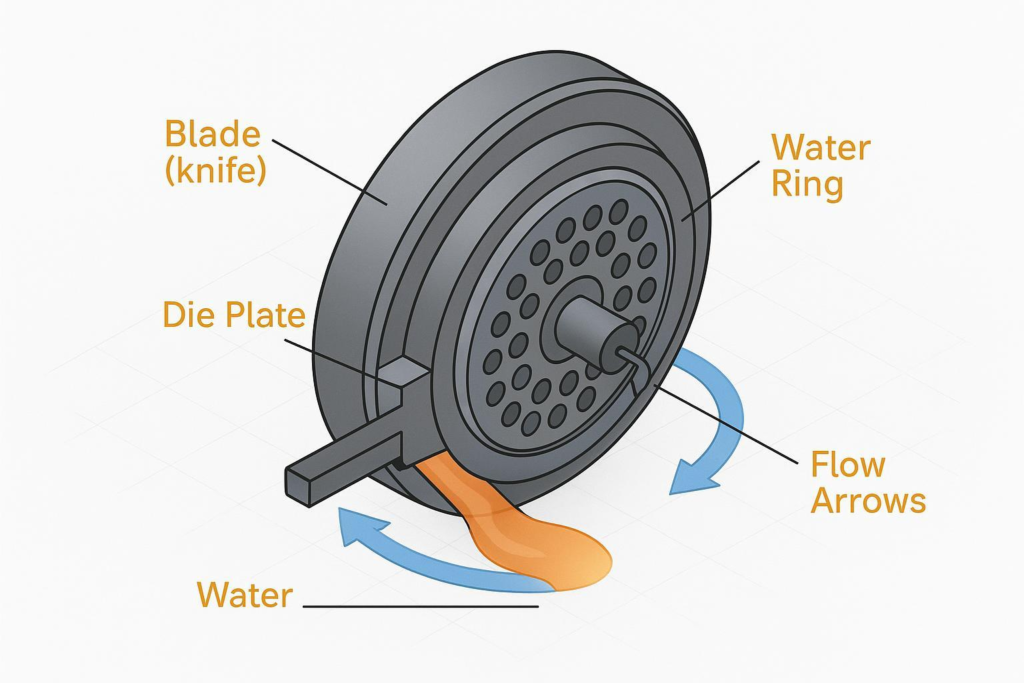

Pellet quality, uptime, and total cost per ton decide whether a water-ring (die-face hot-cut) line is truly performing. In PE/PP service, the blade’s material, coating, edge geometry, and dimensional tolerances interact with die-face condition, water-loop stability, and blade speed. Get any of these wrong and you’ll see tails, fines, inconsistent cut length, or avoidable downtime.

This guide shows how to choose water ring pelletizer blades for PE/PP lines with confidence: clear selection criteria for materials and coatings, practical geometry and preload guidance, startup and shutdown SOPs, OEM-fit tolerances and QC documentation to request, day-to-day operating tips, and a simple model for cost per ton.

Key takeaways

- Start with the recipe and duty cycle: clean, low-fill PE/PP favors D2 or PM-HSS; abrasives or long runs push you toward carbide or surface-engineered edges.

- Prioritize a smooth, flat die face and controlled preload; many “blade problems” are really contact/position or die-surface problems.

- Treat water temperature, flow, and filtration as process variables equal to knife speed; stability beats chasing setpoints.

- Always buy and run to drawings with measured tolerances and traceable QC: hardness, flatness, runout, thickness, coating spec, and lot IDs.

- Track hours/tons between sharpens, regrind before edges are truly dull, and model cost per ton with blades, regrinds, downtime, labor, and scrap.

Materials & surface engineering

Selecting blade material is the single biggest lever in how to choose water ring pelletizer blades for PE/PP lines. The goal is a sharp, stable edge that resists adhesive wear, micro-chipping, and corrosion in a wet, hot environment while matching your die and holder.

Tool steel options for PE/PP

For mostly virgin, low‑fill polyolefins:

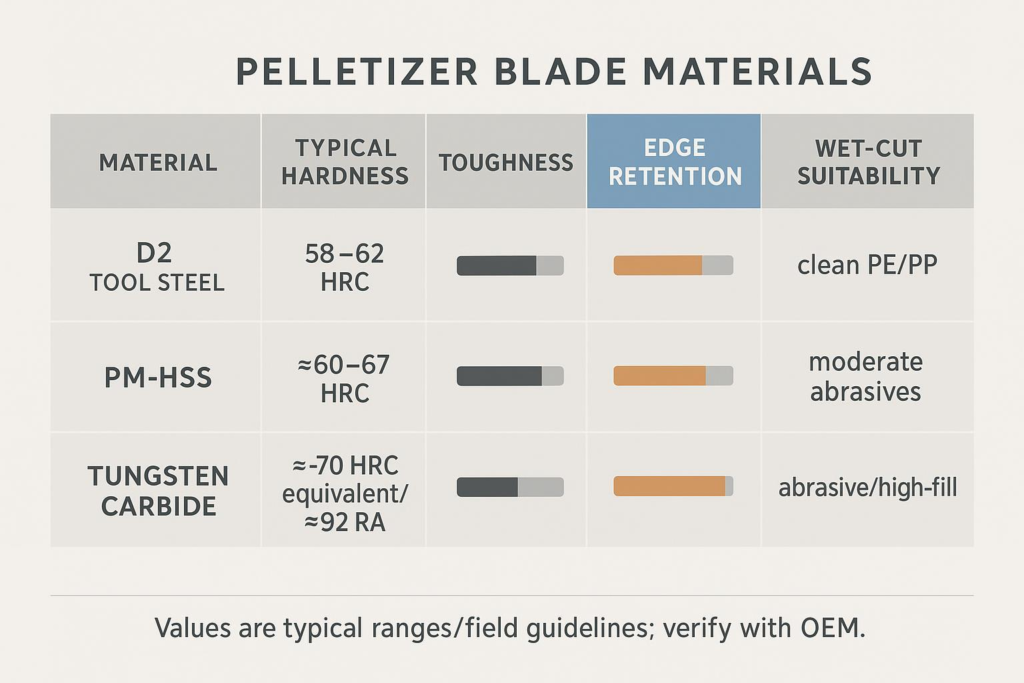

- D2 tool steel provides high wear resistance from chromium carbides at typical 58–62 HRC with moderate toughness. It’s a cost-effective baseline for clean PE/PP when die faces are kept smooth and water chemistry is controlled, as summarized in tool steel handbooks and material notes from industry sources such as the Alro Tool Steel Handbook and comparative write‑ups on D2 vs M2 performance.Alro — Tool Steel Handbook, FCS Steel — D2 vs M2 Performance Comparison (2025)

- PM‑HSS (e.g., M2/PM variants) offers similar or higher hardness with greater toughness thanks to a fine carbide distribution and better hot hardness, which helps during speed/temperature excursions. It’s a strong choice when you need a wider operating window or see occasional abrasives. See overviews like the M2 steel guide for general property ranges.Rapid Protos — M2 Steel Guide

Carbide vs. PM-HSS in filled recipes

In high‑fill or recycled streams, abrasives accelerate wear, and blade life can collapse without a harder edge:

- Tungsten carbide (solid or tipped) delivers exceptional wear resistance (≈92 Rockwell A equivalent, >70 HRC) and edge retention but at the cost of lower toughness. It shines in high‑fill CaCO3 or glass‑filled PP and long runs—provided the holder is rigid and die faces are kept defect‑free to avoid chipping. For design background, see canonical references such as the Designer’s Guide to Tungsten Carbide.General Carbide — Designer’s Guide to Tungsten Carbide

- PM‑HSS remains relevant when variability is high: it tolerates the occasional impact or die-surface imperfection better than carbide, though it won’t match carbide’s wear life in truly abrasive duty. Many plants pair PM‑HSS with disciplined regrind schedules to manage TCO.

Coatings and treatments for wet cutting

Surface engineering can change the “feel” of your edge against a wet die face:

- TiN and TiCN PVD coatings increase surface hardness and reduce friction, which helps with adhesive wear and resin sticking in wet cutting; TiCN typically offers lower friction and better abrasion resistance than TiN. Industrial coating guides summarize these effects across cutting applications.TGW — Understanding Industrial Blade Coating Options, Ecogeo — Guide to Industrial Blade Coating Options

- Diamond‑like carbon (DLC) adds very low friction and a corrosion barrier; studies highlight corrosion benefits in wet environments, which translates well to water-ring duty. Use when water chemistry or corrosion risk is elevated.NIH/PMC — DLC Film Corrosion Evidence

- Carbiding (hardfacing) of edges or leading surfaces can materially extend life in abrasive service, provided post‑process sizing keeps thickness and flatness within drawing spec. For a practical overview of when carbiding helps, see industrial explainers.MAXTOR METAL — Carbiding benefits for blades

Wear in water-ring cutting is a blend of adhesive wear (melt + water), micro‑abrasion (fillers, contaminants), and corrosion‑assisted edge rounding. Choose substrate first to fit the duty, then layer coatings or hardfacings to tune friction and corrosion behavior.

| 材料 | Typical hardness | 強靭さ | Edge retention | Wet‑cut suitability | Typical PE/PP use case |

|---|---|---|---|---|---|

| D2工具鋼 | 58–62 HRC | 適度 | 良い | Good with proper water chemistry | Clean, low‑fill PE/PP with disciplined die maintenance |

| PM‑HSS (M2/PM) | ≈60–67 HRC | 高い | Very good | Very good; good hot hardness | Wider operating windows; light abrasives; variable conditions |

| タングステンカーバイド | >70 HRC equiv (≈92 RA) | 低い | Exceptional | Excellent wear; watch chipping risk | High‑fill abrasives; long runs; recycled content with contaminants |

Note: Values are typical ranges and field guidelines; verify with your OEM and blade vendor.

Case study (illustrative, field guideline — not customer‑authorized): A mid‑scale PE line (virgin PE, 3% CaCO3 contamination typical) switched from D2 to PM‑HSS with TiCN PVD. Over a 12‑week run the PM‑HSS set achieved ~1.8× longer life (from ~200 to ~360 production hours between regrinds), tails/fines rate fell from ~1.8% to ~0.9%, and changeover downtime reduced ~20%. Estimated cost/ton fell modestly when factoring fewer regrinds and lower scrap (plant data used for illustration only). Validate these ranges with site trials and vendor FAI.

Geometry & setup

Blade geometry for die-face cutting is less about fixed, universal angles and more about maintaining a sharp, controlled contact with a flawless die surface. Unlike downstream granulation where angle tables are published, die-face pelletizing relies on edge integrity, alignment, and contact control.

Edge prep and relief angles

Aim for a crisp, defect‑free edge with a fine hone or micro‑chamfer that prevents instant chipping without raising cutting forces excessively. Public OEM tables for relief angles in die-face pelletizing are scarce; treat numeric angles as OEM‑specific. Focus on the evidence‑backed fundamentals: sharp edges and a smooth die face reduce flow disruptions and pellet defects, while grooved or rounded surfaces create tails and fines.Plastics Technology — Sharper dies and smoother extrusions, Plastics Technology — Troubleshooting underwater pelletizing

Preload and compliance control

Knife pressure must be high enough to produce a clean shear yet low enough to avoid accelerated die wear. Many modern systems use spring, pneumatic, or servo mechanisms with automatic compensation to maintain contact as parts heat and wear. MAAG’s Gala EAC pelletizers, for example, offer automatic blade positioning and monitoring to extend blade and die-face life—an indicator of the principle, not a prescription for setpoints.MAAG — Gala EAC pelletizer brochure

Field guideline: validate contact by inspecting pellet cut surfaces and listening for chatter; log adjustments against pellet defects. If the die face shows any scratch pattern or groove, stop and resurface before chasing parameters.

Startup and shutdown SOP

A disciplined sequence prevents die-face damage and quality swings.

- Startup

- Water loop on and stable first; verify temperature and flow, then start cutter at low RPM.

- Confirm die-face cleanliness and condition; if grooves are visible, resurface before production.GLKnife — Underwater die face resurfacing

- Bring melt on gradually with zones at temperature; ramp cutter speed to match throughput.

- Shutdown

- Stop polymer feed and clear material; keep water and cutter running briefly to avoid freeze‑off.

- Ramp cutter down, stop water, then dry components to prevent corrosion; clean die holes for the next start. General auxiliary shutdown practices from extrusion ops apply here as well.Cowin Extrusion — Operation and precautions

Tolerances & OEM fit

Dimensional control and documentation are the backbone of consistent pellet quality. A blade that “almost fits” often drives vibration, noise, and inconsistent pellet length.

Dimensional ranges that matter

Work to drawing and verify:

- Thickness and post‑grind thickness tolerance (define a minimum thickness before replace).

- Flatness and face runout across the cutting span (CMM‑verified).

- Bore diameters, bolt circle, slot spacing/pitch, keyways, and concentricity to the cutting edge.

- Surface finish at the cutting and seating faces; coating thickness and post‑coat sizing.

Because public OEM tolerance tables are rare, define these explicitly on your PO and require a First Article Inspection before serial supply.

For OEM-specific tolerances, blade positioning mechanisms, and model families, consult MAAG’s 2026 Underwater pelletizers overview (Gala); treat your equipment’s official manual as the governing reference for exact limits and settings.

QC docs and traceability to request

Ask vendors to provide a traceable package:

- Material certificate with heat/lot, heat treatment records, and hardness test results (method and sampling plan).

- CMM dimensional inspection: thickness, flatness, runout, bore/slot dimensions, and edge location.

- Surface specs: finish (Ra), coating type and thickness, and post‑coat sizing confirmation.

- Serialization and lot‑linked inspection records; First Article Inspection (FAI) report.

Disclosure: MAXTOR METAL is our product. In QC‑focused projects, MAXTOR METAL can manufacture to drawing and supply FAI and dimensional verification for OEM‑compatible replacements. Keep requests vendor‑neutral by specifying measurements, sampling, and acceptance criteria on your purchase order.

Compatibility risks and mitigation

Common pitfalls include hole‑pattern mismatch, stack‑up tolerance that shifts blade position, thickness drift after multiple regrinds, and coatings that alter effective preload. Mitigate by:

- Obtaining the OEM reference drawing or performing reverse engineering with CMM data.

- Specifying minimum thickness before replace and the number of allowable regrinds.

- Defining coating thickness tolerance and whether sizing is done pre‑ or post‑coat.

- Requiring serialized parts and lot‑level records to track performance.

Operations & troubleshooting

Even the best blade fails in an unstable process. Treat water, melt stability, and knife speed as a single system.

Water system parameters

There is no one “correct” temperature or flow—stability and cleanliness are the goals. In polyolefin recycling contexts, operators commonly run PP water around the mid‑50s °C; your OEM and process may differ, but the principle stands: ensure immediate capture, adequate cooling, and consistent drying to avoid agglomeration and moisture issues.Famous Machinery — PP/PE pelletizing water around 55°C, Sikoplast — Pelletising systems and drying loop

Keep the loop filtered and watch dryer performance; many shops target low final moisture after centrifugal drying to keep pellets free‑flowing.Retech — Plastic pelletizing process and drying

Melt stability and blade speed

Synchronize knife RPM with extrusion throughput and polymer velocity across the die to maintain consistent cut length. Heat management at the die face and stable output—via melt pumps or tightly controlled screw speed—are key to avoiding hole freeze‑offs and irregular pellets.Granuwel — Solving common underwater pelletizing problems, Plastics Technology — Troubleshooting underwater pelletizing

Failure modes and quick fixes

- Tails: often dull edges, inadequate contact, or a grooved die face. Fix with a sharpened/replaced blade, correct preload, and die resurfacing where needed.GLKnife — Die face resurfacing

- Fines/dust: edge damage or surging throughput. Restore edge quality, stabilize feed, and clean/clear die holes and filters.Plastics Technology — Troubleshooting underwater pelletizing

- Agglomeration: insufficient cooling or too‑hot melt/water. Improve water temperature/flow and stabilize melt temps.Feininger — Water ring pelletizer explained

- Oval or inconsistent pellets: variable cut speed or partial freeze‑off. Stabilize RPM to throughput, clear die holes, and verify die temperature balance.Plastics Technology — Follow pelletizing system guidelines

Maintenance & TCO

The cheapest blade is rarely the lowest cost per ton. Plan for controlled regrinds, consistent changeovers, and data‑driven spare strategies.

Regrind and recoating strategy

Field practice on die‑face blades is to regrind before edges are fully dull to avoid tails and fines, often allowing multiple cycles per blade until a minimum safe thickness is reached. The exact cycle count and thickness limit are design‑specific; set them on the drawing and track hours/tons to trigger service. In wet or corrosive duty, coatings like TiN/TiCN or DLC, and options like carbiding, can extend service life—ensure post‑coat sizing keeps you in tolerance.Energycle — Maintenance tips for plastic cutting

Spare sets and changeover planning

Maintain matched spare sets ready to install. Rotate sets to equalize wear, and log tons‑to‑threshold to forecast changeovers. Consider downtime impact: a slightly higher‑cost blade that doubles life or reduces change frequency can lower cost per ton when downtime is expensive.

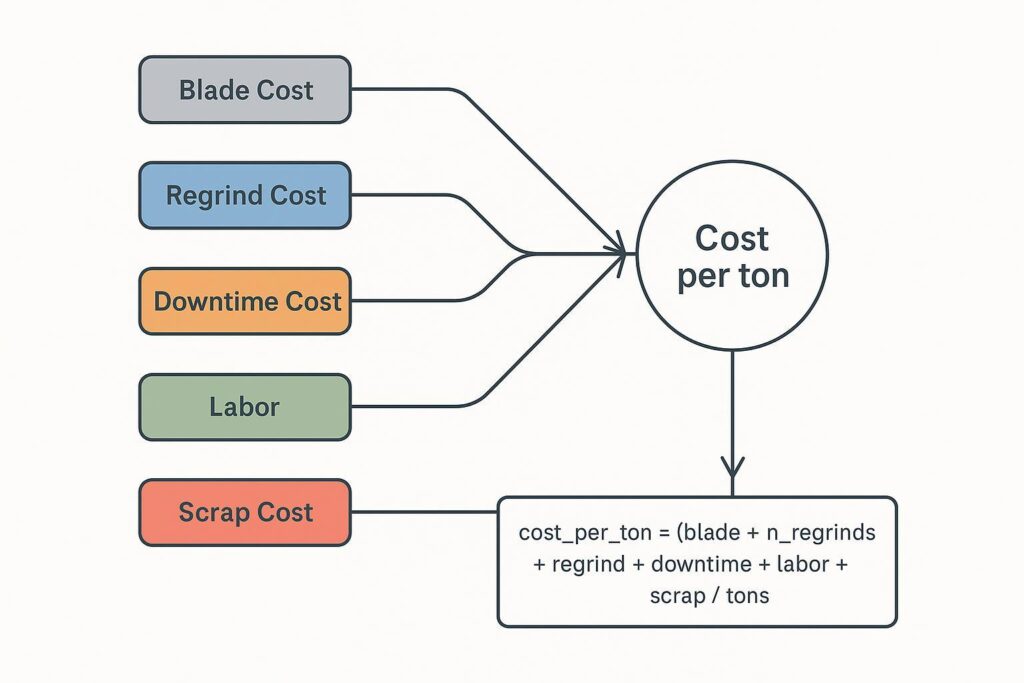

Cost-per-ton modeling

A simple model helps compare options objectively:

cost_per_ton = (blade_cost + n_regrinds × regrind_cost + downtime_cost + labor + scrap_cost) ÷ tons_produced

Populate the variables with your plant’s numbers and log real results over several runs to compare materials/coatings and regrind intervals.

Case study (illustrative sample): A mid‑scale PE line trialed two strategies over a 12‑week sample period. A (baseline): D2 blades, 2 regrinds/set, 8 changeovers, 0.9% scrap. B (upgrade): PM‑HSS + TiCN, 1 regrind/set, 4 changeovers, 0.5% scrap. Using plant rates (blade cost $600/set; regrind $80; downtime cost per change $1,200; throughput 120 tons/week), cost/ton fell from ~$6.25 to ~$4.30 (≈31% reduction). Data source: vendor case reports and internal trial notes; results vary by plant and should be validated on site.

結論

When you’re deciding how to choose water ring pelletizer blades for PE/PP lines, start with the recipe and run length to pick a substrate (D2 or PM‑HSS for clean polyolefins; carbide for abrasive or long‑run duty), add coatings to control friction and corrosion, and protect your die face. Control contact with disciplined preload and watch the water loop like a core process variable. Buy and operate to drawings with measured tolerances and traceable QC. In practice, verify drawings against your OEM pattern, set and record preload, track tons to the regrind threshold, and compare cost per ton across materials and coatings over multiple runs. That’s how you turn blade choices into stable pellets, high uptime, and a cost curve that moves in the right direction.