Corrugated packaging blades are essential components of industrial machines, designed to cut and shape corrugated materials with precision. These blades play a crucial role in the production of corrugated cardboard, where accuracy and speed are paramount.

The significance of these blades is underscored by the growing demand for corrugated packaging. For instance:

- The global corrugated packaging market is projected to reach $250 billion by 2026.

- Corrugated packaging constitutes a substantial segment of the $1 trillion packaging market anticipated by that time.

- The rise of online shopping has heightened the need for advanced packaging solutions, making these blades indispensable.

Nanjing Metal specializes in manufacturing high-quality corrugated packaging blades to optimize machine performance. Whether you require a standard or lama personalizzata, Nanjing Metal can produce the perfect solution for your needs. To learn more, please Contatti them today.

Punti chiave

- Corrugated packaging blades are used to cut and shape materials. They help make packaging faster and reduce waste during production.

- Strong materials like high-carbon steel and tungsten carbide make blades last longer. These materials keep blades sharp and save money on replacements.

- Cleaning and sharpening blades often helps them work better and last longer. This also avoids delays caused by broken or dull blades.

- Custom blades can be made for specific jobs. They help speed up production, improve product quality, and use less material.

- New blade technology, like special coatings and smart features, makes cutting easier and improves efficiency in factories.

Understanding Corrugated Packaging Blades

What Are Corrugated Packaging Blades?

Role in Industrial Machines

Corrugated packaging blades are important tools in factory machines. These blades are made to cut and shape corrugated materials accurately. They are used in machines that make boxes, cartons, and other packaging items. Their sharp edges and strong build help them work fast without losing precision. Adding these blades to your machines makes cutting smoother and boosts productivity.

Why They Matter for Packaging

Efficiency is very important in making corrugated cardboard. Corrugated packaging blades help cut materials neatly and consistently. This reduces waste and saves time during production. For example, using good-quality blades ensures clean cuts, which make strong and nice-looking packaging. Reliable blades also help machines run smoothly, so you can meet deadlines and produce more items.

How Corrugated Packaging Blades Work

Processo di taglio

These blades use sharp edges and special angles to cut. When the blade touches the material, it applies pressure to make a clean cut. Some blades, like slotter blades, can cut and score at the same time, making the process faster. This cutting method keeps the material strong, which is important for durable packaging.

Here’s a comparison of slotter blades and older cutting methods:

| Caratteristica | Lame Scanalatrici | Older Cutting Methods |

|---|---|---|

| Cutting Performance | Excellent and precise | Often less effective |

| Durata | Very durable with heat treatment | Si consuma più velocemente |

| Precisione | Accurate cuts with sharp angles | May lack accuracy |

| Velocità | Funziona bene ad alte velocità | Slower and less reliable |

| Funzionalità | Cuts and scores in one step | Needs extra tools |

This table shows how slotter blades are better in speed, precision, and durability.

Types of Cuts

Corrugated blades can make different cuts based on their design. Straight cuts create smooth edges for boxes. Perforated cuts make tearing easier. Serrated edges are great for cutting thick materials. Circular blades are used for continuous cutting jobs. Choosing the right blade helps you meet specific packaging needs.

Materials Used for Blades

Materiali comuni delle lame

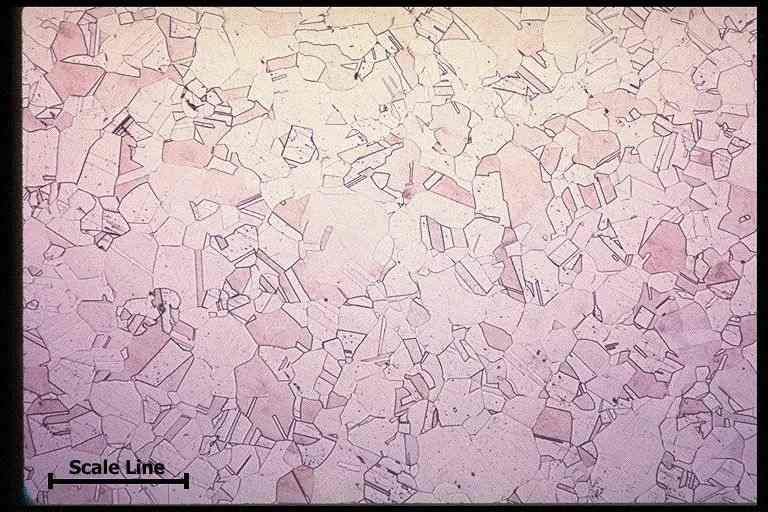

The performance of these blades depends on the materials used. High-carbon steel, stainless steel, and tungsten carbide are common because they are strong and sharp. These materials are tested to handle fast cutting. For example, tests check how well they resist wear and stress over time.

Why Material Quality Matters

Good materials make blades last longer and work better. High-quality blades stay sharp, so you don’t need to replace them often. This saves money and keeps production steady. Advanced manufacturing methods also make blades stronger. By choosing top materials, you ensure your blades perform well for a long time.

Mancia: Check your blades often for wear to keep them working efficiently.

Applications of Corrugated Packaging Blades

Usage in Packaging Machines

Corrugated packaging blades are key parts of packaging machines. They cut and shape corrugated materials with great accuracy. This is important for making high-quality boxes, cartons, and custom packaging. These blades stay sharp and strong, even during fast production.

For example, die-cutting machines use these blades to create detailed shapes. This helps meet different packaging needs in many industries. Using good-quality blades reduces waste and improves efficiency. This saves money and makes better products.

Role in Production Lines

Corrugated knives are crucial for smooth production lines. They handle nonstop cutting, keeping the process running without delays. These blades cut quickly and precisely, helping meet tight deadlines.

Strong materials make these blades last longer, so they need fewer replacements. This is important for big factories where downtime can be costly. Adding corrugated blades to your machines increases output, improves product looks, and keeps customers happy.

Here’s a table showing the benefits of using corrugated knives:

| Beneficio | Descrizione |

|---|---|

| Efficienza produttiva | Faster machines increase how much you can make. |

| Miglioramento della qualità | Clean cuts make packaging look better and stronger. |

| Efficienza dei costi | Less waste and fewer repairs save money. |

| Prestazioni ambientali | Uses less energy and eco-friendly materials. |

| Maggiore efficienza produttiva | Better tools mean faster work and more profit. |

| Costi di produzione ridotti | Good tools lower waste and mistakes, saving money. |

| Maggiore competitività del mercato | Great packaging makes customers happier and loyal. |

| Benefici ambientali | Follows rules and helps the environment, boosting brand image. |

Maintenance of Corrugated Packaging Blades

Pratiche di manutenzione regolare

Taking care of corrugated blades keeps them working well for longer. Clean them often with a soft cloth and safe cleaner. This removes dirt that can make the blade dull or cut poorly.

Check your blades regularly for damage like chips or uneven edges. Fix problems quickly to avoid bigger issues. Sharpening the blades when needed also helps them cut better. Use the right tools to keep the blade strong.

Mancia: Plan regular checks to catch problems early and avoid expensive fixes.

Signs of Wear and Tear

Knowing when blades are worn out helps you act fast. Dull blades are a common sign. If cutting gets harder or less clean, it’s time to sharpen or replace them.

Uneven or rough cuts also show the blade needs attention. Loud noises or shaking during use can mean the blade is damaged or not aligned. Watching for these signs keeps your blades in good shape and your machines running smoothly.

Types of Corrugated Packaging Blades

Straight Corrugated Blades

Features of Straight Blades

Straight blades make clean, smooth cuts on materials. Their flat edges are great for cutting straight lines. Made from strong metals like high-carbon steel, they stay sharp. These blades work well for fast and repeated use. Heat-treated surfaces make them stronger and last longer.

Straight blades are perfect for precise cutting jobs. They waste less material and make even cuts. This makes them a reliable choice for packaging production.

Common Uses in Industry

Straight blades are used a lot in packaging factories. They cut materials for boxes, cartons, and other packaging items. These blades are key for making clean edges for folding and assembly. They also cut big sheets into smaller pieces.

Besides packaging, straight blades are used in other industries. For example, they cut inserts and labels in printing jobs. Their steady performance ensures smooth work and good results.

Serrated Corrugated Blades

Benefits of Serrated Edges

Lame seghettate have jagged edges that cut better. These edges grip materials tightly, making cutting easier. They are great for thicker or tougher materials. Serrated blades help avoid tearing and make neat cuts. Their design spreads pressure evenly, so they last longer.

These blades are perfect for heavy-duty cutting tasks. They handle tough jobs while staying precise. This makes them useful for industrial machines in packaging.

Applicazioni nel packaging

Serrated blades are used for strong packaging needs. They cut thick materials for shipping and storage boxes. These blades keep packaging sturdy and reliable.

They are popular in industries like food and drinks. Packaging here must protect items like fresh food. Serrated blades also save time by lasting longer and needing fewer replacements.

Perforation Corrugated Blades

Purpose of Perforation

Perforation blades make small cuts for easy tearing. They are great for packaging with tear-off sections. These blades make opening packages simple while keeping them strong.

Their sharp edges and patterns ensure neat and exact cuts. Perforation blades also speed up production by reducing extra cutting steps.

Industries Utilizing Perforation

Perforation blades are used in industries needing easy-to-open packaging. Retail and online stores use them for tear-off package sections. Food packaging also uses these blades for quick access to products.

Other industries, like electronics and cars, use them too. They create dividers and inserts for protective packaging. Their flexibility makes them useful for many packaging tasks.

Circular Corrugated Blades

Benefits of Circular Shape

Circular blades are great for fast and smooth cutting. Their round design lets them cut nonstop, which saves time. These blades spin easily, lowering friction and wear. This helps them work well, even with heavy use.

Circular blades make clean and accurate cuts. Their sharp edges waste less material during production. The round shape spreads pressure evenly, making the blades last longer. This means fewer replacements, saving money and effort.

Common Uses in Factories

Circular blades are used to cut large sheets into smaller pieces. They are also important for making foldable packaging with neat cuts. These blades are key in industries like packaging and printing.

They help create boxes, cartons, and inserts with clean edges. Their strength and speed make them perfect for busy production lines. Using circular blades boosts productivity and keeps product quality high.

Specialty Corrugated Blades

Special Features of Custom Blades

Specialty blades are made for jobs regular blades can’t do. They have unique shapes, coatings, or materials for specific tasks. Some are designed to cut soft materials without damage. Others are tough enough for hard, rough surfaces.

These blades are great for tricky cutting jobs. Their smart designs help them work well in tough conditions. Many have heat-resistant coatings to stay strong and last longer.

Uses in Different Industries

Specialty blades are used in many fields. Food companies use them to cut packaging that keeps food fresh. Car factories use them for protective packaging for parts. Electronics makers use them for precise inserts and dividers.

Choosing specialty blades solves hard cutting problems. They improve production and make better products. Their flexibility makes them useful for businesses with specific needs.

Industrial Applications of Corrugated Packaging Blades

Industria dell'imballaggio

Cutting Corrugated Boxes

Lame per Cartone Ondulato are key for cutting corrugated boxes. They make clean cuts, keeping boxes strong and sturdy. These blades work well for both small and large boxes. Their sharpness and strength suit fast production lines. Using these blades reduces waste and ensures neat cuts for carton boards.

Shaping Custom Packaging

Custom packaging needs precise and flexible cutting. Corrugated blades help create unique shapes and designs. They easily cut patterns and slots for special packaging. For example, die-cutting machines use these blades for custom-sized packages. This improves how packaging looks and works, perfect for retail and online stores.

Printing and Converting

Precision Cutting for Labels

Corrugated blades cut labels and inserts with great accuracy. They handle delicate materials without damage. Their sharp edges make them ideal for cutting corrugated products for labels. Industries like food, drinks, and electronics need this precision. Adding these blades to your machines keeps quality consistent.

Creating Inserts for Products

Corrugated blades are great for making protective inserts. These inserts fit specific shapes to keep items safe during shipping. For example, car and electronics packaging uses inserts to protect fragile parts. These blades ensure inserts are both useful and look good.

Food and Beverage Sector

Packaging for Perishable Goods

Food packaging uses corrugated blades to keep items fresh. These blades cut materials that seal tightly, blocking air and dirt. For instance, fruit and vegetable boxes need clean cuts for proper sealing. These blades help meet food safety rules and keep products fresh.

Ensuring Freshness and Safety

Corrugated blades help keep food safe and fresh. Smooth cuts reduce contamination risks. Slotting and perforation make packages easy to open but still secure. High-quality blades ensure food stays fresh and safe during transport.

Industria automobilistica

Protective Packaging Solutions

Corrugated blades help make protective packaging for car parts. This packaging keeps delicate items like sensors and mirrors safe during transport. The blades cut materials to fit snugly around the parts. This stops movement and prevents damage.

For example, die-cut inserts cushion fragile items. These inserts are shaped to match the parts perfectly. This method keeps items safe and avoids scratches or breaks. Using strong blades ensures the packaging meets standards and protects the parts well.

Custom Packaging for Parts

Car parts come in many shapes and sizes, needing custom packaging. Corrugated blades help create designs that fit each part exactly. Whether you need slots, holes, or special shapes, these blades cut with precision.

Custom packaging makes assembly lines faster. Workers can easily find and grab parts without confusion. For instance, perforated packaging lets workers tear open sections quickly. This saves time and keeps operations smooth. Reliable blades help make packaging that boosts productivity and protects parts.

Industria elettronica

Safe Packaging for Components

Electronics need packaging that blocks static, moisture, and damage. Corrugated blades help make boxes and inserts for sensitive items like circuit boards and screens. These blades cut cleanly, so the packaging seals tightly to protect the contents.

With corrugated knives, you can make inserts that hold items securely. This stops movement during shipping and lowers the chance of damage. For example, foam-lined inserts add extra cushioning for fragile electronics. Precise cutting tools help meet industry standards and keep products safe.

Reducing Damage During Transport

Shipping electronics can cause vibration, impact, and temperature problems. Corrugated blades help design packaging to reduce these risks. By cutting materials to fit perfectly, you can make snug boxes that absorb shocks and stop movement.

Perforated sections make opening easy without ruining the packaging. This is helpful for retail electronics, where secure but simple packaging is important. Advanced blades help create packaging that protects items and satisfies customers.

Retail and E-commerce

Efficient Packaging for Shipping

Retail and e-commerce need fast and efficient packaging. Corrugated blades cut materials quickly and accurately, making boxes ready for shipping on time.

For example, circular blades cut large sheets into smaller pieces for packages. This speeds up production and reduces waste. High-quality blades improve the packaging process and help meet tight deadlines. Efficient packaging also lowers shipping costs by using less material and creating compact designs.

Enhancing Customer Experience

Packaging affects how customers feel about a product. Corrugated blades help make neat and useful designs that improve unboxing. Clean cuts and precise shapes make packaging look professional.

Custom packaging, like tear-off sections, makes opening easier for customers. They can open packages without damaging the items inside. Advanced blades help create packaging that impresses customers and builds loyalty.

Custom Applications

Special Solutions for Specific Needs

Different industries need different types of packaging. Corrugated knives help meet these specific needs. Custom blades can cut materials into exact shapes and sizes. This makes sure your packaging fits your product perfectly.

For example, food companies may need blades to make easy-to-tear packaging. Electronics makers often need blades to create snug inserts for fragile parts. Custom blades adjust to these needs, making packaging both useful and efficient.

Using custom blades can also solve problems like wasting materials or slowing production. These blades help you meet customer needs while keeping quality high.

Mancia: Talk with blade makers to design tools that fit your needs. This teamwork helps your production line work better.

Advantages of Customization

Custom blades bring many benefits to your business. First, they make work faster and smoother. Blades made for specific tasks cut quicker and more neatly. This saves time and boosts productivity.

Second, they improve how your packaging looks and works. Clean cuts make packaging look professional and work well. This is very important in retail and online shopping, where packaging affects customer happiness.

Third, custom blades let you keep up with changing trends. As customer needs change, you can update your packaging without big changes to your machines. Custom blades give you the flexibility to stay competitive.

Finally, custom blades help the environment. They reduce waste, saving materials and money. This also shows your company cares about being eco-friendly, which improves your brand image.

Nota: Custom blades may cost more at first, but they save money over time. They improve speed, quality, and reduce waste, making them worth the investment.

The Importance of Custom Blades

Enhancing Operational Efficiency

Tailored Solutions for Specific Needs

Custom blades are made to fit your specific production needs. Unlike regular blades, they handle special tasks better. For example, a box factory switched to custom micro-tooth blades. This change cut their downtime from 14 hours to under 5 hours each month. This shows how custom blades can improve how your machines work.

These blades also solve problems unique to your industry. Whether you need sharp cuts for detailed designs or tough blades for hard jobs, custom tools help machines run smoothly. By choosing Lame Personalizzate, you can make work faster and get reliable results.

Streamlining Production Processes

Custom blades make production easier by lasting longer and needing less care. A 2022 report found companies saved 28% in yearly costs with custom blades. These blades don’t wear out quickly, so they need fewer replacements.

Here’s a comparison of standard and custom blades:

| Fattore | Lama standard | Lama personalizzata |

|---|---|---|

| Cuts per Blade | 8,000 | 32,000 |

| Blade Changes (per month) | 12 | 3 |

| Tempo di inattività mensile | 14 hours | 4 hours |

This table shows how custom blades save time and boost production by reducing downtime.

Reducing Waste and Costs

Minimizing Material Waste

Custom blades make clean cuts, which means less wasted material. Fewer mistakes during cutting save resources and help the environment. Using these blades helps you use materials wisely and supports green manufacturing.

Lowering Overall Production Costs

Custom blades cost more upfront but save money over time. They last longer, so you don’t need to replace them often. Fewer blade changes also mean lower labor costs and less machine downtime. For instance, companies using custom blades lowered monthly costs from $800 to $450, including labor. This makes custom blades a smart choice for saving money.

Improving Product Quality

Achieving Precise Cuts

Custom blades make exact cuts, which is key for good packaging. Whether cutting boxes or detailed designs, these blades stay accurate. Clean cuts make products look better and work well, pleasing customers.

Maintaining Packaging Integrity

Strong blades avoid damaging materials, keeping packaging sturdy. This is vital for industries like food and electronics, where safe packaging matters. Custom blades help you make packaging that meets standards and keeps customers happy.

Adapting to Market Demands

Customization for Different Industries

Each industry has its own packaging needs. Corrugated packaging blades must adjust to meet these demands. For example, food companies need blades for easy-to-open packages. Electronics makers require precise blades for protective inserts. Custom blades help solve these specific challenges.

A blade for car parts can cut inserts to protect fragile items. Retail packaging blades can make tear-off sections for easier use. Choosing custom blades ensures your packaging fits your product perfectly. This not only speeds up production but also makes customers happier.

Flexibility in Design Changes

Market trends change fast, and packaging tools must keep up. Custom blades can adjust to new designs or materials easily. If you launch a new product, a custom blade can handle the changes without slowing production.

This flexibility reduces downtime and keeps work running smoothly. Whether you need a special edge or a unique material, custom blades keep your machines ready for new challenges.

Collaborating with Experts

Benefits of Working with Specialists

Working with skilled blade makers gives you expert advice. They understand your industry and suggest the best blade designs. These specialists also ensure high-quality blades for reliable performance.

Nanjing Metal, a trusted industrial blade supplier, has 18 years of experience. Their team works with you to create blades that improve production and efficiency.

Accessing Advanced Technologies

Experts also use the latest blade technology to help you. Companies like Nanjing Metal use advanced materials and coatings for stronger, sharper blades. These upgrades reduce waste, save money, and improve packaging quality.

Visit their pagina iniziale to learn more. Ready to discuss your needs? Contatti their sales team today!

Maintenance and Technological Advancements

Importanza della manutenzione regolare

Ensuring Optimal Performance

La cura regolare mantiene corrugated packaging blades working well. Clean blades often to remove dirt and glue. This lowers friction and helps them cut smoothly. Lubricate blades to stop overheating, which can cause damage. Sharp blades cut better, saving time and reducing mistakes. Keeping blades sharp also reduces wasted materials and improves production speed. Fixing small issues early avoids delays and costly replacements.

Mancia: Regular maintenance saves money. It boosts energy efficiency and lowers costs over time.

Prolungamento della durata della lama

Taking care of blades makes them last longer. Regular sharpening and lubrication prevent wear and keep blades strong. Fixing small problems early stops them from becoming bigger issues. Well-maintained blades cut more precisely, helping you make better packaging. By caring for your blades, you save money and keep production steady.

Common Maintenance Practices for Corrugated Knives

Procedure di pulizia

Clean blades often to keep them working well. Use a soft cloth and safe cleaner to remove dirt and glue. This stops buildup that can dull the blade. Avoid rough materials that might scratch the blade. Clean blades work smoothly and last longer.

Inspection Techniques

Check blades regularly to find problems early. Look for chips, uneven edges, or alignment issues. These can affect cutting accuracy. Use tools to inspect blades closely and make sure they stay sharp. Fixing small damage quickly keeps blades reliable.

Signs of Deterioration

Identifying Wear Patterns

Wear marks show when blades need care. Dull edges make cutting harder and less clean. Rough cuts mean blades need sharpening or replacing. Overheating can leave marks or weaken the blade. Spotting these signs early helps avoid bigger problems.

Recognizing Performance Issues

Blade problems can cause loud noises or shaking during use. Hard-to-cut materials or uneven results mean blades need fixing. Solving these issues quickly keeps blades dependable and production smooth.

Nota: Bad blades waste materials and slow production. Regular care avoids these problems and keeps work running efficiently.

Innovations in Blade Technology

Advanced Coating Techniques

Modern blades use special coatings to work better and last longer. Coatings like titanium nitride or diamond-like carbon make blades stronger and more precise. These coatings lower friction, helping blades cut smoothly without overheating. Coated blades resist wear and rust, so they stay sharp longer.

For example, titanium-coated blades handle fast cutting without losing sharpness. This makes them great for factories with nonstop production. Choosing coated blades means less maintenance and better efficiency overall.

Mancia: Pick blades with heat-resistant coatings for tough cutting jobs.

New Material Developments

Blade makers now use new materials to make stronger tools. High-speed steel (HSS) and tungsten carbide are very hard and resist wear well. Composite materials are also popular because they mix strength with flexibility.

Blades made from these materials work better under heavy use. For instance, tungsten carbide blades stay sharp even when cutting tough stuff. This reduces downtime and keeps production smooth. Using advanced materials can make your cutting process faster and easier.

Future Trends in Blade Design

Personalizzazione per esigenze specifiche

Blade designs are becoming more customized for different industries. You can now order blades with special shapes, sizes, or edges to match your needs.

Custom blades help reduce waste and make cleaner cuts. For example, perforation blades create tearable packaging that stays strong. Working with blade experts lets you design tools that fit your goals perfectly.

Integration of Smart Technologies

Smart technology is changing how blades are made. Some blades now have sensors to track their performance. These sensors check for wear, heat, or alignment problems. You can use this info to plan maintenance and avoid delays.

Imagine a blade that tells you when it needs sharpening. This keeps quality high and prevents downtime. As smart tech improves, blades will have even more features to help your work.

Nota: Using smart blade technology can make your business stand out.

Corrugated packaging blades are important for factory production. They cut materials neatly, which saves resources and improves product quality. Strong blades last longer, needing less maintenance and reducing machine stops. Custom blades make work easier by solving specific problems, speeding up tasks, and lowering expenses.

Nanjing Metal makes high-quality blades for many industries. Their blades are built to work well and last a long time. Using Nanjing Metal blades can improve your machines and help you get better results.

Domande frequenti

What are corrugated packaging blades used for?

Corrugated packaging blades cut materials like cardboard for making packages. They are used in industries that make boxes, cartons, and inserts. These blades help make clean cuts, reduce waste, and speed up production.

How do you maintain corrugated packaging blades?

Clean blades often with a soft cloth and safe cleaner. Check for chips or dull edges regularly. Sharpen them when needed to keep them cutting well. Taking care of blades makes them last longer and keeps machines working smoothly.

What materials are best for corrugated packaging blades?

High-carbon steel, stainless steel, and tungsten carbide are popular choices. These materials are strong, resist wear, and stay sharp longer. Picking good materials helps blades work better and need fewer replacements.

Can you customize corrugated packaging blades?

Yes, you can get custom blades made for your needs. Custom blades cut more precisely, waste less material, and fit special packaging tasks. They are great for industries with unique production needs.

Why are serrated blades better for thick materials?

Serrated blades hold thick materials tightly, making cutting easier. Their jagged edges spread pressure evenly and stop tearing. This makes them perfect for tough cutting jobs in packaging.

Mancia: Use serrated blades for hard tasks to save time and cut better.

Vedi anche

Aumenta la tua efficienza con la corretta installazione e configurazione dei coltelli rotanti

Come prolungare la durata delle lame del tuo Carton Slotter: consigli e trucchi degli esperti