| Altri nomi | Lama seghettata per gelatina, lama seghettata per tè al latte |

|---|---|

| Luogo d'origine | Cina |

| Applicazione | Alimentare, Imballaggio |

| Materiale | Acciaio inossidabile |

| Numero di modello | GP-JP |

| Servizio dell'OEM | Disponibile |

| Termini di pagamento | L/C, T/T, Western Union |

| Pacchetto | Scatola di cartone, In casse di legno |

| Tempi di consegna | 7-20 giorni |

Condividere a:

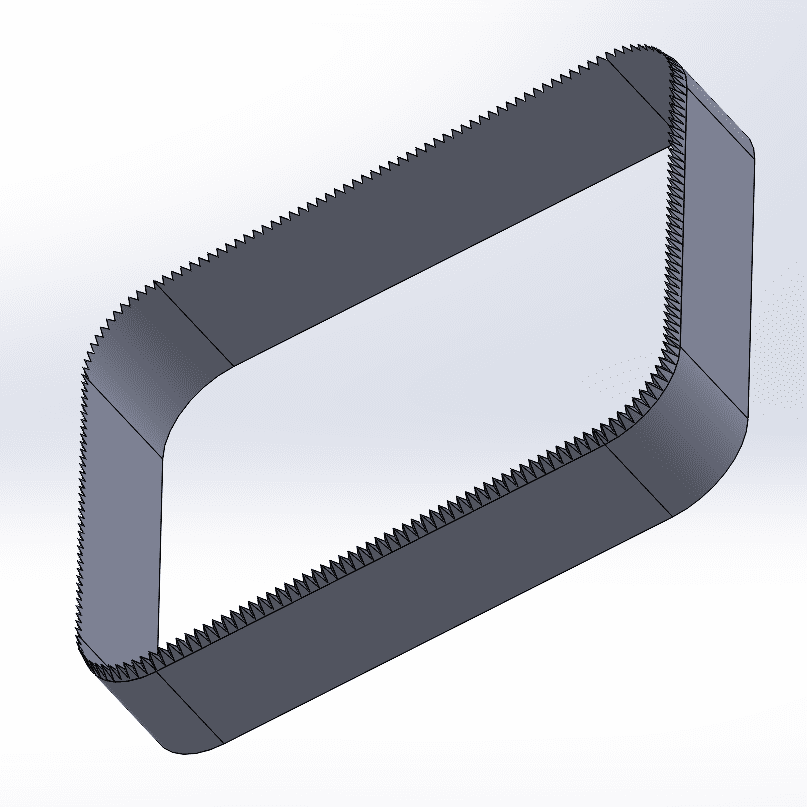

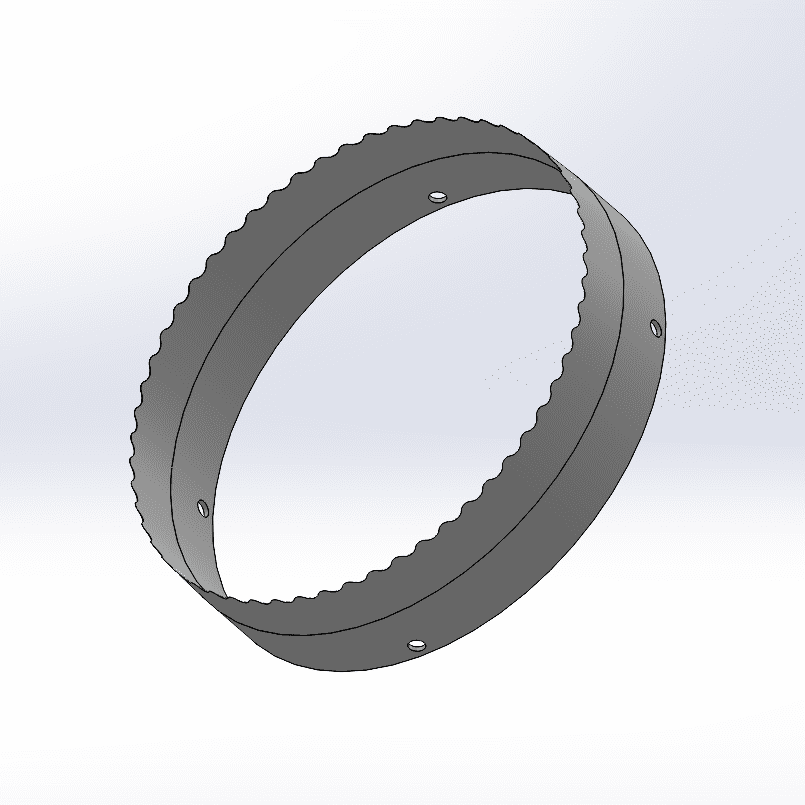

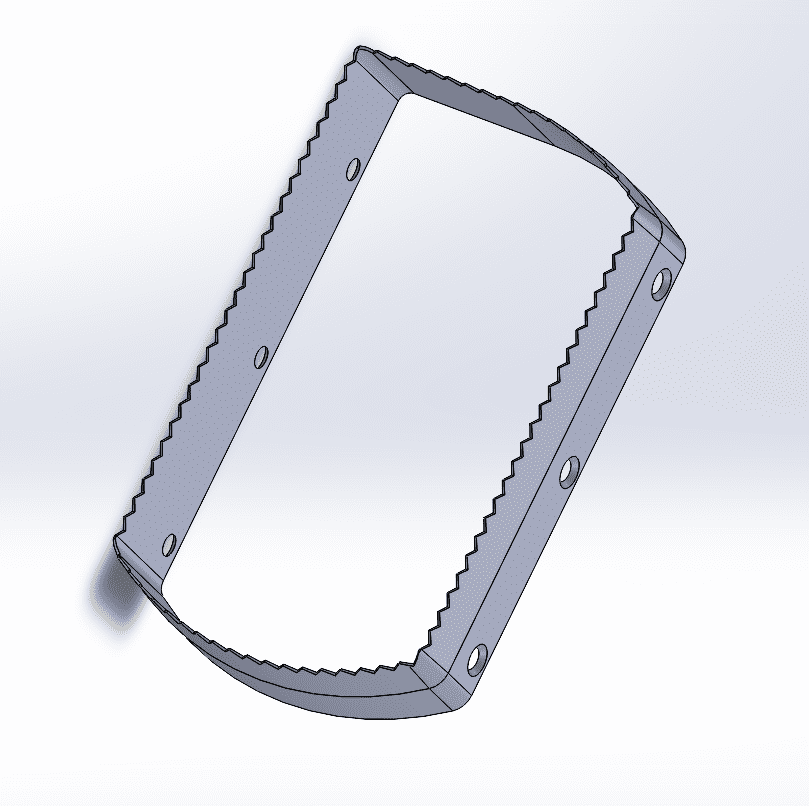

The term “Tooth Punch Blades” refers to a specific type of punch blade characterized by a cutting edge that features a series of teeth or serrations. Unlike punch blades with a continuous, smooth cutting edge, Tooth Punch Blades are designed to create holes or perforations with a specific edge profile or to facilitate tearing or separation of the material being punched. The teeth can vary in size, shape, and spacing depending on the intended application and the desired effect. Tooth Punch Blades are particularly useful for processing materials where a clean, shear-like cut is not always desired, or where a specific texture or tear initiation point is needed around the punched feature. These blades operate in punching machines or presses, similar to other punch blades. Tooth Punch Blades are also sometimes referred to as “serrated punch blades,” “perforating punch blades” (if the teeth are small and closely spaced), “notching punch blades” (if used to create edge notches), or “tear-off punch blades,” depending on the specific application and the resulting hole or cut.

Tooth Punch Blades are used in various industrial and craft applications where a toothed or perforated edge is required in the punched material. Key uses and application scenarios include:

The specific size, shape, and spacing of the teeth on the Tooth Punch Blade are critical to achieving the desired perforation or tear characteristics in the punched material.

The materials used to manufacture Tooth Punch Blades are chosen for their ability to maintain the sharp edges of the teeth under repeated impact and to resist wear. Common materials include:

The selection of the appropriate material depends on the material being punched, the required precision and durability of the teeth, and the production volume. Proper heat treatment is essential to ensure the teeth have the necessary hardness and toughness to perform effectively.

The defining characteristic is the toothed cutting edge. Beyond this, Tooth Punch Blades can have various overall shapes and tooth configurations:

The design of the teeth (size, shape, pitch, angle) is critical and is tailored to the specific material being punched and the desired outcome of the perforation or tear. Precision manufacturing is essential to ensure the teeth function correctly and consistently.

Se non trovi la lama che stai cercando, possiamo anche personalizzarla. Guarda il nostro “Lame personalizzate” per imparare come! Benvenuti a chiedere informazioni!

È facile usufruire della comodità dell'importazione: dal trasporto allo sdoganamento, ci occupiamo dell'intero processo, tu devi solo pagare l'IVA e attendere che la merce arrivi in azienda.

Abbiamo visto le sue lame utilizzate in innumerevoli applicazioni ed è pronto a gestire qualsiasi progetto ci venga proposto, offrendo precisione, durata e prezzi competitivi senza pari.

Che tu fornisca disegni, schizzi o campioni, siamo in grado di disegnare e produrre per te. Abbiamo anche la capacità di assistere nella modifica di progetti e specifiche esistenti per migliorare quasi ogni applicazione di utensili industriali. Contatta il nostro team di vendita dedicato per discutere le tue esigenze specifiche.

Per controllare la qualità vengono eseguiti una serie di test e ispezioni, tra cui l'ispezione del primo articolo, l'ispezione del materiale in entrata e dei materiali certificati, l'ispezione della qualità in corso di lavorazione e l'ispezione della qualità finale.

Che tu sia un importatore, un distributore, un grossista o un utente finale, ti invitiamo a unirti a noi con un MOQ minimo, nessuna seccatura per le richieste e maggiore libertà di acquisto.

Diventa il tuo monitor esclusivo, trasmissione regolare di ogni nodo importante nella linea di produzione, non importa quanto lontano, per comprendere il progresso del prodotto il più lontano possibile!

Nanchino Metal Industrial CO., Limited

Parco industriale Mingjue, Lishui, Nanchino, Jiangsu, Cina

Rimani aggiornato con le nostre ultime novità.