Selezione Attrezzatura per piegatrici specializzata for unique metal shapes requires careful consideration. You must match the tooling to the complexity of the shape. Additionally, you need to think about the type of material you are using. Ensure that the tooling is compatible with your machine. Consider how precise you need the work to be. More than 80% of metal projects utilize specialized press brake tooling for high-quality and consistent results. The right tooling provides accurate bends and saves time. Nanjing Metal allows you to customize options to meet your needs in automotive, construction, and electronics.

Punti chiave

- Specialized press brake tooling is needed to make special metal shapes. Standard tools cannot make these shapes.

- You must know the shape’s difficulty and the material type to pick the right tooling.

- Custom tooling can help projects be faster and more exact. This is very helpful for hard bends and small gaps.

- Make sure your tooling fits your press brake machine. This stops damage and keeps everyone safe.

- Check and care for your tooling often. This helps it last longer and keeps your work good.

- Think about what your industry needs, like cars or electronics, when you pick tooling.

- Quick-change tooling systems help you set up faster and work more in less time.

- Safety features in tooling are very important. Always choose tools that make your shop safer.

Choosing Specialized Press Brake Tooling

Profile Complexity

Working with unique metal shapes can be hard. Some shapes, like Z-shapes, offsets, and hems, need extra care. Regular press brake tooling cannot always make these shapes well. You need specialized press brake tooling for these jobs.

Here are some problems you might face when picking tooling:

- If you pick the wrong die opening, thick material can crack or bend wrong.

- The type of material changes how it bends. Each metal acts differently.

- The bending force must match the tool’s strength. If not, the tool or machine can break.

- Tonnage is important. The tool must handle the needed force.

The table below shows how different tooling types help with tricky shapes:

| Tipo di utensile | Descrizione | Scopo |

|---|---|---|

| Offset Dies | Makes Z-shaped or offset bends, with two angles in one stroke. | Keeps bends straight and accurate. |

| Offset Bending Tooling | Bends in two ways at once, making a Z-shaped profile. | Cuts down on extra setups. |

Specialty tooling, like offset dies, helps you make hard shapes faster. This saves time and makes bends more exact.

Application Needs

Think about your project before you pick press brake tooling. Every industry needs something different. For example, car parts need tight bends that repeat. Building projects need big, strong shapes. Electronics need tiny, exact bends.

Press brake tooling can be made for many uses. The table below shows how tooling types fit different jobs:

| Tipo di utensile | Application Needs | Benefici |

|---|---|---|

| Segmented Tool | Hard bending jobs, detailed designs | Lets you change and adapt for specific needs. |

Press brakes are important in many industries. They help you make tough shapes and sharp angles. This matters for custom jobs. You get the right tool for your work, whether it’s cars, buildings, or electronics.

Tip: Always pick tooling that fits your project. Custom tools can make your work better and faster.

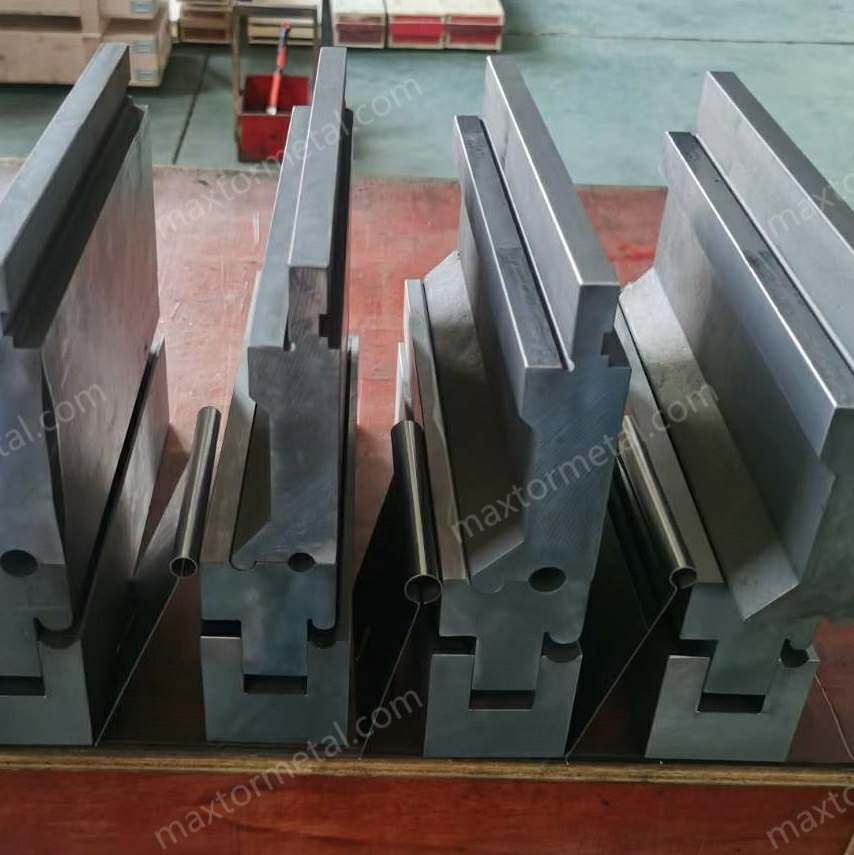

Shop Capabilities

Your shop’s tools and machines matter when picking tooling. You need to check if your press brake tooling fits your machine and your work goals. The table below shows what to think about:

| Fattore | Descrizione |

|---|---|

| Tipo di materiale e spessore | The kind and thickness of metal change what tooling you need. |

| Tooling Compatibility | The tooling must fit your press brake machine for safety. |

| Precision and Tolerances | Projects needing high precision need tooling that keeps tight tolerances, especially for thin metals. |

| Tooling Durability and Maintenance | Strong tooling and easy care help save time and money. |

| Production Volume and Speed | How much and how fast you work changes what tooling you pick. |

New shop technology can help you get better results. Strong steels and new alloys make tooling last longer. Ceramic coatings help stop wear and boost performance. Some shops use smart sensors to watch tooling all the time. These new ideas help you keep your tooling working well and accurate.

What Is Specialized Press Brake Tooling

Specialized press brake tooling lets you make metal shapes that normal tools cannot. You use this tooling for tricky bends, sharp angles, or special metals. It gives you more control and better results in your projects.

Caratteristiche principali

Ingegneria di precisione

You need to be very exact when making hard parts. Specialized press brake tooling uses tight rules so every bend matches your plan. For example, you can use it to make detailed Z-shapes for electronics. The tool’s design keeps each bend the same. This helps your parts fit together just right.

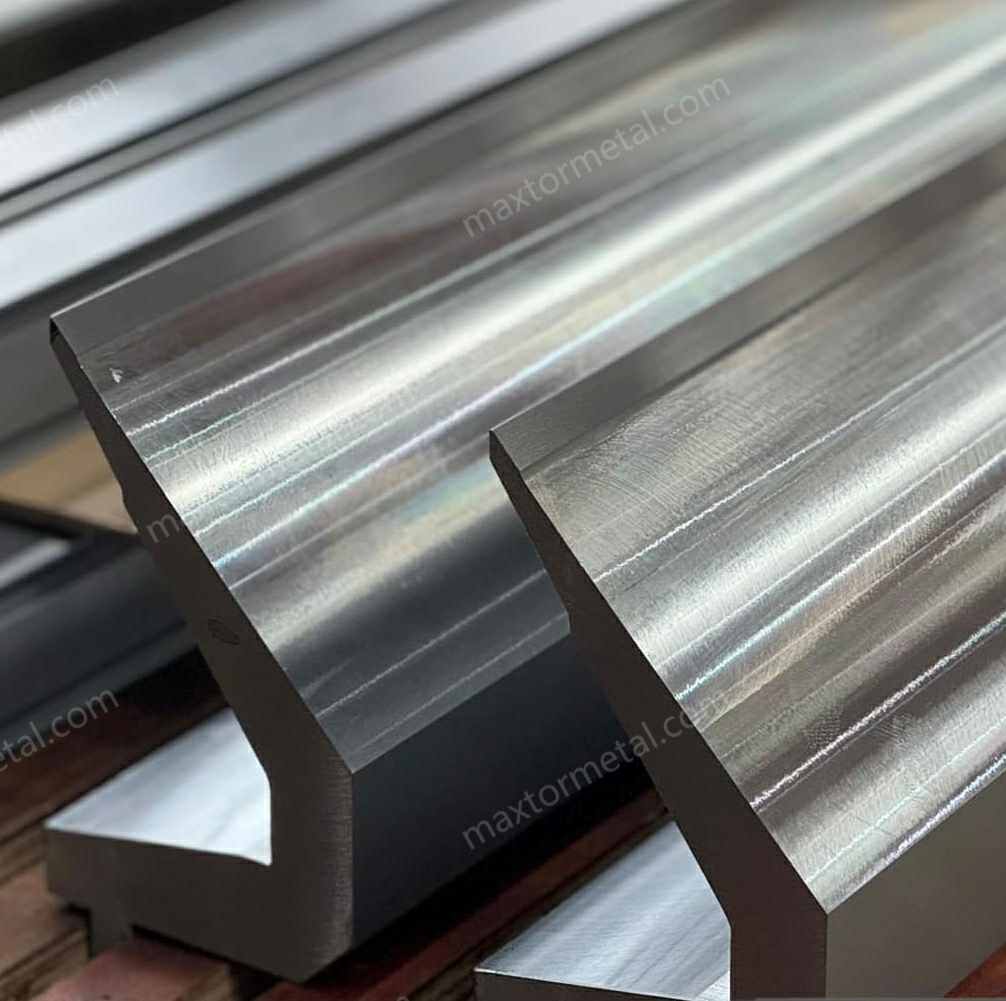

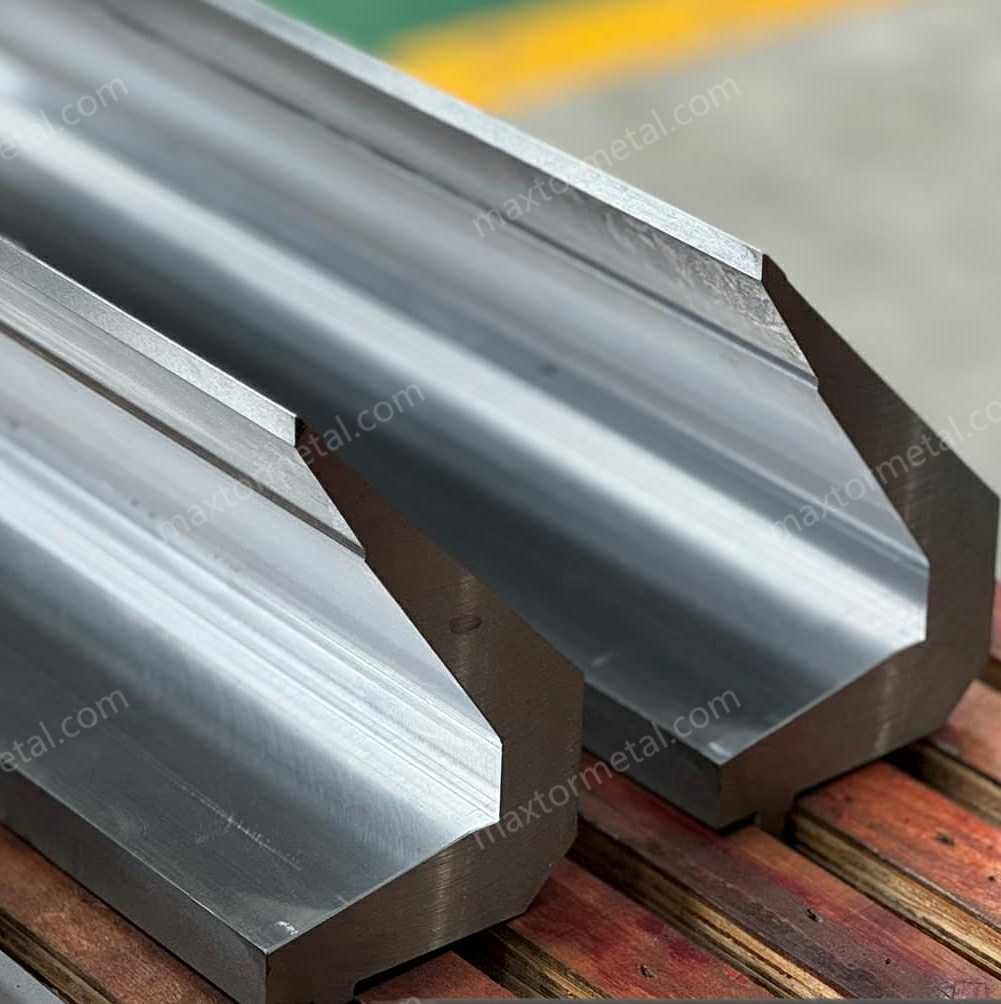

Material Durability

You want your tooling to last a long time, even if you use it a lot. Nanjing Metal makes press brake tooling from 42CrMo alloy steel. This steel gets very hard after heat treatment. It does not wear out fast and keeps its shape, even if you make many parts. You can use different tool pieces for flexible setups. The tool’s tolerance stays at ±0.02mm, so your bends stay correct. If you need special blades for certain metals, you can find more choices on the pagina delle lame personalizzate.

- 42CrMo steel gives strong wear resistance.

- The tooling keeps its hardness after heat treatment.

- You get great durability for tough jobs.

Capacità di personalizzazione

Every job is different. Sometimes, you need tooling made just for your project. Specialized press brake tooling can be made for special uses, like offset punches for car brackets or custom dies for building parts.

Enhanced Safety Features

Safety is important in every shop. Specialized dies may have built-in safety features. These help stop mistakes during fast work. You can work faster and safer, knowing your tooling helps keep you safe.

Compatibility with Advanced Machinery

Modern shops use advanced machines like CNC press brakes. Specialized press brake tooling works with these machines for repeatable, exact bends. You can set your press brake to make the same bend every time. This saves time and helps you make fewer mistakes.

Standard vs. Specialized

You might wonder how standard and specialized press brake tooling are different. The table below shows the main differences:

| Caratteristica | Specialized Tooling | Utensili standard |

|---|---|---|

| Progetto | Custom shapes for complex bend profiles | Modular and widely available |

| Funzione | Handles unique applications with tight tolerances | Suitable for general-purpose fabrications |

| Compatibilità dei materiali | Designed for peculiar materials and unique coatings | Compatible with a range of common materials |

You use standard tooling for easy bends and simple shapes. For example, in building work, standard tooling is good for L-brackets. When you need special shapes with tight rules, you use specialized press brake tooling. Special tools, like gooseneck punches, help you make deep U-shaped parts or big boxes that standard punches cannot do.

| Caratteristica | Punzone a collo d'oca | Punzone standard |

|---|---|---|

| Neck Angle | 42°-45° outward neck | 86° sharp angle |

| Effective Height | Varies, but typically similar | 120mm standard effective height |

| Applicazione | Deep U-shaped parts, large enclosures | General-purpose bends, automotive |

| Compatibilità dei materiali | Thicker materials, complex parts | Standard materials, thin to medium |

| Performance Pressure | Suitable for high-pressure bending | Handles up to 300T/m |

| Sidewall Clearance | Greater than 8cm | Limited clearance |

| Durata | High durability with reinforced back | Durable, but limited for deep bends |

| Typical Industries | Automotive, aerospace, construction | Automotive, metalworking, construction |

Benefits for Unique Profiles

Specialized press brake tooling gives you many benefits for unique metal shapes. You can work faster because this tooling cuts down on waiting and speeds up your work. You can also do tricky bending steps, which is important for electronics and building jobs.

| Beneficio | Descrizione |

|---|---|

| Maggiore efficienza produttiva | Specialized tooling reduces downtime and increases throughput, allowing for faster production cycles. |

| Complex Bending Capabilities | Press brakes can perform intricate shapes and multi-step bending sequences, essential for precision in electronics and construction. |

| Customization and Programming | CNC systems enable extensive customization, allowing for tailored bending sequences for unique project requirements. |

You can use press brake tooling to make more than just right-angle bends. You can make fancy parts for planes, electronics, and other fields. Automation and real-time checks help you keep quality high and waste low. This matters when you need every part to be just right.

Tip: When you pick your tooling, think about the shapes you need, the metals you use, and the machines in your shop. The right tooling helps you get better results in every project.

Types of Specialized Press Brake Tooling

Z-Forming Tools

Z-forming tools help you make Z-shaped bends in metal. These bends have two angles that go in different ways. Z-profiles are used in brackets, supports, and frames. Making these shapes takes a few steps. First, you put metal coils on a decoiler. The metal goes through a straightener. Next, a servo feeder moves the strip to the roll forming part. The strip goes through rolling stations. Each station bends the metal a bit more. This shapes it into a Z profile. At the end, the machine checks the shape. It can punch holes, emboss, and cut the metal to the right size. Z-forming tools let you control each bend. You can add holes or cutouts while you work. This way, you get very exact and repeatable shapes. Z-forming tools are needed for jobs that need tight rules and the same results every time.

Tip: Z-forming tools are good for small or big jobs. You can use them for custom brackets or lots of parts.

Offset Tools

Offset tools let you make two bends at once. You use these tools to make Z-shaped or offset profiles. These shapes help parts fit in small spaces. Offset tools are used for custom brackets, enclosures, and frames. Here is a table that shows why offset tools are helpful:

| Vantaggio | Descrizione |

|---|---|

| Aumento della produttività | You do not need to move the metal many times. This is good for making lots of parts. |

| Improved Assembly Fit | Z-profiles help parts fit well in small spaces. |

| Cost-Effective Manufacturing | You save money by using less work and time. Fewer tool changes and faster work save money. |

| Enhanced Design Flexibility | You can make creative shapes for enclosures, brackets, and frames. |

Offset tools help you work faster. They also make your parts fit better. You can meet hard design needs without extra work.

Hemming Dies

Hemming dies let you fold the edge of metal over itself. You use these dies to make strong, smooth edges. Hemming is used in cars, appliances, and electronics. Hemming dies bend and flatten the edge in one step. The table below shows why hemming dies are useful:

| Vantaggio | Dettagli |

|---|---|

| Controllo di precisione | Hemming dies stop the metal from bouncing back. You can get very close tolerances, like ±0.1 mm. |

| Alta efficienza | You bend and flatten the edge at the same time. This means you do not need extra steps. |

| Versatilità dei materiali | Hemming dies work with many metals, like cold-rolled steel, stainless steel, and aluminum. |

| Improved Product Quality and Safety | Hemming takes away sharp edges and burrs. This makes parts safer and look better. |

You can change hemming dies for different metals. This stops scratches or sticking. Hemming dies help you make safe, smooth parts.

Radius & Gooseneck Dies

You often need to bend metal into shapes that standard tools cannot handle. Radius and gooseneck dies help you solve these challenges. These types of press brake tooling give you more options for making complex parts with high precision.

Radius dies let you create smooth, rounded bends. You use them when you want to avoid sharp corners or when the material needs a gentle curve. This helps prevent cracks and keeps the metal strong. You see radius dies in projects where safety and appearance matter, such as furniture edges or appliance panels.

Gooseneck dies have a special shape. The neck curves outward, which gives you extra space. This design lets you bend deep boxes or parts with tall sides. You can also use gooseneck dies for profiles with flanges or offsets. These dies help you reach tight corners and make intricate shapes.

Here are some common uses for radius and gooseneck dies:

- Deep Box Bending: Gooseneck dies work well for deep box bending because the extended neck does not hit the sides of the box.

- Intricate Profiles: You can bend profiles with multiple flanges, recesses, or offsets with high-quality press brake tooling.

- Tight Corners: The unique shape of gooseneck dies allows you to bend tight corners with great precision.

You can choose from different sizes and shapes of these dies. This flexibility helps you match the tooling to your project. When you use the right tooling, you get better results and reduce mistakes. You also improve tooling durability because the tool fits the job.

Tip: Always check your part drawings before you pick radius or gooseneck dies. The right choice saves time and keeps your fabrication process smooth.

Custom Tooling Solutions

Sometimes, your project needs a tool that does not exist yet. You may need to make a special part or work with a new material. Custom tooling solutions help you meet these needs. You can design a tool that matches your exact requirements.

Nanjing Metal offers OEM and ODM services for custom press brake tooling. You can work with their team to create a tool that fits your machine and your project. This service is helpful if you want to solve a unique bending challenge or improve your production process.

- Nanjing Metal’s OEM/ODM service enables the production of custom designs tailored to specific requirements.

- This service is ideal for clients seeking manufacturers who can create unique tooling solutions for press brakes.

You can send your drawings or ideas to the team. They will help you choose the right materials and design. You get a tool that works well and lasts a long time. Custom tooling solutions also help you keep high precision in your work.

You can use custom tooling for many applications. For example, you might need acute angle punches for sharp bends or joggle tooling for stepped profiles. You can also ask for offset punches or special dies for new products. This approach helps you stay flexible and meet new challenges in fabrication.

Note: Custom tooling solutions give you an advantage when you need to make parts that standard tools cannot handle. You can improve your workflow and keep your production line running smoothly.

Press Brake Tooling System Compatibility

Picking the right press brake tooling system helps you make good bends. You want your parts to look nice and work well. Your tooling must match your metal, your machine, and your setup. This section shows you what to check for system compatibility.

Abbinamento dei materiali

You need to use tooling that fits your metal. The metal you pick is very important. It affects how well your tooling works. Heat treatment also matters a lot. If you choose the right die material, your tooling lasts longer. Your bends will look better. For example, a strong die works well with stainless steel. This helps your machine last longer too. You can make more parts faster.

Material compatibility is needed for every press brake tooling system. You should know what kind of metal you have. Mild steel, aluminum, and stainless steel are all different. Each metal has its own strength. If you use the wrong tooling, your tool can break. Your bends might not look good.

| Fattore | Descrizione |

|---|---|

| Compatibilità dei materiali | Know your metal type and strength before picking tooling. |

| Tooling Geometry and Design | The shape of your tooling must fit the bend you want. |

| Tonnage Requirements | Make sure your tooling can handle the force needed for your material. |

Tip: Always check your metal and how thick it is. This helps you avoid problems and keeps your tooling safe.

Machine Requirements

Your press brake tooling system must fit your machine. You need to see if your tooling works with CNC or hydraulic press brakes. Some machines need special shapes or sizes for tooling. CNC systems help you get more exact bends. You can repeat bends easily with CNC.

Here is a table to help you know what to check:

| Requirement Type | Descrizione |

|---|---|

| Selezione dei materiali | Pick the right materials for your tooling to get better performance and durability. |

| Compatibilità della macchina | Make sure your tooling fits both CNC and hydraulic press brake systems. |

| Tecniche di fabbricazione | CNC machining gives you precise tooling and longer life. |

- CNC machining helps you get the right size and smooth surfaces.

- Custom tooling lets you make special bends that regular tools cannot do.

- Always look at your machine’s details before you buy new tooling.

Clamping & Alignment

Clamping and alignment systems are very important for your press brake tooling system. Good clamping stops your metal from getting scratched. It keeps your workpiece safe. Good alignment puts your tooling in the right spot. This helps you get the same bend every time.

- Use the right clamping system to hold your tooling tight.

- Check alignment before each job so you do not make mistakes.

- Calibrate and take care of your clamping and alignment systems often. This keeps your tooling working well and helps it last longer.

If you keep your clamping and alignment systems working well, you get better results. You work faster and make fewer mistakes. You also waste less metal and save money.

Note: A good press brake tooling system helps you bend metal better and reach your production goals.

Ensuring Efficiency and Quality

Setup Best Practices

You can make your work faster by using some smart steps. Utensili a cambio rapido systems help you switch tools quickly. This means you spend less time getting ready and more time making things. Offline programming lets you plan your bends before you start. You can get your work ready ahead of time and skip waiting.

- Use quick-change tooling systems to swap tools fast.

- Plan your bends with offline programming.

- Try staged bending to do hard jobs in fewer steps.

- Make your setup steps the same each time for better results.

- Use CNC technology to help with changes and stop mistakes.

- Plan your bending order to use fewer tool swaps and save time.

When you use quick-change tooling and offline programming together, you make setup easier. Staged bending lets you do more bends at once, so parts move faster. These ideas help you work better and keep your shop running smoothly.

Manutenzione

Taking care of your press brake tooling helps it last longer. You stop damage by checking your tools often. Looking at your tools helps you find problems early. Fixing tools on time keeps your bends right and your parts good.

- Check your tools for damage or wear.

- Clean and oil your tools after you use them.

- Keep your tools in a dry, safe spot to stop rust.

- Set up regular times to check all your equipment.

Storing your tools the right way keeps them safe from rust and harm. These habits help your tools last longer and work better. You make sure every part you make is good quality.

Sicurezza

Safety is always the most important thing in your shop. You should always follow the machine’s manual. Always put and hold metal sheets in place before bending. Never turn off safety devices like light curtains. Keep your hands away from the machine when it is working.

- Follow the manual for every job you do.

- Hold metal sheets tight before you bend them.

- Keep all safety devices turned on.

- Never put your hands in the machine while it is running.

- Listen for strange sounds or shaking.

- Use the emergency stop if something seems wrong.

- Make a plan for emergencies.

- Teach everyone first aid and keep supplies close.

If you follow these safety rules, you keep yourself and your team safe. You also help your shop stay good at making quality parts.

Applicazioni nel mondo reale

Automobilistico

Press brake tooling is used a lot in making cars. When you look at a car, you see smooth metal and strong frames. These parts need special tools to make them. Specialized tooling shapes metal for doors, hoods, and other car parts. You can make deep bends and tricky Z-shaped brackets with these tools. These shapes help cars stay safe and light.

Car factories use strong steel and aluminum. You need the right tooling to bend these metals without breaking them. Quick tool changes help you keep up with fast work. Custom dies let you make new car parts or special pieces for electric cars. Using the right tools helps every part fit well and look good. This means car parts meet safety and design rules.

Tip: Always check your tools before you start a new job. Taking care of your tools keeps your parts the same and your machines working well.

Aerospaziale

Making airplane parts needs very exact work. Every bend must be just right. Even small mistakes can be unsafe. Specialized press brake tooling shapes light metals like titanium and aluminum. You can make thin, strong parts that keep planes safe and light.

Here is a table that shows how you use special tooling for important airplane parts:

| Component Type | Importance in Aerospace |

|---|---|

| Fuselage Sections | Needed for the plane’s body and safety |

| Wing Spars | Helps the wings work well |

| Landing Gear Parts | Needed for safe takeoff and landing |

These parts are in every airplane. Each one needs perfect bends and smooth edges. Specialized tooling helps you meet strict airplane rules. You also waste less metal and save time with the right tools.

Note: Always do quality checks when making airplane parts. This keeps every part safe and working right.

Costruzione

You see metal work everywhere in building jobs. Buildings, bridges, and stadiums all use metal made with press brake tooling. You need to make beams, brackets, and panels that fit together well. Specialized tooling helps you make custom shapes for windows, doors, and frames.

Building projects often use thick steel or special metals. You need strong tools to bend these heavy pieces. Custom dies help you make new shapes for modern buildings. The right tools help you finish faster and make fewer mistakes.

- Use strong dies for thick beams.

- Pick custom tools for special shapes.

- Check your tools often to keep your work safe.

Remember: Good tools help you build strong, safe buildings that last a long time.

Elettronica

You see electronics everywhere. Phones, computers, and home appliances all use metal parts. These parts need to be small, light, and strong. You need special tools to make these shapes. Press brake tooling helps you bend metal sheets into the right forms for electronic devices.

When you work in electronics, you often use thin metals like aluminum or stainless steel. These metals can bend or crack if you do not use the right tools. Specialized press brake tooling lets you make tiny bends and sharp angles. You can create cases, brackets, and connectors that fit together perfectly.

Nanjing Metal has experience making tools for electronics factories. You can ask for custom dies that match your product designs. For example, you might need a die to make a phone case with small holes for buttons. You might need a tool to bend a thin bracket for a computer. Custom tooling helps you get the exact shape you want.

Here are some ways you use specialized tooling in electronics:

- Make small enclosures for circuit boards.

- Bend thin brackets for mounting screens.

- Form connectors that need tight bends.

- Create covers with smooth edges for safety.

Tip: Always check your part drawings before you choose your tooling. The right tool gives you better results and saves time.

You must also think about quality. Electronics need parts that fit together without gaps. If your bends are not exact, the parts will not work. Specialized tooling helps you keep every bend the same. This means your products look good and work well.

You can use a table to see how different tools help in electronics:

| Tipo di strumento | Use in Electronics | Beneficio |

|---|---|---|

| Hemming Dies | Fold edges on device covers | Smooth, safe edges |

| Offset Tools | Make Z-shaped connectors | Fit parts in tight spaces |

| Radius Dies | Create rounded corners | Prevent cracks and sharp edges |

You can also use CNC machines with your tooling. This lets you make many parts that are all the same. You save time and reduce mistakes.

Note: Good tooling helps you make better electronics. You can meet high standards and keep your customers happy.

Actionable Tips for Tooling Selection

Lista di controllo per la selezione

You want to pick the right press brake tooling for your shop. Use this checklist to help you make smart choices:

- Know Your Metal

Check the type and thickness of the metal you plan to bend. Different metals need different tooling. - Review Your Machine Specs

Look at your press brake’s tonnage and compatibility. Make sure the tooling fits your machine. - Match Tooling to Profile

Choose tooling that matches the shape you want to create. Z-shapes, offsets, and hems need special tools. - Check for Custom Needs

Decide if you need custom tooling for unique parts or projects. - Inspect for Durability

Pick tooling made from strong materials like alloy steel. Durable tools help you keep high quality in your work. - Plan for Safety

Make sure the tooling has safety features. Safe tools protect you and your team. - Think About Setup and Changeover

Quick-change tooling saves time. Look for tools that make setup easy.

Tip: Use this checklist before you buy new tooling. You will avoid mistakes and keep your shop running smoothly.

Errori da evitare

You can make better choices if you know what mistakes to avoid. Here are some common errors:

- Ignoring Material Differences

You might use the wrong tooling for a metal type. This can damage your tools or ruin your parts. - Skipping Machine Compatibility

If you do not check your machine specs, the tooling may not fit. Always match tooling to your press brake. - Overlooking Precision Needs

Some jobs need tight tolerances. If you pick general-purpose tooling, you may not get the results you want. - Trascurare la manutenzione

Dirty or worn tooling can cause bad bends. Clean and inspect your tools often. - Forgetting Safety

Never remove safety guards or skip safety checks. Unsafe practices can lead to injuries.

Alert: Avoid these mistakes to keep your shop safe and your parts accurate.

Further Resources

You can learn more about press brake tooling from these sources:

| Resource Type | Descrizione |

|---|---|

| Manufacturer Guides | Read manuals and guides from tooling makers. |

| Online Tutorials | Watch videos that show setup and bending tips. |

| Industry Forums | Join forums to ask questions and share advice. |

| Technical Articles | Find articles on metal forming and tooling. |

| Training Workshops | Attend workshops for hands-on learning. |

Note: Keep learning to improve your skills and stay up to date with new tooling options.

You need special press brake tooling to shape metal profiles right. Nanjing Metal offers strong tools, custom designs, and tools for many jobs. These choices help you get better results and keep your work high quality. Look at your tools now and ask an expert for help. If you want tips, contattare un tecnico commerciale Oggi.

Domande frequenti

What is specialized press brake tooling?

Specialized press brake tooling helps you make unique metal shapes. You use it for complex bends, tight angles, or special materials. This tooling gives you more control and better results than standard tools.

How do I know if I need custom press brake tooling?

You need custom press brake tooling when your project has unique shapes or strict tolerances. If standard tools cannot make your part, custom tooling is the best choice.

Can I use the same press brake tooling for different metals?

You can use some press brake tooling for different metals. However, you should always check the tool’s material and design. Some metals need special dies for best results.

How often should I inspect my press brake tooling?

You should inspect your press brake tooling before each job. Look for wear, cracks, or damage. Regular checks help you keep your bends accurate and your shop safe.

What safety features should I look for in press brake tooling?

Look for press brake tooling with built-in safety features. These may include alignment guides or safety locks. Good safety features help prevent accidents and keep your team safe.

How do I choose the right press brake tooling for my machine?

Check your machine’s specifications. Make sure the tooling fits your press brake’s size and clamping system. If you use CNC machines, pick tooling designed for automated setups.

Can I get help with press brake tooling selection?

Yes, you can ask experts or manufacturers for advice. They can help you choose the right press brake tooling for your project and machine.

Vedi anche

Come Funziona un Punzale per Pressa Piegatrice nella Piegatura della Lamiera

Suggerimenti per la manutenzione degli utensili per presse piegatrici per utensili di lunga durata

Come gli utensili per presse piegatrici personalizzati aumentano l'efficienza della tua produzione