Cortando o problema

Os fabricantes enfrentam uma pressão crescente para cortar materiais de forma mais rápida, limpa e com menos desperdício. As lâminas mecânicas tradicionais muitas vezes têm dificuldade em acompanhar o ritmo. Elas deixam bordas desfiadas, retardam a produção e causam perdas dispendiosas de material. É aí que entra a faca de corte quente chega — uma solução de corte mais inteligente, precisa e altamente eficiente.

Vamos explorar por que as facas de corte a quente estão transformando indústrias e como elas podem beneficiar suas operações.

1. Por que usar uma faca de corte a quente? Principais vantagens

1.1 Cortes limpos e precisos: o poder das bordas seladas a quente

As facas de corte a quente utilizam uma lâmina aquecida eletricamente — normalmente entre 200 °C e 600 °C, dependendo do tipo de material — para cortar os materiais derretendo a área de contato. Essa técnica não apenas corta, mas também sela as bordas do tecido simultaneamente. O resultado? Um acabamento liso e selado, sem desfiar, ideal para materiais sintéticos e multicamadas.

Isso é especialmente valioso em setores onde a aparência do produto e a durabilidade das bordas são importantes. Em aplicações têxteis, testes demonstraram que as lâminas de corte a quente reduzem o desfiamento das bordas em mais de 90% em comparação com as lâminas a frio tradicionais (Fonte: Revista de Têxteis Técnicos, 2022).

🔬 Como funciona: O calor amolece fibras termoplásticas como poliéster ou náilon. À medida que a lâmina passa, ela derrete e reune as fibras da lâmina, formando uma vedação firme.

| Método de corte | Resistência à desfiação de bordas | Acabamento pós-corte necessário? | Adequação do material |

| Lâmina de Aço Tradicional | Baixo | Sim | Papel, chapas metálicas |

| Faca de corte quente (lâmina aquecida) | Alto | Não | Poliéster, Nylon, Cintas, Laminados |

Em mercados de alta precisão, como têxteis médicos ou interiores aeroespaciais, a capacidade de garantir a integridade das bordas é essencial para a segurança e a estética.

1.2 Velocidade escalável: aumentando a produção com ferramentas de corte com faca quente

Tempo é dinheiro na indústria. Com facas de corte a quente, você ganha ambos.

Como essas facas cortam e selam em um único movimento, não há necessidade de pós-processamento, como aparar ou queimar as bordas. Isso se traduz em uma redução de 25–40% no tempo total do ciclo, dependendo da aplicação.

Um estudo de 2023 realizado por Insights da CuttingTech descobriram que as fábricas que usam ferramentas de corte com faca quente em suas linhas de embalagem relataram:

- Aumento da produtividade do 32%

- 22% redução nas horas de trabalho por lote

- 18% redução nos custos de energia (devido a ciclos de processamento mais rápidos)

| Processo | Tempo por unidade | Etapas necessárias |

| Acabamento tradicional de corte e borda | 18–22 segundos | Cortar → Aparar → Selar a quente |

| Faca de corte quente | 10–14 segundos | Corte a quente em uma etapa |

Em sistemas de produção vertical de alta velocidade, como processamento de tecido rolo a rolo ou produção contínua de correias, as lâminas de corte a quente integram-se a sistemas automatizados e reduzem o tempo de inatividade causado pela substituição ou atolamentos de lâminas.

1.3 Construído para versatilidade: uma ferramenta, muitos setores

As facas de corte a quente não se limitam a apenas um setor. Seu verdadeiro ponto forte reside na compatibilidade com diversos materiais, incluindo:

- Têxteis sintéticos: poliéster, nylon, misturas de Kevlar

- Filmes plásticos: filme retrátil, espuma EVA, vinil

- Espumas e compósitos: isolamento automotivo, EVA, espumas de células fechadas

- Tecidos técnicos: aramidas, tecidos revestidos, meios filtrantes

Em setores como o aeroespacial, onde laminados compostos são empilhados e unidos, ou o automotivo, onde os materiais do forro do teto e das capas dos assentos são multicamadas, as facas de corte a quente oferecem resultados consistentes mesmo em contornos irregulares ou curvos.

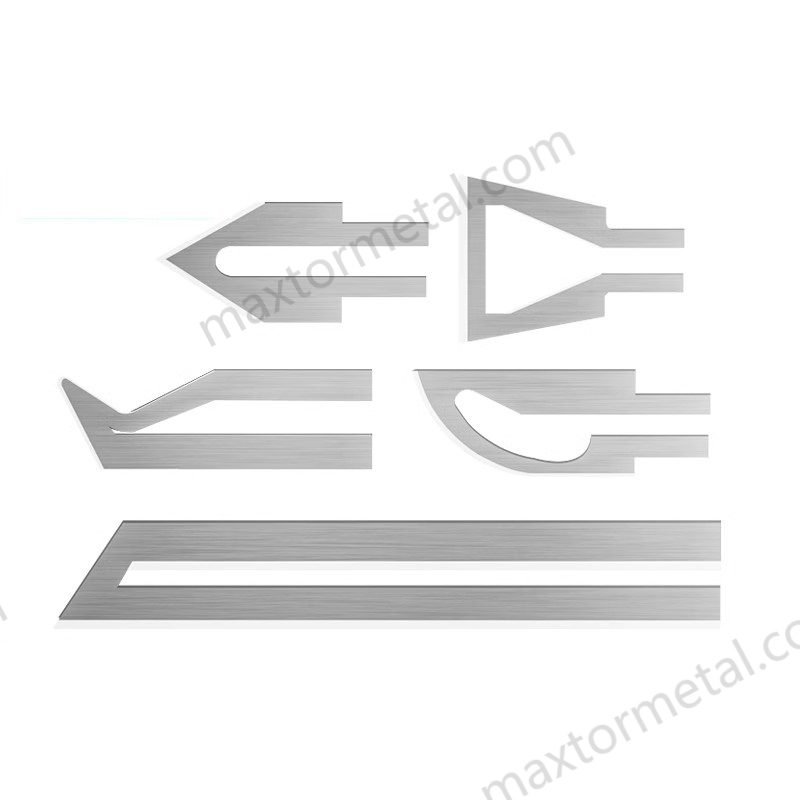

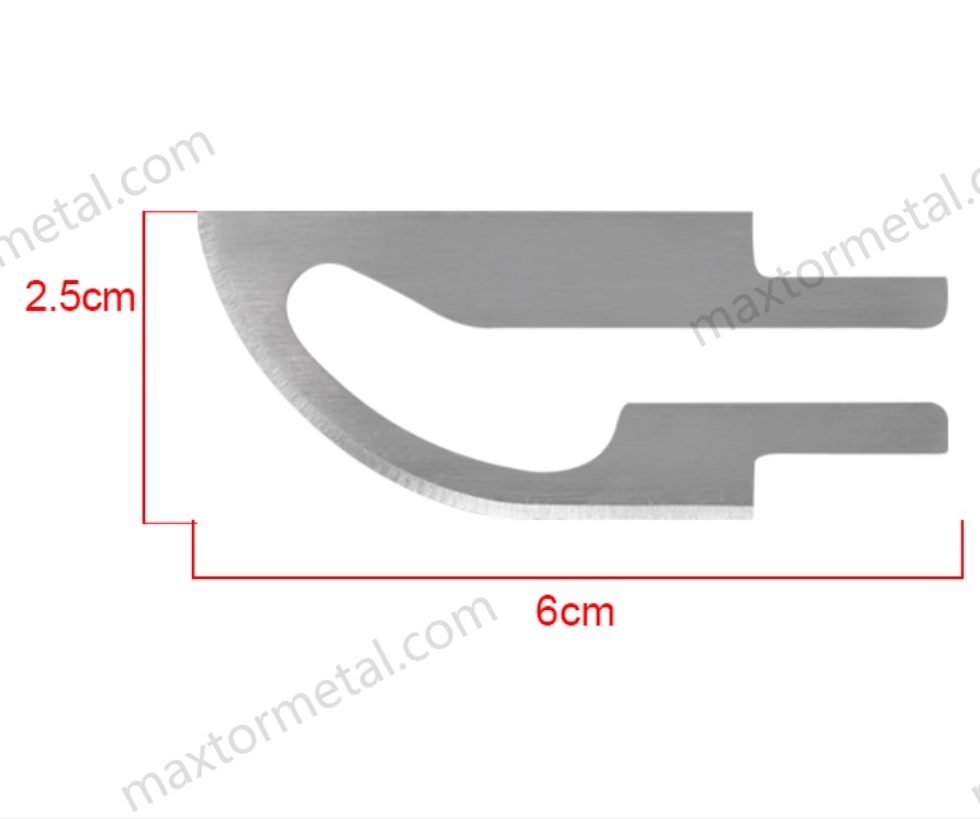

🛠 Dica profissional: Com configurações de calor ajustáveis e lâminas intercambiáveis (planas, curvas, entalhadas), as facas de corte a quente podem se adaptar a dezenas de demandas de produção usando uma única máquina.

2. O ROI das facas de corte a quente

2.1 Menos desperdício, maior rendimento: cortando custos cortando corretamente

Resíduos, defeitos e perda de tempo drenam os lucros. Ao adotar lâminas de corte a quente, os fabricantes não só economizam material, como também aumentam a produtividade.

Com base na avaliação comparativa realizada pela Associação Europeia de Eficiência de Corte (ECEA, 2023), a economia média após a mudança para sistemas de facas de corte a quente foi:

- Resíduos de matéria-prima: ↓65%

- Retrabalho/rejeições: ↓50%

- Tempo de inatividade da ferramenta: ↓40%

| Categoria de Custo | Lâminas Tradicionais | Sistema de faca de corte a quente |

| Resíduos médios (por 1000 cortes) | 80–120 unidades | 20–30 unidades |

| Taxa de Defeitos (%) | 8–12% | 2–4% |

| Custo de acabamento pós-corte ($) | $0,05–$0,10/item | $0 |

Isso significa mais produto utilizável por rolo, menor custo operacional por corte e menos intervenções do operador. Mesmo um aumento de 5% no rendimento ao longo de um ano pode resultar em dezenas de milhares de dólares economizados, especialmente em fábricas têxteis ou de embalagens de alto volume.

2.2 Durável e de baixa manutenção: construído para durar mais

Ao contrário das lâminas tradicionais que perdem o corte rapidamente devido à abrasão mecânica, as facas de corte a quente sofrem degradação mínima do fio porque o calor faz a maior parte do trabalho, e não a pressão ou o atrito.

Os sistemas modernos de facas quentes usam revestido de cerâmica ou lâminas de aço inoxidável combinadas com controladores de temperatura regulada, permitindo que as lâminas permaneçam eficazes após milhares de cortes.

Principais métricas de durabilidade (com base nos testes internos do Nanjing Metal):

- Vida útil da lâmina: até 3 a 5 vezes maior que as lâminas mecânicas

- Frequência de substituição: Uma vez a cada 4–6 semanas (em vez de semanalmente)

- Tempo médio de manutenção por semana: menos de 15 minutos

🔧 Lista de verificação de manutenção:

– Limpe os depósitos de carbono semanalmente

– Verifique o alinhamento das lâminas mensalmente

– Substituir a serpentina de aquecimento anualmente (com base na operação média de 2 turnos)

Este modelo de manutenção de baixo contato é ideal para operações contínuas de alta velocidade, onde o tempo de inatividade é igual à perda de receita.

3. Resultados do mundo real: história de sucesso do cliente

Cliente: GlobalTex Co. – Istambul, Turquia

Indústria: Têxteis técnicos (cintas, correias, tecidos para exterior)

Desafio:

- 12% de produto estavam sendo descartados devido a bordas desfiadas

- 3 operadores necessários para aparar pós-corte e selar com chama

- A capacidade de produção foi limitada a 1.200 unidades/hora

Solução:

A GlobalTex mudou para a estação de facas de corte a quente totalmente integrada da Nanjing Metal, construída sob medida com cabeçotes de lâmina dupla e alimentação automatizada.

Resultados (após 6 meses):

| Métrica | Antes | Depois (Corte Quente) | Melhoria |

| Taxa de sucata | 12% | 3.5% | ↓ 71% |

| Produção (unidades/hora) | 1,200 | 1,680 | ↑ 40% |

| Custo de mão de obra por dia | $300 | $180 | ↓ 40% |

| Devoluções de produtos (mensais) | 80 unidades | 39 unidades | ↓ 51% |

“Costumávamos passar horas aparando fios soltos. Agora podemos trabalhar em turnos mais longos com menos defeitos e um produto mais limpo. O ROI ficou claro em três meses.”

— Ali Demir, gerente de operações, GlobalTex Co.

Este caso mostra claramente como a tecnologia de lâmina correta não apenas melhora a qualidade do produto, mas também reduz o custo total de propriedade (TCO) ao longo do tempo.

4. Soluções de lâminas personalizadas por Nanjing Metal

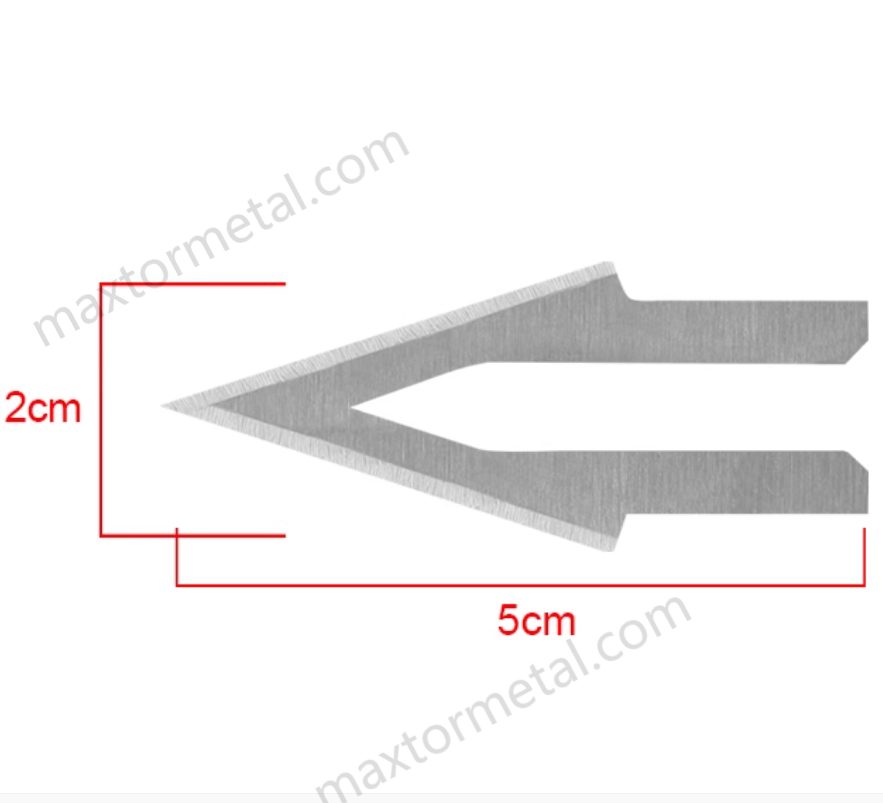

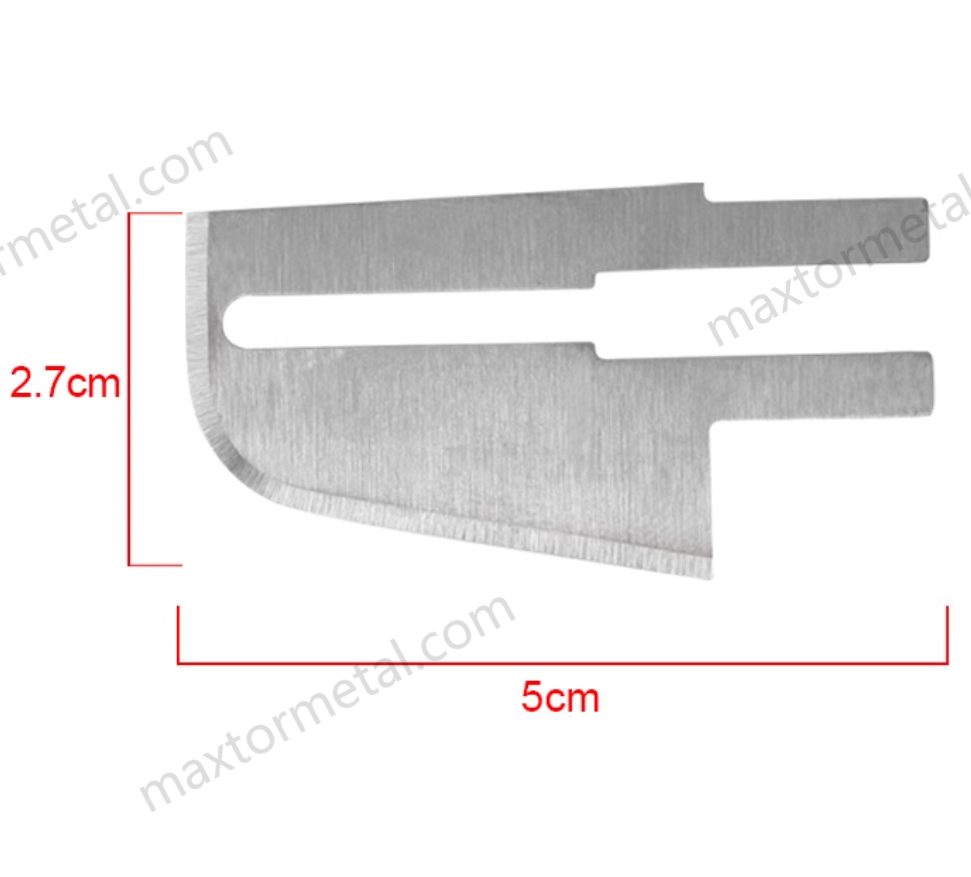

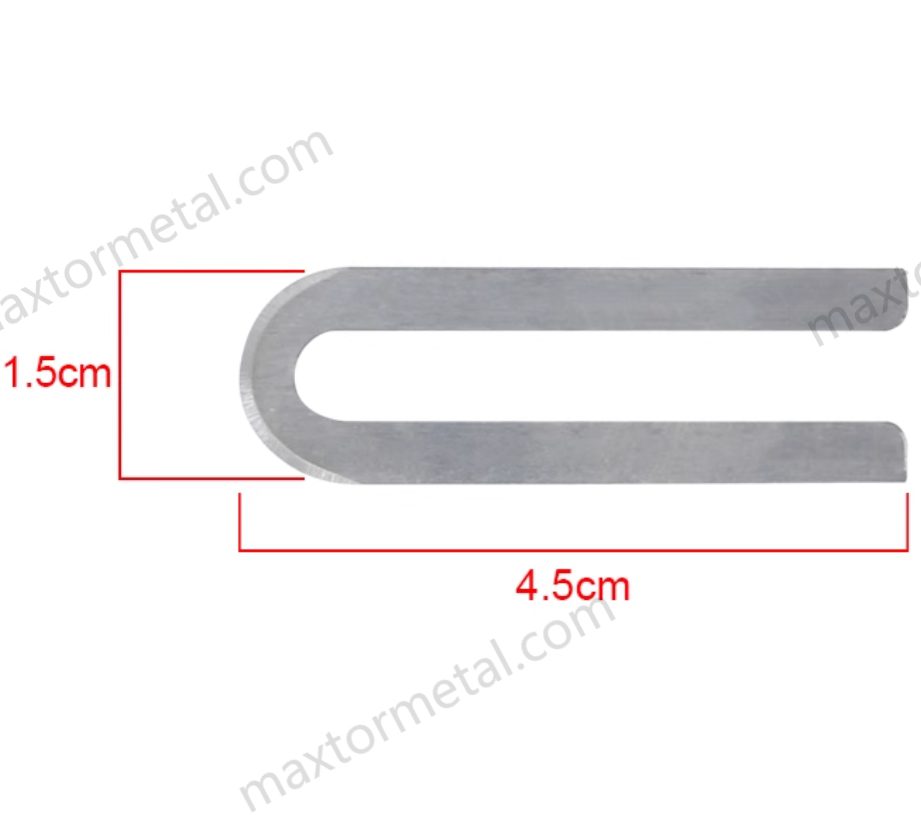

Não existem duas indústrias iguais. É por isso que a Nanquim Metal oferece facas industriais personalizadas Projetado para sua aplicação específica. Seja na indústria têxtil, de embalagens, automotiva ou em outras áreas, nossa equipe de design trabalha com você para construir a lâmina ideal.

Com tempos de resposta rápidos, garantia de qualidade e controle rigoroso de materiais, garantimos que cada faca de corte a quente atenda aos seus padrões.

📐 Precisa de uma lâmina para um material exclusivo? Podemos desenvolvê-la. Revestimentos, formatos e perfis térmicos personalizados disponíveis.

5. Dicas fáceis de manutenção

Para manter seu facas de corte quente trabalhando de forma eficiente e segura, siga estas etapas de manutenção simples, mas cruciais:

🛠 Manutenção diária:

- Limpeza da lâmina: use um pano de microfibra para remover resíduos de plástico ou acúmulo de carbono após os turnos.

- Verificação visual: procure por deformações ou descolorações. Isso pode indicar superaquecimento ou oscilação de energia.

🔄 Manutenção semanal:

- Aperte parafusos e suportes: vibrações podem afrouxar os acessórios.

- Inspecione os elementos de aquecimento: use uma pistola térmica para verificar a distribuição uniforme do calor.

⚙️ Manutenção Mensal:

- Calibração: garanta que os controladores de temperatura sejam precisos.

- Substituição da lâmina: se o desgaste for visível ou a resistência aumentar, substitua a lâmina, mesmo que ela ainda corte.

| Tarefa | Tempo necessário | Ferramentas necessárias |

| Limpe a face da lâmina | 3–5 minutos | Pano macio, álcool |

| Verifique a faixa de temperatura | 10 minutos | termômetro infravermelho |

| Substituir lâmina | 15–20 minutos | Chave de fenda, luvas |

⏱ Dica: A manutenção da lâmina leva menos de 15 minutos por semana e pode prolongar a vida útil da lâmina em 40%.

6. O Futuro do Corte Industrial

À medida que os materiais se tornam mais complexos — filmes multicamadas, compósitos revestidos, têxteis de origem biológica —, as ferramentas de corte tradicionais não conseguem acompanhar o ritmo. É aí que a tecnologia de facas de corte a quente lidera a próxima geração de corte industrial.

🔮 Tendências emergentes em corte com lâmina aquecida:

- Controle de temperatura baseado em IA: ajusta o calor com base na densidade do material em tempo real.

- Cabeças de lâmina modulares: permitem trocas de materiais sem ferramentas.

- Integração de energia verde: sistemas alimentados por energia solar ou de baixa voltagem otimizados para sustentabilidade.

- Monitoramento de IoT: manutenção preditiva de lâminas por meio de feedback de sensor para reduzir o tempo de inatividade não planejado.

De acordo com um relatório de 2024 da Technavio, o mercado global de facas quentes industriais deve atingir $1,3 bilhão até 2028, crescendo a um CAGR de 6,8%, impulsionado por:

- Aumento da demanda por embalagens para comércio eletrônico

- Crescimento em materiais automotivos leves

- Mudança para a fabricação têxtil automatizada

📢 Na Nanquim Metal, não estamos apenas acompanhando — estamos liderando. Nosso laboratório de P&D está testando facas quentes de última geração com modulação inteligente de temperatura, visando uma tolerância de ±2°C mesmo em ambientes flutuantes.

Próximos passos

Facas de corte a quente são mais do que apenas uma ferramenta — são uma maneira mais inteligente de cortar. Elas ajudam os fabricantes a:

- Obtenha cortes limpos e sem desfiar

- Aumente a velocidade de produção

- Menor desperdício de material

- Economize em custos de manutenção

- Adapte-se às diversas necessidades industriais

Se você está procurando melhorar seu desempenho de corte, Nanjing Metal está aqui para ajudar. Nossa equipe de especialistas trabalhará com você para projetar e entregar uma solução de corte a quente que se adapte ao seu processo e impulsione seus resultados financeiros.

👉 Entre em contato conosco hoje para solicitar uma consulta ou amostra gratuita.

Fontes:

- Relatório de Mercado da Technavio sobre o Mercado de Facas Industriais, 2024

- CuttingTech Insights: Benchmark de Eficiência de Processos, 2023

- Revista de Têxteis Técnicos, Volume 38, Edição 2, 2022

Uma resposta