올바른 것을 선택하다 산업용 슈레더 블레이드 판매 까다로운 작업처럼 보일 수 있습니다. 기계에 맞고, 재료에 적합하며, 신뢰할 수 있는 공급업체에서 제공하는 블레이드를 원하기 때문입니다. 이러한 블레이드의 세계 시장 규모는 약 10억 명에 달할 것으로 예상됩니다. 2025년에는 3억 6,389만 달러꾸준한 성장세를 보이고 있습니다.

- 2024년 시장 규모는 3억 4441만 달러였습니다.

- 2032년에는 5억 3880만 달러까지 증가할 수 있습니다.

이러한 성장세는 여러분에게 그 어느 때보다 더 많은 선택지를 제공하므로, 올바른 선택을 하는 것이 사업에 매우 중요합니다.

주요 요점

- 작업에 맞는 날 유형을 선택하세요. 단축 날은 플라스틱과 섬유에 적합하고, 다축 날은 질기고 다양한 재료를 절단하는 데 더 효과적입니다.

- 용도에 맞는 최적의 날 재질을 선택하세요. 침탄강은 내구성이 가장 뛰어납니다. 초경합금 날은 고무나 거친 재질을 가공하는 데 적합합니다.

- 분쇄하려는 재료에 맞는 칼날을 사용하세요. 올바른 칼날을 사용하면 작업 속도가 빨라지고 칼날 수명도 늘어납니다.

- 구매하기 전에 칼날 디자인을 고려해 보세요. 모양과 두께는 절단 속도와 품질에 영향을 미칩니다. 사용 목적에 맞는 디자인을 선택하세요.

- 칼날이 튼튼하고 견고한지 확인하세요. 단단한 재질은 쉽게 마모되거나 깨지지 않습니다. 이렇게 하면 교체용 칼날을 덜 사게 되어 비용을 절약할 수 있습니다.

- 분쇄기에 칼날이 잘 맞는지 확인하세요. 항상 크기와 장착 방식을 살펴보세요. 이렇게 하면 사용 중 발생할 수 있는 문제를 예방할 수 있습니다.

- 칼날을 자주 관리하세요. 깨끗하게 닦고, 날카롭게 갈고, 점검하여 값비싼 수리비를 예방하십시오. 이렇게 하면 칼날의 수명도 늘어납니다.

- 평점이 좋고 인증을 받은 공급업체에서 구매하세요. 좋은 공급업체는 품질 좋은 칼날을 판매하고 구매 후에도 도움을 제공합니다.

산업용 파쇄기 날 판매 개요

찾을 때 산업용 슈레더 블레이드 판매그러려면 주요 유형, 재질 및 용도를 알아야 합니다. 이 개요는 다양한 선택 사항을 비교하고 유명 브랜드에서 선호하는 제품을 살펴보는 데 도움이 됩니다. 난징 Metal 산업 가지다.

블레이드 유형

파쇄기는 재료 종류에 따라 다양한 종류의 칼날을 사용합니다. 적절한 칼날을 사용하면 기계의 성능이 향상되고 수명도 연장됩니다.

단일 샤프트

단일 축 블레이드는 플라스틱, 목재 및 섬유 파쇄에 적합합니다. 이러한 블레이드는 재활용 및 제품 제조에 사용됩니다. 단일 축 설계는 깔끔한 절단과 안정적인 공급을 제공합니다. 특수 블레이드 모양이나 크기가 필요한 경우, 다음을 참조하십시오. 맞춤형 블레이드 솔루션 귀하의 기기용입니다.

다축

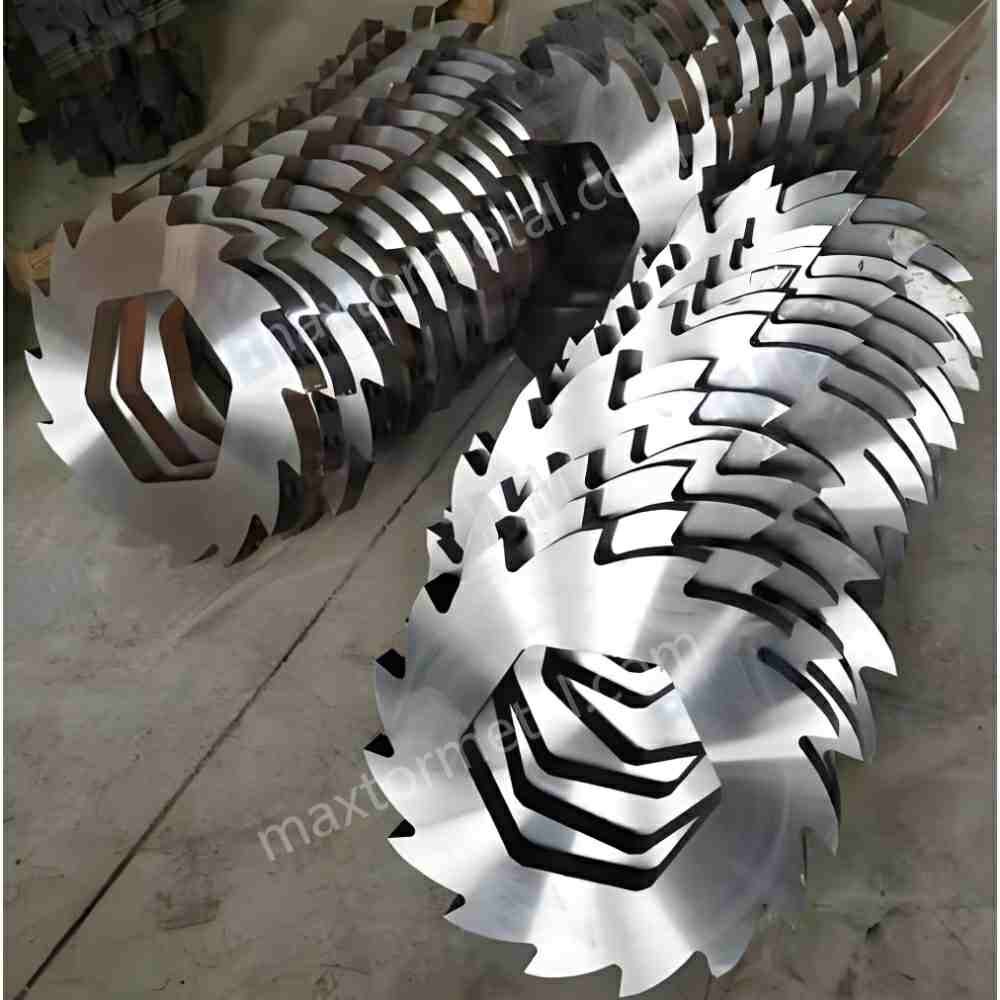

이중축이나 4중축과 같은 다축 블레이드는 혼합 재료, 타이어, 전자 제품 및 건축 폐기물을 파쇄할 수 있습니다. 이러한 블레이드는 폐기물 관리 및 재활용 분야에 사용됩니다. 난징 Metal 산업은 3개, 8개 또는 12개의 갈고리가 달린 다축 블레이드를 생산합니다. 갈고리 모양은 큰 폐기물을 끌어당기고 단단한 재료를 파쇄하는 데 도움이 됩니다.

팁: 다축 블레이드는 크거나 다양한 종류의 물체를 절단하는 어려운 작업에 가장 적합합니다.

블레이드 소재

올바른 것을 선택하다 블레이드 재질 성능과 지속 시간에 중요한 영향을 미칩니다. 종류는 여러 가지가 있으며, 각각 고유의 장점이 있습니다.

| 블레이드 재질 | 시장 점유율(매출) | 노트 |

|---|---|---|

| 침탄강 | 우성 | 높은 탄소 함량과 경도로 인해 강하고 오래갑니다. |

| 공구강 | 해당 없음 | 많이 사용되지만 침탄강만큼 많이 사용되지는 않습니다. |

| 표면 경화강 | 해당 없음 | 내마모성이 우수합니다. |

| 크롬 저합금강 | 해당 없음 | 강점과 강인함을 겸비하고 있습니다. |

공구강

공구강 칼날은 날카롭고 마모에 강합니다. 플라스틱이나 부드러운 재질을 자르는 데 사용할 수 있습니다. 날카로움이 오래 유지되고 관리하기도 쉽습니다.

합금강

합금강 칼날은 질기고 강합니다. 금속이나 단단한 재료를 절단하는 데 적합하며, 쉽게 깨지지 않고 내구성이 뛰어나 오랫동안 사용할 수 있습니다.

카바이드 팁

카바이드 팁 블레이드는 매우 단단하고 수명이 길습니다. 고무, 거친 재질 또는 날카로움을 오래 유지하고 싶을 때 선택하세요. 카바이드 팁 덕분에 블레이드를 자주 교체할 필요가 없습니다.

메모: 침탄강은 매우 단단하고 마모에 강하기 때문에 가장 많이 사용됩니다.

특수한 칼날 재질이나 코팅이 필요하신 경우, 맞춤형 블레이드 옵션 필요한 것을 얻도록 도와드리겠습니다.

응용

산업용 슈레더 블레이드 판매 블레이드는 다양한 산업 분야에서 사용됩니다. 아래 표는 일반적인 블레이드 유형과 주요 용도를 보여줍니다.

| 분쇄기 칼날 종류 | 주요 응용 분야 | 산업 |

|---|---|---|

| 단일 샤프트 | 플라스틱 재활용, 목재 파쇄, 섬유 파쇄 | 재활용, 제조 |

| 이중 샤프트 | Metal 파쇄, 타이어 파쇄, 전자 폐기물 재활용 | 폐기물 관리, 재활용 |

| 과립기 | 플라스틱 재활용, 식품 가공, 제약 | 재활용, 식품, 의료 |

| 다축 | 혼합 재료, 타이어, 전자제품, 건축 폐기물 파쇄 | 재활용, 폐기물 관리 |

찾을 수 있습니다 산업용 슈레더 블레이드 판매 플라스틱, 금속, 고무, 목재 등 다양한 재료에 사용할 수 있습니다. 두께, 구멍 위치, 톱니 모양, 모서리 각도 및 코팅을 원하는 대로 선택할 수 있습니다.

사용자 정의: 최고급 브랜드는 날 두께, 톱니 모양, 코팅 등을 선택할 수 있도록 해줍니다. 이를 통해 날이 기계와 재료에 딱 맞도록 할 수 있습니다.

난징 Metal 산업은 첨단 제조 기술과 엄격한 품질 관리로 잘 알려져 있습니다. 정밀 가공, 단조 및 열처리 공정을 통해 내구성이 뛰어나고 성능이 우수한 칼날을 생산합니다. 모든 칼날은 철저한 테스트와 검사를 거칩니다. 또한 ISO 9001 인증을 준수하여 모든 제품의 신뢰성을 보장합니다.

OEM 및 ODM 서비스도 제공되므로, 귀사의 필요에 맞춰 블레이드를 설계하기 위해 해당 팀과 협력할 수 있습니다. 수입 절차는 간단하며, 모든 단계에서 도움을 받을 수 있습니다.

주요 구매 요인

재료 호환성

선택할 때 산업용 슈레더 블레이드 판매재료를 썰 때, 칼날을 썰고자 하는 재료에 맞춰야 합니다. 각 재료마다 제대로 작업하고 오래 사용하려면 특수한 날이 필요합니다.잘못된 칼날을 사용하면 좋지 않은 결과가 초래되고 더 큰 손상을 입을 수 있습니다.

다음 표는 사용하시는 재료에 맞는 칼날을 선택하는 데 도움이 될 것입니다.

| 재료 | 칼날의 특징 |

|---|---|

| 플라스틱 | 우수한 인성과 중간 정도의 경도로 마모를 방지합니다. |

| 고무 산업 | 마모를 줄이고 작업 속도를 높이기 위해 탄화물 또는 고합금강을 사용합니다. |

| 금속 | 합금강 또는 초경합금으로 제작되어 매우 높은 경도와 내마모성을 갖습니다. |

플라스틱을 파쇄할 때는 내구성이 좋고 경도가 중간 정도인 칼날을 사용하세요. 이런 칼날은 마모가 덜하고 날카로움을 오래 유지합니다. 고무를 파쇄할 때는 카바이드 또는 고합금강 칼날이 가장 좋습니다. 수명이 길고 고무를 빠르게 파쇄합니다. 금속을 파쇄할 때는 경도가 매우 높은 칼날을 선택하세요. 합금강이나 카바이드 칼날은 고강도 작업에도 견딜 수 있고 오래 사용할 수 있습니다.

팁: 항상 사용하려는 재료에 맞는 날을 사용하십시오. 이렇게 하면 더 나은 결과를 얻을 수 있고 날의 수명도 연장됩니다.

많은 분들이 하나의 칼날로 여러 재료를 분쇄할 수 있는지 묻습니다. 하나의 칼날로 다양한 작업을 할 수 있지만, 주된 작업에 맞는 칼날을 사용하는 것이 가장 효과적입니다.

블레이드 디자인

칼날 디자인은 분쇄기의 작동 방식에 큰 영향을 미칩니다. 칼날의 모양, 두께, 그리고 날카로움은 분쇄 속도와 분쇄된 조각의 모양에 영향을 줍니다. 따라서 자신의 필요에 맞는 디자인을 선택해야 합니다.

다양한 날 디자인은 각기 다른 작업에 적합합니다. 외날은 깔끔하게 절단하며 플라스틱과 목재에 적합합니다. 갈고리 또는 쇠갈고리 모양의 다날은 큰 물체를 집어 올리고 혼합 폐기물을 파쇄하는 데 사용됩니다.

- 칼날의 모양은 날의 각도와 톱니 모양처럼 절삭력에 영향을 미칩니다.

- 우수한 칼날 디자인은 균일한 절단면과 뛰어난 품질을 제공합니다.

- 적절한 칼날 모양은 수리 횟수를 줄이고 사용 기간을 연장시켜 줍니다.

적합한 칼날을 선택하면 에너지를 절약하고 더 나은 결과를 얻을 수 있습니다. 날카롭고 튼튼한 칼날은 재료를 잘게 다지는 데 도움이 됩니다. 재료와 작업에 맞춰 칼날 디자인을 교체할 수도 있습니다.

- 파쇄 작업에 맞는 칼날을 선택하세요.

- 날이 기계와 재료에 맞는지 확인하십시오.

- 설계가 청소 및 수리를 쉽게 할 수 있도록 되어 있는지 확인하십시오.

메모: 복잡한 모양의 칼날은 더 많은 점검과 특별한 세척이 필요할 수 있습니다.

내구성

구매할 때는 내구성이 중요합니다. 산업용 슈레더 블레이드 판매오래가고 성능이 뛰어난 칼날을 원하시겠죠. 칼날의 재질, 열처리 방식, 그리고 사용 빈도가 칼날의 수명을 결정합니다.

경도가 높은 날을 찾으세요. 이런 날은 쉽게 마모되거나 깨지지 않습니다. 판매자에게 날의 예상 사용 기간을 문의하세요. 마모를 조기에 발견하고 문제를 예방하기 위해 날을 자주 점검하세요.

많은 분들이 칼날을 얼마나 자주 교체해야 하는지 궁금해하십니다. 이는 사용 빈도와 어떤 재료를 분쇄하는지에 따라 다릅니다. 만약 매일 단단한 재료를 분쇄한다면 칼날을 자주 점검하고, 손상된 부분이 보이면 교체하거나 날카롭게 갈아주세요.

팁: 마모와 파손에 강한 칼날을 선택하세요. 이렇게 하면 비용을 절약하고 파쇄기를 오랫동안 잘 작동시킬 수 있습니다.

기계 적합성

파쇄기 칼날이 기계에 꼭 맞는지 확인해야 합니다. 모든 파쇄기 모델은 크기와 모양이 다르고, 장착 구멍 위치도 다를 수 있습니다. 잘못된 칼날을 사용하면 기계가 흔들리거나 제대로 작동하지 않을 수 있으며, 심지어 파쇄기가 고장 날 수도 있습니다. 칼날의 길이, 너비, 두께를 확인하고 장착 구멍 위치도 살펴보세요. 항상 기계 설명서를 읽거나 판매처에 문의하여 올바른 크기의 칼날을 확인하십시오. 간혹 일반 칼날을 사용할 수 있는지 묻는 분들이 있는데, 일반 칼날이 맞을 수도 있지만 기계에 맞는 전용 칼날을 사용하는 것이 더 좋고 안전합니다.

팁: 구매하기 전에 항상 칼날의 크기와 모양을 확인하세요. 이렇게 하면 실수를 방지하고 분쇄기를 제대로 작동시킬 수 있습니다.

유지

분쇄기 칼날을 잘 관리하면 날카로운 상태를 유지할 수 있을 뿐 아니라 기계의 안전도 지킬 수 있습니다. 칼날을 자주 점검하고 관리하면 문제를 조기에 발견하여 큰 수리로 이어지지 않도록 예방할 수 있습니다.

다음은 몇 가지 간단한 유지 관리 방법입니다.

- 분쇄기를 사용한 후에는 남은 찌꺼기를 깨끗이 치우세요.

- 분쇄기가 작동 중일 때 이상한 소리가 나는지 주의 깊게 들어보세요.

- 오일을 점검하고 움직이는 부품에 오일이 충분한지 확인하십시오.

- 날개와 볼트에 균열이 있는지 또는 헐거워졌는지 살펴보세요.

- 칼날 주변에 아무것도 끼어 있지 않은지 확인하십시오.

- 칼날이 날카로운지 확인하십시오. 무뎌진 칼날은 날카롭게 갈거나 교체하십시오.

간단한 일정을 따르면 됩니다.

- 일일: 날을 살펴보고, 이물질을 제거하고, 이상한 소리가 나는지 들어보세요.

- 주간: 날개가 마모되었는지 확인하고, 벨트 장력을 점검하고, 전기 부품을 점검하십시오.

- 월간 간행물: 모든 부품에 오일을 바르고 유압 시스템을 점검하고 안전 스위치를 테스트하십시오.

메모: 종이에 파쇄기용 오일을 지그재그 모양으로 바른 후 파쇄하세요. 파쇄기를 자주 사용한다면 며칠에 한 번씩, 사용 빈도가 낮다면 일주일에 한 번씩 해주세요.

유지보수 기록을 남겨두세요. 이렇게 하면 파쇄기를 언제 점검해야 하는지 기억하는 데 도움이 됩니다. 이러한 정기적인 관리는 산업용 파쇄기 날을 더 오래, 더 안전하게 사용할 수 있도록 해줍니다.

안전

파쇄기를 사용할 때는 안전이 매우 중요합니다. 칼날은 날카롭고 강력하므로 안전 수칙을 반드시 준수해야 합니다. 칼날 보호대, 비상 정지 버튼 또는 눈에 잘 띄는 안전 라벨과 같은 안전 기능을 갖춘 기계와 칼날을 선택하십시오.

파쇄기를 사용하는 모든 사람에게 안전한 사용 및 관리 방법을 교육하십시오. 파쇄기와 칼날에 중요한 안전 인증이 있는지 확인하십시오. 일반적으로 볼 수 있는 인증은 다음과 같습니다.

| 인증 | 설명 |

|---|---|

| CE | EU 내 대부분의 기계에 필요합니다. 안전, EMC 및 환경 관련 사항을 포함합니다. |

| ISO 12100 | 기계 설계에서 위험 및 안전에 대한 규칙을 설정합니다. |

| ISO 9001 | 품질 관리 및 프로세스 효율성을 점검합니다. |

| ISO 14001 | 환경 관리에 중점을 둡니다. |

| UL | 북미 지역의 전기 및 화재 안전을 점검합니다. |

| CCC | 중국의 안전 및 전자파 규정을 다룹니다. |

| 두번 | 인도에서 수입 기계에 필요합니다. |

| 인메트로 | 브라질의 노동 안전에 대한 내용이 포함되어 있습니다. |

| PSE | Needed for electrical products in Japan. |

| EAC | Important for Russia and nearby countries. |

알리다: Always look for these certifications before you buy. Certified blades and machines help keep workers and your business safe.

Noise & Capacity

Noise and capacity are important when picking shredder blades. You want a blade that works quickly but does not get too loud. Loud machines can make your work area uncomfortable. Some blade shapes help make less noise and keep things safer.

You should check how much material the blade can shred each hour. This is called throughput capacity. Blades with high capacity can shred more waste. High capacity does not always mean more noise. New blade shapes and materials help lower vibration and sound.

Here is a table that shows how blade shape changes noise and capacity:

| 특징 | 설명 |

|---|---|

| Aerodynamic Efficiency | Fewer blades can make each blade work harder, which may lower efficiency. |

| Noise Emissions | New technology helps reduce jet noise, but turbine noise can still be loud. |

| Thrust Performance | Fewer guide vanes do not hurt performance much, but too much blade work can cause problems. |

Pick a blade that fits your shredding needs. If you need to shred lots of material, choose blades with high throughput. If you want a quieter workspace, ask your supplier about low-noise blade choices.

팁: Advanced blade shapes can give you both high capacity and low noise. You do not have to pick just one.

Replacement Ease

Easy blade replacement helps you save time and money. You do not want your shredder to stop for a long time. Some blades have quick-release systems or modular parts. These features help you change blades fast.

Keep extra blades ready. If a blade breaks or wears out, you can replace it right away. Some machines let you change blades yourself. Always follow safety steps and use the right tools.

Here are steps to make blade replacement easier:

- Check your shredder manual for blade change steps.

- Use quick-release or modular blades if your machine allows.

- Keep extra blades in stock for emergencies.

- Train your team on safe blade changes.

- Contact your supplier if you need help or special tools.

메모: Some blade models let you change blades yourself. Always wear gloves and follow safety rules.

When you shop for industrial shredder blades for sale, ask about replacement features. Fast and safe blade changes keep your work running smoothly.

산업용 파쇄기 날 판매: 가격 및 공급업체 비교

Market Price Trends

Historical Pricing Patterns

In the last five years, shredder blade prices have changed a lot. In 2020, prices went up because steel cost more and shipping had problems. In 2022, more companies started selling blades, so prices stopped rising. By 2023, many suppliers made blades better and cheaper for buyers. Prices usually go up when more people want recycling machines or when steel costs more.

Current Market Rates by Region

Shredder blade prices are different in each place. In North America, blades cost more because of strict rules and higher pay for workers. In Europe, prices are close to North America, but you can get more custom blades. In Asia, especially China, blades are cheaper and there are many choices. Here is a table to help you compare:

| Region | Typical Price Range (USD per blade) | 노트 |

|---|---|---|

| 북아메리카 | $150 – $400 | High standards, strong after-sales |

| 유럽 | $130 – $380 | Customization options, certifications |

| Asia | $80 – $250 | Competitive pricing, large selection |

Tip: Always check what comes with the price, like shipping, warranty, and support.

Forecast for 2025

In 2025, prices will likely stay the same or go up a little. Steel might cost more, especially the best kinds. More people will want recycling machines, so prices could rise. Some suppliers use new ways to make blades, which can mean better deals. But if you want special features or certifications, it may cost more. If you buy a lot or need custom blades, you can still get good prices.

Price Influencers

Material Type & Grade

The kind and quality of material in blades changes the price. Tool steel blades are cheaper and work well for plastics and soft things. Alloy steel and carbide-tipped blades cost more because they last longer and can shred harder stuff. Here is a table that shows what changes the price:

| 요인 | 설명 |

|---|---|

| Power and Performance | Better blades cost more because they use new technology. |

| Brand and Supplier Influence | Famous brands charge more for trust and special features. |

| Customization & Special Features | Custom blades or coatings cost more but can help you work better. |

| 유지 관리 및 수명 | Stronger blades last longer and may cost more at first. |

| Market Trends & Economic Conditions | High demand or expensive materials can make prices go up. |

제조공정

How a blade is made also changes its price. Blades made with special forging and heat treatment cost more but last longer. Careful machining makes blades fit better and work well. If you want special coatings, you will pay more.

브랜드 평판

Brand reputation is important when you look at prices. Smaller companies may have lower prices, but you might not get as much help or as many choices. Always think about what you need for service and quality.

Customization & Order Volume

Custom blades cost more than regular ones, but they fit your needs better. If you only buy a few custom blades, each one costs more. If you buy a lot, the price for each blade goes down. Here is a table to show how order size changes price:

| Order Volume | Unit Price Impact |

|---|---|

| 낮은 | Higher unit price due to minimum order size |

| 중간 | Lower unit price possible |

| 높은 | Lowest unit price due to economies of scale |

공급업체 평가

Reliability & Track Record

You need a supplier you can trust. Check how long the company has worked and who buys from them. Good suppliers use strong materials and have a good record with customers. Here is what to look for:

- Make sure the supplier knows your shredding job and how much you shred.

- Check if they use the right heat treatment for strong blades.

- Look for suppliers who know your area or have local help.

- Pick suppliers who offer strong parts and care about safety.

- Choose companies that make it easy to fix and care for blades.

- Ask about warranties for extra peace of mind.

Certifications & Compliance

Certifications show a supplier follows the rules. Look for ISO 9001 and CE certifications. These mean the company uses good quality and safety steps. Many top suppliers in China, Europe, and North America have these. Here is a quick table:

| Company Name | 인증 |

|---|---|

| WANRODE MACHINERY CO., LTD. (China) | ISO 9001:2008, CE certification |

Tip: Always ask to see proof of certification before you buy.

Customer Reviews & Testimonials

Customer reviews help you know if a supplier is good. Read what other buyers say about orders, custom blades, and help after buying. Good reviews from others can help you feel sure about your choice.

애프터 서비스 지원

Good after-sales help is important. Pick suppliers who give technical help, answer fast, and have spare parts ready. This helps you fix problems fast and keep working.

Service Differences

Product Warranty & Guarantees

When you buy industrial shredder blades for sale, check the warranty and guarantee rules. These rules help protect your money and make you feel safe. Different suppliers give different warranty times for electrical parts and cutting assemblies. Some companies pay for repair labor, but others make you pay to ship returns.

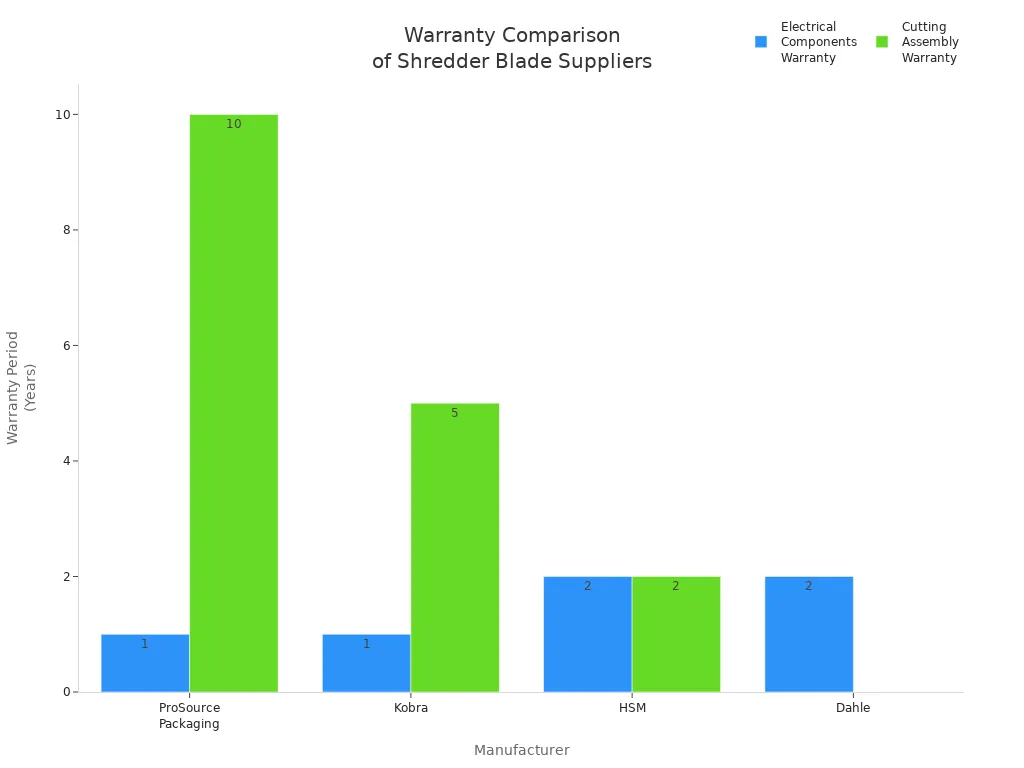

Here is a table that shows how top suppliers compare:

| Manufacturer | Warranty on Electrical Components | Warranty on Cutting Assembly | 추가 참고 사항 |

|---|---|---|---|

| ProSource Packaging, Inc. | 1년 | 10 years | Limited warranty, buyer pays for return freight. |

| Kobra | 1 year (Level 6: 90 days) | 5 years (Level 6: 1 year) | Warranty labor covered for 1 year (Level 1-5), 90 days (Level 6). |

| HSM | 2 years (single-shift) | 2 years (single-shift) | Varies by model and usage. |

| Dahle | 2 years | Lifetime on cutting cylinders | Excludes damage from misuse. |

Some suppliers give longer warranties for cutting assemblies. Dahle gives a lifetime guarantee on cutting cylinders. ProSource Packaging covers cutting assemblies for ten years. Always read the warranty before you buy. Ask your supplier what is included and what is not.

팁: A long warranty usually means the supplier trusts the quality of their industrial shredder blades for sale.

Lead Time & Delivery Options

Lead time means how long it takes to get your industrial shredder blades for sale after you order. Delivery options show how fast and safe your blades will arrive. Suppliers have different lead times based on how many blades you buy and if you want custom designs.

Here is a table that shows normal lead times:

| Quantity (pieces) | Lead time (days) |

|---|---|

| 1 – 10 | 15 |

| 11 – 50 | 20 |

| 51 – 100 | 20 |

| > 100 | To be negotiated |

Some suppliers can ship in-stock products fast. You might get your blades in just three days. Custom blades can take seven to fifteen days. Big orders may take longer, so talk to your supplier about the delivery time.

- Fast Delivery: 3 days for in-stock products

- Custom Orders: 7–15 days

- Bulk Orders: Negotiated lead time

메모: Always ask about shipping and tracking. Good suppliers give updates and help with import papers.

맞춤형 서비스

Customization lets you get industrial shredder blades for sale that fit your machine and material. Many suppliers offer custom blade shapes, sizes, coatings, and mounting choices. You can pick the thickness, tooth design, and edge angle. Some companies offer OEM and ODM services, so you can work with their engineers to design special blades.

If you need blades for special materials or want better shredding, customization is best. Suppliers may need drawings or samples to match your needs. Custom blades may cost more and take longer, but they help you get better results.

팁: Customization helps you fix shredding problems and work better. Ask your supplier about design help and testing.

Technical Consultation & Training

Technical consultation and training help you use your industrial shredder blades for sale safely and well. Good suppliers give advice on picking blades, setting up machines, and caring for them. You can get help with installing, fixing, and checking performance.

Some companies train your staff. Training teaches safe handling, blade changes, and regular care. You learn to spot wear, sharpen blades, and stay safe. Technical support can include manuals, videos, or visits.

- Consultation: Get expert advice on blade choice and machine fit.

- Training: Learn safe use, maintenance, and replacement steps.

- Support: Access manuals, guides, and customer service.

알리다: Well-trained workers help blades last longer and keep your workplace safe. Always ask about training and support when you buy.

구매자 체크리스트

Pre-Purchase Steps

You should make a plan before buying industrial shredder blades for sale. These steps help you avoid mistakes and pick the right blades.

Define Shredding Requirements

- Figure out what materials you want to shred. Make sure your shredder can handle those materials.

- Decide how much you need to shred at once. Think about the amount you want to process each time.

- Check what security level you need for shredded material. Use the 7 shredder security levels to help you choose.

- Pick the cutting type you want, like strip-cut or cross-cut. This depends on how small you want the pieces.

- Look at the shredder’s safety features. Choose features that help keep you safe while using the machine.

Tip: Write down your shredding needs before you shop. This helps you compare industrial shredder blades for sale.

Set Budget and Timeline

Set a budget for your blades and services. Decide how much you want to spend. Plan when you want your blades delivered and installed. If you want custom blades, give extra time for making and shipping.

Research Potential Suppliers

Look for suppliers with good experience. Check how long they have been in business. Read customer reviews and see what people say about them.

Identify Required Blade Specifications

Make a list of blade specifications you need. Include blade type, material, size, and any special features. If you want a custom blade, visit the 커스텀 블레이드 페이지 to see your choices.

Review Industry Standards and Certifications

Check if the blades and supplier meet important standards. Use the table below to see key certifications and quality checks:

| Standard/Certification | 설명 |

|---|---|

| ANSI/ASME B94.55M | Cutting tool dimensions |

| DIN 1838 | Hardness specifications (HRC 58-62) |

| Third-party analysis | Material composition verification |

| Production audits | Quality checks during heat treatment |

| Sample testing | Performance under load conditions |

| Weld penetration tests | Quality of brazed carbide tips |

| Factory access | Transparency in supply chain |

| Material certifications | Assurance of quality and compliance |

Note: Always ask for proof of certification when you compare industrial shredder blades for sale.

Prepare a List of Evaluation Criteria

Make a checklist of what matters most to you. Include price, blade material, customization, lead time, warranty, after-sales support, and supplier reputation. Use this list to compare different suppliers and products.

Supplier Questions

Ask clear questions when you talk to suppliers about industrial shredder blades for sale. This helps you learn what each company offers and how they meet your needs.

What materials and grades are available for your shredder blades?

Ask what kinds of steel or alloys they use. Find out if they offer tool steel, alloy steel, or carbide-tipped blades. This helps you match the blade to your shredding material.

Can you provide custom blade designs or sizes?

See if the supplier can make blades to your exact needs. Nanjing Metal Industrial offers custom blade solutions on their 커스텀 블레이드 페이지.

What is the typical lead time for orders?

Ask how long it takes to make and deliver your blades. Find out if custom orders or big orders take longer.

What quality control processes do you use?

Ask about the supplier’s quality checks. See if they use third-party analysis, production audits, or sample testing to check blade performance.

Are your products certified to meet industry standards (e.g., ISO, CE)?

Ask for proof of certifications like ISO 9001 or CE. This shows the supplier meets safety and quality standards.

What after-sales support and warranty do you offer?

Find out what help you get after buying. Ask about warranty time, replacement rules, and technical support.

Can you provide references or customer testimonials?

Ask for feedback from other buyers. Customer reviews and testimonials help you know if the supplier is reliable.

What are your payment and shipping terms?

Check payment options and shipping rules. Ask about delivery times, shipping costs, and help with importing.

Do you offer technical consultation or training?

See if the supplier gives training for your team. Technical support and training help you use and care for your blades safely.

Tip: Write down supplier answers to these questions. This makes it easier to compare your options for industrial shredder blades for sale.

비교표

Use the table below to compare features and services from different suppliers. Fill in the details as you research each company.

| 특징 | Supplier 1 | Supplier 2 | Supplier 3 |

|---|---|---|---|

| 상표 | |||

| Shaft Count | Single, Double, Multi | ||

| 블레이드 디자인 | Hook, Square, Claw | ||

| 블레이드 재질 | Tool Steel, Alloy, Carbide | ||

| 사용자 정의 | 예/아니요 | ||

| 적용 분야 | Plastics, Metal, Rubber | ||

| End User Industry | Waste Mgmt, Recycling | ||

| Region | |||

| Company Footprint | Years in business, reach | ||

| 가격 | |||

| Lead Time | |||

| 인증 | ISO, CE, etc. | ||

| 애프터 서비스 | Support, Training | ||

| Warranty | |||

| 고객 리뷰 |

Note: This table helps you see the strengths and differences between suppliers. Use it to find the best industrial shredder blades for sale for your needs.

결정 및 다음 단계

Balancing Needs

Assessing Priorities

Before you buy industrial shredder blades for sale, set your main goals. Make a list of what you want most. Do you want blades that last longer, cost less, or shred faster? Think about what you shred every day and how much you do. If you shred hard things, you need strong blades. If your business is small, saving money might be most important. Write down what you must have and what would be nice to have. This helps you focus on what matters and not get distracted.

팁: Make a list of your top three needs. Use it when you look at blade choices.

Weighing Budget vs. Performance

You need to balance your budget and how well the blade works. Here are some steps to help you decide:

- If you want to save money, carbon steel blades are good for light jobs.

- If you need strong blades, pick alloy steel or tool steel. These last longer and can shred tough things.

- If you work in rough places, tungsten carbide blades stay sharp and do not wear out fast.

You should also:

- Know your work area and what you shred.

- Compare the first price with how long the blade will last.

- Make sure the blade fits your machine.

A cheap blade may wear out fast. A more expensive blade may last longer and save money later. Always pick a blade that matches your main job and machine.

Considering Lead Time and After-Sales Service

How fast you get your blades and the help you get after buying are important. Fast delivery keeps your work going. Good after-sales help lets you fix problems quickly. Ask how long it takes to get your blades. Find out if the supplier helps with setup, training, or repairs. Pick suppliers who answer fast and have spare parts ready.

메모: Good service means less waiting and fewer problems.

Customization vs. Standard Solutions

You can pick custom blades or standard blades. Custom blades fit your machine and material best. They may cost more and take longer to arrive. Standard blades are ready to ship and come faster. They work for most shredding jobs. If you have specific needs, custom blades work better. If you want fast delivery, standard blades are a good pick.

| Solution Type | 장점 | 단점 |

|---|---|---|

| 사용자 정의 | Perfect fit, better results | Higher cost, longer lead time |

| 기준 | Lower cost, fast delivery | May not fit specific needs |

팁: Pick custom blades for special jobs. Choose standard blades for normal shredding.

실수 방지

Overlooking Compatibility

Always check if the blade fits your shredder. The wrong size or type can cause problems or break your machine. Match the blade to your shredder’s needs. Read the manual and ask your supplier for help.

가격에만 집중하다

Low prices can cause trouble. Cheap blades may break or wear out fast. You should think about quality and how long the blade lasts. Think about the cost of fixing or replacing blades.

Ignoring Supplier Reputation

Who you buy from matters. If you buy from unknown companies, you may get bad blades or poor help. Check the supplier’s history, reviews, and support. Good suppliers help you avoid problems.

Neglecting Certification and Compliance

Certified blades are safer and better quality. If you skip this, you might get unsafe blades. Look for ISO, CE, or other certifications. Ask for proof before you buy.

Underestimating Maintenance Needs

Taking care of blades keeps them working well. If you skip care, blades get dull and machines can break. Plan to clean, sharpen, and check blades often. This saves money and stops problems.

⚠️ 알리다: Avoid these mistakes to keep your shredding safe and working well.

Common Buyer Mistakes:

- Not checking the maker or support.

- Picking the wrong blade size or type.

- Forgetting about quality and trust.

- Not checking space or how to install.

- Not planning for more shredding in the future.

Planning Maintenance

Establishing a Maintenance Schedule

A good schedule keeps your industrial shredder blades for sale working longer. Plan regular checks and care based on how much you use your shredder and what you shred.

| 일 | 빈도 | 목적 |

|---|---|---|

| 블레이드 검사 | 주간 | 일찍 손상을 찾으세요 |

| 청소 | 사용 후 | 칼날이 둔해지는 것을 방지하세요 |

| 날카롭게하다 | 월간 간행물 | 칼날이 잘 작동하도록 하세요 |

| 대사 | 필요에 따라 | 작업을 중단하지 마십시오 |

Set reminders for each job. Write down what you do and when. This helps you find problems early and keep your shredder running.

Stocking Spare Blades and Parts

Keep extra blades and parts ready. If a blade breaks or wears out, you can change it fast. This stops long delays and keeps your work going. Store blades in a dry, safe place. Check your stock often and order more before you run out.

팁: Always have at least one spare blade for every machine.

Training Operators and Maintenance Staff

Teach your team how to use and care for industrial shredder blades for sale. Show them how to check, clean, and change blades safely. Teach them how to spot damage. Well-trained staff help blades last longer and stop accidents.

- Hold training often.

- Use manuals, videos, or guides from your supplier.

- Let staff ask questions and give feedback.

Setting Up Supplier Communication Channels

Stay in touch with your supplier. Good contact helps you fix problems fast and get advice. Set up clear ways to order, get help, and ask questions. Ask for contact details and the best way to reach them, like email or phone.

메모: Good supplier contact makes care and fixing problems easier.

If you follow these steps, you can make smart choices, avoid mistakes, and keep your industrial shredder blades for sale working their best.

Picking the right industrial shredder blades for sale in 2025 needs good planning. First, know what you want to shred and what results you need. Next, decide how much money you can spend and when you need the blades. Look up different suppliers and ask them lots of questions. Make sure the blades have safety features and plan how you will take care of them. Teach your team how to use the blades and think about what you might need later. Use the checklist and comparison table to help you choose well. If you want expert help or a special price, talk to a sales engineer 여기. Smart choices help your business do well for a long time.

자주 묻는 질문

What materials can industrial shredder blades for sale process?

These blades can shred plastic, metal, rubber, wood, and paper. Pick the right blade for your main material. This helps you get better results and makes blades last longer.

How often should I replace industrial shredder blades for sale?

Check your blades every week for damage. Replace them if you see chips, cracks, or dull edges. If you use your shredder a lot or shred tough stuff, you may need to change blades more often.

Can one blade type handle different materials?

One blade can shred many materials. But you get better results if you use the right blade for your main job. The right blade helps stop damage and keeps your shredder working.

How do I know if a blade fits my shredder?

Read your shredder’s manual to check blade size. Measure the blade’s length, width, and mounting holes. Ask your supplier for help if you are not sure.

What safety features should I look for?

Look for blade guards, emergency stops, and clear labels. Make sure your blades have certifications like ISO or CE. These features help keep you safe.

Is it easy to install new industrial shredder blades for sale?

Most new shredders let you change blades with simple tools. Always follow the manual and wear gloves. Some shredders have quick-release systems for fast changes.

Do I need to sharpen industrial shredder blades for sale?

Yes, sharpening helps blades work better and last longer. Use the right tools or ask a professional for help. Sharp blades cut cleaner and do not wear out as fast.

Where can I find custom industrial shredder blades for sale?

Many suppliers offer custom blades for your needs. You can ask for special sizes, shapes, or coatings. Always check if the supplier can help with design.

또한 참조

효율적인 재활용을 위한 플라스틱 슈레더 블레이드 선택 방법

산업용 분쇄기 블레이드 및 그 응용 분야에 대한 가이드

하나의 응답