Automotive AHSS grades like DP, TRIP, and martensitic steels can turn a routine slit into a line-stopping headache. Burrs and micro‑chipping surge, edge ductility drops, and downstream formability (HER) suffers. This guide gives plant, process, and maintenance leaders practitioner-grade parameters—material and hardness ranges, coating choices, edge geometry targets, and clearance settings—plus a concise troubleshooting matrix. The goal: cleaner edges, fewer defects, and predictable performance when slitting AHSS.

Key takeaways

- Optimize clearance as a percentage of strip thickness by grade strength; AHSS typically needs 10–16% t, higher than mild steel.

- For knife materials, prioritize PM tool steels at 60–62 HRC for toughness + wear; add PVD coatings to control heat and adhesion.

- Use a micro-edge hone (10–30 µm typical) and polished faces to cut micro‑chipping and improve edge ductility.

- Validate with on-line checks: burnish/fracture zones, burr height trends, and targeted edge ductility tests for critical parts.

- Don’t chase maximum hardness; balance hardness with toughness to avoid brittle chipping, especially on martensitic grades.

Why AHSS changes the rules

AHSS combines high tensile strength with multiphase microstructures (martensite in ferrite), which raises cutting forces and amplifies sensitivity to parameter errors. Mechanical cutting reduces edge ductility; minimizing damage in the shear-affected zone is essential for better HER. Guidance from WorldAutoSteel notes that while mild steels may run at ~6–8% clearance (as % of thickness), AHSS grades—especially >1400 MPa—often require significantly larger clearances to reduce galling and stress at the cutting edge. See the slitting and clearance discussions in the AHSS portal for context in the industry’s own words in the AHSS Guidelines on slitting and clearance and the broader cutting guidance in WorldAutoSteel’s cutting and trimming overview.

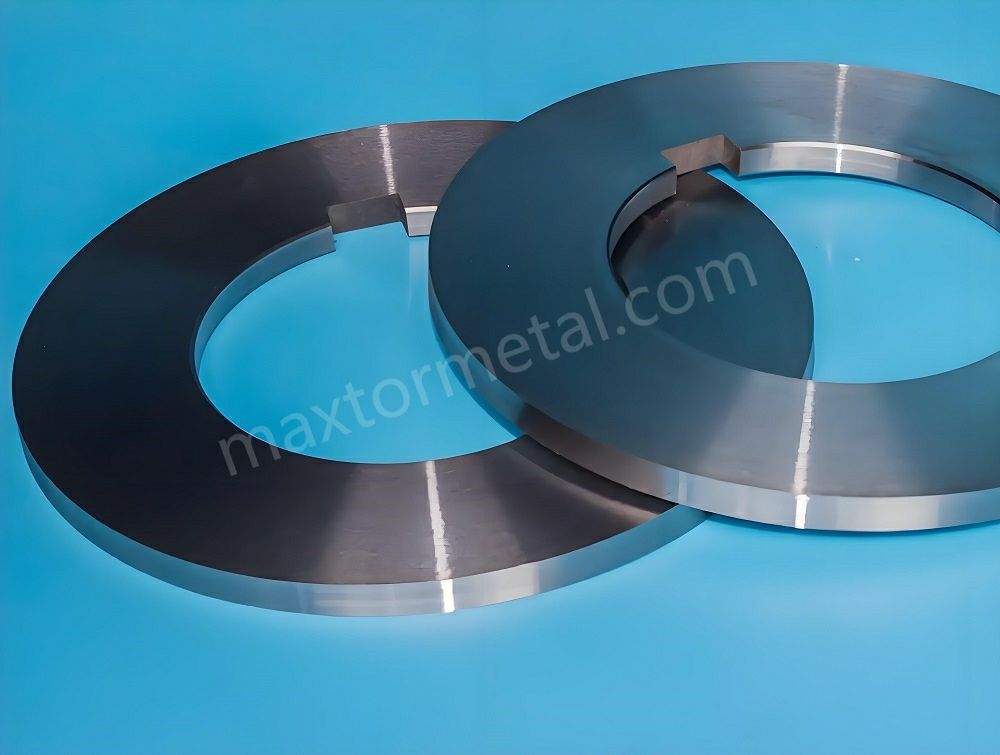

Selecting Steel Slitting Knives for AHSS: material, hardness, coatings, geometry

Choosing the right combination prevents plastic deformation on one end and brittle chipping on the other. Think of it as balancing three levers—hardness, toughness, and friction/heat control.

- Materials and hardness

- PM tool steels (e.g., Uddeholm Vanadis 4 Extra, Vanadis 8; Böhler K390): run around 60–62 HRC (some up to ~64) for AHSS cutting, offering high wear resistance with better chipping resistance than conventional D2. Uddeholm’s AHSS tooling notes emphasize these PM grades for edge stability in severe applications; see Uddeholm’s AHSS tooling solutions and the Vanadis 4 Extra data.

- D2 (1.2379): workable at ~58–62 HRC but more prone to micro‑chipping in AHSS; consider PM alternatives for long runs or harsher grades.

- H13: tougher at ~52–56 HRC; useful where impact/shock dominates, but lower wear resistance may shorten intervals.

- Carbide or carbide‑tipped: consider for extremely abrasive or coated AHSS; ensure arbor support to manage brittleness.

- Coatings and surface treatments

- TiAlN/AlTiN: 1–4 µm PVD layers with high hot hardness and oxidation resistance; suited to dry or high-speed conditions typical of AHSS. See Oerlikon’s product pages on AlTiSiN/AlCrN families such as BALIQ TISINOS PRO.

- TiN/TiCN: 1–4 µm; TiN around ~2000–2500 HV; TiCN harder (~3000+ HV) but lower temperature ceiling; useful for adhesion reduction. Industry overviews provide representative ranges, e.g., TGW’s coating guide.

- DLC (ta‑C/a‑C:H): very low friction (COF <0.1 possible) and high hardness; useful when adhesive pickup/galling is the problem, including some coated steels. See Oerlikon’s DLC overview for cutting tools dan Ionbond’s DLC technology page.

- Edge geometry and finish

- Micro‑edge hone: start with 10–30 µm for balanced AHSS, moving toward 20–50 µm if chipping persists on martensitic grades or where line shocks exist. Present these as validation ranges; direct standards are scarce. Uddeholm recommends polished faces for AHSS cutting tools; aim for fine finishes (e.g., Ra ≤0.2 µm on critical faces) to reduce notch initiation as outlined in Uddeholm’s AHSS guidance.

Summary table: material, hardness, coating, geometry (starting points)

| Choice | Typical working range | Where it helps | Cautions |

|---|---|---|---|

| PM tool steels (Vanadis 4 Extra, Vanadis 8, K390) | 60–62 HRC (some up to ~64) | High wear + chipping resistance for AHSS | Validate edge hone; excessive hardness without toughness can chip |

| D2 (1.2379) | 58–62 HRC | Baseline availability and cost | More chipping risk in AHSS; consider PM alternative for long runs |

| H13 | 52–56 HRC | Impact/shock, tough conditions | Lower wear resistance; shorter intervals |

| Carbide/carbidetipped | N/A (very high HRA) | Highly abrasive or coated AHSS | Brittleness; requires stable support |

| TiAlN/AlTiN PVD | 1–4 µm | Heat/oxidation resistance at speed | Regrind removes coating; plan recoat |

| TiN/TiCN PVD | 1–4 µm | Adhesion control; entry option | TiCN lower temp ceiling; validate |

| DLC | 0.3–1 µm+ | Low friction; galling control | May not suit high-heat spots; validate |

| Micro-edge hone | 10–30 µm (20–50 µm if chipping) | Reduces micro‑chipping; smoother entry | Too large hone can raise burr; trial |

| Surface finish | Target fine finish (e.g., Ra ≤0.2 µm) | Lower friction and notch sites | Requires careful grinding/polish |

Setup parameters that control burrs and HER

Clearance dominates burr formation and edge damage in AHSS. Start from strength- and thickness-based rules, then validate on line with edge-quality checks.

- Clearance as % of thickness (starting bands)

- Mild steel: ~6–8% t

- AHSS 600–980 MPa: ~10–14% t

- UHSS >1400 MPa: ~14–16%+ t

These align with the ranges discussed in the AHSS portal. For context and deeper explanation of how clearance shapes the shear‑affected zone, consult the AHSS Guidelines on clearance.

- Alignment, tension, and speed checklist

- Knife parallelism and arbor runout: verify before production. Misalignment adds uneven burr and accelerates wear.

- Tension: keep strip tension consistent; excessive tension increases edge tearing, while too little can cause wandering and knife marks.

- Speed: higher speeds can alter deformation zones; some studies on electrical steel show clearance and speed significantly affect burr and deformation. Treat speed changes as a controlled trial variable and re‑validate edge outcomes; see a peer‑reviewed overview in Szada‑Borzyszkowska et al. (2023) on shear‑slitting effects.

- Verification and HER awareness

- Inspect rollover, burnish, and fracture zones; in AHSS, burr height alone may not track wear predictably. The AHSS portal notes the need for broader edge-quality criteria in WorldAutoSteel’s slitting notes.

- For critical parts, run edge ductility checks: hole expansion testing (ISO 16630) or simple bend tests. SSAB provides context for edge ductility evaluation in SSAB’s insight on determining AHSS ductility.

Clearance quick table (validate per line)

| Strength/grade band | Thickness example | Starting clearance |

|---|---|---|

| Mild steel | 0.040 in (1.0 mm) | 6–8% t (0.0024–0.0032 in) |

| DP/TRIP 600–980 MPa | 0.040 in (1.0 mm) | 10–14% t (0.004–0.0056 in) |

| Martensitic/UHSS >1400 MPa | 0.040 in (1.0 mm) | 14–16%+ t (0.0056–0.0064 in) |

Troubleshooting matrix: AHSS slitting defects

Use the following as a first-response playbook; verify each change on a short coil segment before scaling.

| Gejala | Likely cause | Corrective action | Pencegahan |

|---|---|---|---|

| High burr or ragged edge | Clearance too low/high; dull edge; misalignment; debris | Adjust toward 10–16% t for AHSS; resharpen; realign; clean spacers/arbor | Calibrate clearance per grade; scheduled inspections; cleanliness SOP |

| Micro‑chipping on knife edge | Excessive hardness or brittle steel (e.g., D2); inadequate edge hone; shock from poor support | Switch to PM steel at 60–62 HRC; add 10–30 µm micro‑hone; verify arbor rigidity and guides | Specify PM grade + hone; maintain support hardware; avoid overtight clearances |

| Galling/adhesive pickup | High friction with coated steels; rough tool faces; unsuitable coating | Apply TiAlN or DLC; polish rake/flank; increase clearance slightly; ensure lubrication/cleanliness | Match coating to job; keep finishes fine; enforce cleaning between coils |

| Plastic deformation/edge rollover | Tool hardness too low; overload; poor clearance | Increase hardness within toughness limits; optimize clearance; moderate speed/tension | Specify correct HRC; confirm clearance; monitor load indicators |

| Knife marks/edge wave | Misalignment; uneven tension; worn bearings | Realign knives; stabilize tension; service bearings | Pre‑run alignment check; tension control; preventive maintenance plan |

Sources for mechanisms and remedies include the AHSS portal and Uddeholm’s AHSS tooling and coating pairing guidance: see WorldAutoSteel’s tooling and die wear overview dan Uddeholm’s PVD pairing guidance.

Maintenance and lifecycle policy

Treat slitting knives as engineered consumables with a documented lifecycle.

- Resharpening triggers: in AHSS, burr height may not rise steadily with wear; also track rollover growth, burnish/fracture consistency, and microscopic edge defects. WorldAutoSteel’s slitting notes outline why. See the AHSS slitting guidance.

- Regrind and re‑coat plan: preserve geometry and micro‑edge radius; re‑apply PVD after regrind when coatings are critical for adhesion/heat resistance, per Uddeholm’s coating guide.

- Spare‑stock policy: maintain a rotation that supports regrind/recoat turnarounds without forcing emergency runs on dull knives.

- For practical upkeep checklists and storage/handling tips, review METAL’s neutral maintenance resources such as industrial blade maintenance tips.

Practical micro‑example: specifying a DP780 knife set (METAL)

Disclosure: METAL is our product.

For a common automotive AHSS like DP780 at 0.040 in (1.0 mm), a balanced starting specification can look like this to minimize burrs and micro‑chipping while preserving edge ductility:

- Knife material: PM tool steel comparable to Uddeholm Vanadis 4 Extra, specified at 60–62 HRC for a balance of wear and toughness.

- Coating: TiAlN (1–3 µm) to manage heat and oxidation at typical line speeds; consider DLC if adhesive pickup appears on coated coils.

- Edge preparation: 15–25 µm micro‑edge hone; fine‑polished rake/flank faces.

- Clearance: 10–12% of thickness (0.004–0.0048 in for 0.040 in stock) as a starting point; validate with short‑run trials.

- Verification: inspect burnish/fracture proportions and run spot bend/edge‑ductility checks on critical parts.

For further context on coatings and life‑management practices without sales language, see METAL’s overview on slitter blade coatings and durability guidance.

References and further reading

- WorldAutoSteel’s AHSS portal offers slitting, clearance, and cutting guidance that ties directly to edge ductility/HER: see AHSS Guidelines on slitting and clearance dan cutting/blanking/shearing/trimming.

- Uddeholm’s practitioner‑oriented documents explain why PM steels and polished, coated surfaces matter for AHSS cutting tools: Tooling solutions for AHSS dan PVD coating pairing guidance.

- SSAB provides useful context on evaluating edge ductility in automotive steels: Determining AHSS ductility.

- For a peer‑reviewed discussion of how clearance and speed shape deformation and burr formation in shear‑slitting (on electrical steel), see Szada‑Borzyszkowska et al. 2023. Coating property ranges and use‑cases are summarized across vendor‑neutral overviews and PVD provider pages cited above.

Next steps

If you share your target grade, thickness, and current burr/HER limits, we can return a simple parameter card (material, HRC, coating, edge prep, and clearance) tailored to your line—and quote the exact Steel Slitting Knives to match those specs.