleksibel.

- Metal: Lembaran tipis aluminium atau baja digunakan untuk kemasan khusus atau ventilasi udara.

- Kardus: Lebih tebal dan lebih kuat dari kertas. Anda dapat melihatnya di kotak dan bahan kemasan tugas berat.

- Laminasi dan komposit: Ini menggabungkan beberapa bahan untuk kekuatan ekstra atau fitur khusus.

Setiap material membutuhkan pendekatan yang berbeda. Misalnya, kertas mudah dipotong, tetapi film plastik membutuhkan presisi yang lebih tinggi. Metal membutuhkan bilah yang lebih kuat. Jika Anda menggunakan pisau yang salah, Anda mungkin mendapatkan tepi yang kasar atau bahkan merusak material Anda.

Kiat: Selalu sesuaikan pisau dengan bahan yang akan dipotong. Ini akan menjaga hasil potongan tetap bersih dan mesin tetap bekerja dengan lancar.

Bidang Aplikasi

Anda akan menemukan pisau perforasi di banyak industri. Berikut ini adalah beberapa aplikasi teratas:

- Kemasan: Makanan, medis, dan barang-barang konsumen semuanya menggunakan bilah berlubang untuk fitur atau ventilasi yang mudah dibuka.

- Produk kertasPikirkan tentang buku catatan, tiket, dan kupon.

- Ventilasi udara: Lembaran logam tipis dilubangi untuk aliran udara dalam peralatan dan kendaraan.

- Barang konsumen: Barang-barang seperti tisu, kertas tisu, dan produk sekali pakai memerlukan pemotongan yang presisi.

| Bahan Pisau | Terbaik Untuk | Aplikasi Umum |

|---|---|---|

| Baja Berkecepatan Tinggi | Pemotongan seimbang, baik untuk kertas/plastik | Kertas, plastik tipis |

| Besi tahan karat | Tahan korosi, higienis | Kemasan makanan, medis |

| Karbida Wolfram | Bahan yang keras, tahan lama, dan kuat | Karton, pekerjaan bervolume tinggi |

| Keramik | Tajam, penggunaan khusus | Lingkungan yang keras |

Anda akan melihat bahwa kemasan menggunakan banyak bahan yang berbeda. Pisau yang tepat menjaga bahan kemasan Anda tetap kuat tetapi mudah dibuka. Dalam aplikasi pisau berlubang, Anda memerlukan pisau yang cocok dengan bahan dan pekerjaan. Ini membantu Anda mendapatkan hasil terbaik setiap saat.

Gambaran Umum Pisau Perforasi

Jenis-jenis Pisau Perforasi

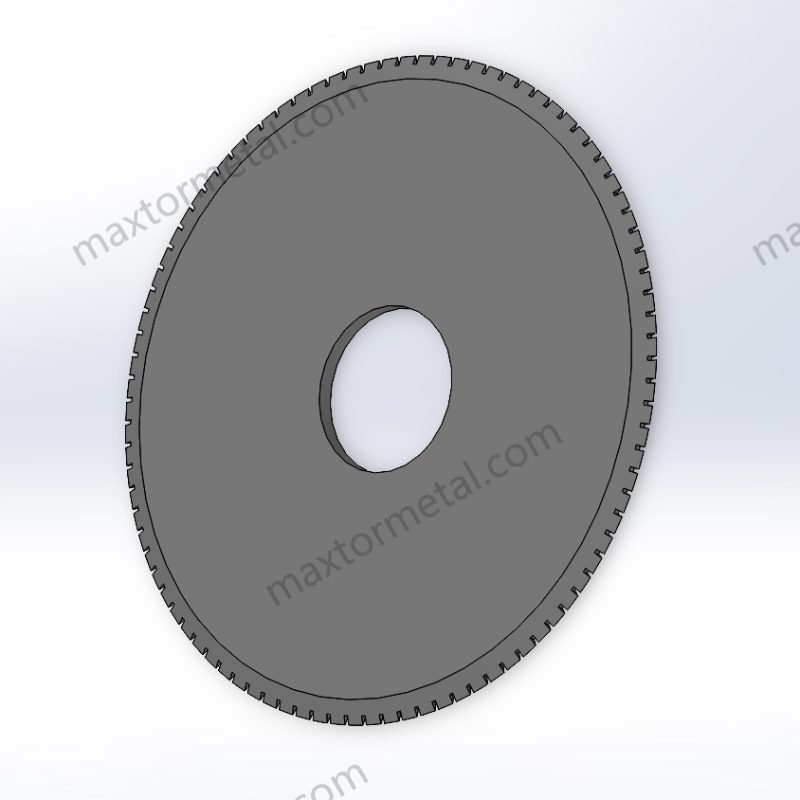

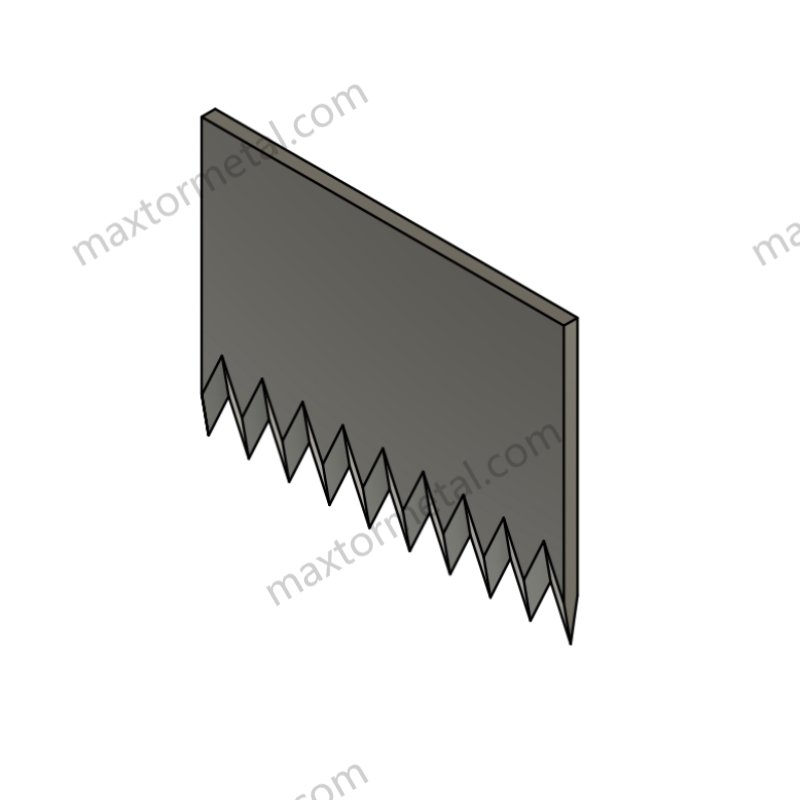

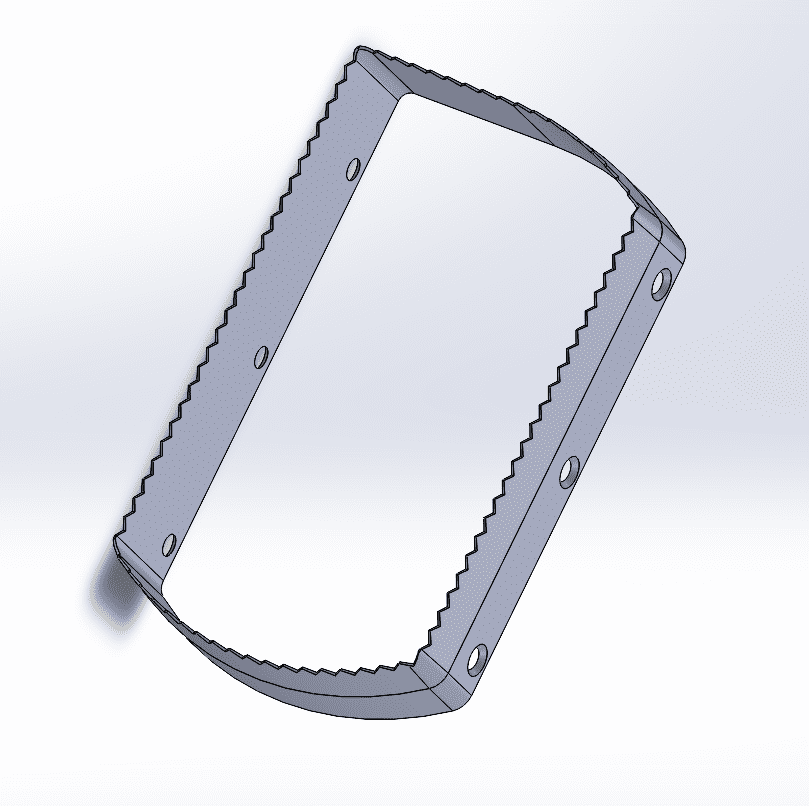

Saat Anda melihat pisau perforasi, Anda akan melihat beberapa jenis utama. Masing-masing paling cocok untuk pekerjaan pemotongan dan material tertentu. Yang paling umum adalah pisau bergigi, pisau putar, pisau datar, dan bentuk khusus. Pisau bergigi memiliki ujung tajam yang membuat lubang kecil dalam satu garis. Pisau putar berputar saat memotong, yang membantu saat Anda membutuhkan potongan cepat atau panjang. Pisau datar cocok untuk garis lurus dan sederhana. Pisau industri berlubang khusus dapat disesuaikan dengan bentuk atau ukuran khusus yang Anda butuhkan. Anda mungkin juga melihat bilah perforasi melingkar di banyak mesin. Bilah ini menggelinding di atas material, membuat lubang yang rata dan bersih.

Prinsip Kerja

Pisau perforasi bekerja dengan menekan atau menggelindingkan material Anda. Gigi atau tepi pisau akan mendorong, menciptakan deretan lubang atau celah kecil. Hal ini memudahkan untuk merobek atau melipat material nantinya. Pemotongan dengan pisau industri perforasi adalah tentang kontrol. Anda ingin lubangnya pas—tidak terlalu dalam atau terlalu dangkal. Pisau perforasi melingkar membantu Anda mendapatkan hasil yang halus dan dapat diulang, terutama dalam aplikasi berkecepatan tinggi. Pisau yang tepat menjaga proses pemotongan Anda tetap stabil dan produk Anda tampak tajam.

Catatan: Cara Anda menyiapkan pisau mesin industri berlubang dapat mengubah seberapa baik pisau tersebut memotong. Selalu periksa sudut dan tekanan bilah untuk hasil terbaik.

Pisau Mesin Industri Berlubang

Anda akan menemukan pisau mesin industri berlubang di banyak industri. Pisau ini muncul dalam pengemasan, pengolahan makanan, perlengkapan medis, dan banyak lagi. Pisau ini menangani segala hal mulai dari film tipis hingga kardus tebal. Baja perkakas, karbida, keramik, dan baja tahan karat adalah material yang paling umum untuk pisau ini. Masing-masing menawarkan kekuatan yang berbeda untuk memotong. Misalnya, bilah karbida bertahan lama dalam aplikasi yang sulit. Baja tahan karat tahan karat di lingkungan basah. Bilah perforasi melingkar populer karena kecepatan dan keakuratannya. Bila Anda memilih bilah industri berlubang yang tepat, Anda membuat pekerjaan pemotongan Anda lebih mudah dan produk Anda lebih baik.

Memilih Bahan Pisau yang Tepat

Ketika Anda memulai memilih bahan pisau yang tepat, Anda menyiapkan panggung untuk kinerja pemotongan yang lebih baik dan daya tahan bilah yang lebih lama. Bahan yang Anda pilih untuk bilah Anda menentukan seberapa baik bilah tersebut menangani pekerjaan berat, berapa lama bilah tersebut bertahan, dan seberapa bersih tampilan potongan Anda. Tidak semua bahan pisau industri bekerja dengan cara yang sama. Beberapa memberi Anda daya tahan lebih, sementara yang lain berfokus pada kecepatan atau ketahanan terhadap karat.

Bahan Utama untuk Bilah

Perkakas Baja

Baja perkakas menonjol karena ketangguhannya dan kemampuannya untuk mempertahankan ketajaman. Anda dapat menggunakannya untuk memotong kertas, kardus, dan bahkan beberapa plastik. Baja ini menangani panas dengan baik, sehingga Anda mendapatkan kinerja yang stabil selama pengerjaan yang panjang. Baja perkakas memberi Anda keseimbangan yang baik antara kinerja pemotongan dan ketahanan bilah.

Karbit

Mata pisau karbida memiliki kekerasan dan ketahanan aus yang luar biasa. Jika Anda perlu memotong bahan yang abrasif atau tebal, karbida adalah pilihan terbaik. Mata pisau ini tetap tajam untuk waktu yang lama, bahkan pada kecepatan tinggi. Karbida bekerja paling baik jika Anda menginginkan daya tahan maksimum dan kinerja pemotongan terbaik.

Keramik

Mata pisau keramik menawarkan kekerasan tinggi dan stabilitas panas yang sangat baik. Mata pisau ini tidak banyak menghantarkan panas, sehingga tetap dingin selama pemotongan cepat. Anda dapat menggunakan keramik untuk pekerjaan khusus yang membutuhkan gesekan lebih sedikit dan potongan yang lebih halus. Mata pisau keramik juga membantu mengurangi gaya pemotongan, yang berarti mengurangi keausan pada mesin Anda.

Besi tahan karat

Pisau baja antikarat berkilau di lingkungan basah atau yang berhubungan dengan makanan. Pisau ini tahan karat dan korosi, sehingga cocok untuk pengemasan dan pemotongan medis. Meskipun ketahanan ausnya mungkin tidak sebanding dengan baja perkakas atau karbida, pisau ini memberikan kinerja yang andal dan mudah dibersihkan.

Berikut ini sekilas perbandingan antara bahan-bahan ini:

| Bahan | Kekerasan & Ketahanan Aus | Tahan Panas & Retensi Tepi | Tahan korosi | Penggunaan Industri Umum & Catatan |

|---|---|---|---|---|

| Perkakas Baja | Kekerasan tinggi, ketahanan abrasi, ketahanan deformasi | Retensi tepi yang baik pada suhu tinggi | Sedang | Sangat cocok untuk peralatan yang membutuhkan ketangguhan dan ketahanan terhadap panas. |

| Karbit | Kekerasan dan ketahanan aus yang luar biasa | Kekuatan suhu tinggi, ditingkatkan dengan pelapis | Ketahanan korosi rendah | Dominan dalam pengerjaan logam; pelapis meningkatkan ketangguhan dan ketahanan aus. |

| Keramik | Kekerasan tinggi, kompetitif dengan karbida berlapis | Stabilitas suhu tinggi yang sangat baik, konduktivitas panas rendah | Ketahanan korosi rendah | Mengurangi gaya pemotongan dan panas yang dihasilkan; bagus untuk pemotongan khusus. |

| Besi tahan karat | Ketahanan aus lebih rendah dibandingkan dengan baja perkakas dan karbida | Tahan panas sedang | Ketahanan korosi tinggi | Paduan berbahan dasar besi dengan kromium untuk mencegah karat; paling baik untuk pemotongan makanan dan medis. |

Mencocokkan Bahan Pisau dengan Aplikasi

Anda ingin menyesuaikan bilah pisau dengan material yang akan dipotong. Untuk material tebal atau abrasif, karbida atau keramik memberikan ketahanan dan kinerja pemotongan terbaik. Jika Anda bekerja dengan makanan atau produk medis, baja tahan karat adalah pilihan utama untuk keamanan dan ketahanan terhadap korosi. Baja perkakas cocok untuk pekerjaan pemotongan umum yang membutuhkan ujung yang kuat dan andal.

Pelapis dan Perawatan Bilah Umum

Kadang-kadang, Anda membutuhkan daya tahan yang lebih baik atau kinerja pemotongan yang lebih baik. Pelapis seperti titanium aluminium nitrida (TiAlN) atau titanium karbonitrida (TiCN) meningkatkan bilah karbida, sehingga dapat menangani suhu yang lebih tinggi dan pekerjaan yang lebih berat. Pelapis ini mengurangi gesekan dan panas, sehingga bilah Anda bertahan lebih lama dan tetap tajam. Anda juga dapat menemukan perawatan yang membuat bilah baja perkakas atau baja tahan karat lebih tahan terhadap keausan dan goresan.

Kiat: Selalu pertimbangkan material, kecepatan produksi, dan lingkungan saat memilih mata pisau. Pilihan yang tepat akan membuat pemotongan Anda tajam dan mesin Anda dapat bekerja lebih lama.

Faktor Kunci dalam Memilih

Saat memilih pisau berlubang yang tepat, Anda perlu memperhatikan beberapa faktor utama dalam memilihnya. Faktor-faktor ini membantu Anda memperoleh hasil pemotongan terbaik dan menjaga produksi Anda berjalan lancar. Mari kita bahas apa saja yang harus Anda periksa sebelum mengambil keputusan.

Ketebalan dan Kepadatan Material

Menilai Ketebalan Material

Mulailah dengan mengukur seberapa tebal material Anda. Material yang lebih tebal membutuhkan bilah yang lebih kuat dan kaku. Material yang lebih tipis bekerja lebih baik dengan bilah yang tajam dan halus. Ketebalan memengaruhi seberapa cepat Anda dapat memotong dan berapa banyak limbah yang Anda hasilkan.

| Ketebalan Bilah | Kecepatan Pemotongan (m/menit) | Waktu henti (jam/minggu) | Sampah Material (%) |

|---|---|---|---|

| 0,4 mm | 180 | 2 | 1.8 |

| 0,6 mm | 160 | 1.2 | 2.5 |

| 1,0 mm2 | 140 | 0.8 | 3.1 |

Anda dapat melihat bahwa bilah yang lebih tipis memotong lebih cepat tetapi mungkin memerlukan perawatan lebih banyak. Bilah yang lebih tebal memperlambat proses tetapi bertahan lebih lama.

Mengevaluasi Kepadatan Material

Kepadatan menunjukkan seberapa berat dan padat material Anda. Material dengan kepadatan tinggi, seperti tungsten karbida, memberi Anda stabilitas dan daya tahan yang hebat. Namun, material tersebut dapat menjadi getas, jadi Anda perlu menanganinya dengan hati-hati. Selalu sesuaikan bilah dengan kepadatan untuk kinerja pemotongan terbaik.

Dampak pada Pemilihan Pisau

Jika Anda menggunakan mata pisau yang salah untuk ketebalan atau kepadatan material Anda, Anda mungkin mendapatkan potongan yang kasar atau bahkan merusak peralatan Anda. Pengujian terpadu menunjukkan bahwa mengukur ketebalan dan kepadatan membantu Anda memprediksi bagaimana material Anda akan bereaksi selama pemotongan. Langkah ini penting untuk semua aplikasi berlubang.

Kekuatan Perforasi dan Ketahanan Sobek

Kekuatan Perforasi yang Diperlukan

Setiap material memiliki kekuatan yang berbeda. Beberapa membutuhkan kekuatan lebih untuk melubangi. Misalnya, laminasi serat logam Gunakan model khusus untuk memeriksa seberapa besar gaya yang dibutuhkan untuk memotong. Anda memerlukan pisau yang sesuai dengan kekuatan material Anda untuk pemotongan yang bersih dan mudah.

Ketahanan Sobek Material

Ketahanan sobek berarti seberapa baik bahan Anda bertahan setelah dilubangi. Jika bahan Anda terlalu mudah sobek, Anda memerlukan bilah yang lebih lembut. Jika bahannya keras, Anda memerlukan bilah yang lebih kuat. Pengujian seperti ketahanan terhadap benturan dan kekakuan geser membantu Anda menemukan kecocokan yang tepat.

Mencocokkan Desain Pisau dengan Sifat Material

Anda dapat mengubah bentuk gigi pisau, jarak, dan lebar tepi pisau agar sesuai dengan bahan yang Anda gunakan. Ini membantu Anda mendapatkan keseimbangan yang tepat antara mudah robek dan kemasan yang kuat. Selalu uji berbagai desain untuk melihat mana yang paling sesuai dengan kebutuhan pemotongan Anda.

Kecepatan dan Efisiensi Produksi

Pengaruh Kecepatan Produksi terhadap Pilihan Pisau

Pemotongan berkecepatan tinggi memerlukan bilah yang tetap tajam dan dingin. Jika Anda menjalankan mesin dengan cepat, pilih bilah dengan lapisan atau perawatan khusus untuk daya tahan dan kinerja yang lebih baik.

Menyeimbangkan Efisiensi dan Daya Tahan

Anda ingin memotong dengan cepat tetapi juga menjaga agar bilah pisau tetap awet. Perawatan tingkat lanjut seperti pelapis titanium nitrida dapat meningkatkan daya tahan hingga 300%. Ini berarti lebih sedikit waktu henti dan lebih banyak produk yang dibuat.

Menyesuaikan Parameter Pisau untuk Operasi Kecepatan Tinggi

Manufaktur modern menggunakan pemotongan laser dan penggilingan CNC untuk membuat bilah dengan bentuk dan ketajaman yang tepat. Metode ini membantu Anda memperoleh hasil terbaik, bahkan pada kecepatan tinggi. Pemeriksaan kualitas, seperti uji kekerasan dan ketajaman tepi, memastikan bilah Anda memenuhi kebutuhan Anda.

Menentukan Dimensi Pisau Kustom

Saat Anda memesan bilah berlubang khusus, berikan detail seperti diameter luar (OD), diameter dalam (ID), ketebalan hub, jarak gigi, dan lebar tepi. Detail ini membantu produsen membuat bilah yang sesuai dengan aplikasi Anda dengan sempurna.

Kiat: Selalu uji bilah Anda sebelum produksi penuh. Ukur material Anda, tentukan kebutuhan pemotongan Anda, dan bicarakan dengan spesialis. Pengujian sampel membantu Anda menghindari kesalahan dan mendapatkan kinerja pemotongan terbaik.

Pisau Perforasi Kustom

Manfaat Kustomisasi

Bila Anda bekerja dengan material unik atau mesin khusus, bilah standar sering kali tidak berfungsi dengan baik. Bilah perforasi industri yang dirancang khusus memberi Anda keuntungan nyata dalam situasi ini. Anda dapat mengirimkan gambar atau bahkan foto, dan para ahli akan membuat bilah yang sesuai dengan peralatan Anda dengan sempurna. Ini menghemat waktu Anda karena Anda tidak perlu mencari pengganti yang mungkin tidak ada.

Anda juga menghemat uang dalam jangka panjang. Bila Anda memilih bahan bilah yang tepat untuk aplikasi spesifik Anda, Anda memperoleh masa pakai bilah yang lebih lama dan lebih sedikit kerusakan. Ini berarti lebih sedikit perawatan, lebih sedikit pemberhentian untuk perbaikan, dan lebih banyak waktu dengan mesin Anda yang beroperasi. Pemeriksaan kualitas yang ketat memastikan setiap bilah memenuhi standar tinggi, jadi Anda tidak perlu khawatir tentang komponen yang rusak yang menyebabkan perawatan ekstra. Jika Anda perlu mengubah desain, Anda juga dapat melakukannya. Kustomisasi memungkinkan Anda meningkatkan kinerja untuk kebutuhan Anda yang tepat.

Berikut ini adalah beberapa manfaat utama yang Anda dapatkan dari bilah khusus:

- Perputaran cepat untuk desain peralatan yang unik

- Pemilihan material ahli untuk aplikasi Anda, yang mengurangi pemeliharaan

- Beberapa pemeriksaan kualitas untuk mencegah masalah pemeliharaan

- Perubahan desain yang mudah untuk meningkatkan kinerja

- Lebih dari 15 tahun pengalaman industri di balik setiap bilah

Anda dapat melihat perbedaannya pada angka-angka:

| Metrik | Pisau Standar | Pisau Kustom |

|---|---|---|

| Penggantian Bilah Bulanan | 12 | 3 |

| Biaya Pisau Rata-rata | $10 | $30 |

| Total Biaya Bulanan | ~$2,400 | ~$1,000 |

“Kami menghemat waktu mesin dua hari setiap bulan.”

“Pisau kami kini lolos uji kebersihan dengan mudah. Keamanan dan kinerjanya pun meningkat.”

Solusi Nanjing Metal

Jika Anda menginginkan pemasok pisau perforasi yang tepercaya, Anda harus tahu tentang Nanjing MetalPerusahaan ini memiliki 18 tahun pengalaman dalam membuat bilah industri untuk semua jenis aplikasi. Tim mereka tahu cara mendesain dan membuat bilah khusus yang sesuai dengan mesin dan tujuan produksi Anda. Mereka berfokus pada kualitas, keandalan, dan memastikan Anda menghabiskan lebih sedikit waktu untuk perawatan.

Nanjing Metal menawarkan berbagai macam solusi khusus. Anda bisa mendapatkan bilah untuk pengemasan, pengolahan makanan, atau keperluan industri lainnya. Para ahli mereka membantu Anda memilih bahan dan pelapis yang tepat, sehingga Anda mendapatkan kinerja terbaik dan perawatan yang paling sedikit. Banyak pelanggan mempercayai Nanjing Metal karena mereka menyediakan bilah yang lebih tahan lama dan memerlukan lebih sedikit perawatan, yang membuat lini produksi Anda tetap berjalan.

Siap untuk meng-upgrade bilah pisau Anda atau memecahkan masalah pemotongan yang rumit? Hubungi teknisi penjualan melalui Kontak halaman dan lihat bagaimana bilah khusus dapat meningkatkan aplikasi Anda.

Kesalahan dan Tips

Kesalahan Umum

Saat memilih pisau berlubang, Anda mungkin akan menemui beberapa kesalahan umum. Kesalahan ini dapat merusak hasil pemotongan dan memerlukan perawatan lebih.

Memilih Ukuran Gigi yang Salah

Jika Anda memilih ukuran gigi yang salah, hasil pemotongan tidak akan bersih. Gigi kecil lebih cocok untuk bahan tipis. Gigi besar cocok untuk bahan tebal. Pilihan yang salah dapat menyebabkan tepi kasar atau garis berlubang yang lemah. Ini berarti lebih banyak perawatan dan kinerja yang lebih rendah.

Memilih Bahan Pisau yang Tidak Tepat

Beberapa orang menggunakan bilah yang tidak sesuai dengan bahannya. Jika Anda menggunakan bilah yang lembut untuk bahan yang keras, Anda akan melihat hasil pemotongan yang buruk dan cepat aus. Kesalahan ini menyebabkan lebih banyak perawatan dan daya tahan yang berkurang. Selalu sesuaikan bahan pisau dengan pekerjaan Anda untuk kinerja yang lebih baik.

Menggunakan Jenis Pisau yang Salah

Anda perlu memilih jenis pisau berlubang yang tepat. Pisau putar berfungsi baik untuk pemotongan cepat dan panjang. Pisau datar cocok untuk garis lurus. Jenis yang salah dapat memperlambat pemotongan dan menambah biaya perawatan.

Mengabaikan Kompatibilitas Material

Jika Anda mengabaikan reaksi material terhadap bilah pisau, Anda mungkin akan mendapatkan hasil yang buruk. Beberapa material memerlukan bilah pisau khusus untuk pemotongan berlubang yang bersih. Jika tidak memeriksa hal ini, berarti perawatan yang lebih banyak dan kinerja yang lebih rendah.

Mengabaikan Persyaratan Produksi

Anda harus selalu mempertimbangkan kecepatan produksi dan seberapa sering Anda ingin berhenti untuk perawatan. Jika tidak, Anda mungkin memilih pisau yang tidak dapat mengimbanginya. Hal ini menyebabkan lebih banyak waktu henti dan efisiensi pemotongan yang lebih rendah.

Pengujian dan Penyesuaian Praktis

Anda dapat menghindari banyak masalah dengan menguji dan membuat perubahan kecil.

Melakukan Pengujian Sampel

Cobalah potongan sampel sebelum produksi penuh. Ini membantu Anda melihat apakah pisau berlubang memberikan pemotongan dan kinerja yang tepat. Anda dapat menemukan masalah perawatan lebih awal.

Menyesuaikan Pengaturan dan Parameter Pisau

Ubah tekanan, kecepatan, atau kesejajaran pisau Anda. Perubahan kecil dapat meningkatkan kinerja pemotongan dan mengurangi perawatan.

Berkonsultasi dengan Pemasok atau Ahli Pisau

Bicaralah dengan para ahli jika Anda mengalami kesulitan. Mereka dapat membantu Anda memilih pisau berlubang terbaik untuk kebutuhan Anda. Saran ini dapat menghemat waktu dan mengurangi biaya perawatan.

Memantau Kinerja dan Melakukan Perbaikan Iteratif

Pantau hasil pemotongan Anda. Jika Anda melihat masalah, buat perubahan kecil. Ini membantu Anda mempertahankan kinerja tinggi dan mengurangi perawatan seiring berjalannya waktu.

Tips: Pemeriksaan rutin dan penyesuaian cepat menjaga pisau berlubang Anda berfungsi dengan baik dan mengurangi perawatan.

Jika Anda menginginkan saran ahli atau memerlukan solusi khusus, Anda dapat menghubungi produsen pisau industri tepercaya. Untuk bantuan lebih lanjut, jangan ragu untuk menghubungi teknisi penjualan.

Memilih bilah perforasi yang tepat dimulai dengan mengetahui material Anda. Anda memeriksa ketebalan, kepadatan, dan seberapa kuat material tersebut untuk dipotong. Selanjutnya, Anda mencocokkan jenis bilah dan material dengan pekerjaan Anda. Pengujian membantu Anda menghindari kesalahan. Jika Anda menginginkan produsen pisau perforasi terpercaya, Nanjing Metal menghadirkan 18 tahun pengalaman dan pengakuan industri. Siap mendapatkan saran ahli? Hubungi teknisi penjualan Di Sini.

Tanya Jawab Umum

Untuk apa pisau perforasi digunakan?

Anda menggunakan pisau perforasi untuk membuat lubang atau celah kecil pada bahan. Ini membantu Anda merobek, melipat, atau memisahkan produk dengan mudah. Anda sering melihat potongan ini pada kemasan, tiket, dan label.

Bagaimana saya mengetahui bahan bilah pisau mana yang terbaik untuk pekerjaan saya?

Periksa jenis material dan seberapa kuatnya. Untuk barang lunak, gunakan baja perkakas atau baja tahan karat. Untuk pekerjaan keras atau abrasif, cobalah karbida atau keramik. Jika Anda merasa tidak yakin, uji sampel terlebih dahulu.

Bisakah saya mendapatkan pisau khusus untuk mesin saya?

Ya! Anda dapat memesan pisau khusus agar sesuai dengan mesin dan material Anda. Cukup bagikan detail mesin dan kebutuhan pemotongan Anda. Para ahli akan membantu merancang bilah yang tepat untuk Anda.

Seberapa sering saya harus mengganti bilah perforasi saya?

Umur pakai bilah pisau bergantung pada bahan dan seberapa sering Anda menggunakannya. Jika Anda melihat potongan kasar atau memerlukan tenaga lebih, saatnya mengganti bilah pisau. Pemeriksaan rutin membantu Anda menghindari masalah.

Apa yang harus saya lakukan jika bilah pisau saya cepat sekali aus?

Cobalah menggunakan bahan bilah yang lebih keras atau tambahkan lapisan khusus. Pastikan pengaturan mesin sesuai dengan bahan yang digunakan. Jika masih mengalami masalah, mintalah saran dari ahli bilah.

Ingin bantuan lebih lanjut atau solusi khusus? Hubungi teknisi penjualan Di Sini.

Lihat Juga

Apa Itu Bilah Perforasi dan Bagaimana Cara Penggunaannya?

Panduan Lengkap Pisau Pengemas: Jenis, Aplikasi, dan Tips Perawatan untuk Industri Pengemasan

Cara Menemukan Pisau Pemotong Kertas Industri yang Tepat untuk Kebutuhan Anda

Memelihara Pisau Pemisah Gulungan Kertas agar Efisiensi Maksimum

Tanggapan 5