When you choose the best テキスタイル用ロータリースリッターブレード, you enhance the speed and quality of your cutting process. Poor-quality rotary slitter blades can lead to several issues, such as:

- The cutting edge can break if it is not properly aligned

- Rubber bonded spacers may sustain damage

- The blades might not be installed consistently each time

- The fabric could be trimmed unevenly

- The fabric may not remain flat during cutting

Nanjing Metal Industrial offers a wide selection of rotary slitter blades for textiles, crafted from premium materials. You can select blades with specialized edges, exceptional durability, and tailored options to meet your specific requirements.

重要なポイント

- Picking good rotary slitter blades helps you cut faster and better. It also lowers waste and makes products look nicer.

- Choose the right blade material for your textile. Use high-speed steel if you want blades to last longer. Pick tungsten carbide for hard jobs. Use high-carbon steel if you want to save money.

- Think about the edge design. Small edge blades work well for thick fabrics. Large edge blades are best for thin textiles. They help stop tearing.

- Take care of your blades by cleaning and storing them right. This can make blades last up to 35% longer.

- Watch for blade wear by looking for rough edges or harder cutting. Change blades when needed to keep them working well.

- Custom blades made for your needs can help you cut better. They also help you waste less material.

- Supplier help is important. Pick suppliers who can make custom blades and help you fast. This keeps your work going smoothly.

- Buying good blades may cost more at first. But it can save you money later because you will need less fixing and fewer new blades.

Key Features of the Best Rotary Slitter Blade

Blade Materials for Textile Cutting

Picking the right material for rotary slitter blades is important. Every material has its own benefits for different textile jobs. You should think about how the material changes blade life, sharpness, and cutting quality.

高速度鋼(HSS)

High-speed steel is very hard and tough. It works well for fast textile cutting because it does not wear out quickly. HSS blades are good for regular and rough fabrics. M2 steel is a strong type of HSS. It lets machines run longer before you need to change blades. This helps you save time and work faster.

タングステンカーバイド

Tungsten carbide blades are super hard and last a long time. They can cut rough and tough textiles easily. These blades stay sharp for a long time, so you do not need to replace them often. Tungsten carbide is best when you need the best rotary slitter blade for big jobs.

高炭素鋼

High-carbon steel blades cost less and are easy to sharpen. They are good for most textile cutting. You should keep them dry and clean because they can rust if you do not take care of them. D2 steel is a popular high-carbon choice. It gives good wear resistance and is not expensive.

工具鋼

Tool steel blades are strong and last a long time. They work for many kinds of textile materials. You can trust tool steel for steady blade performance and long use. These blades are a good pick when you want something reliable and valuable.

ヒント: Stainless steel and ceramic blades are also sold. Stainless steel does not rust, and ceramic blades stay sharp for a long time but can break easily.

| 材料 | 耐久性 | 利点 | デメリット |

|---|---|---|---|

| ステンレス鋼 | 高い | 耐腐食性、耐久性 | コストが高い |

| 炭素鋼 | 中くらい | コスト効率が高く、研ぎやすい | Prone to rust without care |

| セラミック | 非常に高い | 軽量で超鋭いエッジ | 脆弱で初期費用が高い |

Edge Design and Geometry

The edge design of rotary slitter blades for textiles changes how well you can cut. The right shape helps you waste less and make better products.

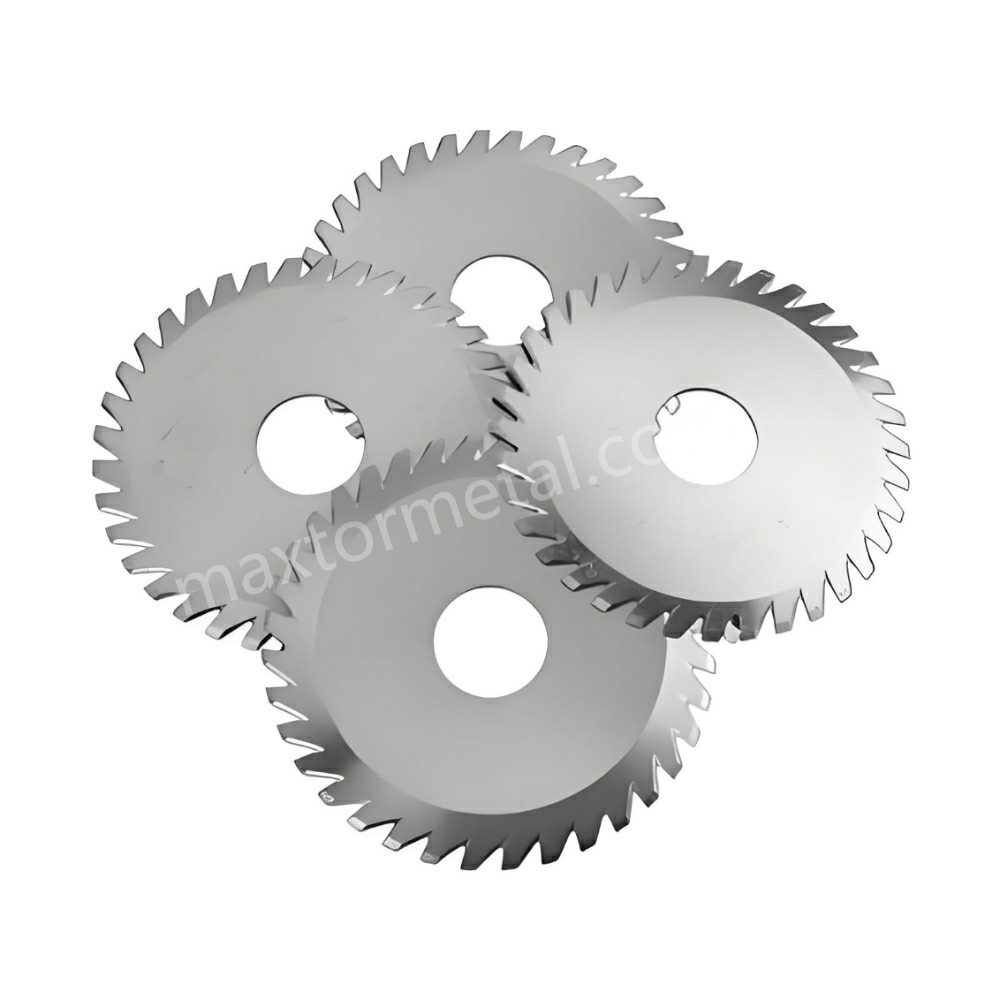

Single-Layer Small Edge Blades

Single-layer small edge blades are great for cutting thick or hard textiles. The sharp, thin edge helps you make neat cuts with less pulling. You will see less fraying and smoother edges. These blades are best when you need exact cuts and less fiber loss.

Double-Layer Large Edge Blades

Double-layer large edge blades are good for thin or soft textiles. The wide edge holds the fabric and stops it from tearing. You get smooth cuts even when working fast. This design is best when you want to keep fabric strong and waste less.

For special blade shapes and edge designs, you can check the カスタムブレードページ for options that fit your needs.

| ジオメトリタイプ | 最適な用途 | パフォーマンス結果 |

|---|---|---|

| Polished bevel | Cotton, woven textiles | Less fabric waste, cleaner cuts |

| Scalloped/wave-edge | Woven textiles | Reduced fraying, smooth edges |

| Micro-serrated | Paper, coated labels | Precise cuts, minimal debris |

耐久性と耐摩耗性

You want blades that last a long time. Durability and wear resistance are important for blade life and cutting quality.

コーティング技術

New coating technologies help blades last longer. Coatings like Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Diamond-Like Carbon (DLC) make blades harder and reduce friction. These coatings help blades fight wear and heat, so they last longer even in tough jobs.

| コーティング技術 | 利点 |

|---|---|

| 窒化チタン(TiN) | Hardness, wear resistance, lower friction |

| 炭窒化チタン(TiCN) | Toughness, high-speed cutting, excellent wear resistance |

| Titanium Aluminum Nitride (TiAlN) | Thermal stability, longer tool life |

| ダイヤモンドライクカーボン(DLC) | Hardness, low friction, improved chip evacuation |

Heat and Friction Resistance

Cutting textiles makes heat and friction. You need blades that can handle these problems and stay sharp. Materials like tungsten carbide and coated steels work well in hot conditions. They keep their edge and give steady results, even during long work times.

- Wear resistance helps blades fight damage and friction, so they last longer and cut well.

- Corrosion resistance matters in wet or chemical places. It stops rust and keeps blades safe and useful.

- Abrasion resistance helps blades stay sharp, especially when cutting rough textiles.

Better blades, like ceramic-coated ones, cut faster and stay sharp longer. This helps you save time and money because you do not need to change blades often.

If you need a special blade for a certain job, you can pick custom options. Custom blades let you match the material and shape to what you need.

Precision and Clean Cutting

When you use a rotary slitter blade, you want every cut to be clean. Clean cuts help you save material. They also make your products look nice. Precision is very important with high-speed machines. If you do not focus on precision, you might get rough edges. You could also see extra fibers or lines that are not straight.

Minimizing Burrs and Debris

Burrs and debris can make your textiles look bad. You want to keep these problems small. The best rotary slitter blades have sharp edges. They also have smooth surfaces. These blades cut fabric without leaving rough spots. Look for blades with a fine surface finish. Make sure the cutting edge angle is designed well.

A smooth blade surface lowers friction. Less friction means less sticking. You also get fewer loose fibers.

Here are some things that help you get fewer burrs and debris:

- シャープネス: A sharp rotary slitter blade cuts clean. It leaves fewer loose threads.

- 表面仕上げ: A smooth blade (Ra 0.2 µm – 0.4 µm) moves easily through fabric. It keeps the cut edge neat.

- エッジジオメトリ: The right cutting edge angle (like 20° or 30°) fits your textile type. It helps you avoid rough edges.

- 並列許容度: When blade surfaces stay parallel (±0.001 mm to ±0.002 mm), you get even slit widths. You also get fewer burrs.

| パラメータ | 説明 | Typical Range for High-Performance Knives | パフォーマンスへの影響 |

|---|---|---|---|

| 並列許容度 | How much the blade surfaces are not parallel | ±0.001 mm~±0.002 mm | Even slit width, fewer burrs |

| Surface Finish (Ra) | How smooth the blade surface is | Ra 0.2 µm – 0.4 µm | Less friction, cleaner cuts |

| Cutting Edge Angle | The angle of the blade’s sharp edge | 20°, 30°, multi-angle grind | Best for material, less debris |

If you want your textiles to look good, check these blade features before you cut.

Consistency at High Speed

High-speed cutting is tough on your rotary slitter blade. You need a blade that stays sharp and steady. This is true even when your machine runs fast. Consistency means every cut looks the same. It does not matter how quickly you work.

- 軸方向および半径方向の振れ: If your blade wobbles (less than 0.005 mm T.I.R.), you might get uneven cuts. You could also see more vibration. A stable blade keeps every cut straight and smooth.

- ブレード材質: Strong materials like high-speed steel or tungsten carbide keep their edge longer. This is true even at high speeds.

- エッジ保持: A blade that stays sharp gives you the same quality cut every time.

Tip: Always check your rotary slitter blade for wear before a high-speed job. A worn blade can make more burrs and uneven cuts.

You can trust a high-quality rotary slitter blade for clean, precise cuts. When you pick the right blade for your textile and machine speed, you get better results. You also waste less material.

Top Rotary Slitter Blades for Textiles

If you want the best rotary slitter blade, you should know which brands are good. You also need to learn what makes each blade special. This part helps you compare top blades and see which ones fit your needs.

Nanjing Metal Industrial Slitter Blades

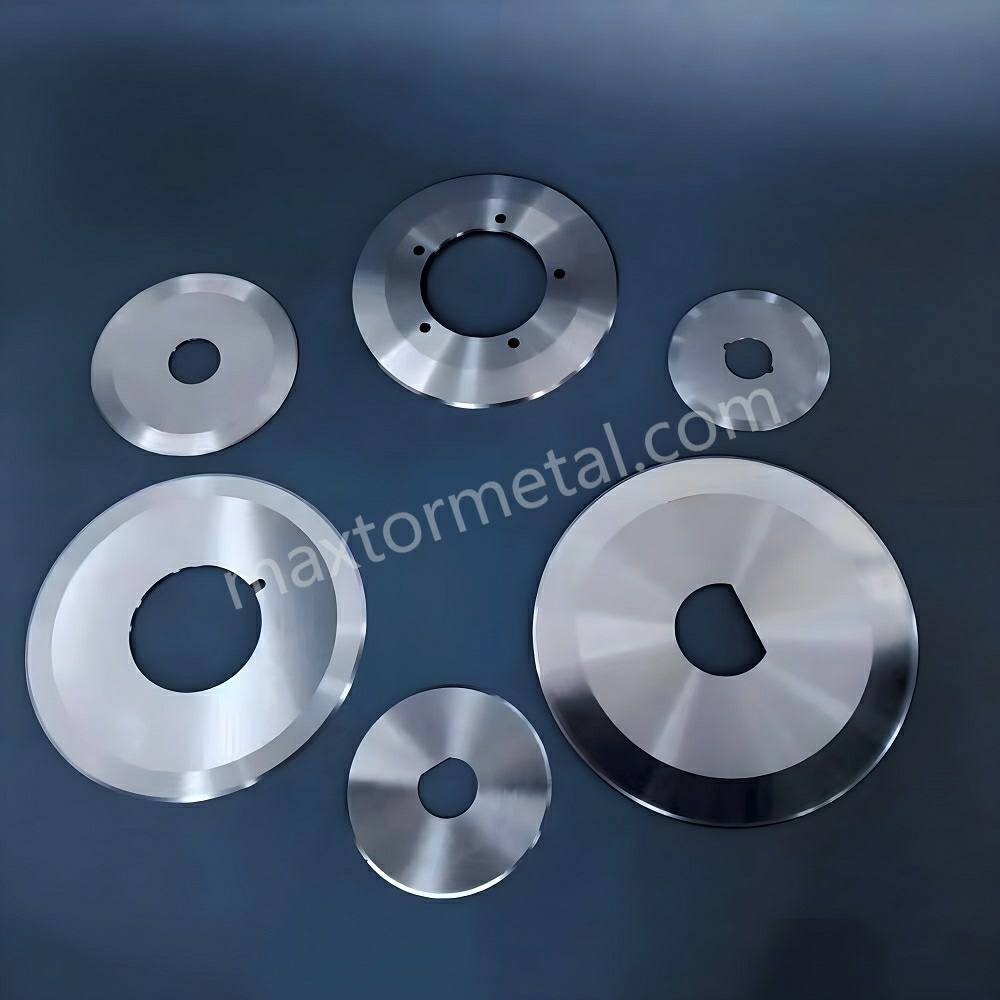

Product Range and Materials

Nanjing Metal Industrial sells many rotary スリッター刃 for textiles. You can pick blades made from high-carbon steel, high-speed steel, tool steel, alloy steel, or stainless steel. Each material has its own strong points. High-speed steel blades last longer and cut faster. High-carbon steel blades are easy to sharpen and cost less. Stainless steel blades do not rust and work well in wet places. You can choose single-layer small edge blades for tough fabrics. Double-layer large edge blades are good for thin, soft textiles. This big selection helps you match the blade to your fabric and cutting speed.

| 特徴 | 説明 |

|---|---|

| 製品ラインナップ | Has many rotary slitter blades for different jobs. |

| カスタマイズオプション | Makes blades with special shapes and sizes for customers. |

| 品質保証 | Checks every blade to make sure it is high quality. |

Customization Services

Sometimes you need a blade that fits your machine or your special fabric. Nanjing Metal Industrial lets you order custom blades. You can ask for blades with non-stick coatings for sticky materials like glue. You can get heat-resistant blades for fast machines. The company can make blades with special shapes, sizes, and edge designs. Custom blades help you get better performance and longer blade life. You get blades that fit your job and last longer.

| Customization Benefit | Impact on Performance and Suitability |

|---|---|

| Special designs | Fit your cutting needs |

| Better durability | Blades last longer |

| Faster cutting | Cuts are quicker and more accurate |

You can ask for blades with special coatings or heat resistance for special textile jobs.

Quality Assurance and Testing

You want blades that work well every time you use them. Nanjing Metal Industrial is ISO certified. The company uses tools like micrometers and hardness testers to check each rotary slitter blade. These tools make sure every blade meets strict rules. You get blades that cut clean and last longer. The company checks the material, the edge, and the finish before shipping. This careful testing means you can trust the blades for fast textile cutting.

- ISO certification means the company cares about quality.

- Every blade gets tested for hardness and size.

- You get blades that meet high standards for textile cutting.

Other Best Slitting Blades for Textiles

You have other choices when you want the best slitting blades. Here are two popular options:

Fabric Hut Rotary Cutter Blade

Fabric Hut rotary cutter blades are sharp and make clean cuts. You can use them for quilting fabrics, cotton, and other soft textiles. These blades are good for home and small businesses. They are easy to change and fit many rotary cutters. You get smooth edges and less fraying.

Shear Slitter Knives

Shear slitting blades are used in many textile factories. You can use them for fast cutting of woven and nonwoven fabrics. These blades make precise cuts and keep the slit width even. Shear slitting blades work well for tough jobs and big rolls. You can get them in tool steel and tungsten carbide. They last long and resist wear.

- Shear slitting blades help you cut textiles quickly and accurately.

- You can use them for paper, labels, and coated fabrics too.

- Many factories pick shear slitting blades because they are reliable.

Other blade types include razor slitting blades and crush cut blades. Razor slitting blades are very sharp and cut thin materials. You can use them for films and light textiles. Crush cut blades work for thick or sticky materials. You can use them for rubber sheets and heavy fabrics.

Pros and Cons of Leading Blades

You want to know what is good and bad about each blade type. This table helps you compare the main points.

| 利点 | デメリット |

|---|---|

| Makes clean cuts without burrs or tears | Needs careful setup and calibration |

| Keeps slit width even with steady tension | May be hard for new operators |

| Cuts many materials with high precision | May cost more at first for machines |

Shear slitting blades and razor slitting blades give you clean cuts and high precision. You must set up your machine carefully for the best results. Crush cut blades are good for thick or sticky textiles, but you may need to replace them more often.

When you pick rotary slitter blades for textiles, think about your fabric, cutting speed, and machine setup. The best rotary slitter blade helps you get clean cuts, waste less, and make more products. You can trust brands like Nanjing Metal Industrial, Fabric Hut, and other top suppliers to give you blades that fit your needs. Custom blades and quality checks help blades work better and last longer.

If you want the best slitting blades for your textile work, look for blades that match your material and speed. Shear slitting blades, razor slitting blades, and crush cut blades each have their own strong points. You can get better results by picking the right blade and keeping it in good shape.

How to Choose the Best Slitting Blades

Assessing Textile Type

Woven vs. Nonwoven Fabrics

You should know your textile before picking a slitting blade. Woven fabrics have threads that cross each other. Nonwoven fabrics use fibers pressed together. Each type needs a different blade for good results. Woven fabrics often need blades with sharp edges. This helps stop fraying. Nonwoven fabrics may need blades with smoother edges. This helps prevent tearing. If your textile is sticky or rough, pick a blade that resists wear or sticking. Some jobs need a burr-free edge for a clean finish. Matching the blade to your textile helps you get better cuts.

材料の厚さ

Material thickness changes how you pick your blade. Thick textiles need strong blades. These blades can handle more force. Thin materials work best with blades that have a fine edge. Thicker materials may need tool steel or tungsten carbide blades. These blades last longer. Softer or thinner textiles often use high carbon steel or stainless steel blades. The surface finish and slit quality also matter. Always check the thickness of your textile before choosing a blade. This helps you avoid problems and keeps your cuts neat.

Matching Blade to Cutting Speed

RPM and Machine Compatibility

Your machine speed, measured in RPM, affects which blade you use. Fast machines need blades that stay sharp and do not overheat. Make sure your blade matches your machine’s speed and tolerance. Fast machines work best with high-speed steel or tungsten carbide blades. Always check if the blade fits your machine holder well. Using the wrong blade may cause uneven cuts or extra wear. Matching the blade to your machine’s speed helps you get better performance.

Blade Size and Mounting

Blade size and mounting are important for safety and accuracy. A blade that is too big or too small can cause problems. Proper mounting keeps the blade stable. This helps you get precise cuts. The right blade size gives you better control and efficiency. Secure mounting stops the blade from wobbling or shifting. The blade’s design and material affect how well it works with different fabrics. Always follow your machine’s rules for blade size and mounting. This keeps your work safe and your cuts accurate.

Evaluating Cost and Value

Long-Term Performance

You want a blade that lasts and does not need to be replaced often. The blade material affects how long it works well. High-quality industrial slitter blades cost more at first. They save you money over time. Durable blades lower maintenance costs. Good suppliers offer blades that last longer and work better. After-sales support helps you keep your blades in good shape. Picking a blade with strong long-term performance helps you avoid downtime and extra costs.

予算の考慮

You must balance your budget with your cutting needs. Some blades cost less but wear out faster. Others cost more but last longer and give better results.

| ブレードタイプ | 初期費用 | メンテナンスコスト | 寿命 | 最適な用途 |

|---|---|---|---|---|

| ハイス鋼 | 中くらい | 低い | 長さ | Fast, regular cutting |

| タングステンカーバイド | 高い | 非常に低い | 非常に長い | Tough, abrasive textiles |

| 高炭素鋼 | 低い | 中くらい | 中くらい | Soft, thin textiles |

| 工具鋼 | 中くらい | 低い | 長さ | Mixed textile types |

Think about how often you need to replace blades. Also think about how much downtime costs your business. A blade that lasts longer may save you more money in the end.

Tip: Always ask your supplier about after-sales support and blade care. Good support helps you get the most value from your blades.

Supplier Support and Customization

Picking a rotary slitter blade is not just about the blade. Supplier support and customization are important too. Good suppliers help you fix problems fast. They answer questions about your blade and machine. You get advice on which blade works best for your fabric and speed.

Customization helps you get the blade you need. You can ask for special shapes, sizes, or coatings. This makes it easier to cut different textiles. Custom blades are great for special fabrics or fast machines. You get neat cuts and waste less material.

Tip: Suppliers with good support help you work without stopping. They send blades quickly, give technical help, and offer spare parts.

Supplier support and customization make textile cutting better in many ways:

- Blades fit your machine just right.

- Custom blades work for sticky or thick textiles.

- Technical help shows you how to set up blades for fast cutting.

- Quick replies from suppliers keep your work moving.

A supplier who customizes blades helps you work faster. You spend less time fixing machines. You get better cuts. If you let experts handle die-cutting, you can focus on your main job. You can trust them to make precise blades.

Automatic fabric cutting machines with custom rotary slitter blades give you:

- Exact cuts for better products.

- Faster work by cutting many layers at once.

- Easy changes to make new products quickly.

Suppliers with smart technology help you save fabric. Their software finds the best way to cut. You waste less and save money.

| Supplier Service | Benefit for Textile Cutting |

|---|---|

| Custom blade design | Fits your textile and machine |

| Technical support | Fixes problems quickly |

| Fast delivery | Stops delays in your work |

| Quality assurance | Makes sure blades work well |

Look for suppliers who give strong support and custom blades. This helps you get the most from your rotary slitter blade. You work better, save money, and make nicer products.

Maintenance Tips for Rotary Slitter Blades

Taking care of your rotary slitter blades helps you get clean cuts. It also makes the blades last longer. You can use these tips to keep your blades working well.

清掃と取り扱い

推奨洗浄剤

Clean your rotary slitter blade often. This stops material from building up and keeps rust away. Cleaning helps your blade stay sharp and cut smoothly. Use gentle cleaners or special blade cleaners. These remove glue, fibers, and dust but do not hurt the blade. Fix knife holders when needed so blades fit right and wear less. Coatings on blades can help them last longer and work better for some jobs.

- Clean blades every day with gentle cleaners.

- Take off glue, fibers, and dust after each shift.

- Fix knife holders often for better cuts.

- Use blade coatings for longer life and better work.

Cleaning your blades every day can make them last up to 35% longer.

Safe Storage

Storing blades the right way keeps them safe from damage and rust. Put each blade in its own sleeve or case. Store blades in a dry place with steady temperature. Do not stack blades together. Stacking can bend or scratch them. Handle blades gently and wear gloves to stop dents or scratches.

- Put blades in sleeves or cases to protect them.

- Keep blades dry and at a steady temperature.

- Never stack blades to avoid damage.

- Use gloves when handling blades for safety.

研磨と交換

Signs of Blade Wear

Watch for signs that your rotary slitter blade is getting old. If you see rough edges, burrs, or cracks in your cut fabric, you may need a new blade. If cutting gets harder or the motor works more, the blade might be worn out. If cutting slows down or gets louder, the blade could be dull. Always check for notches or bent spots on the blade.

- Rough edges or burrs in cut fabric

- Cracks in finished pieces

- Harder cutting or higher motor load

- Slower cutting speed

- Louder noise while cutting

- Notches or bent spots on the blade

プロフェッショナルシャープニング

Sharpening your rotary slitter blade helps it work well. Use a motorized work head for best sharpening. Keep the blade’s edge small, about .008 to .010 inches for most machines. Some machines need an even smaller edge, like .003 to .005 inches. Pick the right grinding wheel so the blade does not get too hot or lose strength. Run the machine with coolant to keep the blade cool and sharp.

- Use a motorized work head to sharpen blades.

- Keep the edge small for good cutting.

- Choose the right grinding wheel to stop overheating.

- Use coolant to keep blades cool while sharpening.

Sharpen blades when you notice cuts are not as good.

Preventing Blade Failures

Overheating and Vibration

You can stop blade problems by cleaning blades often and using the right oil. Oil helps blades wear less, stay cool, and keeps stuff from sticking. Do not push your machine too hard or use too much force. This can crack the blade. Make a regular plan for checking, cleaning, and sharpening blades when they do not work well.

- Clean blades every day to stop buildup and rust.

- Oil blades to lower wear and keep them cool.

- Do not overload or use too much force.

- Check and sharpen blades when needed.

Record-Keeping

Writing down blade care helps you know when to change parts. It also helps you avoid surprise problems. Cleaning and oiling on a schedule keeps blades working their best. Keeping logs helps you plan for new blades and less downtime. Checking blades often makes machines last longer and cut better.

| メンテナンス実務 | Benefit for Rotary Slitter Blades |

|---|---|

| 定期的な清掃 | Blades last longer, cuts stay neat |

| 潤滑 | Less wear, blades do not get too hot |

| Maintenance logs | Know when to replace, less downtime |

| Proactive inspections | Machines last longer, cuts are more exact |

Keeping good records helps your work go smoothly and stops surprises.

If you follow these tips, your rotary slitter blade will stay sharp, safe, and ready for fast textile cutting.

Picking the right rotary slitter blade for textiles helps you get neat cuts. You also work faster and make more products. Here are some important things to remember:

- Strong materials like D2, HSS, and tungsten carbide last longer.

- Good edge retention means you change blades less often.

- Being precise and efficient helps you save money.

Nanjing Metal Industrial sells blades made from quality materials. They also offer custom choices for your needs. If you take care of your blades and get help from your supplier, your blades will work well. For special help, 弊社のセールスエンジニアにお問い合わせください.

よくある質問

What is a rotary slitter blade?

A rotary slitter blade is a circular cutting tool. You use it in slitting machines to cut wide rolls of textiles into narrower strips. It helps you get clean, precise cuts at high speed.

How do you choose the right rotary slitter blade for textiles?

You should match the blade material and edge design to your textile type and cutting speed. Check the thickness of your fabric. Pick a blade that fits your machine and cutting needs.

How often should you replace rotary slitter blades?

You should replace rotary slitter blades when you see dull edges, rough cuts, or more burrs. Regular checks help you spot wear early. Most blades last longer with proper cleaning and sharpening.

Can you sharpen rotary slitter blades at home?

You can sharpen some rotary slitter blades with a motorized sharpening tool. Always follow safety instructions. For best results, ask a professional to sharpen blades for you.

What materials work best for rotary slitter blades in textile cutting?

High-speed steel, tungsten carbide, and tool steel work best for textile cutting. These materials stay sharp longer and resist wear. You should pick the material based on your fabric and cutting speed.

How do you clean rotary slitter blades?

You should clean blades daily with gentle cleaners. Remove glue, fibers, and dust after each use. Store blades in dry cases to prevent rust and damage.

Why does edge design matter for rotary slitter blades?

Edge design affects how cleanly you cut textiles. Sharp edges reduce fraying. Smooth surfaces help you get neat cuts. The right edge design improves your cutting quality and reduces waste.

参照

ロータリースリッターブレードのトラブルシューティングにおける最大の誤りとその修正方法

1件のフィードバック