Yes, you can make Nanjing Metal Industrial shredder blades last longer by 슈레더 블레이드 연마 with a safe, step-by-step process. When you keep your blades sharp, they last longer and you spend less money on new ones. You also get better results when shredding things like plastic, paper, rubber, metal, and wood. One company switched to high-performance blades and saw a 20% increase in efficiency and a 15% decrease in energy use. This helped them save money and have less downtime.

주요 요점

- Sharpening shredder blades helps them last longer and work better. This saves you money because you buy fewer new blades.

- Watch for signs your blades are dull. These signs include slow shredding, jams, or cuts that are not even. This tells you it is time to sharpen the blades.

- Use the correct tools to sharpen your blades. These tools include grinders, files, and stones. The right tools help you get the best results.

- Always wear safety gear when working with blades. Wear gloves and goggles to keep yourself safe from cuts or flying pieces.

- Clean and check your blades often. This helps you find damage early and keeps your shredder working well.

- Sharpen your blades on a regular schedule. How often you sharpen depends on how much you use the shredder. This keeps your shredder working smoothly.

- Replace blades if they have deep chips or cracks. Also replace them if you cannot sharpen them well. This keeps the shredder safe and working right.

- Make sure blades are lined up right and put in tightly. This helps stop jams and keeps the shredder running smoothly.

Blade Dullness Signs

성능 문제

Reduced efficiency

Your shredder blades may start working slower. The machine might need more time to finish the same job. You may have to push harder or run the shredder again. If the shredder jams or stops a lot, the blades are not sharp anymore.

팁: Check the material before shredding. Wet or too much material can jam the shredder. Dull blades are a main reason for slow work.

Here is a table that lists common problems and what causes them:

| Performance Issue | 원인 | 솔루션 |

|---|---|---|

| 재밍 | Too much material, dull blades, wet materials | Use less material, sharpen blades often, keep materials dry |

| 특이한 소음 | Loose blades, worn blades, wrong installation | Tighten blades, check for wear, install blades correctly |

| 블레이드 파손 | Bad material, wrong use, worn blades | Pick good blades, use them right, change old blades |

| 고르지 않은 절단 | Worn blades, wrong installation | Check for wear, line up blades |

Ragged cuts

Dull shredder blades make messy cuts. You might see rough or torn edges on the shredded pieces. The cuts are not straight and look uneven. This makes your work look bad and slows you down.

메모: Messy cuts mean the blade edge is not sharp enough to cut well.

시각적 확인

Nicks and chips

You can find dull or damaged blades by looking at the edges. Small dents, chips, or missing bits show the blade needs fixing. You can feel these spots by gently touching the blade with a gloved finger.

- 칩과 균열

- 둥근 모서리

- Dark spots (blades that get too hot may look blue or dark)

안전 수칙: Always wear gloves when you check blades. This keeps your hands safe from sharp edges.

Edge wear

Sharp blades have straight, even edges. When blades wear down, the edge looks round or uneven. Sometimes, you see shiny or flat spots on the blade. These signs mean the blade needs sharpening.

- Look for chips, cracks, round corners, dark spots, and burn marks with bright light or a magnifying glass.

- Very worn blades show clear signs of damage, edge wear, or bending.

팁: Good light helps you see blade damage fast. Checking blades often keeps your shredder working well.

Tools & Safety

You need the right tools and a safe place to sharpen shredder blades. This helps your blades last longer. It also keeps your shredder working well.

Sharpening Tools

Grinder

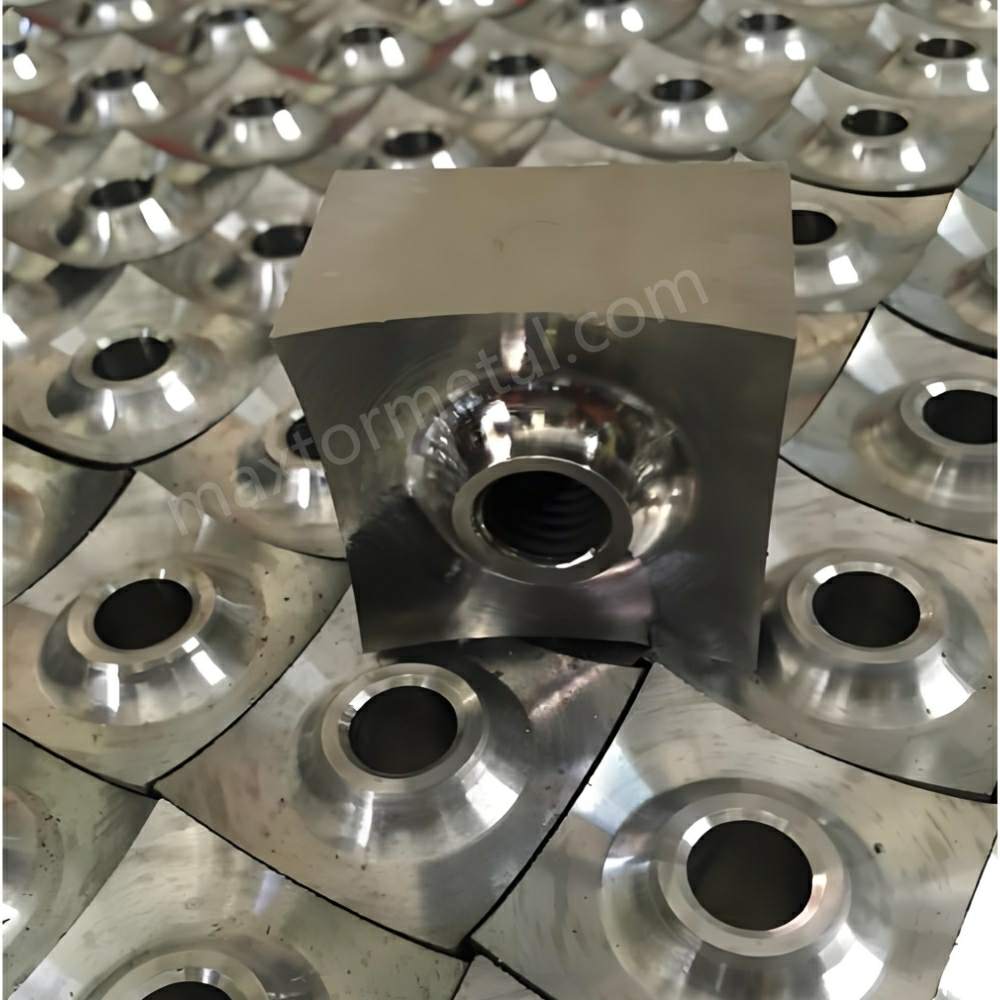

A grinder makes blades sharp fast. Use it for hard jobs or very dull edges. Nanjing Metal Industrial blades are made of strong steel. A grinder works well for these blades. Check your blade type before you start. Single-shaft blades need a flat grind. Multi-shaft or claw blades may need a different way. For custom blades, find more sharpening tips 여기.

File

A file lets you control how you sharpen. Move the file along the blade edge in smooth moves. Use a file for small fixes or tiny nicks. It works for single-shaft, double-shaft, or claw blades. Pick a file that fits your blade edge.

Stone

A stone helps finish the edge and take off burrs. Use it after grinding or filing. Stones have different grits. Pick one that fits your blade’s needs. Nanjing Metal Industrial blades do well with a fine stone. Their smooth edge comes from careful machining.

팁: Clean your sharpening tools after you use them. This keeps them working well and stops damage to your shredder blades.

안전 장비

장갑

Wear gloves to keep your hands safe from sharp edges. Pick cut-resistant gloves for more safety. You can handle blades and tools better when your hands are safe.

고글

Goggles protect your eyes from flying metal bits. Wear them when you use grinders or files. Good eye protection keeps you safe every time.

Hearing protection

Grinders and power tools are loud. Use earplugs or earmuffs to save your hearing. You stay safe and comfy in noisy places.

Workspace Setup

Stable surface

Set up your sharpening spot on a strong table. A sturdy workbench keeps blades steady. This stops slips and accidents.

Lighting

Bright lights help you see blade edges and find damage. Use a lamp with arms you can move. You spot small nicks and chips early.

- Keep your workspace neat to stop clutter and lower accident risk.

- Store tools where you can reach them easily for quick use.

- Use special storage to make tools last longer and stay safe.

- Make safety rules to help everyone use tools the right way.

- Train often to get better at using tools and staying safe.

메모: Nanjing Metal Industrial shredder blades are made with strong forging and heat treatment. They last a long time and you can sharpen them many times. Always use the right tools for your blade type to get the best results.

Blade Removal & Inspection

전원 끄기

You must turn off the shredder before you start. Unplug the power cord so it cannot turn on. This keeps you safe from moving parts and electricity.

안전 팁: Wear safety glasses, gloves, and a dust mask. These protect you from sharp edges and flying pieces.

Safe Removal

Take out shredder blades with care. The steps can change for each shredder type. Here is a simple guide for single, double, and four-shaft shredders:

- Clean around the blade area. Remove any dust or leftover bits.

- Look at the blade spot for damage or things that should not be there.

- Unscrew the bolts on the front. Take off the casing plate.

- If you have a multi-shaft shredder, remove the hexagon nuts from both shafts.

- Slide the front plate toward you. Take out the blades and spacers.

- Be careful with the alloy tips. Handle each blade gently.

- Clean the main shaft and flange before putting in new blades.

- Tighten the flange nuts well so nothing slips when you put it back.

메모: Keep your workspace neat and tidy. This helps stop accidents and makes blade removal easier.

Damage Check

After you take out the blades, you need to check them. Nanjing Metal Industrial blades are strong, but they can still wear out. Use these ways to see if your blades are in good shape:

| Inspection Method | 설명 |

|---|---|

| 시각 검사 | Look for damage, scratches, or bent edges. Check the color and surface. |

| Dimensional Measurement | Use a micrometer to measure blade size. Compare with standard specifications. |

| 경도 시험 | Test the blade with a hardness meter. Make sure it meets hardness standards. |

| Performance Evaluation | Test the blade’s cutting ability and resistance to wear and corrosion. |

Excessive wear

You might see deep scratches, chips, or round edges. If the blade is bent or not the right shape, it is worn out. Shiny or dark spots can mean the blade got too hot. Use a micrometer to see if the blade size is still correct.

팁: If you see cracks or missing pieces, do not sharpen the blade. Broken blades can snap when you use them.

Replacement need

Sometimes, sharpening will not fix a blade. If the blade fails the hardness test or does not cut well, you need a new one. Blades with rust or the wrong shape should not go back in the shredder.

- Change blades with deep chips, cracks, or that cannot be sharpened.

- Always use blades that match the maker’s rules for safety and work.

알림: Checking and removing blades the right way helps them last longer. You save money and keep your shredder working well.

Step-by-Step Guide: Sharpening Shredder Blades

준비

Clean blade

Start your sharpening shredder blades process by cleaning each blade. Dirt, rust, and plastic buildup can hide damage and make sharpening uneven. Use a clean cloth to wipe away dust and debris. For sticky residue, apply a mild solvent and scrub gently. Make sure the blade is dry before you move on.

안전 팁: Put on gloves before you touch the blade. Sharp edges and cleaning chemicals can hurt your hands.

Check the blade for chips, cracks, dents, and corrosion. Shine a flashlight on the blade to spot fine scratches or stress marks, especially near mounting holes. Measure blade thickness with a caliper or micrometer. If the blade is too thin, sharpening may not work. Test the blade’s sharpness by scratching your usual material. If the blade does not cut cleanly, you need to sharpen it.

Secure in vice

Place the blade in a sturdy vice. Make sure the blade sits flat and does not bend. Position the edge you want to sharpen so it is easy to reach. Double-check the vice grip before you start. A loose blade can slip and cause injury.

팁: Confirm the blade sits level and parallel to the material feed. Use a straight edge or dial indicator for best results.

Inspect the blade holders and shaft alignment. Uneven pressure can make blades dull faster or break. Listen for strange noises when you run the shredder. Odd sounds often mean the blade is worn or not lined up right.

날카롭게 하는 방법

수동

You can sharpen shredder blades by hand using a file or sharpening stone. Hold the file at the correct angle and move it along the blade edge in smooth, even strokes. Keep steady pressure and follow the original bevel. Divide the blade into sections and focus on one part at a time. This helps you keep the angle, especially near the tip.

안전 팁: Keep your hands and fingers away from the blade edge. Always wear gloves to avoid cuts.

For multi-claw or custom blades, use a smaller file or stone for each claw. Nanjing Metal Industrial offers 커스텀 블레이드 options for unique shapes and sizes.

Power tool

A bench grinder or rotary tool can make sharpening shredder blades faster. Set the tool to low speed. Gently guide the blade edge against the abrasive surface. Pause often and check the blade temperature. Overheating can weaken the blade.

안전 팁: Wear safety goggles and hearing protection when you use power tools.

Use a fine-grit wheel for finishing. For Nanjing Metal Industrial blades, precision machining and heat treatment help the blade hold its shape during sharpening.

Angle & Technique

Correct angle

Match the sharpening angle to the blade’s original bevel. Most shredder blades need an angle between 20° and 30°. Use an angle guide if you have one. Coloring the bevel with a marker helps you track material removal and keep the right angle.

팁: Incorrect angles can make the blade weak or wear unevenly. Work slowly and check your progress often.

Consistent strokes

Apply even, controlled strokes along the whole edge. Do not push too hard. Excess force can cause nicks or uneven spots. Lock your arms in position and use your core muscles to move. For better control, use your shoulder and elbow. Divide the blade into sections and sharpen each part carefully. Lift the handle slightly to keep the tip in contact with the stone.

메모: Take breaks to inspect your work. Fatigue can lead to mistakes and uneven sharpening.

You can use the marker method to check your progress. Color the blade edge before you start. As you sharpen, the marker disappears where you remove material. This helps you keep the angle and avoid missed spots.

Deburring & Finishing

Remove burrs

After sharpening shredder blades, you often find small metal edges called burrs. Burrs can make the blade rough and cause problems when shredding. You need to remove these burrs to keep the blade smooth and safe.

To remove burrs, use a fine file or a honing stone. Hold the tool at a slight angle and gently move it along the blade edge. Work slowly and check your progress often. You want to feel a smooth edge with no sharp or jagged spots.

팁: Always wear gloves when handling sharpened blades. The edge is very sharp after you finish sharpening.

If you work with multi-claw or custom shredder blades, use a small file for each claw. This helps you reach tight spaces and keeps every part of the blade smooth.

Polish edge

Polishing the edge gives your shredder blades a final touch. A polished edge reduces friction and helps the blade cut better. It also makes the blade last longer.

You can use a fine-grit sharpening stone or a polishing compound. Move the stone or cloth along the blade edge in smooth, even strokes. Wipe the blade clean after polishing to remove any leftover grit or metal dust.

- Polished blades cut materials like plastic, paper, and rubber more easily.

- A smooth edge helps prevent jams and uneven cuts.

- Polishing also protects the blade from rust and wear.

안전 수칙: Store the blade in a safe place after polishing. Keep it away from children and pets.

블레이드 교체 시기

Sometimes, sharpening and polishing cannot fix a blade. You need to know when to replace shredder blades for safety and performance. Look for these signs:

| Sign of Replacement | 설명 | Replacement Scenario |

|---|---|---|

| Decreased Throughput | The shredder works slower than before. | If speed does not improve after sharpening, replace the blade. |

| Excessive Vibration/Noise | The shredder shakes or makes loud sounds. | If noise stays after service, a new blade may be needed. |

| Rising Energy Consumption | The shredder uses more power than normal. | If energy bills go up, check the blade and consider replacement. |

| 자주 있는 잼 | The shredder jams often, even after cleaning. | If jams do not stop, a new blade can solve the problem. |

| Uneven Output | Shredded pieces look different or rough. | If cuts stay uneven, replace the blade for better results. |

| 증가하는 유지 관리 비용 | Repairs cost more than a new blade. | If you spend too much on fixes, get a new blade. |

| Outdated Safety Features | The shredder lacks modern safety parts. | Upgrade to a safer blade or shredder if needed. |

| Downtime Affecting Production | The shredder stops work too often. | If downtime is high, a new blade can help production. |

메모: If you see deep chips, cracks, or the blade cannot get sharp after several tries, it is time to replace it. Using a damaged blade can be dangerous and may harm your shredder.

Check your shredder blades often. Replace them when you see these signs. This keeps your shredder safe and working well.

Reinstall & Test

블레이드 정렬

After sharpening shredder blades, you need to put the blades back in the shredder. You must align each blade with care. Proper alignment keeps your shredder working smoothly and helps the blades last longer. If you do not align the blades, you may see uneven cuts or faster wear.

Here are steps you can follow to align the blades:

- Clean the blade slots and mounting surfaces before you start.

- Place each blade in its correct position. Make sure the edges line up with the feed direction.

- Check the calibration of the shredder components. Use a straight edge or alignment tool to confirm the blades sit evenly.

- Adjust the blade position if you see gaps or uneven spacing.

- Tighten the alignment screws gently. Do not force them, as this can bend the blades.

Misalignment can cause jams and damage. Take your time to get the alignment right.

Secure Fasteners

Once you align the blades, you need to secure them. Fasteners hold the blades in place during shredding. Loose fasteners can lead to vibration, noise, or blade movement.

Follow these steps to secure the fasteners:

- Use the correct bolts and nuts for your shredder model.

- Tighten each fastener in a cross pattern. This helps distribute pressure evenly.

- Check the torque with a wrench. Do not overtighten, as this can damage the blade or mounting plate.

- Inspect each fastener after tightening. Make sure nothing is loose or sticking out.

Always double-check your work. Secure fasteners keep your shredder safe and reliable.

테스트 실행

After you reinstall and secure the blades, you should run a test. Testing helps you spot problems early and ensures your sharpening shredder blades process worked well.

Listen for noise

Start the shredder and listen closely. You want to hear a smooth, steady sound. Loud noises, rattling, or grinding may mean something is wrong. Stop the machine if you hear anything unusual.

- Listen for clicking or banging sounds.

- Check for vibration or shaking.

- If you notice strange noises, turn off the shredder and inspect the blades.

A quiet shredder means the blades are installed and aligned correctly.

Check cut quality

You can check the sharpness and installation with simple tests. Try the paper test first. Feed a sheet of paper through the shredder. If the blade glides through and makes clean cuts, your sharpening shredder blades process succeeded.

Here is a table showing how different blade models perform after sharpening:

| Blade Model | Initial Cuts (sheets) | Dull After (passes) | Total Cut Length (feet) |

|---|---|---|---|

| Gerber Dime | 15 | 300 | 2175 |

| Leatherman Squirt PS4 | 20 | 400 | 4000 |

You can also use other tests:

- Hair whittling test: Try to slice a strand of hair with the blade. If it cuts easily, the edge is sharp.

- Three-finger test: Gently run your fingers along the blade edge (with gloves). You should feel a smooth, sharp surface.

Clean cuts and smooth operation show that your blades are sharp and installed correctly. Regular testing helps you catch problems before they affect your work.

유지 관리 팁

정기 청소

You need to clean your shredder blades after every use. This step helps you maintain the blades and keep your machine running smoothly. Remove all debris, dust, and leftover material from the cutting chamber. Use a brush or compressed air to reach tight spots. Wipe the blades with a dry cloth. If you see sticky residue, use a mild solvent and dry the blades completely before the next use.

팁: Cleaning after each session prevents buildup that can dull your sharp chipper knives and cause jams.

For best results, clean and maintain the blades daily. This habit reduces wear and helps you spot early signs of damage. Weekly, check the belt tension and clean the cooling vents. Monthly, do a deeper clean and inspect all moving parts.

Oiling Blades

Lubrication keeps your shredder working well. Oiling helps reduce friction and protects the blade surface. You can use two main methods to oil your blades.

Shredder oil method

Apply shredder oil directly to the blade edge. Use a small squeeze bottle or an oil applicator. Run the shredder for a few seconds to spread the oil evenly. This method works well for metal, plastic, and rubber shredders. Always use oil that matches your shredder’s requirements.

- Oil the blades after every deep cleaning.

- Check oil levels daily if you use the shredder often.

- Lubricate all moving parts monthly for best performance.

메모: Proper oiling helps you maintain the blades and keeps sharp chipper knives in top shape.

Paper oiling

You can also oil your blades by using oiled paper. Drip shredder oil onto a sheet of paper. Feed the paper through the shredder. The oil coats the blades as the paper passes through. This method is easy and safe for most paper shredders.

- Use this method weekly or after heavy use.

- Repeat the process if the blades seem dry or noisy.

Oiled paper helps you reach all blade surfaces and keeps your shredder running quietly.

Scheduled Inspections

Set a regular schedule to inspect your shredder blades. Check for dullness, cracks, and wear every 40 to 50 hours of use. Look for signs that you need sharpening chipper blades or replacement. Timely sharpening chipper blades keeps your machine efficient and safe.

- Inspect the blades after each cleaning.

- Schedule professional maintenance every six months for heavy use, or once a year for standard use.

- Always check for proper installation and clean and maintain the blades to avoid problems.

Regular inspections and service support from Nanjing Metal Industrial help you keep sharp chipper knives and extend blade life.

Avoid Mistakes

When you sharpen shredder blades, you need to be careful. Some mistakes can make blades wear out faster or cause safety issues. Using good technique and the right tools helps you get better results. It also keeps your shredder working well.

Over-sharpening

You may think sharpening shredder blades a lot is always good. But sharpening too much can make the blade edge thin and weak. Every time you sharpen, you take away some metal. If you do this too often, the blade gets too thin. Thin blades can break or chip when you use them.

팁: Only sharpen if you see dullness, like rough cuts or slow work. Do not sharpen just because it is time. If the blade still works, leave it alone.

Sharpening too much can change the blade’s angle. This makes the blade cut badly and uneven. Always check how thick the blade is before you start. If the blade feels light or looks much thinner, you may need a new blade instead of sharpening again.

Some signs of over-sharpening are easy to spot:

- The blade edge looks very thin or not even.

- You see chips or cracks after you sharpen.

- The blade does not stay sharp for long.

To stop this mistake:

- Look at the blade before you sharpen.

- Only sharpen when you need to, not every time.

- Use gentle strokes to keep the blade’s shape.

Wrong tools

Using the wrong tools for sharpening shredder blades can hurt the blade. Not all files, grinders, or stones work for every blade. A rough file can scratch the blade. A grinder that is too fast can make the blade too hot. Heat makes the metal weak and the blade does not last.

메모: Pick a sharpening tool that matches the blade’s material and design. Nanjing Metal Industrial blades work best with fine-grit stones or good files.

Common mistakes include:

- Using a tool that is too rough or too smooth for the blade.

- Pushing too hard, which can bend or chip the edge.

- Skipping the last step, which leaves rough spots.

You can stop these mistakes by doing a few things:

- Buy good sharpening tools that fit your blade.

- Use gentle moves and practice good technique.

- Clean your tools after you use them so they last.

- Store blades in a safe place to protect the edge.

Taking care of your sharpening shredder blades process with the right tools keeps you safe. It also helps your shredder work well.

If you avoid these mistakes, your shredder blades last longer. Your shredder will run smoothly. Always use careful technique and pick the right tools for the job.

문제 해결

선명도 주파수

Signs You Need to Sharpen

You should look for signs that show your wood chipper blades need sharpening. If you see rough or uneven cuts, the blades may be dull. When your shredder slows down or jams a lot, the blades might not be sharp. You could notice frayed pieces or hear odd sounds when shredding. These problems mean your wood chipper blades are not working right.

Tip: Always look at the blade edge for chips or cracks before you start shredding.

Factors Affecting Frequency

How often you sharpen wood chipper blades depends on many things. Hard materials like metal or tough plastic make blades dull faster than soft stuff. If you shred lots of PET bottle flakes, their hardness will wear down blades quickly. The place where you use the shredder matters too. Hot weather, wet air, or chemicals can make blades wear out sooner. If you use your shredder for a long time or do heavy work, you will need to sharpen the blades more often.

- Hard and strong materials make blades wear out faster.

- Heavy use or long shredding makes blades dull quickly.

- Hot, wet, or chemical-filled places shorten blade life.

- How many times you can sharpen depends on the blade’s starting shape.

- The kind of material you shred changes how often you need to sharpen.

- Foreign objects in the work area can make blades wear out faster.

- The amount of work the shredder does affects sharpening needs.

OEM/ODM Custom Blade Considerations

If you use custom wood chipper blades from an OEM or ODM, you must follow special care steps. Custom blades may have different shapes or materials that change how often you sharpen them. Always read the maker’s rules for your blade type. Check custom blades for damage after every use. If you see strange wear or damage, sharpen or replace the blades. Custom blades often need extra care to work their best.

교체 표지판

돌이킬 수 없는 손상

Sometimes, sharpening will not fix wood chipper blades. Look for these signs:

- Nicks, chips, cracks, or worn edges on the blades.

- Higher energy bills because the shredder works harder.

- More machine stops than usual.

- Finished products look wrong.

- The shredder gets too hot.

- Cutting takes longer than before.

- You need to fix the blades a lot.

- Safety problems.

If you see any of these, you should get new wood chipper blades right away.

Loss of Original Shape

When wood chipper blades lose their shape, they cannot cut well. You might see bent edges, round tips, or uneven spots. These changes make the blades work badly and can hurt your shredder. Always check the blade’s shape before putting it back in. If it does not look like the original, get a new blade.

Excessive Corrosion

Rust can ruin wood chipper blades. Rust spots, pits, or color changes make the blade weak and unsafe. If you see a lot of rust, do not try to sharpen the blade. Get a new one to keep your shredder safe and working well.

Uneven Wear

Causes of Uneven Wear

Wood chipper blades can wear out in different ways. Hard bits can scratch the blade and cause abrasive wear. Sticky stuff can make the blade lose metal, which is adhesive wear. Sometimes, a layer forms on the blade after shredding, called oxidation. Dents, scratches, or cracks can chip the blade. When many types of damage happen together, it is called progressive wear.

| Wear Mechanism | 설명 |

|---|---|

| Abrasive Wear | Material loss from hard particles. |

| Adhesive Wear | Material transfer and shearing off during sticky contacts. |

| Tribo-oxidation | Formation of Fe-oxide on blade surfaces after shredding. |

| 치핑 | Severe damage at the tip and nearby surfaces due to dents or cracks. |

| Progressive Wear | Results from a mix of abrasive, adhesive, and oxidation wear mechanisms. |

Identifying Uneven Edges

You can find uneven wear by looking at the blade edge. Look for shiny spots, rough places, or chipped parts. Use a flashlight to see small scratches or stress marks. Run a gloved finger along the edge to feel for bumps or dips. If you find uneven edges, sharpen or replace your wood chipper blades.

예방 조치

You can stop uneven wear by doing a few easy things:

- Change blade shape and position to lower wear.

- Check and fix blades often to spot damage early.

- Use blades made from materials that fight wear.

Note: Regular care and careful use help your wood chipper blades last longer and work better.

Persistent Dullness

Underlying Mechanical Issues

Sometimes, sharpening shredder blades does not fix dullness. The shredder might have problems inside. Worn bearings or loose shafts can make blades dull fast. Misaligned parts also cause trouble. If you hear grinding or see uneven cuts, check the moving parts. Tighten any bolts that are loose. Replace bearings if they look worn out. Make sure the shafts turn without sticking. Fixing these things helps blades stay sharp longer.

If your shredder sounds odd after sharpening, stop and check it. Fixing problems early stops bigger damage later.

Incorrect Sharpening Technique

Sharpening shredder blades the wrong way keeps them dull. Using the wrong angle or uneven strokes makes the edge bad. Always match the sharpening angle to the blade’s original shape. Use smooth and steady strokes. Do not press down too hard. If you see shiny or rough spots, try again with less pressure. Practice makes your sharpening better.

- Color the blade edge with a marker before sharpening. This shows if you remove metal evenly.

- Check the blade after a few strokes. Look for a smooth and even edge.

Material Compatibility Problems

Some blades do not work well with every material. Hard plastics or metal can dull blades faster. Some materials may even damage the edge. Always check if your blades fit the material you want to shred. If blades get dull after shredding something new, switch back to the right materials. Using the correct blade for each job stops dullness.

When you shred tough materials, check your blades more often. Sharpen or replace them when needed to keep your shredder working well.

Safety Concerns

Blade Installation Errors

Putting shredder blades in the wrong way can cause big problems. If blades are not lined up, you get uneven cuts or loud noises. Loose blades can move and hurt the shredder. Always follow the maker’s instructions when you install blades. Double-check that all bolts are tight and blades sit flat.

Operating Without Safety Gear

You must protect yourself when you sharpen or install shredder blades. Not wearing gloves or goggles is dangerous. You could get cut or hurt your eyes. Always use personal protective equipment like:

- 절단 방지 장갑

- 안전 고글

- Hearing protection

Training helps you use tools safely. Make sure you know how to handle blades and sharpening tools before you start.

Ignoring Warning Signs

Ignoring warning signs can cause accidents. If you see sparks or hear grinding, stop right away. If the shredder slows down, check for problems. Regular checks help you find issues early. Do not use the shredder if something feels wrong.

Safety comes first. Regular checks, the right gear, and careful installation keep you safe and help your shredder last longer.

Sharpen a Paper Shredder

Oiling Method

You can keep your paper shredder working well by using the oiling method. Oiling helps the blades move smoothly and stay sharp. You should use special shredder oil, not regular household oil. Shredder oil does not leave sticky residue and protects the blades from wear.

Here is a simple way to oil your shredder:

- 분쇄기의 전원을 끄고 플러그를 뽑으세요.

- Drip a small amount of shredder oil onto a sheet of paper.

- Feed the oiled paper through the shredder.

- Run the shredder in reverse for a few seconds to spread the oil.

- Wipe away any extra oil from the blades and the shredder opening.

Tip: Oil your shredder blades after every half hour of use. This keeps the blades sharp and prevents jams.

You can also use sharpening sheets. These sheets combine oil and a mild abrasive to clean and sharpen the blades at the same time.

Manual Sharpening

If you want to sharpen a paper shredder at home, you have a few easy options. You do not need special tools for most small shredders. One popular method uses aluminum foil. You can take a few sheets of aluminum foil and feed them through the shredder. The foil helps polish and sharpen the blades. This works best if the blades are only slightly dull.

- Use two or three sheets of foil for each sharpening session.

- Repeat every few weeks to keep the blades in good shape.

If your shredder has built-in sharpening features, check the user manual for instructions. Some shredders have a special mode that sharpens the blades automatically. If your blades are very dull or damaged, you may need to ask a professional to sharpen or replace them.

Note: If the aluminum foil method does not work, do not force more sheets through. You could damage the motor or blades.

유지 관리 팁

Regular care helps your paper shredder last longer and work better. You should clean the blades and the shredder chamber after each use. Remove paper dust and small bits with a soft brush or compressed air. Always unplug the shredder before cleaning.

Here are some easy maintenance tips:

- Oil the blades often to prevent friction and buildup.

- Use sharpening sheets or aluminum foil every few weeks.

- Check for jams and remove stuck pieces right away.

- Inspect the blades for chips or dull spots.

- Read the user manual for any special care instructions.

| 유지 관리 작업 | 얼마나 자주 | 왜 중요한가 |

|---|---|---|

| Oiling blades | Every 30 minutes | Keeps blades sharp and smooth |

| Cleaning chamber | 매번 사용 후 | Prevents jams and buildup |

| Sharpening blades | Every few weeks | Maintains cutting quality |

| Checking for damage | 월간 간행물 | Avoids costly repairs |

Regular maintenance helps you avoid problems and keeps your shredder working safely.

Sharpening Wood Chipper Blades

Removal Steps

You need to remove the blades from your wood chipper before you start sharpening. Always turn off the chipper and unplug it. This keeps you safe from moving parts. Put on gloves and safety goggles. Open the chipper housing and find the blade assembly. Use the right tools to loosen the bolts or screws. Take out the blades carefully. Place them on a clean, stable surface.

Tip: Follow the manufacturer’s instructions for your chipper model. This helps you avoid mistakes and keeps the machine in good shape.

Check each blade for damage. Look for chips, cracks, or bent edges. Clean off any dirt or debris with a cloth. If you see deep cracks or missing pieces, you should replace the blade instead of sharpening.

날카롭게 하는 과정

Sharpening wood chipper blades helps you keep your machine working well. You can use a bench grinder or a sharpening stone. Set the miter at 90 degrees and the table at 45 degrees if you use a grinder. Move the blade back and forth across the wheel with slow, steady motion. Dip the blade in water often to keep it cool. Overheating can make the metal weak.

Use even pressure when you sharpen. Work along the whole edge to keep it straight. Remove any burrs after sharpening. Burrs can make the blade dull faster. If you have more than one blade, balance them. Balanced blades stop vibrations and help your chipper run smoothly.

Here is a simple table to help you remember the steps:

| 단계 | 해야 할 일 |

|---|---|

| Set angles | Miter at 90°, table at 45° |

| Sharpen evenly | Move blade slowly across wheel or stone |

| Cool blade | Dip in water often |

| Remove burrs | Use a fine file or stone |

| Balance blades | Check weight and shape of each blade |

Note: Sharpening chipper knives with care helps you get clean cuts and keeps your chipper safe.

Reinstallation

After you finish sharpening, you need to put the blades back in the chipper. Make sure each blade is dry and free of debris. Place the blades in their slots. Line up the edges with the feed direction. Tighten the bolts or screws to the correct torque. Do not overtighten, as this can bend the blade.

Check that all blades sit evenly. Spin the drum by hand to make sure nothing rubs or sticks. Close the chipper housing and plug in the machine. Run a test with a small branch or piece of wood. Listen for smooth operation and check the cut quality.

Regular cleaning and lubrication after each use help your chipper blades last longer. Set a sharpening schedule based on how often you use the chipper. Replace blades when they are too damaged to sharpen.

Sharpening shredder blades often helps you spend less money. It also makes your shredder cut better and keeps it safe. If you take care of your blades, they last longer. You will have fewer problems with your shredder.

- Clean your blades and look at them often.

- Pick the right tools to sharpen shredder blades.

- Check your blades on a schedule to find issues early.

자주 묻는 질문

How often should you sharpen shredder blades?

You should check your shredder blades every 40 to 50 hours of use. If you notice dull cuts or jams, sharpening shredder blades right away helps keep your machine working well.

Can you sharpen all types of shredder blades?

Yes, you can sharpen most shredder blades, including single-shaft, double-shaft, and multi-claw designs. Always use the right tools and follow the correct sharpening shredder blades process for your blade type.

What tools work best for sharpening shredder blades?

You can use a file, sharpening stone, or grinder. Pick a tool that matches your blade’s material and shape. For best results, use a fine-grit stone or a quality file.

How do you know when to replace a shredder blade?

Replace your blade if you see deep chips, cracks, or if sharpening shredder blades does not restore a sharp edge. Blades that lose their original shape or show heavy rust also need replacement.

Is it safe to sharpen shredder blades at home?

Yes, you can sharpen shredder blades at home if you follow safety steps. Always unplug the machine, wear gloves and goggles, and use a stable work surface.

Does sharpening shredder blades improve performance?

Sharpening shredder blades helps your shredder cut cleaner and faster. Sharp blades reduce jams and lower energy use. You get better results with less effort.

Can you use oil when sharpening shredder blades?

You can use a little oil on the sharpening stone to make the process smoother. Oil helps remove metal dust and keeps the blade edge even.

What happens if you over-sharpen shredder blades?

Over-sharpening shredder blades makes the edge thin and weak. Thin blades can break or chip easily. Only sharpen when you see signs of dullness.

또한 참조

산업용 분쇄기 블레이드 및 그 응용 분야에 대한 가이드

단일 샤프트 분쇄기 블레이드의 비밀 풀기: 유지 관리, 선택 및 문제 해결 가이드

분쇄기 블레이드: 분류, 재료 선택, 서비스 수명 및 설계 기술 분석