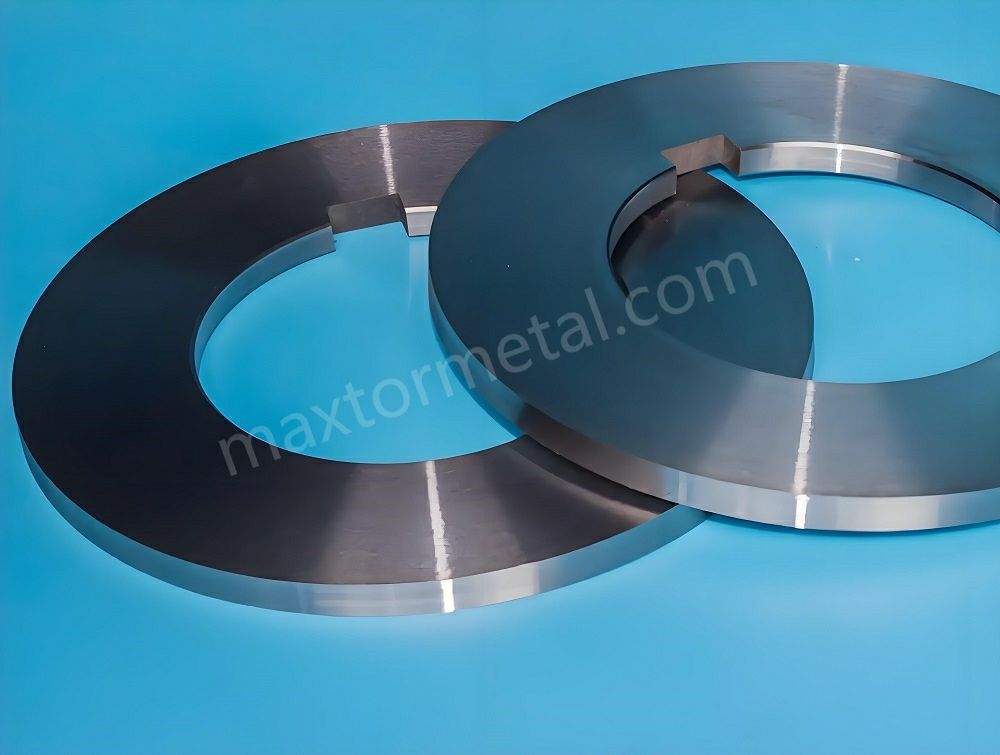

Lame per taglierina rotativa personalizzate Ti aiutano a tagliare meglio. Durano più a lungo e lavorano più velocemente. Scegliendo un coltello personalizzato, questo si adatta alle tue esigenze aziendali. Puoi ottenere dimensioni speciali e materiali resistenti. Questo ti aiuta a tagliare con meno sprechi. Le tue macchine possono lavorare più a lungo senza fermarsi. Questi coltelli sono utilizzati in molti settori. Ecco alcuni esempi:

| Industria | Descrizione dell'applicazione |

|---|---|

| Elaborazione Metal | Taglio di bobine e lamiere con precisione |

| Confezione | Realizzazione di rotoli e fogli di plastica e carta |

| Lavorazione alimentare | Affettare e porzionare i prodotti per l'efficienza |

| Lavorazione del legname | Sagomatura e rifilatura di impiallacciatura e compensato |

| Tessili | Utilizzato nella lavorazione dei tessuti per diversi lavori |

| Stampa | Utilizzato per realizzare materiali stampati |

Acquistare lame rotanti personalizzate è una scelta intelligente. La tua attività otterrà risultati migliori e lavorerà più velocemente.

Punti chiave

- I coltelli rotanti personalizzati offrono una migliore qualità di taglio. Ciò significa tagli più puliti e precisi. Questi coltelli sono realizzati su misura per la tua macchina. Questo aiuta a ridurre i tempi di fermo e la necessità di riparazioni. L'utilizzo di coltelli personalizzati può ridurre notevolmente i costi. Ti aiutano a sprecare meno e a cambiare le lame meno spesso. I coltelli rotanti personalizzati utilizzano materiali resistenti. Questo li rende più durevoli e funzionano meglio. Puoi scegliere la dimensione, la forma e il materiale che desideri. Questo aiuta i tuoi coltelli ad adattarsi perfettamente alle tue attività di taglio. Acquistare coltelli personalizzati migliora la produttività della tua attività. Migliora anche i tuoi prodotti, quindi i clienti sono più soddisfatti. La personalizzazione ti consente di ottenere lame con design speciali. Queste possono risolvere problemi di taglio difficili in molti settori. Scegliere i coltelli personalizzati giusti può rendere il tuo lavoro più veloce. Può anche aiutarti a spendere meno per la gestione delle tue macchine.

Lame da taglio standard: limitazioni

Problemi di qualità del taglio

Risultati incoerenti

Vuoi che ogni taglio abbia lo stesso aspetto. Ma le lame standard spesso non sono d'aiuto. Potresti notare bordi irregolari o tagli irregolari sui tuoi prodotti. A volte, senti rumori strani quando la macchina è in funzione. Questi rumori indicano che il bordo della lama presenta scheggiature, ammaccature o crepe. Se la lama non si adatta bene alla tua macchina, si usura in modo anomalo. Questo causa tagli scadenti e maggiori sprechi. I tuoi clienti vogliono una buona qualità. Se non riesci a fornirgliela, potrebbero perdere la fiducia in te.

- Tagli irregolari sui rotoli finiti

- Scheggiature o crepe lungo il bordo della lama

- Rumori strani durante il taglio

- Modelli di usura incoerenti

Bave e detriti

Le lame standard spesso lasciano sbavature e detriti. Questi piccoli frammenti possono attaccarsi al prodotto e peggiorare la situazione. Bisogna dedicare più tempo alla pulizia, il che rallenta il processo. Le sbavature possono anche inceppare le macchine. Questo significa che le macchine smettono di funzionare e si produce meno. È necessario ottenere tagli lisci e puliti ogni volta. Le lame standard rendono questo difficile.

Tempi di inattività e manutenzione

Frequenti cambi di lama

Hai bisogno che le tue macchine continuino a funzionare. Le lame standard si usurano rapidamente. Devi fermarti spesso solo per sostituirle. Ogni sostituzione richiede tempo e denaro. Se usi la lama sbagliata per il tuo materiale, si usura ancora più velocemente. Devi controllare e riparare le lame ogni giorno. Questo ti toglie tempo prezioso da dedicare alla crescita della tua attività.

Aumento dei costi

Fermare le macchine costa di più. Quando si cambiano le lame, si perde tempo nella produzione dei prodotti. Inoltre, si spende di più per nuove lame e per pagare i lavoratori. La tabella seguente mostra come le lame migliori possono essere d'aiuto, ma le lame standard no.

| Tipo di innovazione | Impatto sui tempi di inattività e sui costi |

|---|---|

| Lame con punta in carburo | Durano più a lungo, quindi devi cambiarli meno e ripararli meno spesso. |

| Lame rivestite | Taglia meglio, così sprechi meno e risparmi denaro. |

Le lame standard non offrono tutti questi vantaggi. Con il tempo si finisce per spendere di più. Le lame di buona qualità garantiscono tagli più netti e fanno risparmiare denaro. Le lame affilate aiutano a tagliare più velocemente e a finire in tempo.

Sfide di adattamento e compatibilità

Limitazioni di dimensioni e tolleranza

Ogni macchina è diversa. Le lame standard sono disponibili solo in determinate dimensioni e forme. Può essere difficile trovarne una adatta alla tua macchina. Se la lama non è adatta, non funziona bene. La lama potrebbe oscillare o piegarsi, rendendo i tagli irregolari. Hai bisogno di una lama adatta alla tua macchina. Le lame standard non offrono molta scelta.

Limitazioni materiali

Tagli molti materiali come carta, plastica, metallo o tessuti. Le lame standard potrebbero non essere adatte a tutti. Alcuni materiali causano un'usura più rapida della lama o la fanno aderire. Potresti vedere ruggine o residui di cibo sul filo della lama. Questo peggiora i tagli e richiede più riparazioni. Hai bisogno di lame adatte ai tuoi materiali e che mantengano le tue macchine in buone condizioni.

Suggerimento: scegliere la lama giusta per il materiale e la macchina ti aiuta a realizzare prodotti migliori e ad avere meno tempi di fermo.

Se vuoi tagliare meglio, valuta di utilizzare più delle semplici lame standard. I coltelli rotanti personalizzati risolvono questi problemi e ti aiutano a offrire ai tuoi clienti la qualità che desiderano.

Coltelli rotanti personalizzati: vantaggi prestazionali

Scegliendo lame rotanti personalizzate, otterrai un taglio migliore. Queste lame circolari sono realizzate appositamente per le tue esigenze. Aiutano la tua attività a lavorare in modo più rapido e fluido. Vediamo come queste lame possono aiutarti.

Ingegneria di precisione

Dimensioni e tolleranze personalizzate

Vuoi che ogni taglio sia perfetto. Le lame rotanti personalizzate ti permettono di scegliere qualsiasi dimensione o spessore. Le lame si adattano perfettamente alle tue macchine. Non avrai problemi di lame allentate o strette. Otterrai la tolleranza giusta per il tuo lavoro.

| Specifica | Tolleranza |

|---|---|

| Tolleranza di spessore | ±0,0015 mm |

| Tolleranza di planarità | ±0,001 mm |

| Gamma di durezza | HRC 45-65 |

Queste tolleranze ridotte garantiscono sempre gli stessi risultati. Non si spreca materiale né si ottengono tagli irregolari. Le macchine funzionano meglio e più velocemente.

- Le superfici prive di ossidazione mantengono puliti i coltelli circolari.

- La distorsione minima fa sì che le lame restino affilate e precise.

- La maggiore resistenza all'usura garantisce una maggiore durata della lama.

- L'assenza di residui nocivi rende il processo più sicuro per il tuo team.

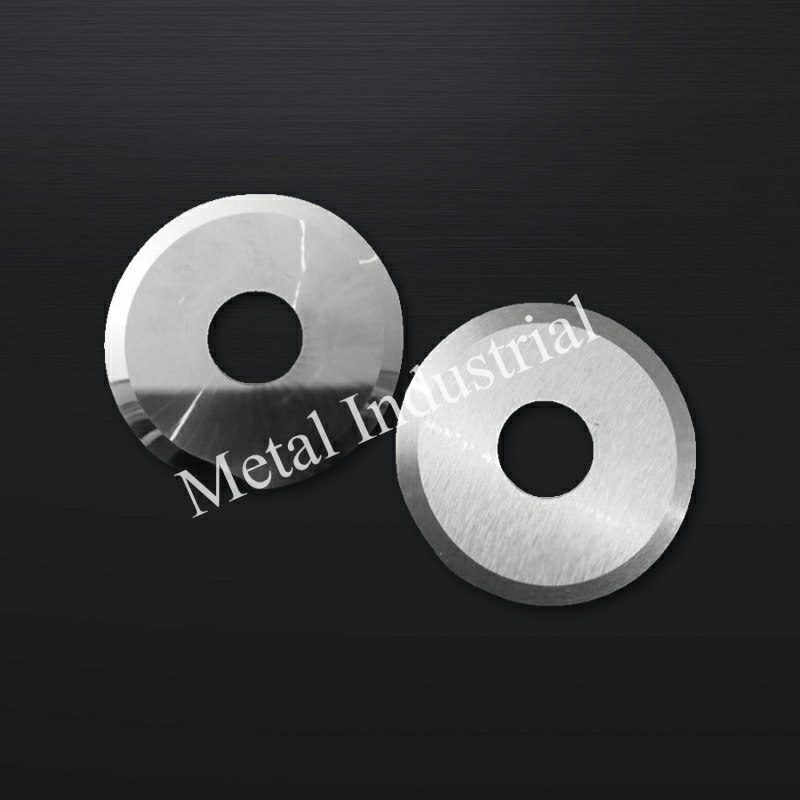

Materiali specializzati

Puoi scegliere tra numerosi materiali per i tuoi coltelli rotanti personalizzati. Nanjing Metal Industriale La lama è disponibile in acciaio ad alto tenore di carbonio, acciaio per utensili, acciaio rapido e carburo di tungsteno. Ogni materiale ha la sua resistenza. L'acciaio rapido è adatto per lavori rapidi. Il carburo di tungsteno dura a lungo. È possibile adattare la lama al materiale da lavorare, come carta, pellicola, metallo o tessuti. Questo aiuta a tagliare meglio e a utilizzare le lame più a lungo.

Prestazioni di taglio migliorate

Tagli puliti, sbavature minime

Vuoi che i tuoi prodotti siano puliti e affilati? Le lame rotanti personalizzate eseguono tagli netti e praticamente senza sbavature. I tuoi rotoli finiti sono lisci. Non devi perdere molto tempo a pulire. Le tue macchine si inceppano meno spesso. Puoi produrre più prodotti invece di dover risolvere i problemi.

Risultati coerenti

Le lame rotanti personalizzate garantiscono sempre lo stesso taglio di qualità. Non si notano bordi irregolari o linee storte. I clienti notano la qualità. Si fidano dei vostri prodotti perché sono sempre belli. Questo aiuta la vostra attività e fa sì che i clienti tornino.

Caso di studio reale: aumento dell'efficienza produttiva

Un'azienda di imballaggi ha iniziato a utilizzare lame rotanti personalizzate di Nanjing Metal Industrial. Aveva bisogno di dimensioni e tipi di bordi speciali. Dopo il passaggio, le lame 30% sono state sostituite meno frequentemente. La velocità di produzione è aumentata di 20%. Hanno ottenuto meno scarti e tagli più puliti. In un altro caso, un rotolo di grandi dimensioni è stato tagliato in rotoli più piccoli per macchine speciali. Questo ha ridotto i tempi di fermo delle macchine e ne ha migliorato la produttività. Anche un'azienda farmaceutica ha utilizzato lame rotanti personalizzate per soddisfare le rigide normative sulla larghezza delle pellicole. Queste storie vere mostrano come le lame personalizzate aiutino a tagliare meglio e a lavorare più velocemente.

Tabella di confronto delle prestazioni

Vuoi sapere la differenza? Ecco come le lame rotanti personalizzate si confrontano con le lame standard:

| Caratteristica/Vantaggio | Lame per taglierina rotativa personalizzate | Lame standard |

|---|---|---|

| Su misura per le esigenze della linea di produzione | SÌ | NO |

| Prestazioni ottimali | Sì, tramite un abbinamento preciso | Limitato |

| Capacità multifunzionale | Sì, può tagliare, piegare e perforare in una sola passata | NO |

| Riduzione dei tempi di inattività | Sì, grazie alla personalizzazione | NO |

| Aumento della produzione | Sì, supporta un'elevata efficienza nella produzione di cartone | NO |

| Precisione di taglio | Alto, con sbavature minime | Moderato, più sbavature |

| Durata della lama | Lungo, per via del materiale e della vestibilità | Cambiamenti più brevi e frequenti |

Lame per taglierina rotativa personalizzate ti danno più controllo e un taglio migliore. Durano anche più a lungo. Otterrai di più da ogni lama.

Suggerimento: le lame rotanti personalizzate ti aiutano a tagliare meglio e più velocemente. Risparmi tempo, sprechi meno e realizzi più prodotti.

Le lame rotanti personalizzate sono una scelta intelligente per qualsiasi attività. Otterrete un taglio migliore, maggiore efficienza e risultati affidabili. Avrete sempre le lame circolari giuste per il vostro lavoro.

Qualità e durata delle lame da taglio personalizzate

Scegliendo lame rotanti personalizzate, si ottiene una qualità migliore. Il giusto materiale e il giusto design della lama aiutano a ottenere tagli netti. Vediamo come il materiale e la progettazione rendono le lame più durature e più performanti.

Selezione dei materiali

Il materiale che scegli per le tue lame rotanti personalizzate influisce su ogni taglio. Ogni tipologia ha i suoi punti di forza. Puoi scegliere la lama più adatta al tuo lavoro.

Acciaio al carbonio

L'acciaio ad alto tenore di carbonio è duro e mantiene bene il filo. Offre una buona qualità a un prezzo inferiore. Questo materiale è ideale per tagliare carta e imballaggi. Le lame rimangono affilate a lungo, quindi è necessario sostituirle meno spesso. Le lame in acciaio ad alto tenore di carbonio sono ideali per carta, pellicole e lavori simili.

Acciaio ad alta velocità

L'acciaio rapido è molto resistente e non si usura rapidamente. Puoi far funzionare le tue macchine più velocemente e ottenere comunque buoni tagli. Questo materiale gestisce il calore, quindi è ideale per lavori rapidi su metallo e pellicola. Le lame durano più a lungo, quindi ti fermi meno spesso e ottieni di più. Le lame in acciaio rapido rimangono affilate anche quando il lavoro si fa duro.

Acciaio per utensili e carburo di tungsteno

L'acciaio per utensili è resistente e dura a lungo. Puoi usare queste lame per lavori pesanti e tagli frequenti. Mantengono il filo, quindi ottieni buoni tagli con materiali spessi o duri. Il carburo di tungsteno è ancora più duro e si consuma molto lentamente. Puoi usare queste lame per lavori difficili e lunghe tirature. Le lame in carburo di tungsteno durano più a lungo, quindi ti fermi meno spesso e ottieni tagli migliori.

Ecco una rapida occhiata a come questi materiali si confrontano:

| Materiale | Proprietà meccaniche chiave | Proprietà chimiche chiave | Applicazioni adatte |

|---|---|---|---|

| Acciaio ad alto tenore di carbonio | Molto duro, non si consuma velocemente | Può arrugginire, necessita di cure | Carta, pellicole |

| Acciaio per utensili | Super duro, non si consuma rapidamente | Difficile da realizzare | Fogli Metal, cose spesse |

| Acciaio ad alta velocità | Molto duro, rimane affilato fino a 500°C | Gestisce bene il calore | Metals, plastica, taglio veloce |

| Carburo di tungsteno | Molto duro, non si consuma facilmente | Può rompersi se colpito duramente | Cose dure, acciaio, rame, lavori pesanti |

Suggerimento: scegliere il materiale giusto per la lama ti aiuta a ottenere una qualità migliore e a raggiungere i tuoi obiettivi.

Longevità e affidabilità

Vuoi che le tue lame rotanti personalizzate durino a lungo? Il materiale e il design giusti aiutano le tue lame a funzionare sempre bene. Spendi meno per nuove lame e le tue macchine funzionano di più.

Usura ridotta

Le lame in acciaio rapido e carburo di tungsteno non si usurano rapidamente. Otterrai tagli più precisi prima di doverle sostituire. Questi materiali resistono ai lavori più impegnativi e rimangono affilati, quindi non dovrai preoccuparti di lame smussate.

- Acciaio rapido: resistente e facile da affilareAdatto a molti lavori.

- Carburo di tungsteno: molto duro e non soggetto a usura rapida. Ottimo per lavori difficili o rapidi.

- Acciaio per utensili: resistente e tenace. Adatto ai lavori pesanti.

- Carburo C2: ideale per tagli grossolani o di grandi volumi.

Durata di vita estesa

Le lame rotanti personalizzate, realizzate con materiali resistenti, durano molto più a lungo. Otterrai tagli migliori da ogni lama. Questo significa meno fermi macchina e costi inferiori. Le tue macchine funzioneranno meglio e i tuoi clienti otterranno prodotti migliori.

| Tipo di materiale | Proprietà | Applicazioni |

|---|---|---|

| Acciaio per utensili D2 | Resistente e duro; non adatto per lavori rapidi. | Utilizzato per il taglio della carta. |

| M2/HSS | Utilizzato per le pellicole; non dura a lungo. | Non sono buoni come le leghe nuove. |

| Carburo solido | Molto resistente, ideale per lavori impegnativi. | Taglia la fibra di vetro e altri materiali duri. |

| Cermet | Gestisce bene il calore; mantiene i bordi puliti. | Adatto per pellicole e fogli. |

| Nitruro di titanio (TiN) | Rende le lame scivolose; impedisce che le sostanze appiccicose si attacchino. | Aiuta i coltelli da taglio a lavorare meglio. |

Nota: la durezza aiuta la lama a durare più a lungo. La robustezza impedisce alla lama di rompersi. Entrambi sono importanti per avere delle buone lame.

Caso di studio: durata prolungata della lama

Un'azienda di imballaggi ha iniziato a utilizzare lame rotanti personalizzate in carburo di tungsteno. Prima, le lame venivano sostituite ogni due settimane. Dopo il passaggio, le lame venivano sostituite solo ogni due mesi. Questo ha permesso loro di risparmiare oltre 60% in tempi di fermo e costi di riparazione. L'azienda ha ottenuto macchine di migliore qualità e più affidabili. La loro linea di produzione è durata più a lungo e i clienti hanno ricevuto prodotti migliori.

Perché la qualità è importante per la tua attività

Vuoi che ogni prodotto sia di alta qualità. Le lame rotanti personalizzate ti aiutano a raggiungere questo obiettivo. La lama giusta significa meno cambi, meno sprechi e clienti più soddisfatti. Risparmi tempo e denaro. E costruisci anche un'ottima reputazione per la tua attività.

- Una qualità migliore significa che ne sprechi meno.

- Una maggiore durata delle lame significa che le macchine si fermano meno spesso.

- Le lame di buona qualità ti aiutano a completare gli ordini in tempo.

Scegli lame rotanti personalizzate per la tua attività. Otterrai lame di qualità migliore, più durature e clienti più soddisfatti.

Produzione personalizzata per esigenze uniche

Se vuoi che la tua linea di produzione funzioni al meglio, hai bisogno di più delle normali lame. La produzione personalizzata ti consente di controllare ogni fase del processo di taglio. Riceverai lame realizzate appositamente per le tue esigenze. Questo ti aiuta a risolvere problemi specifici e a lavorare più velocemente di altri nel tuo settore.

Soluzioni su misura

Forme delle lame e tipi di bordi

Ogni lavoro e materiale richiede una lama diversa. La produzione personalizzata ti consente di scegliere tra diverse forme di lama e tipologie di taglio. Puoi scegliere bordi sottili e dritti per la carta. Puoi optare per biselli lucidi per i tessuti. Puoi utilizzare lame in metallo duro resistenti per i fogli metallici. Queste opzioni ti aiutano a ottenere il taglio e la finitura perfetti per i tuoi prodotti.

| Industria | Tolleranza di taglio richiesta | Geometria della lama consigliata |

|---|---|---|

| Carta/Etichette | ±0,2 millimetri | Sottile, bordo dritto, smussatura bassa |

| Taglio tessile | ±0,5 millimetri | Bordo fine, bisello lucidato |

| Fogli di plastica | ±0,3 millimetri | Lame rivestite, smusso medio |

| Metal Foil | ±0,1 millimetri | Rigido, in metallo duro, angolo di smusso elevato |

La giusta forma della lama aiuta a ottenere risultati migliori. Ad esempio, una lama microdentata per la carta kraft garantisce tagli più netti e riduce gli strappi sui bordi. Una smussatura lucida per il cotone riduce lo spreco di tessuto. Le lame sottili con taglio ondulato e rivestimento DLC aiutano a far durare più a lungo le etichette termiche. Questi esempi mostrano come le lame personalizzate facciano una grande differenza.

La produzione personalizzata sfrutta nuovi metodi per realizzare la lama più adatta al tuo lavoro:

- La stampa 3D aiuta a realizzare rapidamente nuove forme di pale

- Lame con bordi speciali per lavori di taglio difficili

- Ingegneria attenta per la massima qualità

- Design dei bordi delle lame che durano più a lungo

- Trattamenti termici e a freddo per lame più resistenti

Riceverai un coltello circolare personalizzato adatto al tuo lavoro. Puoi vedere più opzioni e saperne di più sulla produzione personalizzata su pagina delle lame personalizzate.

Adatto per macchine specifiche

Vuoi lame che si adattino perfettamente alle tue macchine. La produzione personalizzata garantisce che ogni lama si adatti perfettamente alla tua attrezzatura. Non avrai problemi come vibrazioni, tagli errati o usura irregolare. Le tue lame si adattano perfettamente alla tua configurazione, così impiegherai meno tempo a riparare i pezzi e più tempo a realizzare i prodotti.

La produzione personalizzata consente inoltre di aggiungere rivestimenti speciali alle lame. I rivestimenti PVD e CVD aumentano la durata delle lame e impediscono che i residui si incastrino. È possibile utilizzare materiali resistenti come il carburo di tungsteno o la ceramica di zirconia per ottenere lame ancora più resistenti. Prendersi cura delle lame e scegliere il materiale giusto contribuisce al buon funzionamento delle macchine.

Suggerimento: la produzione personalizzata ti aiuta a risolvere i problemi di adattamento e prestazioni prima che si verifichino. Otterrai lame adatte alle tue macchine e ai tuoi materiali.

Nanjing Metal Industrial è nota per la produzione di lame per impieghi speciali. Potete contare sulla loro competenza e competenza anche per i lavori più impegnativi.

Approvvigionamento flessibile

Prezzi Competitivi

Vuoi ottenere il massimo dal tuo investimento. La produzione personalizzata ti offre opzioni adatte al tuo budget e ai tuoi obiettivi. Puoi collaborare con un fornitore che sa di cosa hai bisogno e ti aiuta a trovare la soluzione migliore. Questo significa che le tue macchine funzionano meglio, hai meno tempi di fermo e spendi meno.

| Strategia di approvvigionamento | Impatto sui costi e sulla qualità del servizio |

|---|---|

| Partnership di personalizzazione e ingegneria | Miglioramenti misurabili nelle prestazioni, aumento dei tempi di attività e riduzione dei costi operativi. |

| Valutazione del fornitore | Influisce sui costi operativi a lungo termine e sulla qualità del prodotto, sottolineando la necessità di competenza e affidabilità. |

| Investimenti in soluzioni di alta qualità | Migliore qualità del prodotto, riduzione degli sprechi e maggiore efficienza operativa, con conseguenti notevoli risparmi sui costi. |

Scegliere il partner giusto per la produzione personalizzata influisce sui costi, sulla qualità del prodotto e sulla competitività. Dovresti cercare un fornitore con competenza, esperienza e onestà. Acquistare soluzioni di taglio di alta qualità ti garantisce prodotti migliori, meno sprechi e maggiore efficienza.

Supporto e servizio

Hai bisogno di più di una semplice lama. La produzione personalizzata offre un supporto e un servizio eccellenti. Riceverai assistenza nella scelta dei materiali, nell'aggiunta del tuo logo e nell'assistenza post-vendita. Servizi come la riaffilatura e il rivestimento prolungano la durata delle tue lame. Le garanzie di qualità ti proteggono dai problemi e ti fanno sentire al sicuro.

| Tipo di servizio | Descrizione |

|---|---|

| Personalizzazione minore | Sono disponibili opzioni di personalizzazione del logo, della grafica e della confezione. |

| Selezione dei materiali | Le opzioni includono acciaio per utensili 52100, acciaio inossidabile e acciaio ultra rapido. |

| Supporto post-vendita | Supporto completo, inclusi servizi di riaffilatura e rivestimento. |

| Servizi di garanzia | Garanzie leader del settore contro i difetti, a garanzia dell'affidabilità del prodotto. |

Riceverai anche:

- Assistenza tecnica 24 ore su 24, 7 giorni su 7 per problemi

- Monitoraggio degli ordini e aggiornamenti non appena si verificano

- Spedizione veloce per consegne rapide ovunque

- Produzione espressa per ordini urgenti

Nota: con la produzione personalizzata, avrai a disposizione un partner che ti assisterà in ogni fase. Potrai concentrarti sul tuo lavoro mentre gli esperti si occuperanno delle tue lame.

La produzione personalizzata ti offre la flessibilità, la qualità e l'assistenza di cui hai bisogno per ottenere risultati eccellenti. Riceverai coltelli adatti alle tue macchine, ai tuoi materiali e ai tuoi obiettivi. Puoi fidarti del processo e dei risultati.

Applicazioni e successi industriali

Imballaggi e carta

Vuoi che il tuo imballaggio e la tua carta abbiano un bell'aspetto? Le lame rotanti personalizzate ti aiutano a raggiungere questo obiettivo. Queste lame effettuano tagli puliti e netti ogni volta. Riduci gli sprechi e i bordi irregolari. Le tue macchine funzionano più a lungo senza fermarsi. Le aziende che utilizzano queste lame hanno visto grandi cambiamenti.

| Tipo di miglioramento | Descrizione |

|---|---|

| Prestazioni di taglio migliorate | Le lame rotanti personalizzate tagliano meglio, consentendo di ottenere prodotti di qualità superiore. |

| Tempi di inattività ridotti | Questi coltelli aiutano le macchine a funzionare di più, consentendoti di svolgere più lavoro. |

| Vantaggi operativi | Grazie a questi coltelli le aziende risparmiano denaro e lavorano meglio. |

Le lame rotanti personalizzate sono adatte per rotoli di carta, cartone, etichette e pellicole per imballaggio. Puoi scegliere la lama più adatta al tuo lavoro. Questo ti aiuta a realizzare prodotti che soddisfano standard elevati e a soddisfare i clienti.

Suggerimento: utilizzando lame rotanti personalizzate si risolvono meno problemi e si realizzano prodotti di qualità superiore.

Metal e sviluppo di pellicole

Per lavorare metalli e pellicole, servono lame resistenti. Le lame rotanti personalizzate aiutano a tagliare materiali resistenti come alluminio, rame e pellicole plastiche. Queste lame utilizzano rivestimenti e materiali speciali per durare più a lungo.

| Tipo di rivestimento | Benefici | Materiali utilizzati |

|---|---|---|

| PVD | Prolunga la durata delle lame e previene l'usura e la ruggine. | Carburo di boro, carburo di titanio, nitruro di titanio |

| malattie cardiovascolari | Aiuta le lame a funzionare meglio e a durare più a lungo. | Carburo di titanio |

| Aggiornamento del materiale della lama | Rende le lame più resistenti e aiuta le macchine a funzionare più a lungo. | Carburo di tungsteno, ceramica di zirconia, CPM10V, coltelli con fondo intarsiato in carburo |

Le lame rotanti personalizzate ti aiutano a tagliare bobine, lamine e pellicole metalliche con elevata precisione. Sostituisci meno lame e fermi macchina meno frequentemente. La tua linea lavora più velocemente e risparmi denaro.

- Si ottengono tagli netti e meno disordinati.

- Le tue macchine funzionano meglio e durano più a lungo.

- Puoi ricevere più ordini e far crescere la tua attività.

Settori tessile e medico

Desideri tagli sicuri e precisi nei lavori tessili e medicali? Le lame rotanti personalizzate ti offrono entrambe le cose. Queste lame sono progettate per tagli fluidi e precisi. Puoi scegliere lame per tessuti speciali, pellicole medicali o prodotti per l'igiene.

| Caratteristica | Descrizione |

|---|---|

| Precisione | Progettato per tagli fluidi e precisi su molti materiali. |

| Personalizzazione | Sono disponibili lame per esigenze di taglio particolari. |

| Compatibilità dei materiali | Ottimo per lavori medici e mantiene le cose pulite. |

| Durata | Realizzato con materiali resistenti che durano a lungo. |

| Versatilità | Lavora per la produzione di tessuti e dispositivi medici. |

Le lame rotanti personalizzate ti aiutano a rispettare le rigide normative in ambito medico e tessile. Ottieni risultati puliti e sicuri ogni volta. Le lame durano più a lungo, quindi ne devi sostituire meno.

- Lavori più velocemente e meglio.

- Per ogni lavoro si soddisfano esigenze di taglio specifiche.

- Offrite ai clienti prodotti sicuri e di alta qualità.

Nota: i coltelli rotanti personalizzati semplificano il tuo lavoro e ti aiutano a fare meglio degli altri.

L'utilizzo di lame rotanti personalizzate garantisce il successo in molti settori. Queste lame aiutano a tagliare meglio, lavorare più velocemente e risparmiare denaro. Offrono ai clienti la qualità che desiderano.

Altri settori specializzati

Le lame rotanti personalizzate sono utili per i lavori di taglio più impegnativi in molti settori. Alcuni settori, come quello automobilistico, elettronico, aerospaziale e alimentare, hanno esigenze specifiche. Le lame standard spesso non sono adatte a questi lavori. Le lame rotanti personalizzate offrono gli strumenti giusti per lavorare al meglio.

Se lavori nel settore automobilistico, tagli guarnizioni e materiali isolanti in gomma. E tagli anche materiali compositi. Devi essere molto preciso. Le lame rotanti personalizzate ti permettono di scegliere la forma e il materiale della lama migliori. Otterrai tagli netti e meno sprechi. La tua linea di produzione sarà più veloce e i tuoi pezzi saranno migliori.

Le fabbriche di componenti elettronici devono essere molto attente. Tagliano pellicole e lamine sottili. Tagliano anche laminati per circuiti stampati. Le lame rotanti personalizzate aiutano a evitare sbavature e l'adesione di piccoli pezzi. I prodotti rimangono puliti e sicuri. Rispettano regole rigorose e non perdono molto tempo a correggere gli errori.

Le aziende aerospaziali utilizzano lame rotanti personalizzate per i lavori più impegnativi. Tagliano fogli di fibra di carbonio e lamine speciali. Queste lame devono rimanere affilate e non usurarsi rapidamente. Le lame rotanti personalizzate possono essere realizzate con carburo di tungsteno o rivestimenti speciali. Otterrete sempre gli stessi ottimi risultati. Il vostro team non dovrà perdere molto tempo a riparare o sostituire le lame.

Gli impianti di lavorazione alimentare utilizzano lame rotanti personalizzate per tagliare pellicole e involucri per imballaggio. Tagliano anche carte speciali. Queste lame devono rimanere affilate e non arrugginire. Le lame rotanti personalizzate, realizzate in acciaio inossidabile o con rivestimenti, aiutano a mantenere la pulizia. Meno fermate e le macchine continuano a funzionare.

Ecco una tabella che mostra come le lame rotanti personalizzate aiutano diversi settori:

| Industria | Sfida di taglio | Soluzione per coltelli personalizzati | Vantaggio chiave |

|---|---|---|---|

| Automobilistico | Gomma, isolamento, compositi | Geometria specializzata, leghe resistenti | Tagli netti, meno sprechi |

| Elettronica | Film sottili, lamine, laminati | Bordo sottile, design anti-sbavatura | Nessun detrito, parti sicure |

| Aerospaziale | Fibra di carbonio, lamine speciali | Lame rivestite in carburo | Lunga durata, precisione |

| Lavorazione alimentare | Pellicole, involucri, carte per imballaggio | Acciaio inossidabile, resistente alla corrosione | Igiene, nitidezza |

Suggerimento: puoi richiedere lame rotanti personalizzate con rivestimenti o profili speciali. Questo ti aiuterà a risolvere problemi che le lame standard non riescono a risolvere.

Le lame rotanti personalizzate ti permettono di controllare i tuoi lavori di taglio. Scegli la lama più adatta al tuo materiale e alla tua macchina. Realizzi prodotti migliori e riduci i tempi di fermo. Risparmi denaro e le persone si fidano del tuo lavoro.

Noterai il cambiamento quando utilizzerai lame rotanti personalizzate. I tuoi prodotti saranno più belli. Le tue macchine funzioneranno più a lungo. I tuoi clienti si fideranno di te di più. Potrai accettare nuovi lavori e rispettare regole rigide.

Se vuoi avere successo nel tuo campo, scegli lame rotanti personalizzate. Otterrai la risposta giusta per le tue esigenze. Lavorerai in modo più intelligente e otterrai risultati migliori.

Calcolo del ROI: risparmio sui costi ed efficienza

Quando acquisti lame rotanti personalizzate, vuoi vedere risultati concreti. Questi utensili non si limitano a tagliare. Ti aiutano a risparmiare denaro e a velocizzare il lavoro. Le tue macchine continuano a funzionare senza fermarsi troppo spesso. Vediamo come puoi verificare se il tuo investimento vale la pena.

Costi di manutenzione ridotti

Le lame rotanti personalizzate ti aiutano a risparmiare sulle riparazioni delle macchine. Utilizzando lame specifiche per le tue macchine, risolvi meno problemi. Non devi cambiare le lame così spesso. Il tuo team può dedicarsi alla produzione anziché alle riparazioni.

Ecco come una cura intelligente delle lame può farti risparmiare denaro:

| Descrizione della prova | Impatto sul risparmio dei costi di manutenzione |

|---|---|

| Le lame ben tenute durano 20% più lungo rispetto a quelli trascurati. | Si acquistano meno spesso nuove lame, risparmiando così denaro. |

| La configurazione ottimizzata riduce l'attrito della lama fino a 15%. | Minore attrito significa che le lame durano più a lungo e costano meno. |

| I meccanismi di raffreddamento riducono l'usura delle lame della taglierina del 25%. | Le lame si consumano più lentamente, quindi è necessario riparare meno le macchine. |

| La regolazione della pressione di taglio aumenta la durata della lama di 10-15%. | Le lame durano più a lungo, quindi si spende meno in riparazioni. |

Si verificano meno guasti e si riducono i tempi di fermo macchina. Il team di manutenzione lavora meglio e più velocemente. Si acquistano meno pezzi di ricambio e si ha meno bisogno di riparazioni di emergenza. Questo aiuta la tua azienda a risparmiare denaro.

Suggerimento: acquistando lame rotanti personalizzate avrai meno problemi e più tempo per lavorare.

Velocità di produzione migliorata

Vuoi che le tue macchine lavorino velocemente e non si fermino mai? Le lame rotanti personalizzate ti aiutano a ottenere di più. Queste lame si adattano perfettamente alle tue macchine. Eseguono tagli puliti e non si inceppano spesso. Non devi fermare la linea per riparare i problemi.

Ecco come vincere:

- Si cambiano le lame più velocemente e si aspetta meno.

- I tagli netti significano che non è necessario rifare il lavoro.

- Meno inceppamenti consentono alle macchine di funzionare più a lungo.

- I buoni risultati ti aiutano a terminare i lavori in tempo.

Il tuo team lavora più velocemente e riesce a fare di più. Puoi ricevere più ordini e completarli più velocemente. Le lame rotanti personalizzate ti aiutano a lavorare meglio e più velocemente ogni giorno.

Nota: lavorare più velocemente ti aiuta a guadagnare di più e fa sì che la tua attività abbia una buona visibilità.

Valore a lungo termine

Vuoi che i tuoi soldi aiutino la tua attività a lungo. Le lame rotanti personalizzate durano più a lungo e funzionano meglio. Risparmi denaro ora e in futuro.

Ecco alcuni modi in cui queste lame possono aiutare la tua attività:

| Metrico | Impatto sul ROI |

|---|---|

| Tempi di inattività ridotti | Le macchine si fermano meno spesso, quindi guadagni di più. |

| Miglioramento dell'efficienza del team | Il tuo team lavora 25% più veloce. |

| Minori sprechi ambientali | Sprechi meno e aiuti il pianeta. |

Sprechi meno e il tuo team lavora meglio. Le tue macchine durano più a lungo. Inoltre, rispetti le normative ambientali, il che aiuta la tua attività a distinguersi. Col tempo, questi vantaggi si sommano. Ti rendi conto che acquistare lame rotanti personalizzate è stata una scelta intelligente.

Avviso: scegli lame rotanti personalizzate per lavorare meglio, risparmiare denaro e rafforzare la tua attività.

Ottieni più di una semplice lama. Ottieni uno strumento che aiuta il tuo team, velocizza il lavoro e ti offre valore per anni. Fai la scelta giusta e vedrai la differenza ogni giorno.

Scegliere lame rotanti personalizzate aiuta la tua attività a ottenere risultati migliori. Queste lame durano più a lungo e si adattano perfettamente alle tue esigenze. Sempre più aziende ora desiderano utensili che taglino con cura e che utilizzino nuove idee. Gli esperti consigliano di scegliere il coltello giusto, acquistare lame di buona qualità e prendersi cura delle proprie lame. Osserva come tagli ora e scopri se un nuovo materiale per lame può aiutarti a ottenere risultati migliori. Fai in modo che il tuo prossimo acquisto sia importante: parla con un addetto alle vendite. Qui per conoscere le scelte personalizzate.

Domande frequenti

Cosa sono i coltelli rotanti personalizzati?

I coltelli rotanti personalizzati sono utensili da taglio speciali. Sono realizzati su misura per la tua macchina e per il materiale che vuoi tagliare. Puoi scegliere dimensioni, forma e materiale. Questi coltelli ti aiutano a realizzare tagli netti e precisi. Inoltre, velocizzano il tuo lavoro.

Perché dovrei scegliere lame rotanti personalizzate invece delle lame standard?

Le lame rotanti personalizzate tagliano meglio delle lame standard. Durano più a lungo e riducono i tempi di fermo macchina. Queste lame sono pensate per le tue esigenze. Risparmi denaro e il tuo lavoro viene completato più velocemente.

Quali settori utilizzano lame rotanti personalizzate?

Molti settori utilizzano lame rotanti personalizzate. Le si trovano nell'industria dell'imballaggio, della carta, dei metalli, tessile, medica e alimentare. Queste lame sono adatte a molti lavori e materiali.

Come faccio a sapere qual è il materiale più adatto alla mia applicazione?

Scegli il materiale della lama in base al tipo di taglio che devi effettuare. L'acciaio ad alto tenore di carbonio è adatto alla carta. Il carburo di tungsteno è più resistente per i lavori più impegnativi. In caso di dubbi, puoi chiedere consiglio al tuo fornitore.

Posso ordinare lame rotanti personalizzate per qualsiasi macchina?

Sì! È possibile ottenere lame rotanti personalizzate per quasi tutte le macchine. Basta fornire al fornitore i dettagli o i disegni della macchina. Il fornitore realizzerà lame che si adattano perfettamente alla macchina.

In che modo i coltelli rotanti personalizzati contribuiscono a ridurre gli sprechi?

Le lame rotanti personalizzate effettuano tagli estremamente precisi. Si notano meno sbavature e si crea meno disordine. I prodotti hanno un aspetto migliore e si spreca meno materiale.

Qual è il tempo di consegna tipico per i coltelli rotanti personalizzati?

I tempi di consegna dipendono dall'ordine e dal tipo di lama. La maggior parte dei fornitori invia lame rotanti personalizzate in due o quattro settimane.

I coltelli rotanti personalizzati richiedono una manutenzione speciale?

Le lame rotanti personalizzate si prendono cura di voi come le lame normali. Pulitele e affilatele spesso per mantenerle sempre efficienti. Alcuni materiali, come il carburo di tungsteno, richiedono meno cure.

Vedi anche

La Guida Definitiva alla Scelta del Materiale per la Tua Lama per Taglierina Rotativa

Come massimizzare l'affilatura della lama della taglierina per prestazioni di taglio superiori

Come Ottenere Tagli Perfetti con Lame per Taglierina Rotativa per Carta