찾을 수 있습니다 치퍼 블레이드 불균형 by listening for strange noises or feeling strong shaking when the chipper is working. Finding problems early helps you stay safe and makes your machine last longer. Many accidents happen when people do not notice imbalances. If you check your equipment often, you will have fewer breakdowns and your work will be safer. Beginners and experts can learn to spot these problems fast.

주요 요점

- Listen for odd sounds from your chipper. Weird noises can mean blade imbalance.

- Feel for strong shaking when you use the chipper. Too much vibration may show the blades are not balanced.

- Check your chipper blades often for damage. Look for nicks, chips, or cracks to stop imbalance.

- Clean your chipper after you use it. Taking out debris helps keep balance and stops vibration.

- Always put blades in pairs. This makes the weight even and lowers the chance of imbalance.

- Use a vibration analyzer to find balance problems. This tool can spot issues before they get worse.

- Keep a maintenance log. Writing down checks and fixes helps you watch the chipper’s condition over time.

- Follow what the manufacturer says for installation and care. Using these rules keeps the chipper safe and working well.

Why Imbalance Matters

Machine Performance Impact

If chipper blades are not balanced, the machine can shake. This shaking is called vibration. Vibration can hurt important parts inside the chipper. Bearings can wear out quickly. The chipper might break if you do not fix the problem. You may see the chipper does not cut wood well. It might not work as fast or smooth as before. The table below lists what can happen if blades are imbalanced:

| 결과 | 설명 |

|---|---|

| Extreme vibration | Rotor shakes because blades are uneven. |

| Damage to bearings | Vibration makes bearings wear out faster. |

| Machine failure | The chipper can break if used too long this way. |

To stop these problems, use good blades. 난징 Metal 산업 sells blades that help your chipper work better.

Operator Safety Risks

Imbalance is not just bad for the chipper. It can be dangerous for you. Too much vibration can make bolts and fasteners loose. Loose parts might fly off or break the chipper. You could get hurt if you are close. Strong shaking makes the chipper hard to control. This can cause accidents. If you check for imbalance and fix it soon, you keep yourself and others safe.

Physics of Imbalance

Centrifugal Force Effects

When a chipper blade spins, it makes centrifugal force. If one side is heavier, the force pulls unevenly. This makes the chipper shake. Faster spinning makes the force stronger. Even a small weight change can cause big problems.

Vibration comes from rotating imbalance. This means the weight around the spinning part is not even. As the blade turns, uneven weight pushes and pulls the chipper. These pushes and pulls make vibrations you can hear and feel.

Small Weight Deviations

A tiny chip or dent on a blade can matter. Small weight changes can cause imbalance. There are two main types of imbalance. Static imbalance is when weight is uneven in one plane. Dynamic imbalance is when weight is uneven in many planes. Both types make the chipper shake in different ways. Over time, shaking can wear out parts and make your chipper last less.

If you use good blades and check them often, you lower the risk of imbalance. Blades from trusted brands help your chipper stay safe and work well.

Detecting Chipper Blade Imbalance

Chipper blade imbalance can make your chipper shredder have big problems. You should look for signs early to keep your machine safe and working well. This part will show you how to tell if your brush chipper knives are not balanced and what you can do.

Warning Signs

특이한 소음

You might hear weird sounds when your chipper runs. These noises often mean something is wrong with the brush chipper knives. Listen for clanking, rattling, or grinding. These sounds can start fast or get worse slowly. If you hear new or louder noises, stop the chipper and check the blades.

과도한 진동

Vibration is another clear sign of chipper blade imbalance. If you feel strong shaking in the handles or body, the brush chipper knives may not be balanced. Sometimes, the whole chipper shredder will move or bounce. If you sharpened the blades and now feel more vibration, the blades may not be put in right or some bolts are loose. Always check all fasteners after sharpening.

Other warning signs are:

- Chips that look uneven or rough

- Stringy slivers mixed with the chips

- Too much dust coming out of the chipper

- Large, uneven chunks in the output

If you see any of these, check the chipper knife condition right away.

Sensory Checks

시각 검사

You can often find problems just by looking at the brush chipper knives. Use the table below to help you check:

| Inspection Method | 설명 |

|---|---|

| 시각 검사 | Look for overall appearance, obvious damage, scratches, or bent parts. Check color and surface quality. |

| Detailed Surface Check | Look for scratches, cracks, and other defects. Make sure markings are correct and in the right place. |

Check the blades every time you stop for fuel. Regular checks help you find small problems before they get big.

| 검사 빈도 | 추천 |

|---|---|

| Regular Checks | Check blades every fuel stop for signs of wear and damage to keep safe and working well. |

Feeling for Vibration

Put your hand gently on the chipper while it runs. If you feel strong or uneven shaking, the brush chipper knives may be out of balance. Compare how the machine feels before and after you sharpen or change the blades. If the vibration gets worse, you may need to add or take away weight to fix the balance.

Diagnostic Tools

Vibration Analyzer

A vibration analyzer is a tool that checks balance. It measures how much the chipper shakes while running. You can use this tool to find out if the vibration comes from the blades or another part. Many repair shops have these analyzers, but you can also get small ones for home use.

Gravity Spin Test

You can use a gravity spin test to check blade balance at home. Take off the blade and put it on a round rod or shaft. Let the blade spin freely. If one side always drops to the bottom, the blade is heavier on that side. You may need to add or take away weight to balance it.

Tip: If you notice dull blades, weird chips, or more vibration after fixing, check for loose bolts or wrong installation. Fix these problems before using the chipper again.

By following these steps, you can keep your chipper working well and avoid expensive repairs. Always watch the chipper knife condition and act fast if you see any warning signs.

Chipper Blade Imbalance Causes

Blade Wear and Damage

Your chipper shredder may shake more as the brush chipper knives get old or damaged. When blades have nicks, chips, or cracks, they lose balance. This makes the machine shake and can wear out other parts faster. If you see damage on the blades, you should fix it soon. Worn blades can make your chipper use more power and get hotter. Sometimes, the machine takes longer to cut or needs repairs more often.

Common signs of blade wear and damage are:

- Nicks, chips, or cracks you can see on the blade edge

- The chipper uses more energy when running

- 기계가 더 자주 작동을 멈춥니다

- Chips come out in different sizes or look rough

- The chipper gets too hot

- It takes longer to cut wood

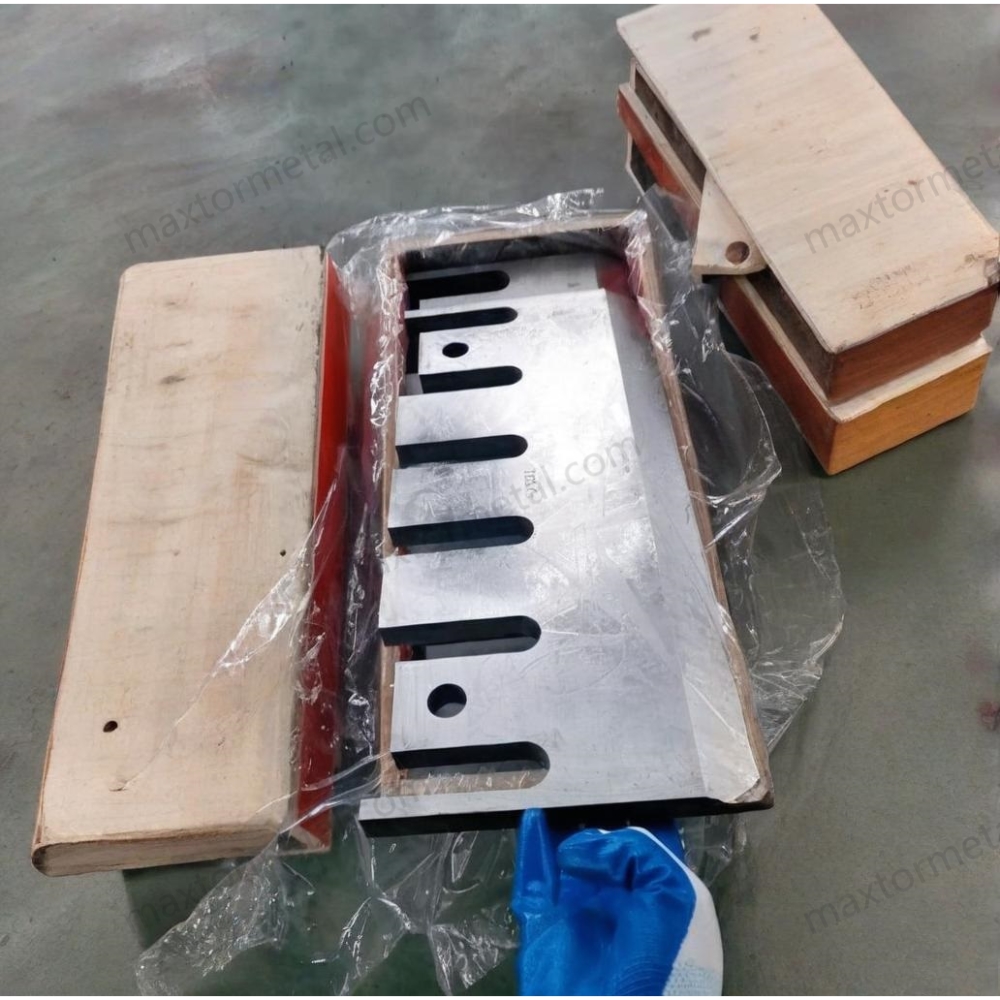

You can stop many of these problems if you change brush chipper knives before they get too old. Using good chipper knives made from strong materials like D2, DC53, HSS, or Tungsten Carbide helps your machine last longer and stay balanced. For more about custom blade choices, visit the 커스텀 블레이드 페이지.

부적절한 설치

Putting in chipper knives the right way is very important for balance. If you do not install the brush chipper knives right, the machine can start shaking right away. Always follow the maker’s instructions. Make sure each blade sits flat and tight on the mount. If one blade is higher or lower, the chipper will not spin evenly.

You should change blades in pairs. If you only change one, the weight can be off and cause chipper blade imbalance. Always check that bolts are tight and do not forget any washers or spacers. If you feel more shaking after changing blades, stop and check your work. Sometimes, you need to add or take away weight to fix the balance.

Rotor and Flywheel Issues

The rotor and flywheel help the chipper spin smoothly. Problems with these parts can make the machine shake a lot and be unsafe. Dirt, missing weights, or loose bolts can all cause imbalance. Sometimes, the rotor or flywheel may have factory mistakes, rust, or heat damage.

Here is a table with common causes and signs:

| Cause of Imbalance | Symptoms of Vibration |

|---|---|

| Dirt buildup | The machine does not run steady |

| Missing balance weights | Strange noise when running |

| Factory mistakes | |

| Heat damage | |

| 녹 | |

| Loose bolts | |

| Broken rotors/blades |

If your chipper makes new noises or shakes more, check the rotor and flywheel. Clean off dirt and tighten all bolts. If you find broken or missing parts, fix them before using the chipper again. Keeping these parts in good shape helps stop chipper blade imbalance and keeps your brush chipper knives working well.

Debris Build-Up

Debris build-up is a common cause of chipper blade imbalance. When you use a wood chipper, small pieces of wood, bark, and dirt can collect inside the machine. These materials often stick to the rotor, flywheel, or even the blades themselves. Over time, this extra weight makes one side heavier than the other. The chipper then starts to vibrate and shake.

You should check for debris after every use. Use a brush or air hose to clean out the chipper. Pay close attention to the area around the blades and the rotor. If you let debris build up, the machine will not run smoothly. The vibration can damage bearings and other parts. You may also notice that the chipper does not cut wood evenly.

Tip: Always turn off the chipper and disconnect the power before cleaning. This keeps you safe from moving parts.

A clean chipper works better and lasts longer. Regular cleaning helps prevent chipper blade imbalance and keeps your machine in good shape.

Anvil-to-Knife Clearance

The space between the anvil and the knife is called the anvil-to-knife clearance. This gap is very important for chipper blade balance and cutting performance. If the clearance is too wide or too narrow, the chipper will not cut wood properly. You may see poor chip quality and more vibration.

You can spot problems with anvil-to-knife clearance by looking at the chips that come out of the machine. Signs of poor performance include:

- Stringy slivers mixed with the chips

- Too much dust in the output

- Uneven chunks of wood

These signs mean the clearance needs adjustment. You should check the anvil-to-knife clearance often. Use a feeler gauge to measure the gap and adjust it to the manufacturer’s recommendation. Proper clearance helps the chipper cut cleanly and reduces stress on the blades.

Note: Keeping the right clearance also helps your chipper blades last longer and prevents chipper blade imbalance.

Regular checks and adjustments make sure your chipper works safely and efficiently.

Correcting Imbalance

Safe Shutdown

You must always put safety first when you fix chipper blade imbalance. Before you touch any part of the chipper shredder, make sure the machine is off and cannot start by accident. Follow these steps to shut down your chipper safely:

- Shut down the engine.

- Wait for all moving parts to stop.

- Disconnect the spark plug wire.

These steps protect you from injury. You should never skip them, even if you are in a hurry. If you follow this routine every time, you lower the risk of accidents.

팁: Always wear gloves and safety glasses when working on brush chipper knives.

Blade Removal and Inspection

After you shut down the chipper, you can start removing the brush chipper knives. Use the right tools for your machine. Loosen the bolts that hold the blades in place. Take out each blade carefully. Place the blades on a clean, flat surface.

Look at each blade closely. Check for cracks, chips, or dents. If you see any damage, you should sharpen or replace chipper knives before you use the chipper again. Damaged blades can cause more vibration and make balance issues worse. You may also notice uneven wear on the brush chipper knives. This can happen if you do not check the blades often.

메모: Keep track of the order and position of each blade. This helps you put them back in the right place.

Weighing and Pairing Blades

You need to weigh each brush chipper knife before you put them back in the chipper. Use a small scale that can measure in grams. Write down the weight of each blade. If you find that one blade is heavier than the others, you may need to add or subtract weight to get a good balance.

Pair blades that have almost the same weight. This step helps stop chipper blade imbalance. If you use a machine that checks balance, you can test the blades before you install them. Balanced blades reduce vibration and help your chipper shredder run smoothly.

If you cannot match the weights, you should get new brush chipper knives. Using blades with different weights can cause more balance issues and damage your chipper. Always check the weight before you put the blades back.

알리다: Never mix old and new blades. Always use pairs with similar wear and weight.

Balancing Rotor and Flywheel

You must balance the rotor and flywheel to fix chipper blade imbalance. These parts spin very fast inside your wood chipper. If they are not balanced, your machine will shake a lot. The machine can wear out faster. You might feel strong shaking or hear loud sounds if the rotor or flywheel is not balanced.

First, clean the rotor and flywheel well. Take off all dirt, wood chips, and dust. Even tiny bits of debris can cause chipper blade imbalance. Use a brush or air to clean every part. Look for rust, dents, or missing balance weights. If you see damage, fix or replace the part before moving on.

Then, check the rotor and flywheel for uneven wear. Look for spots that look heavier or lighter. Sometimes, you will see marks or holes from the factory. These show where weight was taken away to balance the part. If you see new damage or repairs, you may need to balance the rotor again.

A dynamic balancing machine gives the best results. This tool spins the rotor and flywheel very fast. It finds where the weight is not even. You or a technician can add or remove small weights until the rotor spins smoothly.

Dynamic balancing is the only way to fix all types of imbalance on fast rotors. The best thing to do on a farm is to check and balance rotors before they break. For example, after you change knives or fix the drum, balance it right away. Do not wait for big problems to start.

If you do not have a balancing machine, you can use a simple way. Take out the rotor and put it on two flat supports. Spin it gently by hand. If one side always drops down, that side is heavier. Mark the heavy spot with chalk. Carefully grind or file a little metal from the heavy spot. Test again until the rotor stays in any spot you leave it.

Here is a short checklist for balancing:

- Clean all parts first.

- Check for damage or missing weights.

- Use a dynamic balancing machine if you can.

- Mark and fix heavy spots if you balance by hand.

- Check balance again after every repair or blade change.

Balancing the rotor and flywheel helps stop chipper blade imbalance. Your chipper will run smoother, last longer, and be safer to use.

예방 유지 관리

정기 검사

You should check your chipper every day before you use it. Regular inspections help you find problems early and keep your machine running safely. Look at the brush chipper knives for dull edges, chips, or cracks. Make sure all bolts are tight and the blades sit flat. If you see any damage, fix it before you start the chipper. This habit helps you avoid sudden breakdowns and keeps you safe.

- Check for dullness, chips, or cracks on the blades.

- Make sure bolts and fasteners are tight.

- Inspect the blade position and mounting.

- Look for signs of rust or wear on moving parts.

Tip: Daily inspections take only a few minutes but can save you from big repairs later.

Cleaning and Debris Removal

Keeping your chipper clean is important for smooth operation. Debris can build up inside the machine and cause chipper blade imbalance. After each use, turn off the chipper and let it cool down. Use a brush or stick to clear out wood chips and dust from the chute and discharge area. Wipe the outside with a dry cloth to remove dirt and sap. Always check for branches, leaves, or other debris that might block moving parts.

Follow these steps for effective cleaning:

- Turn off the chipper and wait until it cools.

- Use a brush or stick to clear the chute and discharge area.

- Wipe down the outside with a dry cloth.

- Remove any branches, leaves, or sap from moving parts.

A clean machine works better and lasts longer. Cleaning also helps you spot problems with brush chipper knives before they get worse.

Blade Sharpening and Replacement

Sharp brush chipper knives are key to good performance. When blades get dull, the chipper works harder and may vibrate more. You should sharpen or reverse the blades when you notice a drop in performance, like slower cutting or a drop in engine speed. Some users sharpen blades every few seasons after tens of hours of use. Others may need to reverse blades every 15 minutes if working with tough material. If you find yourself changing blades more than every 20 hours, check if there is a problem with the blades or the way you use the chipper.

- Sharpen or reverse blades when you see a drop in performance.

- Replace blades if they are chipped, cracked, or worn out.

- Always use matching pairs to keep the chipper balanced.

Note: Keeping your brush chipper knives sharp and balanced helps prevent chipper blade imbalance and keeps your machine safe.

유지 관리 로그

Writing down what you do for your chipper helps you keep it safe. Maintenance logs let you remember every inspection, repair, and blade change. This record helps you find problems before they get worse. You can use logs in many ways. Track each time you check or change chipper blades. This shows how often you sharpen or replace them.

Write down any vibration, noise, or uneven cutting you see. You can look at these notes later to spot chipper blade imbalance. Record the results of balance checks or gravity spin tests. This helps you know if a blade or rotor keeps causing trouble. Use logs to plan cleaning and debris removal. Clean machines have fewer balance problems.

Write down anvil-to-knife clearance measurements. This helps you keep the gap right and stop extra vibration. Add real-time monitoring tools like thermal infrared sensors to your logs. These tools can warn you about chipper blade imbalance early. Use mobile apps to update logs quickly. This lets everyone on your team see new information and work together.

A maintenance log can be a simple table:

| 날짜 | 수행된 작업 | 블레이드 상태 | Vibration Level | 노트 |

|---|---|---|---|---|

| 2024-06-01 | Blade Sharpened | 좋은 | 낮은 | 문제 없음 |

| 2024-06-10 | Balance Checked | Slight Wear | 중간 | Cleaned rotor |

| 2024-06-15 | Blade Replaced | Chipped | 높은 | Found loose bolts |

Tip: Check your maintenance logs every month. Look for things like lots of blade changes or repeated vibration. This helps you fix small problems before they turn into big repairs.

Keeping good maintenance logs makes your chipper safer and more dependable. You also save money by finding chipper blade imbalance early and stopping expensive breakdowns.

Blade Balance SOPs

Symmetrical Installation

You should always install blades in a symmetrical way. This means you place each blade so that the weight is even on both sides of the rotor. If you do not do this, the chipper will shake and wear out faster. You can use a simple checklist to help you remember each step:

- Lay out all blades before you start.

- Match blades by weight and size.

- Place each blade in the correct spot on the rotor.

- Tighten bolts in a crisscross pattern.

Tip: Mark each blade and its position. This helps you put them back in the same place after sharpening or cleaning.

Symmetrical installation keeps the machine balanced. It also helps you get even chips and smooth operation.

Following Manufacturer Specs

You should always follow the instructions from the manufacturer. These instructions tell you the right way to install and balance the blades. You can find the specs in the user manual or on the company’s website. Important specs include:

| 사양 | 왜 중요한가 |

|---|---|

| Blade torque setting | Keeps blades tight and safe |

| Blade clearance | Ensures clean cuts and less vibration |

| Blade pairing rules | Helps keep balance |

If you skip these steps, you may damage the machine or make it unsafe. Always use the right tools for each job. Check the specs every time you change or sharpen blades.

Note: If you lose the manual, contact the company for a new copy. Never guess the specs.

Training and Safety

You need proper training before you work on blade balance. Training helps you learn the right way to handle sharp blades and heavy parts. You should know how to use all the tools and safety gear. Good training also teaches you what to do if something goes wrong.

Here are some safety rules to follow:

- Wear gloves and eye protection.

- Turn off the chipper and disconnect power before you start.

- Use the right tools for each step.

- Work with a partner if the blades are heavy.

Alert: Never rush the job. Take your time to check each step.

You can ask your supervisor or a skilled coworker for help if you are not sure. Many companies offer short training classes. These classes show you how to balance blades and keep the chipper safe.

By following these SOPs, you help your machine last longer and keep everyone safe.

Troubleshooting Vibration

When you notice your chipper shaking or making strange noises, you need to act quickly. Vibration can damage your machine and make it unsafe. This section will help you find out why your chipper shakes and what you can do to fix it.

Persistent Vibration Issues

Sometimes, you may still feel shaking even after you check the blades and clean the machine. This means there could be a deeper problem. You should look for clues to find out what is wrong. The table below shows common symptoms, what causes them, and how you can solve them:

| 증상 | 원인 | 솔루션 |

|---|---|---|

| Unstable machine, abnormal noise | Imbalanced flywheel, loose bolts, damaged rotor or blades | Check flywheel for proper balance and clean any lodged debris. Tighten all bolts and inspect for wear. Replace or repair rotor and blades if needed. |

You should start by checking the flywheel. Make sure it spins evenly and does not have dirt stuck to it. Next, use a wrench to tighten all bolts. Look at the rotor and blades for cracks or worn spots. If you see damage, you may need to repair or replace these parts. Cleaning and tightening often fix most problems. If the chipper still shakes, you may have a bigger issue.

Tip: Write down what you check and fix in your maintenance log. This helps you remember what you did and spot patterns over time.

도움을 구해야 할 때

You can fix many problems yourself, but sometimes you need an expert. If you have tried all the steps and the chipper still shakes, call a service technician. You should also get help if you see:

- Cracks in the rotor or flywheel

- Broken or missing balance weights

- Strange noises that do not stop

- Smoke or burning smells

A trained technician has special tools to find hidden problems. They can balance the rotor or flywheel with a machine. They can also replace parts that are hard to reach. Getting help early can save you money and keep you safe.

Alert: Never use a chipper that shakes a lot or makes loud noises. This can be dangerous.

Upgrading Components

If you want your chipper to run smoother and last longer, you can upgrade some parts. Newer blades made from strong materials like D2, DC53, HSS, or Tungsten Carbide stay sharp longer and keep better balance. You can also ask for custom blades that fit your machine perfectly.

Other upgrades include:

- Heavy-duty bearings for smoother spinning

- Improved mounting hardware for tighter blade fit

- Advanced vibration dampers to reduce shaking

You should talk to your supplier about the best upgrades for your chipper. Upgrading parts can help you avoid future problems and make your work easier.

Note: Always follow the manufacturer’s instructions when you install new parts or upgrades.

By following these steps, you can solve most vibration problems and keep your chipper working safely.

Checking for chipper blade imbalance and vibration keeps you and your machine safe. Doing this helps you work without accidents and makes your chipper last longer. Always use good blades and follow a regular maintenance plan. If your chipper still shakes or you cannot fix it, ask a sales engineer for help. Stay careful and keep your chipper working its best!

자주 묻는 질문

What causes chipper blade imbalance?

Chipper blade imbalance can happen for many reasons. Worn blades are one cause. Improper installation can also make the chipper shake. Debris build-up adds extra weight. Damaged rotors can make things worse. Even small chips or dents can cause shaking.

How often should you check for chipper blade imbalance?

Check for chipper blade imbalance every time before you use the chipper. Regular checks help you find problems early. This keeps your chipper safe and working well.

Can you fix chipper blade imbalance yourself?

You can fix small chipper blade imbalance problems by cleaning and checking the blades. You can also balance the blades yourself. If the problem is big, ask a technician for help.

What tools help detect chipper blade imbalance?

You can use a vibration analyzer to check for shaking. A gravity spin test helps you find uneven weight. A simple scale can show if blades weigh the same. These tools help you spot chipper blade imbalance.

Why does vibration increase after sharpening blades?

Vibration can get worse if you put blades in unevenly. Loose bolts after sharpening can also cause shaking. Always check blade balance and make sure bolts are tight before using the chipper.

How do you prevent chipper blade imbalance?

Clean out debris after each use. Check blades for wear or damage. Install blades in pairs to keep balance. Follow the manufacturer’s instructions every time.

What happens if you ignore chipper blade imbalance?

If you ignore chipper blade imbalance, your chipper can break. Unsafe vibration can hurt you or others. The machine may not last as long. Chips may look rough or uneven.

When should you replace chipper blades?

Replace chipper blades when you see chips or cracks. Uneven wear means it is time for new blades. Sharp and balanced blades keep your chipper safe and working well.

또한 참조

산업용 드럼 치퍼 나이프: 절단 속도, 인성 및 칩 품질의 균형 유지