When you recycle tires, 타이어 슈레더 블레이드 are very important. The right blades help your work go faster and smoother. They also give you cleaner results and can save you money. New technology, like dual-shaft and quad-shaft systems, has made things better for many places. Look at how these different technologies compare:

| Technology Type | 효율성에 미치는 영향 | 비용 절감 |

|---|---|---|

| Dual-shaft and quad-shaft | More tires shredded, uses less energy | Costs less to run |

| AI-driven optimization | Changes for different tires and sizes | Less waste, more good results |

You might want to check your blades now. Upgrading them could help your work a lot.

주요 요점

- Tire shredder blades are very important for recycling tires. The right blades make the job faster and give better results.

- If you use high-quality blades, you can save a lot of money. Good blades mean less time fixing machines and lower repair costs.

- New technologies, like dual-shaft systems, help shredders work better. They let you shred more tires using less power.

- Check and take care of your blades often to stop sudden problems. This helps your machines work well and saves you money.

- Custom blades made for your needs can make recycling better. They help you cut different kinds of tires and materials easily.

- Strong, high-quality blades last longer and work better. You will not need to replace them as much, and they give steady results.

- A good blade design is very important for shredding well. Things like blade thickness and edge shape change how well they cut and how the machine works.

- Buying advanced blades helps you work faster and helps the environment. It cuts down on waste and helps you get more useful material.

Tire Shredder Blades and Recycling Efficiency

Tire shredders are very important in recycling. Tire shredder blades are the main part of these machines. Using the right blades helps you work faster. You also get cleaner materials and less waste. Let’s see how this helps you.

Blade Quality and Performance

You want tire shredders that last a long time. The quality of the blades matters a lot. Good materials and careful making help your machines work better. 난징 Metal 산업 checks every blade with a careful process. This makes sure each blade is strong and sharp. Here’s what makes the best blades different:

| 특징 | 고품질 블레이드 | 저품질 블레이드 |

|---|---|---|

| 능률 | Works faster and better | Slower and may stop working |

| 내구성 | Lasts longer with strong materials | Wears out faster and breaks easier |

| 재료 품질 | Made from strong tool steel | Made from weaker materials |

| 정밀 가공 | Sharp edges from careful cutting | Not as sharp, gets dull quickly |

| Performance Consistency | Works well with many types of tires | May not work well with tough tires |

블레이드 난징 Metal 산업 go through many steps to make them strong. You can trust them for hard jobs.

Impact on Steel and Rubber Separation

Tire shredders do more than just cut tires. They help you take steel out of rubber. This is important for recycling. Good blades make this job easier. You get cleaner rubber and steel. You can sell or use these materials without extra work. You do not need to change your equipment. Here’s how good blades and machines help:

| 측면 | 설명 |

|---|---|

| Precision Craftsmanship | Blades are made with care in many steps for best results. |

| Proprietary Manufacturing | Working with big companies makes blades work better. |

| Versatility of Machines | Machines can handle many kinds of tires for better recycling. |

Tip: Cleaner separation means less waste and more money for you.

You also help the planet. Good tire shredder blades save space in landfills. They stop water from collecting in tires. They lower the chance of fires. You make recycling safer for everyone.

- Environmental Protection: Less landfill space and fewer health problems.

- Resource Recovery: More rubber for new things, less pollution.

- Waste Reduction: Smaller pieces are easier to move.

- Fire Prevention: Shredded tires are less likely to catch fire.

Role in Reducing Downtime

You want tire shredders that do not stop often. Good blades help your machines keep working. Smart tools let you check blades before they break. You can fix things before they cause problems. This means your machines work longer and you spend less money fixing them. You get more work done and save money.

New blades and technology let you watch blade health all the time. You know when to change or fix them. This keeps your machines running well. You avoid sudden problems. You use your equipment better and spend less.

Note: Less downtime means you can recycle more tires and keep your business moving.

What Defines High-Quality Tire Shredder Blades

If you want good tire shredders, you need strong blades. High-quality tire shredder blades help your recycling work go better. These blades make your job easier and more steady. Let’s look at what makes these blades special.

Materials and Durability

Tires are hard to cut, so you need tough materials. The right material helps blades last longer and cut well. Here are some strong choices:

| 재료 | 속성 | Lifespan Comparison |

|---|---|---|

| 합금강 | Strong and does not rust; good for wet places | Moderate to High |

| 카바이드 | Very hard and does not wear out fast; good for rough stuff | 높은 |

| 냉간 가공 다이스 강 | Wears down slowly and is tough; saves money for some jobs | Moderate to High |

If you pick these materials, you change blades less often. You also finish more work with your tire shredders. Nanjing Metal Industrial uses special heating and shaping to make blades stronger. You can get custom blades for your needs on the 커스텀 블레이드 페이지.

Tip: The right material helps your tire shredders last longer and break less.

블레이드 디자인 특징

Blade design is very important for tire shredders. The shape, thickness, and edge style change how your machine works. Here is how these features help:

| 측면 | 설명 |

|---|---|

| Rigidity | Thick blades stay strong and do not bend. |

| 에너지 효율성 | Thin blades cut better and use less power. |

| 절단 품질 | Thin blades make clean cuts but can bend. |

You want blades that can cut rubber and plastic. Strong blade shapes and tough tips help tire shredders last longer. Wide edges spread out the force, so blades wear down slower.

- Edge shape helps with hard jobs.

- Blades should keep cutting and not wear out fast.

- Good design lets tire shredders cut tires quickly and neatly.

제조공정

How blades are made is very important. Good making means tire shredders work better and last longer. Here is what to look for:

- Blades made to be strong and exact.

- Made from good materials so they last longer.

- Designed to cut tough tires easily.

- Built for hard work in tire shredders.

- New designs help with new recycling jobs.

- Works with many tire shredders for more choices.

Industry rules matter too. Certifications like ISO 9001 and CE show blades are safe and high quality. Here is a quick guide:

| 인증 | Impact on Product Reliability |

|---|---|

| ISO 9001 | Follows rules for good quality. |

| CE | Meets European safety rules for safer blades. |

| ISO 14001 | Shows care for the planet and good making. |

Note: Good manufacturing means your tire shredders stay strong and safe for a long time.

Tire Shredding Process Optimization

Making the tire shredding process better helps your recycling work. Picking the right blade is important at every step. You can shred more tires and get better pieces. It is also easier to work with different materials. Let’s see how you can make each part work best for you.

Primary Shredding

Primary shredding is the first step. Tire shredders cut whole tires into big pieces. The blade you use here is very important. These machines turn slowly but use strong force. They break tires into chunks that are two to eight inches wide. You can shred up to 30 metric tons every hour. This means you move lots of tires fast.

- Triangular blades help the machine work better.

- These blades last longer, so you buy new ones less often.

- V-shaped spiral blades give even force for every tire.

- You get the same results each time you shred.

- Extra knives clean the main blades by themselves. This keeps the machine working well.

Primary shredding makes waste smaller. It is easier to move and sort. You help the planet by keeping tires out of landfills. You also help old materials get used again.

Tip: The right blades for primary shredding mean less stopping and better recycling.

Secondary Shredding

After the first cut, you do secondary shredding. This step makes the pieces smaller and all the same size. Special blades help you get tiny pieces. You need this for making fuel or reusing plastic.

- Sizing screens let only small pieces go forward.

- You can pick the screen size you want. This gives you better shredded pieces.

- Changing the space between blades lets you pick the size you need.

- You get the same size pieces every time.

- Same size pieces burn better if you use them for fuel.

With the right blades for this step, you get cleaner and purer material. You can use it for more things and get better results.

Note: Adjusting your secondary shredding helps you meet tough quality rules.

Customization for Specific Needs

Not every tire shredding job is the same. You may have different tire sizes or mixed materials. Custom blades help with these problems. Triplus® knife design works for many tire types. You can shred rubber, steel belts, and fiber parts well.

- Custom blades wear out slower and last longer.

- You shred more tires and get better pieces.

- New technology helps you separate materials better. The next steps are easier.

Multi-shaft and claw blade designs help with hard or big waste. Here is a quick look at both:

| Design Type | 장점 | 단점 |

|---|---|---|

| 다축 | Good for tough materials | May not work well with stretchy things |

| Claw Blade | Pulls in big items, stops jams | 만들기가 더 어렵다 |

You can pick the best blade for your machine and your job. This helps you handle any recycling problem.

Tip: Custom blades and setups let you shred more kinds of tires and materials with less trouble.

If you make each step better, you get better results. You save money and your machines work better.

Operational Benefits of Advanced Blades

When you use advanced blades in your tire shredders, you get many good things. These new blades can make your recycling work much better. Let’s see how these changes help you do more with less effort.

Productivity Gains

You want your tire shredders to be fast and handle more tires. Advanced blades help you do this. They cut tough rubber easily, so you finish more tires in less time. Here is what happens when you use new technology:

- Automation and smart tools make work safer and easier.

- IoT lets you watch how your shredder works right now.

- Predictive tools warn you about problems before they stop your machine.

- Data tools change settings by themselves for the best results.

- Fast cutting machines help you finish jobs sooner.

- You can shred more tires without hiring more people.

- Better efficiency means you spend less and earn more.

You notice these changes every day. Your team fixes fewer problems and gets more work done. You also get cleaner steel and rubber to sell or use again.

Tip: Advanced blades make your tire shredders work better and help your business grow.

Maintenance and Lifespan

It is hard when your tire shredders break a lot. Advanced blades help stop this. They are made from strong materials and smart designs. They cut rubber but do not wear out fast. This means you do not spend as much time or money fixing them.

These blades last longer than normal ones. You do not have to stop your machines often to change or sharpen them. Over time, you get more hours of work and fewer problems. Your tire shredders keep running, so you finish jobs and keep customers happy.

Note: Blades that last longer mean less stopping and more recycling.

비용 효율성

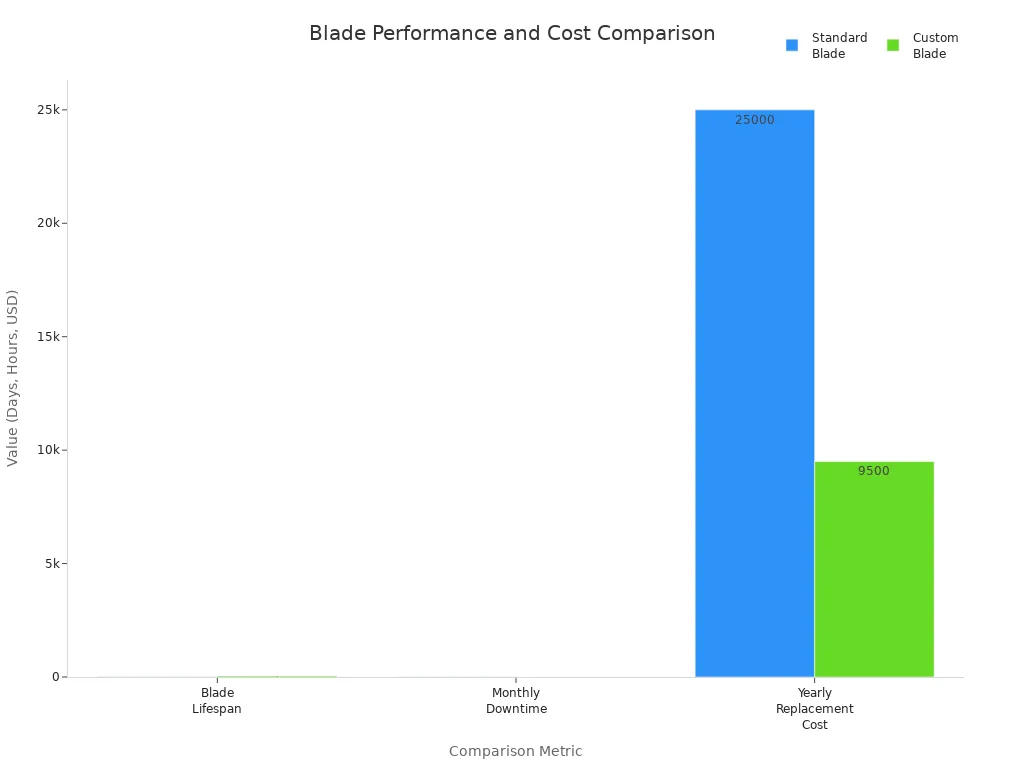

You want to save money where you can. Advanced blades help you do this. They last longer, so you do not stop as much. You also do not need as many emergency repairs. Here is how the numbers compare:

| 비교 | 표준 블레이드 | 커스텀 블레이드 |

|---|---|---|

| 블레이드 수명 | 10일 | 40일 이상 |

| 월별 다운타임 | 16시간 | 5시간 |

| 연간 교체 비용 | $25,000 | $9,500 |

You can see the difference right away:

- Downtime is 65% less with custom blades.

- Emergency repairs drop by 70%.

- Blade life can be 50% longer.

These savings give you more money for other things. You also do not worry about machines breaking all the time. With good tire shredders, you can plan better and keep working.

Callout: Buying advanced blades saves money fast. You do more work, fix less, and keep recycling moving.

Buyer Concerns and Solutions

When you want new blades for your tire shredders, you may have many questions. You want blades that last a long time. You want them to be easy to take care of. You also want to buy from someone you trust. Let’s look at the most important things to think about.

Blade Replacement Cycles

You want blades that work well for a long time. If you change blades too much, you lose time and money. Many recycling places have problems like blade wear, jams, and motor trouble. You can fix these problems by using high-quality blades and checking them often.

Here is a table with common problems and how to fix them:

| 도전 | 해결책 |

|---|---|

| Blade wear | Check blades often. Sharpen or change them when needed. Use strong materials. |

| Jamming issues | Sort tires before shredding. Use metal detectors. Pick machines that stop jams. |

| Motor problems | Take care of the motor. Do not push machines too hard. |

| Noise and vibration | Make sure blades are lined up. Change old bearings. Use pads to stop shaking. |

| Dust accumulation | Clean often. Use dust collectors. |

| Hydraulic system failures | Look for leaks. Change fluid and filters when needed. |

Tip: Checking your blades and picking the right material helps you stop surprise problems and keeps your tire shredders working.

유지 관리 팁

Taking care of your blades helps them last longer. You do not need special tools, just good habits. Here is a table with easy steps you can do every day:

| Maintenance Practice | 설명 |

|---|---|

| Daily Inspection | Look for broken or chipped blades before you start. This helps you stop big problems. |

| 청소 | Clean off dirt after each shift. Less dirt means blades stay sharp. |

| Correct Operation | Teach your team to feed tires slowly and smoothly. This keeps blades from wearing out fast. |

| Periodic Sharpening | Sharpen blades when they get dull. Try to keep the edge the same. |

| 문제 해결 | Watch for dull blades or uneven cuts. Fix these problems fast to keep things working. |

If you do these things, you will fix machines less and recycle more. You can also ask your supplier for tips on blade care.

Note: Good care means fewer problems and more steady work.

Supplier Selection

Picking the right supplier is as important as picking the right blade. You want someone who knows what you need and helps you get good results. Here is a simple list to help you:

- Know your work area and what you shred. Think about wetness, heat, and how tough the tires are.

- Think about cost. Look at price and how long the blade lasts. Spending more now can save money later.

- Make sure the blade fits your machine and works with your setup.

Nanjing Metal Industrial gives OEM and ODM services. You can get blades made just for your machines. They check materials before making blades and test each blade many times. You can send them your drawings or samples, and they will help you get the right design.

| 품질 관리 조치 | 설명 |

|---|---|

| Material Inspections | They check materials before making blades to make sure they are good. |

| Quality Checks | They check blades many times while making them. |

| 사용자 정의 옵션 | You can change designs to make blades work better for you. |

| Testing and Inspections | They check blades at every step, from start to finish. |

- You can get custom designs for your needs.

- They help you change designs for better results.

- You get blades that fit your recycling work.

Callout: A good supplier helps you save money, avoid problems, and get blades that fit your tire shredders just right.

Expert Tips for Tire Shredder Blades

Matching Blades to Operations

Picking the right blade is very important. You need blades that fit the material you shred. If you use the wrong blade, it wears out faster. You also get messy cuts. Look at this table to help you choose:

| 폐기물 유형 | Best Blade Material | Reason for Selection |

|---|---|---|

| Paper & Cardboard | Carbon Steel or Low-Alloy Tool Steel | These blades work well because paper is soft. They do not wear out fast. They also cost less. |

| Plastics (Soft & Hard) | Tool Steel (D2, H13) or High-Speed Steel (HSS) | These blades are strong. They can cut plastic many times without breaking. |

| Rubber & Tires | H13 Tool Steel or Bimetallic Blades | These blades are tough. They can handle rubber and steel inside tires. |

| Wood & Biomass | H13 or D2 Tool Steel | These blades are hard and strong. They can cut wood with knots and nails. |

| Metals (Aluminum, Copper, Thin Steel) | H13 or M6V | H13 blades do not chip. M6V blades stay sharp longer. |

| E-Waste (Circuit Boards, Wires, Electronics) | M6V or Tungsten Carbide (TCT) | These blades are very tough. They can cut hard things like glass and metal. |

Rubber and tires need strong blades. H13 tool steel or bimetallic blades are best. For other materials, check the table for the right blade. Using the right blade helps you save money and get better results.

Tip: Always pick a blade that matches your waste. This helps your blades last longer and makes shredding easier.

Monitoring and Replacement

You want your blades to work well every day. Check them often to find problems early. Look for chips, dull edges, or other damage. If you see any, sharpen or change the blade right away. Bad blades slow down your machine. They also make shredding harder. Sharp blades give you clean cuts and steady work.

Make a plan to check blades on a schedule. Write down what you see each time. This helps you know when to change blades before trouble starts. Use simple tools to check blade thickness and sharpness. If your machine slows down or cuts badly, check the blades first.

Note: Fixing blade problems quickly keeps your tire shredding smooth. It also stops long breaks and saves money.

직원 교육

Your team helps keep blades safe and working well. Training teaches everyone how to use machines and care for blades. Here are ways training helps:

- Workers learn to run shredders and do maintenance.

- Training helps staff spot dangers and use safety gear.

- Skill checks make sure everyone knows what to do.

You can have short training before each shift. Show your team how to check blades and report problems. Remind them to follow safety rules and wear gear. When everyone knows their job, tire shredding is safer and works better.

Callout: Trained workers help stop accidents. They keep machines running and get the most from your blades.

Picking the right blades is very important for tire recycling. Good blades help you work faster and get cleaner results. You also have less machine stopping time. Many companies saw big changes after they switched blades. Some finished jobs 30% faster. Others got better tire-derived fuel. These changes happen when places upgrade their shredders or get help from experts.

- Better blades let you collect more tires and reach new goals.

- Custom blades match your needs and help recycle more things.

Want to improve your recycling? Ask a sales engineer at Nanjing Metal Industrial for help picking the best blades. 오늘 저희에게 연락하세요.

자주 묻는 질문

What are tire shredder blades?

Tire shredder blades are special cutting tools. You use them in machines to break down old tires. These blades help you turn whole tires into small, reusable pieces.

How often should I replace tire shredder blades?

You should check your tire shredder blades every week. Replace them when you see chips, dull edges, or cracks. Regular checks help you avoid machine problems.

Can I use the same blades for different materials?

You can use some tire shredder blades for rubber, plastic, or wood. For best results, pick blades made for your main material. This helps your machine work better.

What makes a tire shredder blade high quality?

High-quality tire shredder blades use strong steel. They have sharp edges and precise shapes. Good blades last longer and give you cleaner cuts.

How do I maintain tire shredder blades?

Clean your blades after each use. Check for damage before you start the machine. Sharpen dull blades right away. These steps help your blades last longer.

Why does blade design matter in tire shredding?

Blade design changes how well your machine cuts tires. The right shape and thickness help you get even pieces. Good design also keeps your machine from jamming.

Are custom tire shredder blades worth it?

Custom tire shredder blades fit your machine and your needs. You get better results and less downtime. Many recycling centers choose custom blades for tough jobs.

How do tire shredder blades help with recycling?

Tire shredder blades break tires into small parts. This makes it easier to separate rubber and steel. You can recycle more material and help protect the environment.

또한 참조

효율적인 재활용을 위한 플라스틱 슈레더 블레이드 선택 방법

산업용 분쇄기 블레이드 및 그 응용 분야에 대한 가이드