| Nama Lain | Pemotong Skor, Pemotong Penghancur, Pisau Potong Skor, Pisau Pemotong Ulang, Pemotong Penghancur, Pisau Piring |

|---|---|

| Tempat Asal | Tiongkok |

| Aplikasi | Plastik, Kertas, Papan, Non-anyaman, Film, Foil, Label, Pita, Tekstil, Pengemasan, Karpet, Tas, Tabung, Inti, Karet |

| Bahan | 65Mn,9CrSi,Cr12MoV,SKD-11,HSSl |

| Nomor Model | CV-CK |

| Layanan OEM | Tersedia |

| Ketentuan Pembayaran | L/C, T/T, Western Union |

| Kemasan | Kotak Karton, Peti Kayu |

| Waktu Pengiriman | 7-20 Hari |

Bagikan ke:

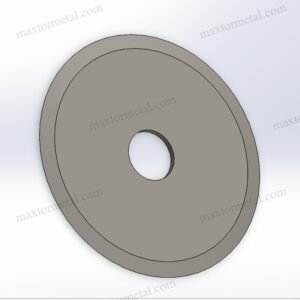

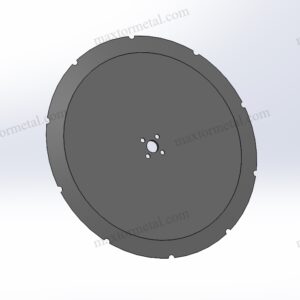

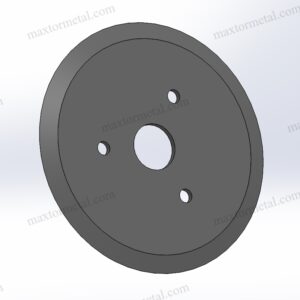

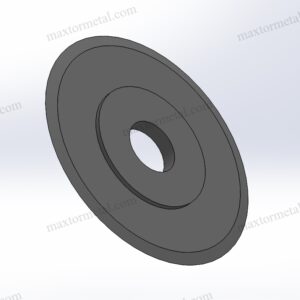

Pisau melingkar, juga dikenal sebagai pisau putar atau pisau cakram, adalah alat pemotong dengan bentuk melingkar dan tepi luar yang tajam. Alat ini dirancang untuk memotong bahan melalui gerakan putar, sering kali terhadap bilah lawan atau landasan. Istilah “pisau melingkar"bersifat luas dan mencakup berbagai macam alat pemotong berbentuk cakram yang digunakan di berbagai industri untuk mengiris, membelah, melubangi, dan menggores berbagai bahan. Tindakan berputarnya memungkinkan pemotongan yang terus-menerus dan efisien, sehingga ideal untuk proses produksi berkecepatan tinggi.

Pisau melingkar memiliki aplikasi yang luas di berbagai industri karena efisiensinya dan fleksibilitasnya dalam memotong berbagai material. Beberapa kegunaan utamanya meliputi:

Pemilihan material untuk pisau bundar sangat bergantung pada material yang akan dipotong, kecepatan operasi, dan masa pakai bilah pisau yang dibutuhkan. Material yang umum digunakan meliputi:

Pelapis seperti titanium nitrida (TiN), kromium nitrida (CrN), atau karbon seperti berlian (DLC) dapat diterapkan untuk meningkatkan kekerasan permukaan, mengurangi gesekan, dan memperpanjang umur pisau bundar, terutama saat menangani bahan abrasif atau lengket.

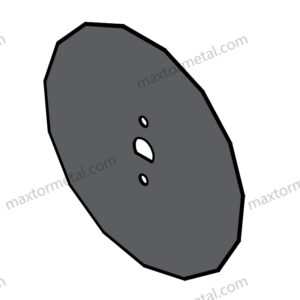

Pisau melingkar tersedia dalam berbagai bentuk dan konfigurasi tepi untuk mengoptimalkan kinerja pemotongan untuk aplikasi tertentu. Bentuk umum meliputi:

Prinsip kerja pisau melingkar melibatkan gerakan berputar yang dikombinasikan dengan tekanan terkendali terhadap material yang dipotong. Ketajaman dan geometri ujung pemotong, beserta kecepatan putaran dan sifat material, menentukan kualitas dan efisiensi pemotongan. Dalam banyak aplikasi, pisau melingkar bekerja sama dengan landasan, bilah penyeimbang, atau rol lain untuk memberikan dukungan dan memastikan pemotongan yang bersih.

" Selamat datang untuk bertanya!

Jika Anda tidak menemukan bilah geser yang Anda cari, kami juga dapat menyesuaikannya, lihat “Pisau Kustom" kami untuk mengetahui caranya!

Nikmati kemudahan impor yang mulus. Dari transportasi hingga bea cukai, kami menangani seluruh proses. Anda hanya perlu membayar PPN dan menunggu barang tiba di perusahaan.

Kami telah melihat pisau kami digunakan dalam berbagai aplikasi dan siap menangani proyek apa pun yang Anda berikan kepada kami – memberikan akurasi, daya tahan, dan harga kompetitif yang tak tertandingi.

Baik Anda menyediakan gambar, sketsa, atau sampel, kami mampu menggambar dan memproduksi untuk Anda. Kami juga memiliki kemampuan untuk membantu memodifikasi desain dan spesifikasi yang ada untuk meningkatkan hampir semua aplikasi perkakas industri. Silakan hubungi tim penjualan khusus kami untuk mendiskusikan persyaratan spesifik Anda.

Serangkaian pengujian dan inspeksi dilakukan untuk mengontrol kualitas, termasuk inspeksi artikel pertama, inspeksi bahan masuk dan bahan bersertifikat, inspeksi kualitas dalam proses, serta inspeksi kualitas akhir.

Baik Anda seorang importir, distributor, grosir, atau pengguna akhir, kami menyambut Anda untuk bergabung dengan MOQ minimum, tanpa kerumitan untuk pertanyaan, dan lebih banyak kebebasan untuk pembelian.

Jadilah pemantau eksklusif Anda, transmisi reguler setiap node penting dalam lini produksi, tidak peduli seberapa jauh, kemajuan produk sejauh mungkin untuk dipahami.

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China

Tetap ikuti berita terbaru kami.