You have hard jobs in fiber and PCB manufacturing. You need things to be exact and strong every day. 超硬カミソリ刃 help you make smooth cuts and work fast. Tungsten carbide is very hard and lasts a long time. Look at how it matches up with other materials:

| 材料 | Mohs Hardness | Vickers Hardness (Hv) |

|---|---|---|

| Tungsten Carbide (WC) | 9 | 2400 |

| Silicon Carbide (SiC) | 9-9.5 | 2400-2800 |

| Titanium Diboride (TiB2) | 9-9.5 | 3000-3500 |

| Boron Carbide (B4C) | 9-9.5 | 3000 |

Tungsten carbide blades last long and save you money each time you cut.

重要なポイント

- Carbide razor blades are very hard and last longer than steel blades. This helps you save both time and money. These blades make very exact cuts with few mistakes. This gives you high-quality products in fiber and PCB manufacturing. Tungsten carbide blades do not get damaged by heat or wear easily. This makes them great for fast production lines with less stopping time. Custom carbide blades can be made for special cutting needs. This helps make work faster and more accurate. Cleaning and sharpening your carbide blades often can make them last much longer. Using carbide blades makes less waste and gives better product quality. They make clean and smooth cuts. Picking the right blade type and features is very important. It helps you get the best results in your cutting jobs. Buying carbide razor blades helps you work better and spend less money in manufacturing.

Carbide Razor Blades: Industry Importance

Meeting Precision Demands

People who make fiber and PCB need exact tools. Carbide razor blades help you get very accurate results. These blades can cut with tiny errors, less than ±0.01 mm. This means every cut looks the same. Your products stay even and neat. Carbide razor blades keep edges smooth and clean. You can use them to cut thousands of pieces each day.

Carbide razor blades use strong C2 carbide. This material does not wear out fast. The blades stay sharp longer than other types. Some blades have coatings like titanium nitride. These coatings help stop wear and lower friction. The blades last longer and work better. The weight in these blades is balanced. This stops them from shaking. You get straight cuts every time.

If you need special blades, you can get custom ones. You can go to the カスタムブレードページ to find what you need. Custom blades help you work more exactly and faster.

Overcoming Traditional Blade Limits

Making fiber and PCB can be hard. Old steel blades get dull quickly. You have to change them a lot. This takes time away from making things. Carbide razor blades fix this problem. Their sharp edge lasts a long time. You do not need to replace them often. You save money and your machines work longer.

Tungsten carbide makes these blades very hard. They do not get damaged by heat. You can cut tough stuff without worry. Carbide razor blades work well on fast production lines. You get fewer stops and better results.

You want blades that help you work fast and smart. Carbide razor blades are strong, sharp, and save money. You get more from every blade and every cut.

Unique Properties of Tungsten Carbide Blades

Sub-Micron Edge Sharpness

You need blades with very sharp edges. Sharp edges help you make clean cuts. Tungsten carbide blades can be super thin and smooth. This helps you cut fiber and PCB materials better. The edge stays sharp for a long time. You do not have to change blades often.

Here is a table that shows how tungsten carbide compares to other blade materials:

| ブレード材質 | 硬度(HRC) | 推奨エッジ半径 |

|---|---|---|

| タングステンカーバイド | 85~90HRC | 20~50µm |

| セラミックブレード | 90HRC以上 | 5~15µm |

High-Speed Fiber Cutting

You cut fibers fast every day. Sub-micron sharpness helps you work quickly. The blade slices fibers with less force. You see fewer rough edges and more even pieces. Your line moves faster because you fix fewer mistakes.

FPCB Micro-Slitting

You need to cut flexible printed circuit boards very carefully. A sharp blade lets you make tiny cuts without hurting the board. You get clean lines and smooth edges. This helps you meet strict rules in electronics work.

Here is a table that explains how edge sharpness affects cutting quality:

| ツールタイプ | エッジのシャープネス | 切断品質への影響 |

|---|---|---|

| MCD | Atomically sharp | Makes surfaces smooth and needs less force, great for very exact work |

| PCD | Limited by grain size | Surface may not be as smooth, not as sharp as MCD |

硬度と耐摩耗性

You want blades that last a long time. Tungsten carbide blades are very hard and strong. Their tight structure helps them stay sharp and not break. You spend less time changing blades and more time working.

Look at the hardness values for tungsten carbide:

| Hardness Scale | Tungsten Carbide Typical Value | 注記 |

|---|---|---|

| Vickers Hardness (HV) | 1,500 – 3,000 HV | Depends on grain size and cobalt content |

| Rockwell Hardness A (HRA) | 88 – 95 HRA | Standard for tungsten carbide |

| Rockwell Hardness C (HRC) | ~69 – 81 HRC | Approximate equivalent for comparison |

You can see how tungsten carbide compares to other materials in wear resistance:

| 材料 | Hardness (HV) | Microstructure | アプリケーション |

|---|---|---|---|

| タングステンカーバイド | >1600 | Dense, fine-grained | Cutting tools, mining components |

| ハイス鋼 | Lower than WC | Coarser structure | General machining tools |

Tip: Pick blades with higher hardness. They last longer and work better for tough jobs.

Thermal Stability in Cutting

You need blades that work well when hot. Tungsten carbide blades keep their hardness even at high heat. You can use them for fast cutting and not worry about dull edges.

- Thermal stability helps blades resist heat damage.

- The blade does not break or rust during quick cutting.

- You get faster work and less stopping.

Carbide Razor Blades give you sharpness, hardness, and heat strength. You get all these in one tool for fiber and PCB jobs.

Fiber Manufacturing Applications

Chemical Fiber Cutting

You work with chemical fibers every day. You need blades that cut cleanly and keep waste low. Carbide Razor Blades help you reach this goal. These blades stay sharp and cut fibers with high efficiency. You see less waste because the blades make smooth cuts and do not damage the fibers.

Consistent Lengths and Clean Edges

You want every fiber to be the same length. Clean edges matter for quality. Carbide blades help you get both. Here is how they help:

- The blades keep their sharp edge for a long time. You get clean cuts every time.

- The design of the blade reduces heat. This means fibers do not melt or fray.

- You see less waste because the cuts are precise.

Tip: Use blades with high cutting efficiency to lower fiber waste and improve product quality.

Synthetic Fiber Staple Precision

You need to cut synthetic fibers like polyester, nylon, and aramid. These fibers are strong and tough. Carbide blades give you the precision you need. You get exact cuts and long blade life.

- The blades work well with high-strength fibers.

- You see low wear, so you do not change blades often.

- The blades handle short-cutting processes for glass fiber and carbon fiber.

- You can sharpen the blades up to three times. This extends their life.

- The quality of the blade material keeps your cuts sharp and clean.

| Fiber Type | カッティングチャレンジ | Carbide Blade Solution |

|---|---|---|

| Polyester | Tough, abrasive | High precision, low wear |

| ナイロン | Flexible, strong | Consistent sharpness |

| Aramid | 非常に強い | Long service life |

| Glass Fiber | 脆い | Clean, accurate cuts |

| Carbon Fiber | Hard, abrasive | Maintains edge quality |

Automated Line Productivity

You want your production line to run smoothly. Carbide blades help you keep up with fast speeds and high volumes. The blades do not dull quickly, so you stop less often to change them. You see more finished products and less downtime.

- The blades keep their edge during long runs.

- You get fewer stops for blade changes.

- Your line moves faster and stays productive.

Note: Reliable blades help you meet production goals and keep costs low.

You can trust carbide blades to deliver clean cuts, consistent lengths, and high productivity in fiber manufacturing.

PCB and FPCB Cutting Solutions

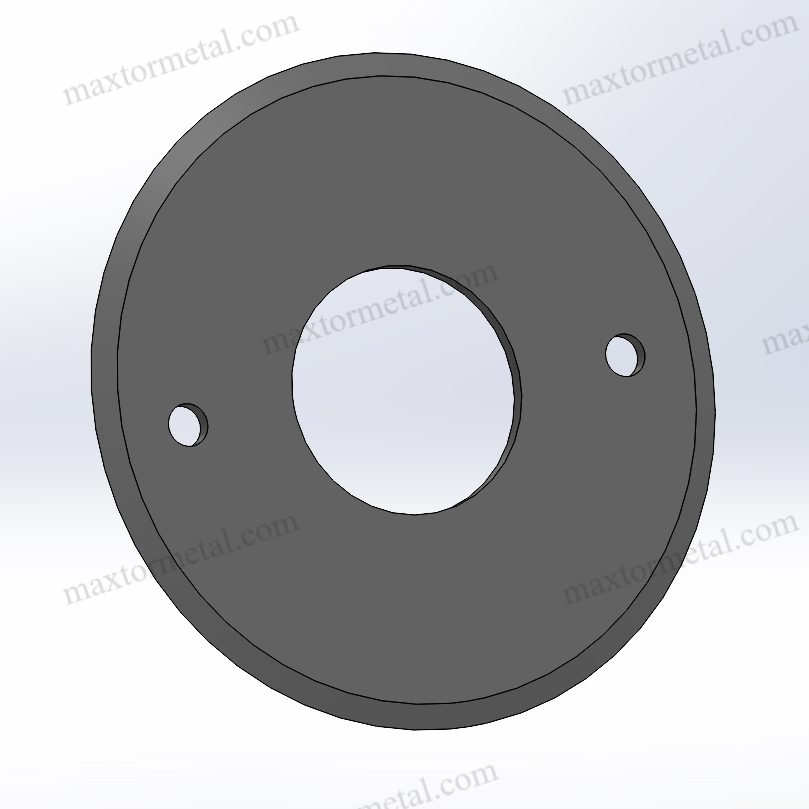

Printed circuit boards (PCBs) and flexible printed circuit boards (FPCBs) need precise cutting. You want every board to have clean edges and exact shapes. Carbide Razor Blades help you reach these goals. You can use these blades for micro-slitting, panelization, and many other PCB processes.

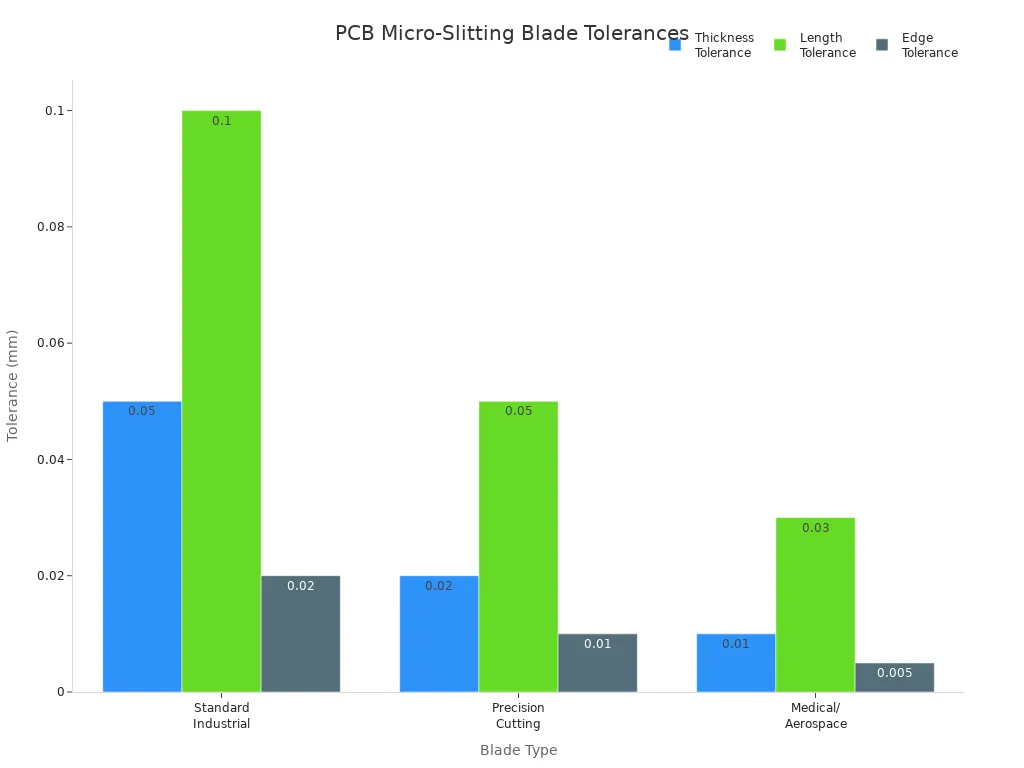

PCB Micro-Slitting

Micro-slitting means you cut very thin lines in PCBs. You need high accuracy for this job. Carbide Razor Blades give you tight tolerances. You can keep thickness, length, and edge measurements close to your target.

| ブレードタイプ | 厚さ許容差(mm) | 長さ許容差(mm) | エッジ許容差(mm) |

|---|---|---|---|

| 標準工業用 | ±0.05 | ±0.10 | ±0.02 |

| 精密切断 | ±0.02 | ±0.05 | ±0.01 |

| 医療/航空宇宙 | ±0.01 | ±0.03 | ±0.005 |

You can see that precision cutting blades give you much tighter tolerances than standard blades. This means your PCBs will have more consistent shapes and sizes.

バリのないエッジ

You want smooth edges on every PCB. Burrs are tiny pieces left after cutting. Burrs can cause problems in electronics. Carbide Razor Blades help you avoid burrs. The sharp edge slices cleanly through the board. You get smooth, flat edges every time.

Tip: Use blades with sub-micron sharpness to reduce burrs and improve product quality.

Carbide Razor Blades in PCB Panelization

Panelization means you group many PCBs together before cutting them apart. You need blades that can handle many cuts in a row. Carbide Razor Blades stay sharp for a long time. You can cut hundreds or thousands of boards before changing the blade.

- You get even cuts across the whole panel.

- The blade does not bend or break during fast cutting.

- You save time because you do not stop often for blade changes.

Note: Reliable blades help you keep your production line moving and meet your delivery deadlines.

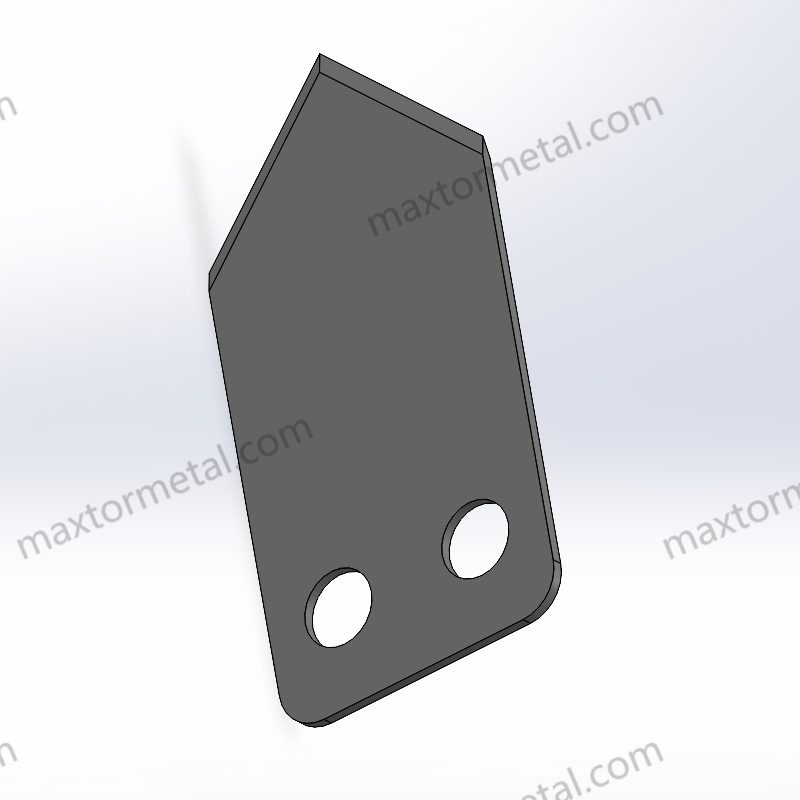

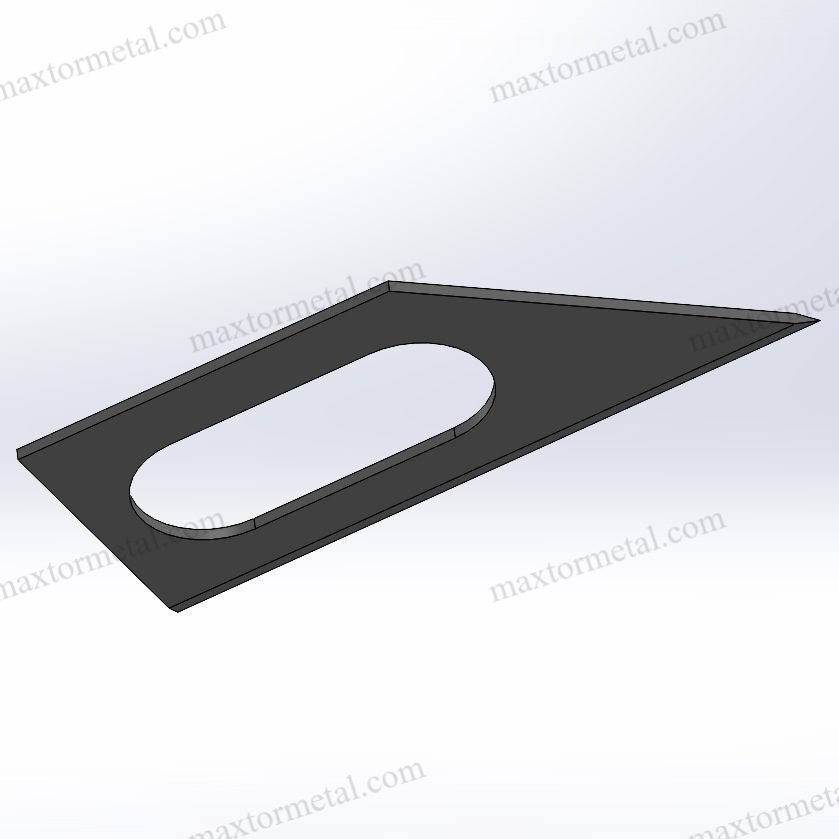

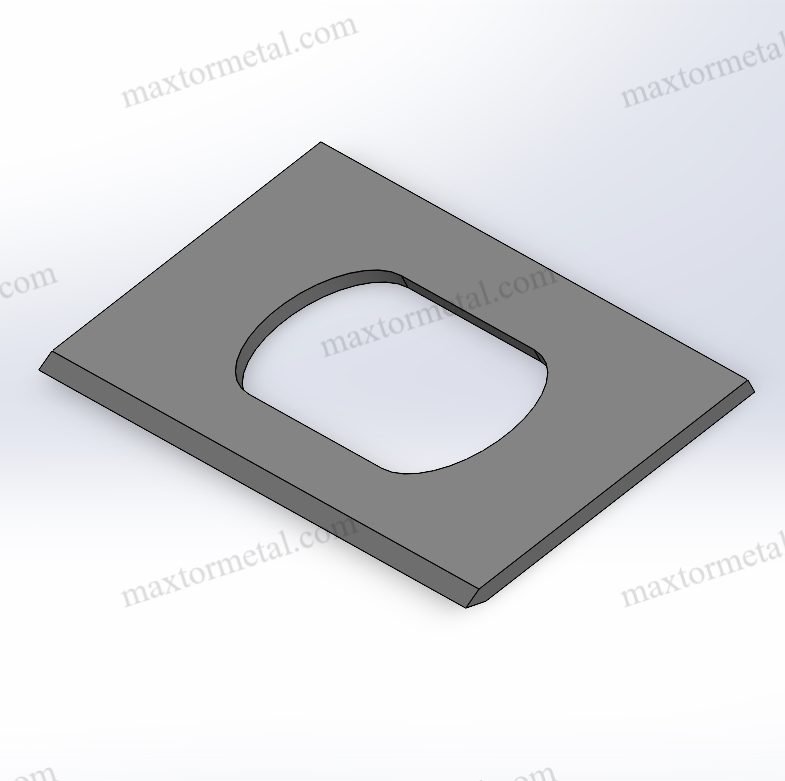

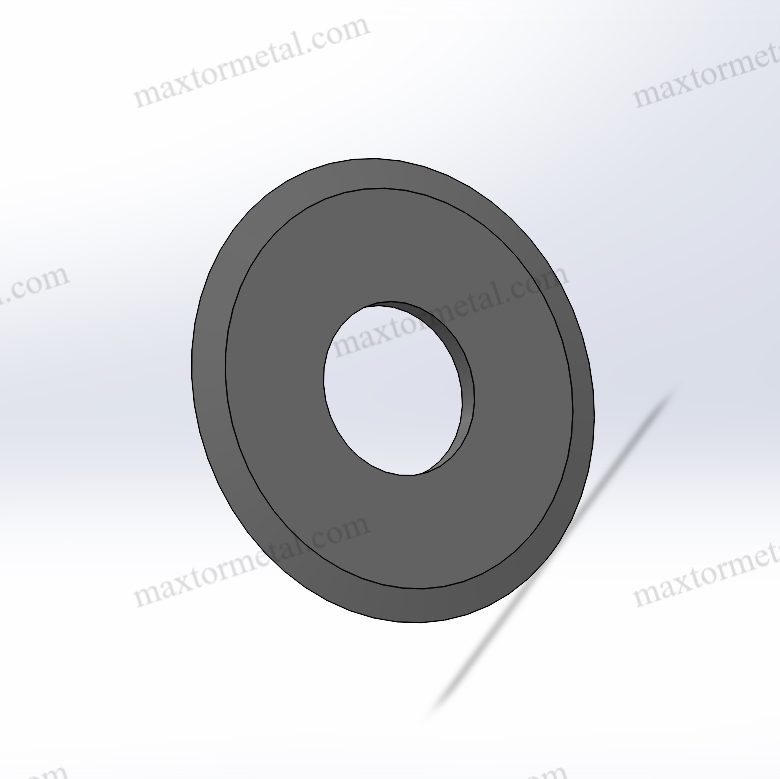

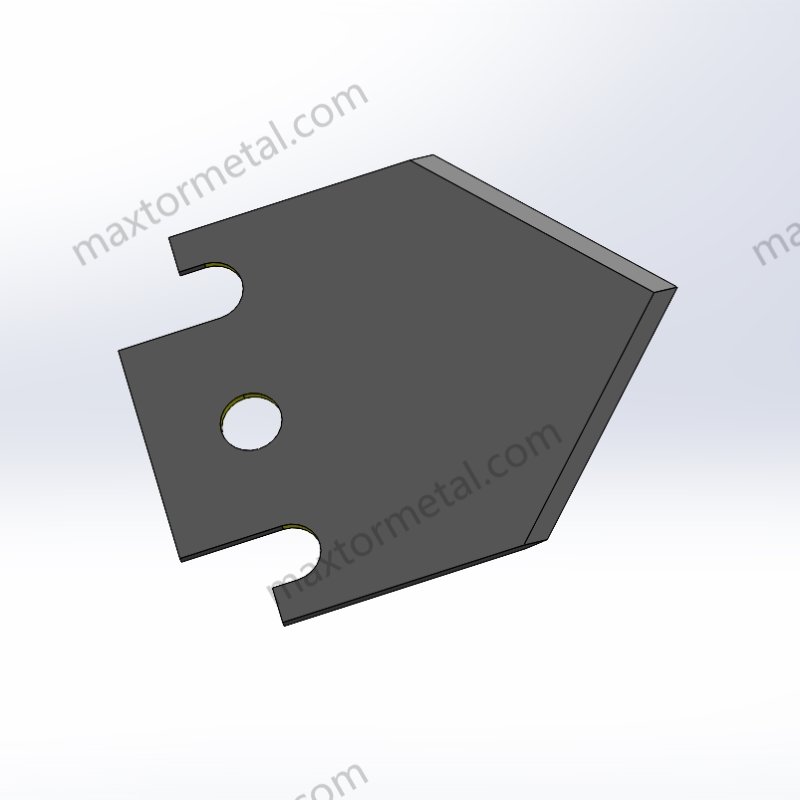

Blade Types for PCB

You have many blade choices for PCB work. Tungsten carbide blades are the most common. These blades use ultrafine tungsten carbide. They reach a hardness of 93.5 HRA. You can use them for V-CUT knives and Gong blades. These tools help you cut straight lines and separate panels.

南京Metal工業 offers a wide range of tungsten carbide blades for PCB manufacturing.

- V-CUT knives help you make straight grooves in PCBs.

- Gong blades help you separate boards from panels.

- Both blade types give you clean, accurate cuts.

Tip: Choose the right blade type for your PCB process to get the best results.

You can trust carbide blades to deliver high precision, long life, and smooth edges in every PCB and FPCB cutting job.

Efficiency, Cost, and Quality Impact

Longer Blade Life, Less Downtime

You want your machines to work longer without stopping. Carbide Razor Blades help you do this. These blades last much longer than steel blades. Tungsten carbide blades can last 50 to 200 times longer than stainless steel blades. You spend less time changing blades and more time making products. Sharp blades keep your production line moving fast. You avoid delays and stay on schedule.

| ブレードタイプ | Average Lifespan (hours) | Changeover Frequency | ダウンタイムの影響 |

|---|---|---|---|

| ステンレス鋼 | 10–50 | 高い | 頻繁な停車 |

| タングステンカーバイド | 500–10,000 | 低い | Minimal interruptions |

Tip: Pick blades that last longer. This helps you work more and stop less.

メンテナンスコストの削減

You want to save money on fixing machines. Tungsten carbide blades help you in many ways:

- Tungsten carbide blades last longer than stainless steel blades.

- Better cuts from carbide blades mean fewer delays and mistakes.

- Using the wrong blade can cost more and be unsafe.

Long-lasting blades mean you buy fewer new ones. Your team spends less time changing and fixing blades. You also lower the chance of accidents from old blades. This keeps your workspace safer and saves money.

Enhanced Product Quality

You want every product to be high quality. Carbide blades help you make clean and exact cuts. Sharp blades give you smooth edges and perfect shapes. Your fiber and PCB products look good and work well. You see fewer mistakes and less waste. Customers trust your products because they are always good.

| Quality Factor | Impact of Carbide Blades |

|---|---|

| エッジの滑らかさ | High, fewer burrs |

| Cut Accuracy | Precise, tight tolerances |

| Product Consistency | Reliable, repeatable results |

Note: Good cuts make better products and happier customers.

You work faster, spend less, and make better products when you use the right blades.

Comparing Blade Materials

Carbide vs. Steel

When picking blades for fiber or PCB work, you look at carbide razor blades and steel blades. Steel blades have been used for a long time. They are strong and bend easily. But steel blades get dull fast. You have to change them a lot, which slows you down.

Carbide razor blades are much harder. They stay sharp much longer than steel blades. You spend less time swapping blades and more time making good products. Carbide blades do not wear out or get hot as quickly as steel. You can use them for hard jobs without worrying about breaking them.

| 特徴 | Carbide Razor Blades | スチールブレード |

|---|---|---|

| 硬度 | Very high (85–90 HRC) | Moderate (55–65 HRC) |

| エッジ保持 | 素晴らしい | 公平 |

| 耐摩耗性 | Outstanding | 適度 |

| 寿命 | 50–500x longer | 短い |

| メンテナンス | 低い | 高い |

| Cost Over Time | Saves money | Higher replacement cost |

Tip: If you want to change blades less and get smoother cuts, carbide razor blades are the best pick.

Carbide vs. Ceramic

You might also think about using ceramic blades for cutting. Ceramic blades are very hard. They stay sharp for a long time and are good for careful jobs. But ceramic blades can break or chip if you use them for tough work or if something bumps them.

Carbide razor blades are both hard and tough. You can use them for careful and heavy jobs. Carbide blades handle bumps and shaking better than ceramic blades. You get steady results on busy lines.

Here is a table to help you see the differences between carbide and ceramic blades:

| 特徴 | Carbide Razor Blades | セラミックブレード |

|---|---|---|

| 強靭さ | High, suitable for heavy-duty use | Low, more brittle |

| 耐久性 | Excellent, long lifespan | Good, but prone to chipping |

| 切削精度 | Good, can handle tough materials | Excellent, ideal for precision tasks |

| エッジ保持 | Very good, can be resharpened | Exceptional, remains sharp longer |

| 重さ | Heavier than steel | Lightweight, reduces hand fatigue |

| アプリケーション | Industrial, construction, heavy-duty | Food prep, electronics, crafting |

- Ceramic blades are harder than 2,500 HV. They work best for fast jobs that do not need much force.

- Carbide blades are between 1,500–2,000 HV. They do not break easily and are good for hard, bumpy cuts.

- Ceramic blades are great at not wearing out. Carbide blades are better when you need both careful cuts and strength.

Note: Pick carbide razor blades if you need a blade that can handle shaking and tough stuff. Choose ceramic blades for gentle, careful jobs with less chance of breaking.

Cost-Benefit for Industry

Switching to carbide razor blades helps your business in many ways. You get blades that last longer, make better cuts, and stop less often. Carbide blades can last 50 to 500 times longer than steel blades. You change blades less, so your machines keep working and your team stays busy.

- Longer wear means you buy fewer blades.

- Better cuts mean your products look nicer and you waste less.

- Less stopping helps you finish work on time and save money.

Using carbide razor blades helps you work faster and make better things. You spend less on fixing and changing blades. Over time, you save more money. Your line runs better, and your products are always high quality.

👍 Picking carbide razor blades helps you work smarter, save money, and get better results.

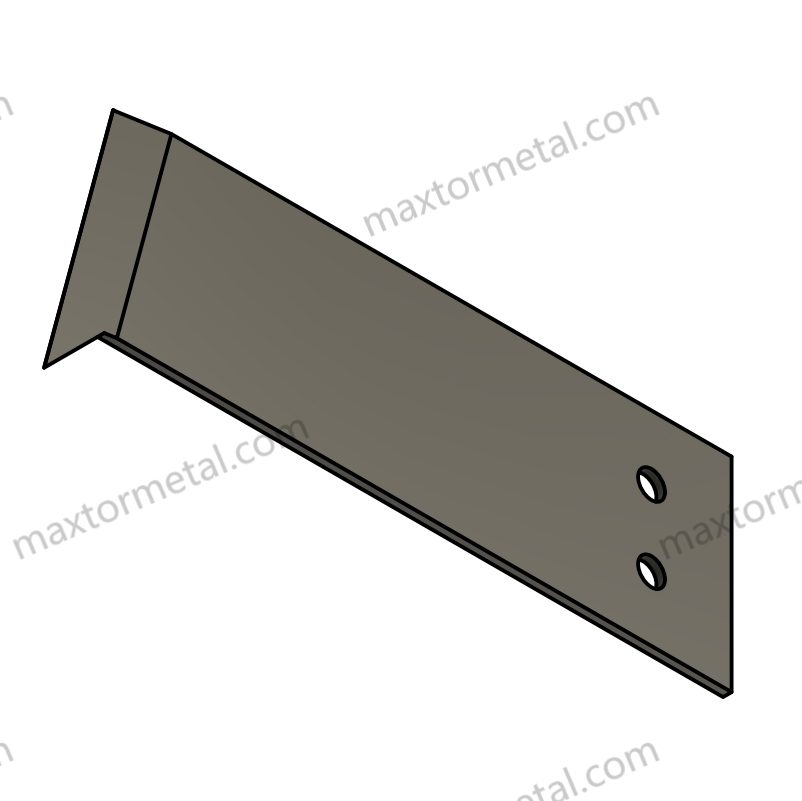

Choosing the Right Carbide Razor Blade

選考基準

You want to pick the best carbide razor blade for your work. First, look at the blade type, what it is made of, and what it does best. The table below helps you see the choices:

| ブレードタイプ | 材料 | 主なメリット | ベストユースケース |

|---|---|---|---|

| タングステンカーバイド | 超硬合金 | 耐摩耗寿命の延長、低摩擦 | 長期にわたる高速生産ライン |

Think about these things when you choose a blade: The blade angle is usually between 12° and 20°. The right angle depends on how thick your material is. Blade sharpness and shape matter too. A blade with 2 or 3 sides can cut smoother and with less rubbing. Web tension and speed are important. If the tension is balanced, your material will not stretch or change shape. Blade thickness, edge angle, and tip shape also matter. These things help you get clean and exact cuts.

Tungsten carbide blades are special because they are very hard. They last a long time and do not wear out fast. Different grades and ways of making the blade can change how long it lasts. Pick a blade that fits your job for the best results.

Tip: Always choose a blade with features that match your fiber or PCB job. This helps you get better cuts every time.

カスタマイズオプション

Sometimes you need a carbide razor blade made just for your job. There are many ways to customize your blade. The table below shows what you can pick:

| カスタマイズ機能 | 詳細 |

|---|---|

| Blade Shapes | Straight, curved, wavy, toothed, serrated, scalloped, notched, pointed tip, multiple-edged |

| 材料 | High speed steel, tungsten carbide, solid ceramic, and others |

| コーティング | TiN, TiC, TiCN, PTFE, Ceramic, Diamond |

| Packaging Options | Bulk, individual, or premium packaging |

| Part Identification | Logos or unique identifiers |

| Quality Documentation | COC, FAI, SPC, Cpk, etc. |

| Expediting Options | Options for expedited delivery available |

You can also ask for: OEM and ODM services if you have specific needs. Custom designs made just for you. Help with CAD drawings or samples if you need them.

Note: Custom blades help you fix special cutting problems and make your work better.

メンテナンスのベストプラクティス

You want your carbide razor blade to last a long time. Taking care of your blade is important. Here are some good tips: Clean your blades often so nothing builds up on them. If you clean them every day, they can last 25–35% longer. Check the cutting edge after each use to see if it is worn or broken. Use the right coolant when you cut to stop the blade from wearing out too soon. Keep your blades in a dry place so they do not rust or get damaged. Sharpen your blades with a stone or diamond wheel when they get dull.

Here are three big reasons to take care of your blades: 1. Cleaning stops rust by getting rid of water and chemicals. 2. Keeping the blade sharp helps it cut better and with less rubbing. 3. Good care makes your blade work up to 20% better.

🛠️ If you take care of your carbide razor blade, it will stay sharp, safe, and ready for every job.

Carbide razor blades let you make exact cuts in fiber and PCB work. You use them for a long time before changing. This means your machines stop less often. Your products look better and work well. These blades are tough and work fast. You do not need to buy new blades as much. You save money because you replace blades less.

- Pick tungsten carbide blades if you want blades that work well.

- Get better cutting tools so they last longer.

Want to make your work better? Talk to our sales engineers for help with carbide razor blades.

よくある質問

What makes carbide razor blades better for fiber and PCB cutting?

Carbide razor blades have very sharp edges. They stay sharp for a long time. These blades do not wear out fast. You get clean cuts every time. Your machines stop less often.

How often should you replace carbide razor blades?

Carbide razor blades last longer than steel blades. Change them when the edge gets dull. If cuts are not good, replace the blade. Check your blades often to keep things working well.

Can you use carbide razor blades for both fiber and PCB materials?

You can use carbide razor blades for fiber and PCB. These blades work for hard and soft jobs. You get accurate cuts in both areas.

Do carbide razor blades need special maintenance?

Clean carbide razor blades after you use them. Keep them dry so they do not rust. Sharpen them with a diamond wheel if needed. Taking care of blades helps them last longer.

Are carbide razor blades cost-effective for high-volume production?

Carbide razor blades help you save money. They last longer and need fewer changes. You spend less on fixing and get more products made.

What blade shapes are available for carbide razor blades?

You can pick straight, curved, serrated, or pointed blades. Choose the shape that matches your job. Custom shapes help with special cutting needs.

How do carbide razor blades improve product quality?

Carbide razor blades make smooth and exact cuts. Your products look nice and work well. People trust your products because they are good.

参照

Tungsten Knife: Is It Worth It? Pros, Cons & Applications in Industry

Why Tungsten Carbide Knives Chip — Common Failure Modes & How to Avoid Them

Tungsten Carbide vs Steel for Industrial Blades: Performance, Wear & Cost