고성능 목재 슈레더 칼날로 목재 폐기물 수익 극대화

Upgrade to high-performance wood shredder knives to make more money from wood waste. New shredding technology breaks down wood fast. It makes less waste and lowers storage costs. You can fit more wood in each load. This saves fuel and labor. Shredding also makes it easier to move and handle wood. This helps your business run better and […]

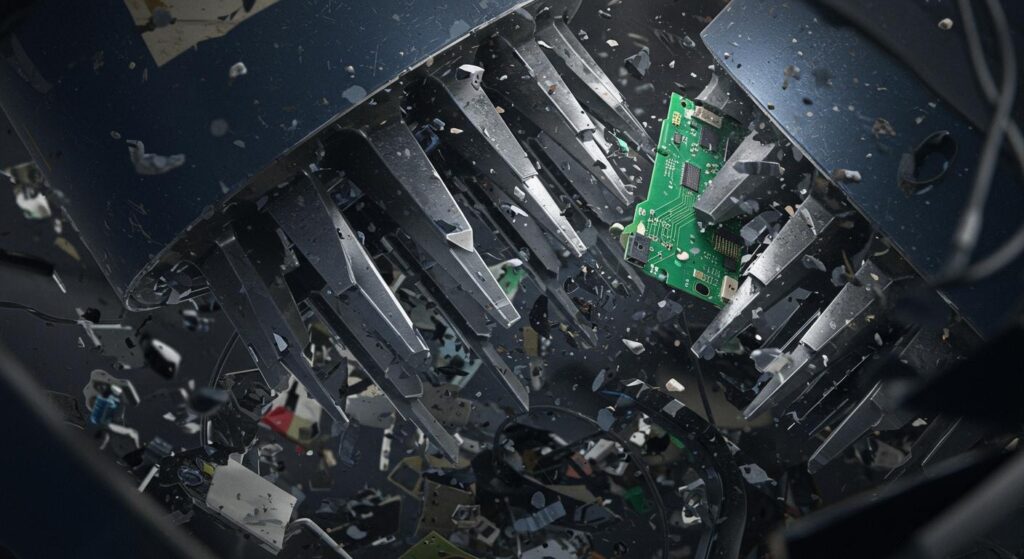

안전한 파쇄를 위한 전자 폐기물 슈레더 블레이드의 필수 기능

You have more problems when you try to handle e-waste safely. If you throw away e-waste the wrong way, it can leak private data. It can also hurt the earth. Good E-waste shredder blades help you follow safety rules. They also help you meet laws about e-waste. In 2021, people made 57.4 million tons of e-waste. Only 17.4% of […]

효율적인 재활용을 위한 플라스틱 슈레더 블레이드 선택 방법

Choosing the right plastic shredder blades helps you recycle better. If you pick the wrong blades, they can get dull fast or even break. This happens more with hard or fiber-filled plastics. When this happens, you have to stop work and pay more money. Better blades, like high-speed steel or tungsten carbide, last longer. They help your work […]

싱글 샤프트 슈레더 블레이드 디자인의 궁극적인 가이드

Single shaft shredder blades are important in shredding work. Blade design helps machines work better and last longer. These blades are used for tough jobs. When you shred big things like metal or plastic, hook-shaped blades grab and rip them apart. This makes shredding work well. The blade material helps blades stay sharp and strong. They do not […]

최신 프레스 브레이크 응용 분야에서 툴링을 위한 DXF 파일의 역할

You use dxf files for tooling when you need exact results in modern press brake work. Dxf files work like a digital link between your design software and your factory process. You can see how dxf adds smart steps to your work. When you use dxf, you make each step faster and more correct. Dxf lets you […]

로터리 벤딩 툴링: 흠집 없이 완벽한 굽힘 달성

회전식 벤딩 툴링을 사용하면 튜브를 매끄럽게 굽힐 수 있습니다. 튜브에 자국이 남지 않습니다. 적합한 벤더를 선택하면 훌륭한 결과를 얻을 수 있습니다. 올바른 재료를 사용해야 하며, 벤딩 공정을 직접 제어해야 합니다. 고급 툴링은 문제 발생을 방지하는 데 도움이 됩니다. 이러한 툴에는 자국이 남지 않는 인서트와 합성 다이 표면이 포함되어 있습니다. 이러한 툴은 타원, 주름, […]을 방지하는 데 도움이 됩니다.

굽힘의 ABC: 프레스 브레이크 펀치 및 다이 초보자 가이드

When you work with metal, you need tools that help you bend it into the right shape. The press brake punch and die act like a mold and a hammer, shaping sheet metal with care. These tools matter because they give you: Key Takeaways Press Brake Punch and Die What Are They When you work with metal, […]

최고의 프레스 브레이크 툴링 브랜드: 시장을 선도하는 브랜드는 누구인가?

When you want good press brake brands, these ten are popular: These press brake tooling brands are leaders. They focus on making high-quality tools. They also work on new ideas and help customers well. You need a brand that gives you good results every time. Here is what makes these brands special: Factor Description Quality Control Good […]

맞춤형 프레스 브레이크 툴링 구매 전 물어봐야 할 상위 10가지 질문

Are you sure your press brake tooling fits your needs? If you ask good questions before buying, you can save money and avoid costly mistakes. When you choose custom tooling manufacturers you receive expert assistance and solutions tailored specifically for you. Use this checklist to help you make informed decisions. Consider quality, compatibility, safety, and value for […]

툴링 가격이 결정의 유일한 요소가 아닌 이유: 비용-편익 분석

You might think press brake tooling price is most important. Press brake tooling price can change your budget in many ways. If you only look at press brake tooling price, you might miss hidden costs. These hidden costs can hurt your financial plans. Press brake tooling price can look cheap, but low quality can cause problems. You […]