| 다른 이름 | 스코어 커터, 크러시 커터, 스코어 컷 나이프, 리커터 나이프, 크러시 커터, 접시형 나이프 |

|---|---|

| 원산지 | 중국 |

| 적용 분야 | 플라스틱, 종이, 보드, 부직포, 필름, 호일, 라벨, 테이프, 섬유, 포장, 카펫, 가방, 튜브, 코어, 고무 |

| 재료 | 65Mn,9CrSi,Cr12MoV,SKD-11,HSSl |

| 모델 번호 | CV-CK |

| OEM 서비스 | 사용 가능 |

| 결제 조건 | L/C, T/T, 웨스턴 유니온 |

| 포장 | 종이 상자, 나무 상자 |

| 배송 시간 | 7-20일 |

공유하기:

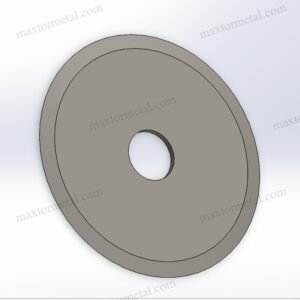

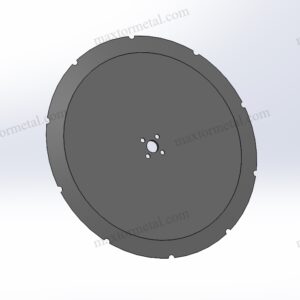

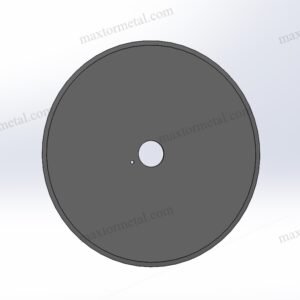

원형 칼회전식 칼날 또는 디스크 나이프라고도 하는 는 원형 모양에 날카롭게 깎인 바깥쪽 날이 있는 절삭 공구입니다. 회전 운동을 통해 재료를 절단하도록 설계되었으며, 종종 반대쪽 칼날이나 모루에 대고 절단합니다. "원형 칼"는 광범위한 분야를 아우르며, 다양한 산업 분야에서 다양한 소재의 슬라이싱, 슬리팅, 천공 및 스코어링에 사용되는 다양한 디스크형 절삭 공구를 포괄합니다. 회전 동작으로 연속적이고 효율적인 절삭이 가능하여 고속 생산 공정에 이상적입니다.

원형 칼 다양한 소재 절단에 있어 효율성과 다재다능함으로 인해 다양한 산업 분야에서 광범위하게 활용되고 있습니다. 주요 용도는 다음과 같습니다.

원형 칼의 소재 선택은 절단되는 소재, 작업 속도, 그리고 칼날의 필요 수명에 따라 크게 달라집니다. 일반적인 소재는 다음과 같습니다.

질화티타늄(TiN), 질화크롬(CrN), 다이아몬드 유사 탄소(DLC)와 같은 코팅을 적용하면 표면 경도를 높이고, 마찰을 줄이며, 특히 연마성이나 끈적끈적한 재료를 다룰 때 원형 칼의 수명을 연장할 수 있습니다.

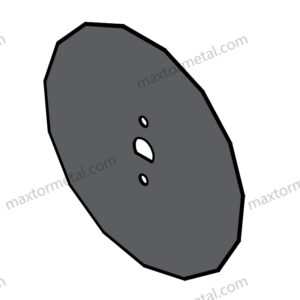

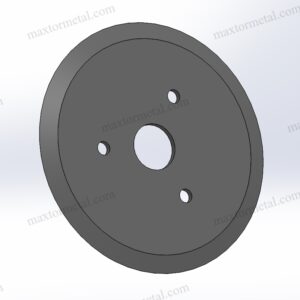

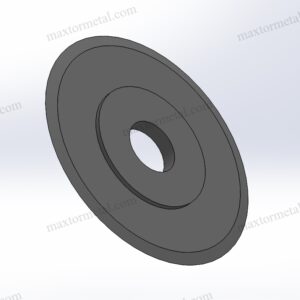

원형 칼 다양한 모양과 날 구성으로 특정 용도에 맞춰 절삭 성능을 최적화할 수 있습니다. 일반적인 모양은 다음과 같습니다.

원형 칼의 작동 원리는 회전 운동과 절단 대상 재료에 대한 제어된 압력의 조합입니다. 절삭날의 날카로움과 기하학적 구조, 회전 속도 및 재료 특성은 절단의 품질과 효율성을 결정합니다. 많은 경우, 원형 칼은 모루, 카운터 블레이드 또는 기타 롤러와 함께 작동하여 지지력을 제공하고 깨끗한 절단을 보장합니다.

원하는 전단날을 찾을 수 없는 경우 당사에서 맞춤 제작할 수도 있습니다. "맞춤형 블레이드"를 참조하여 방법을 알아보세요!

번거롭지 않은 수입의 편리함을 누리세요. 운송부터 통관까지, 저희가 전체 과정을 처리합니다. 고객님은 VAT만 지불하시고 회사에 상품이 도착하기를 기다리시면 됩니다.

저희 블레이드는 수많은 애플리케이션에서 사용되며 뛰어난 성능을 입증했으며, 고객님의 어떤 프로젝트든 처리할 준비가 되어 있습니다. 정확성, 내구성, 그리고 비교할 수 없는 경쟁력 있는 가격을 제공합니다.

도면, 스케치 또는 샘플을 제공해 주시면 저희가 설계하고 제조해 드립니다. 또한 기존 디자인 및 사양을 수정하여 거의 모든 산업용 공구 응용 분야를 개선하는 데 도움을 드릴 수 있습니다. 특정 요구 사항에 대해 논의하려면 전담 영업팀에 문의하십시오.

품질 관리를 위해 초기 샘플 검사, 입고 자재 검사 및 자재 인증, 공정 중 품질 검사, 최종 품질 검사를 포함한 일련의 테스트와 검사가 수행됩니다.

수입업체, 유통업체, 도매업체 또는 최종 사용자이든 상관없이 최소 MOQ, 번거롭지 않은 문의 및 더 많은 구매 자유를 통해 귀하의 참여를 환영합니다.

귀하의 전담 모니터가 되어 생산 라인의 모든 중요한 지점에 대한 정기적인 정보를 제공합니다. 아무리 멀리 떨어져 있어도 제품의 진행 상황을 최대한 파악할 수 있도록 돕겠습니다.

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China