あなたの用途に合ったミシン目ブレードの選び方

You need to know how to select perforating blades that are right for your specific job. Start by matching the blade type, tooth size, and blade material to your cutting requirements. Consider the material you will be perforating and its thickness. Pay attention to the blade design, tie width, coatings, operating speed, and compatibility with your machine. The table below highlights common blade materials and their typical uses: Blade Material Key Characteristics Typical Applications Tool Steel Strong, heat-resistant, durable Ideal for tough, custom perforating knives Stainless Steel Rust-resistant, easy to clean Perfect for food packaging and medical products Tungsten Carbide Extremely hard, long-lasting Suitable for fast operations, plastics, and textiles High-Carbon Steel […]

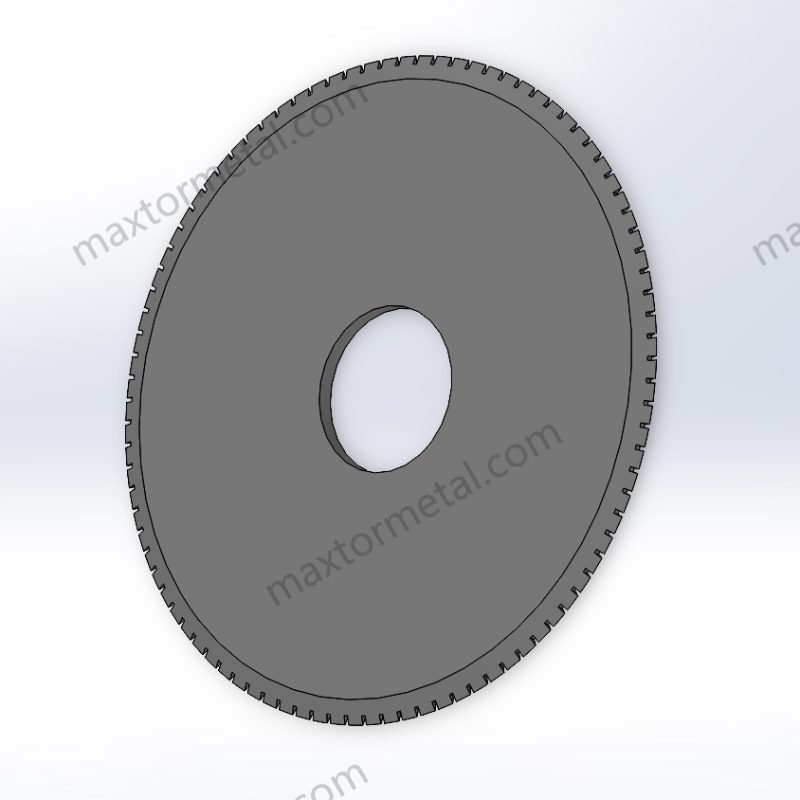

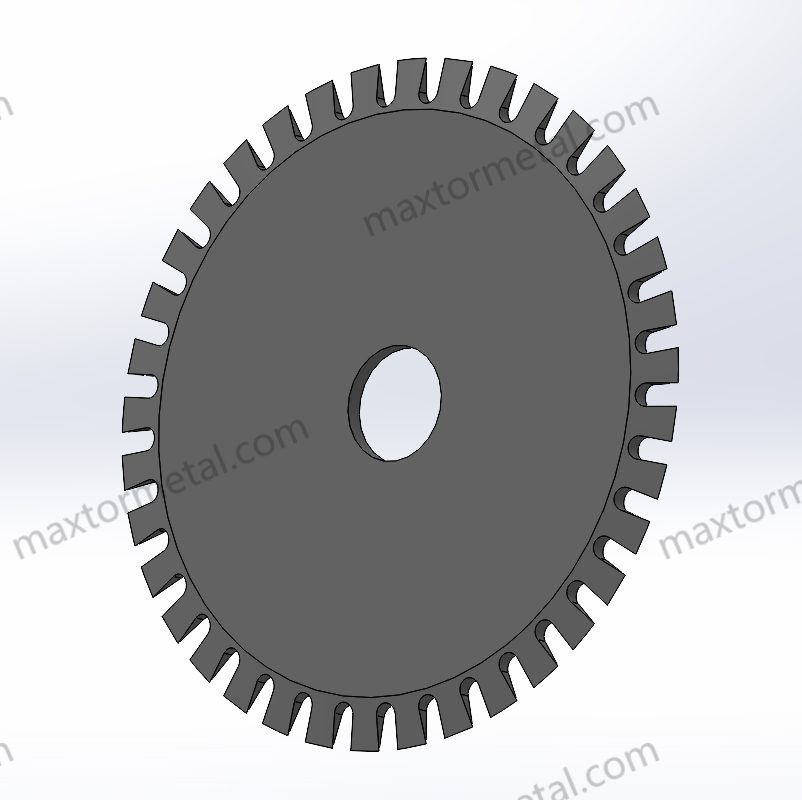

紙用円形ミシン目ナイフ:紙とフィルムのスリット効率を向上させる

Circular perforating knives for paper help you work faster. They let you make clean and exact cuts when you slit paper. You see big changes in packaging, paper converting, and food factories. Sharp perforating blades lower downtime and give steady quality. Factories say they work up to 20% faster. They also have 20-30% less packaging waste. Custom blade designs make work 53% more efficient. Special coatings help blades last up to 40% longer. Efficiency Aspect Impact on Slitting Efficiency in Industrial Paper Processing Production Line Efficiency Annual increase of 12-15% Production Speed Up to 20% faster production Waste Reduction Decrease in packaging waste by 20-30% Blade Durability Coatings extend blade life by 25-40% […]

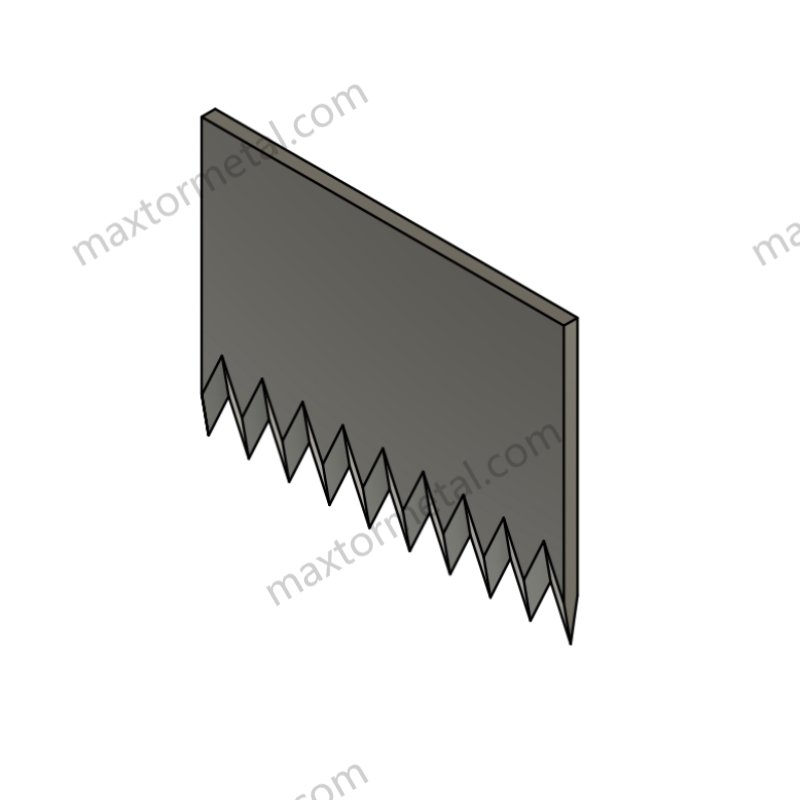

最適な性能のためのミシン目ブレードの幾何学

When selecting perforating blade knives, the perforating blade geometry plays a crucial role. Factors such as edge angle, tooth profile, thickness, and material compatibility all influence how effectively the blade perforates. Aligning the blade geometry with your specific application allows for faster cutting and cleaner perforations. The table below demonstrates that a multi-angle perforating blade geometry reduces cutting time by nearly half and generates less heat damage compared to conventional blades. Parameter Multi-angle Blade Conventional Blade Statistical Significance Cutting Time (seconds) 46.0 ± 3.4 86.6 ± 17.3 p < 0.001 Max Bone Temp (°C) 32.3 ± 2.2 39.5 ± 4.1 p < 0.001 Optimal results come from using the appropriate perforating blade geometry for […]

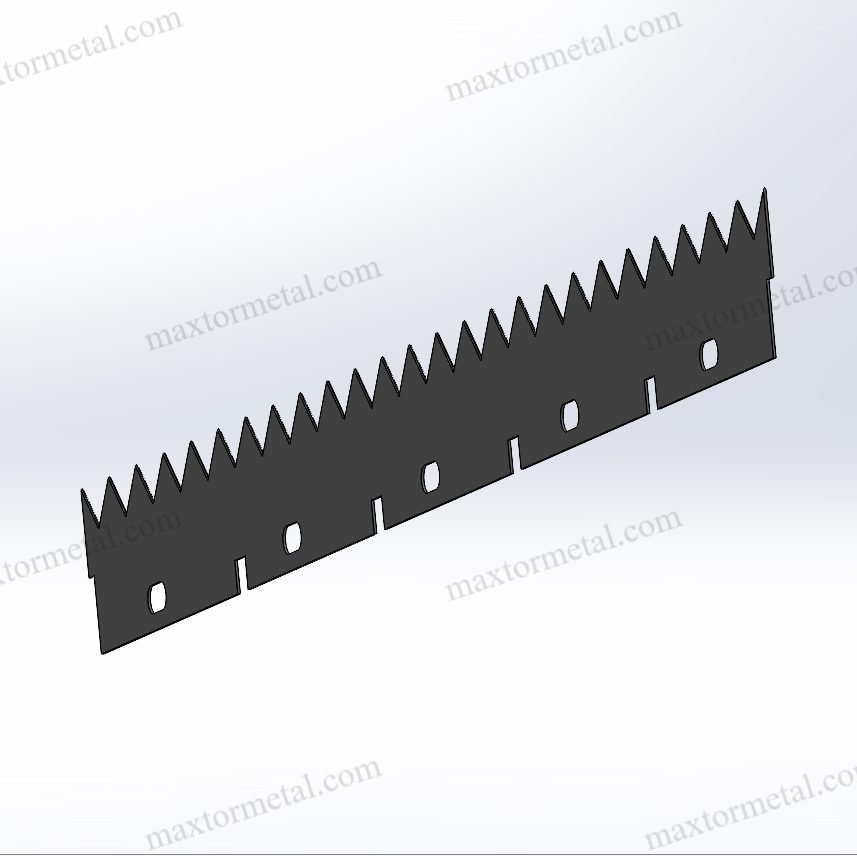

カスタムミシン目ブレード:独自の工業用切断ニーズに対するソリューション

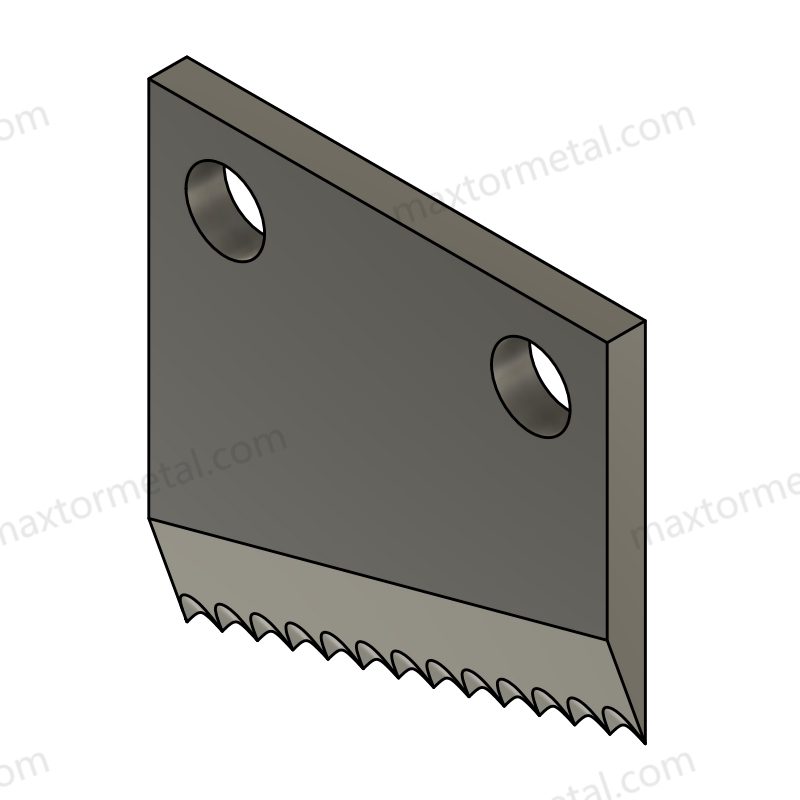

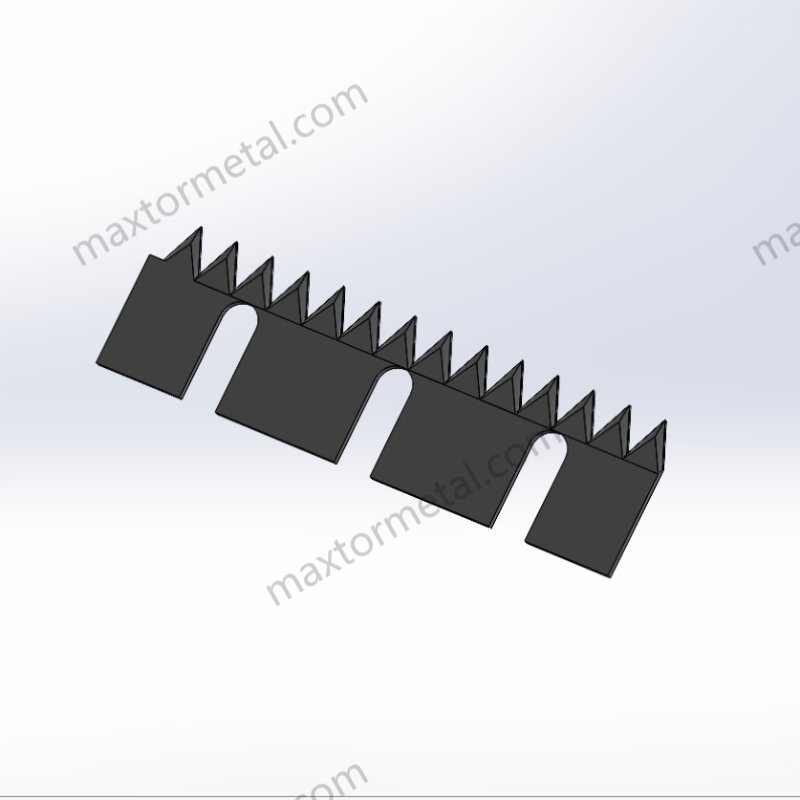

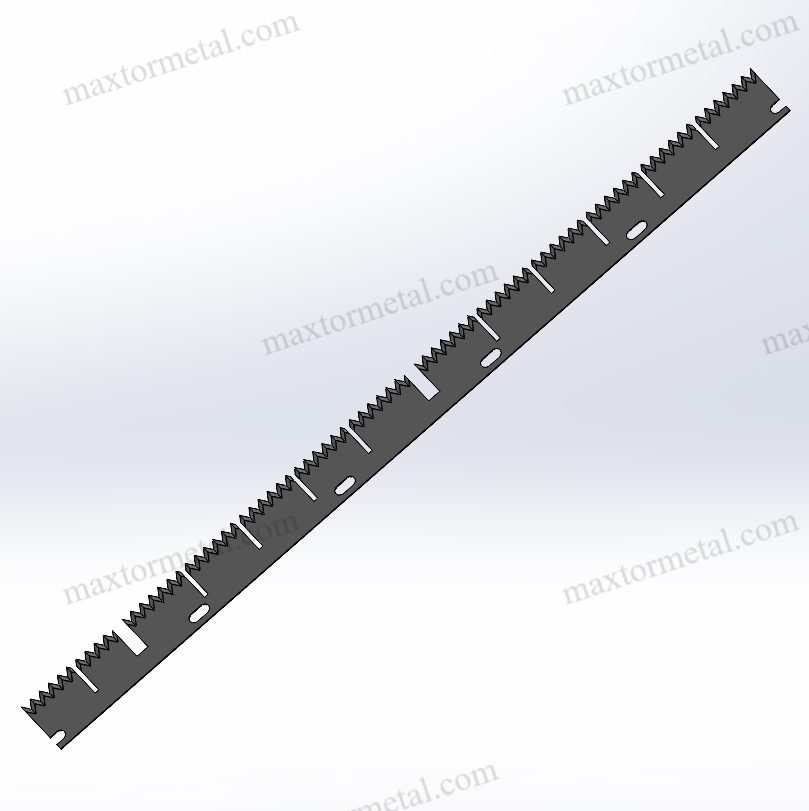

Custom perforating blades help you make neat, easy-to-tear lines. You use custom blades to match your exact needs in packaging and textiles. They also work in other industries. Key Takeaways Custom Perforating Blades Overview What Are Perforating Blades Perforating blades make small cuts or holes in things. These blades help you tear packaging, paper, and textiles easily. You can pick from many shapes and sizes. Some blades cut straight lines. Rotary perforating blades make round, continuous cuts. The way the teeth look and the blade’s style change how it works. You need to pick the right blade for your material and machine. This helps you get the best results. Custom perforating […]

ミシン目ブレードの材料選定とその用途

Choosing the right perforating blade material selection depends on the specific application. The material you choose directly impacts the blade’s performance and durability. Engineers consider the type of material being cut, the required toughness of the blade, and the operating speed. Companies like Nanjing Metal offer a wide range of perforating blades and provide expert guidance to help customers select the best perforating blade material selection for their needs. Careful consideration of both technical requirements and work conditions ensures a more efficient and cost-effective perforating process. Key Takeaways Why Blade Material Selection Matters Performance and Longevity Blade material selection is very important. It decides how long a perforating blade will last. It also affects […]

プラスチックフィルムとホイルに完璧なミシン目を作る方法

Achieving perfect perforations on plastic film and foil begins with picking the right tools. When you use high-quality perforating blades for plastic film, every cut will meet your needs. You should pick blades that fit the plastic type and thickness. The blade’s quality can really change your results: Maxtor Metal has trusted blades for many uses in the plastic industry. You can improve your work process by setting up carefully and using the best blades for your plastic jobs. Key Takeaways Blade Selection Perforating Blades for Plastic Film To get great results, you need the right perforating blades for plastic film. These blades make small holes or cuts in the plastic. This […]

高度な材料加工用高精度ミシン目ブレード

Micro-perforating blades make tiny holes or cuts in things. They are important in advanced material processing. These blades help companies work faster and make better products. Maxtor Metal is a top company with many perforating blades for packaging and other uses. The blades are accurate and dependable. Many industries use perforating blades every day and see good results. Perforating blades make tear lines that help materials come apart easily. Makers use these blades to work faster and get the same results each time. Key Takeaways Micro-Perforating Blades Overview Definition and Function Micro-perforating blades are special tools. They make tiny holes or cuts in materials. These blades help companies add tear lines or air […]

コスト効率の良いソリューション:ミシン目ブレード研磨サービスでミシン目ブレードを交換するか、それとも研磨するか

穿孔刃研磨サービスを利用して刃を再生すると、新しい刃を頻繁に購入するよりも費用を節約できます。鋭い刃は長持ちし、コスト削減にも役立ちます。また、機械の動作速度が上がり、停止頻度も減ります。包装、医療、食品加工などがその例です。業種によって穿孔に必要なものは異なります。特殊な素材や刃の形状が必要になる場合もあります。企業は刃の使用方法を見直し、業務に最適な刃を選択する必要があります。重要なポイント:再生と交換のコスト比較 企業が刃の再生と交換を検討する際、大きなコストの違いに気づきます。再生、つまり研磨は、新品の刃を購入するよりも初期費用が安くなります。研磨によって刃は再び鋭くなり、[…]

工業用アプリケーションにおけるロータリーミシン目ナイフとスタティックミシン目ブレードの比較

工業用穿孔工具に適した工具を選ぶことは重要です。それぞれの作業のニーズによって異なります。ロータリー式穿孔ナイフシステムは非常に高速で、作業が止まることのない作業に適しています。スタティック式穿孔刃はよりきれいな切断面を実現します。見た目が重視される場合に最適です。性能、効率、コスト、メンテナンスについて検討する必要があります。また、どの工具が自分の作業に適しているかを検討してください。ロータリーナイフは、作業量の多い梱包や繊維製品に最適です。スタティック式穿孔刃は、直線できれいな線が必要な作業に適しています。重要なポイント ロータリー式穿孔ナイフの定義 ロータリー式穿孔ナイフは、工場で使用される特殊な工具です。[…]

あなたのパッケージングラインに合ったミシン目ブレードの選び方

包装用穿孔ブレードの選択は重要です。2022年の調査によると、包装ラインにおける問題の68%は、不適切なブレードの選択が原因です。材料とニーズに適したブレードを選択すれば、作業のスピードアップと製品の品質向上につながります。ブレードの選択は、速度、廃棄物、修理費用に影響します。下の表は、高度な穿孔ブレードがどのように優れた成果をもたらすかを示しています。メリット 影響 説明 生産効率 高度な穿孔ブレードを使用することで、ラインの稼働率は年間12~15%向上します。スループット速度 最適なブレードを使用することで、ラインの稼働率は最大20%向上します。廃棄物削減 これらのブレードは、包装ラインの稼働率を[…]